Showing results 1 - 154 of 154

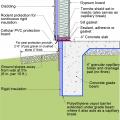

A concrete slab floor can be elevated above local grade as a strategy to prevent flood damage.

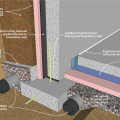

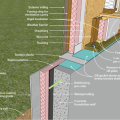

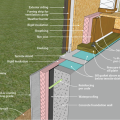

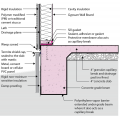

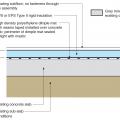

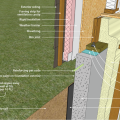

A concrete slab-on-grade foundation with exterior insulation, which can be elevated above the local grade as a flood-prevention strategy.

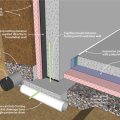

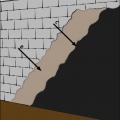

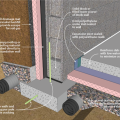

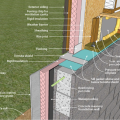

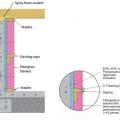

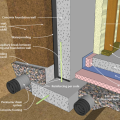

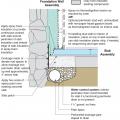

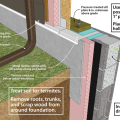

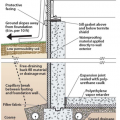

A dimpled plastic water barrier protects the insulated concrete form basement walls and carries any ground water down the walls to the footing drain to minimize the opportunity for water intrusion and frost heave.

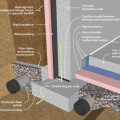

A dimpled rain mat and perforated drain pipe provide drainage around the basement foundation.

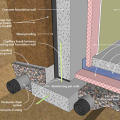

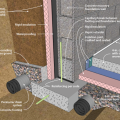

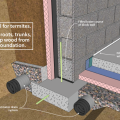

A layer of pea gravel or crushed stone, 4 inches thick and sloped 5%, provides a pest-resistant ground break around the perimeter of a basement foundation

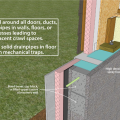

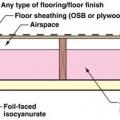

Air seal the floor above an unconditioned basement or crawlspace and make sure floor insulation is in full contact with the underside of the subfloor.

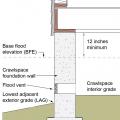

Although crawlspaces are not recommended in flood-prone areas, they can be designed or retrofitted to greatly increase resistance to flood damage.

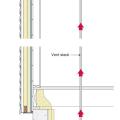

An exhaust fan pulls damp air out of a retrofitted sealed crawlspace while drawing in dry air from the living space

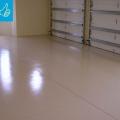

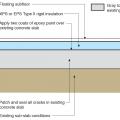

An uninsulated (or existing insulated) basement slab is retrofitted to reduce moisture transmission by sealing with epoxy paint.

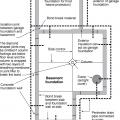

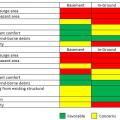

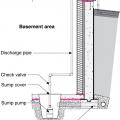

Basement plan showing sump pump location and perimeter drain that empties to the sump pit

Because the above-grade potions of the wall lack exterior insulation, condensation and even ice form during cold winter conditions

Before sealing and insulating the crawlspace, the windows were sealed, the window wells backfilled, and sumps pumps were installed that discharged to the gutter downspouts

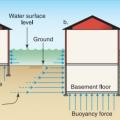

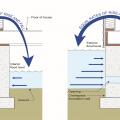

Buoyancy force on dry floodproofed homes with deep basements leads to possible foundation damage

Detail of radon vent stack connection to existing basement slab – retrofit basement construction

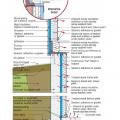

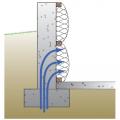

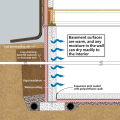

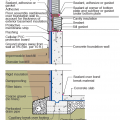

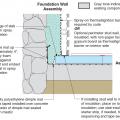

Drainage and waterproofing system components in a basement, single perimeter drain system, footing detail

Epoxy paint is installed to provide a moisture control layer on the surface of an existing basement slab

Example of an earth-sheltered home in hot climate Tempe, AZ uses the cooling properties of the ground to decrease cooling costs

Exterior fiberglass insulation on this new home was (incorrectly) cut to terminate below-grade after backfill, which will expose the above-grade portions of the foundation wall to cold temperatures

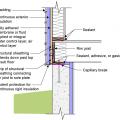

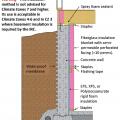

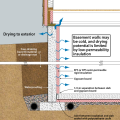

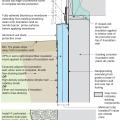

Exterior surface of below-grade walls finished as follows: For poured concrete, concrete masonry, and insulated concrete forms, finish with damp-proof coating

Exterior surface of below-grade walls finished as follows: For wood-framed walls, finish with polyethylene and adhesive or other equivalent waterproofing

Exterior XPS basement insulation is correctly installed to completely cover the foundation wall

Flood vents allow floodwaters to enter and exit the crawlspace without causing hydrostatic pressure differences

Foil-faced rigid foam and spray foam can be used to insulate a basement on the interior; use good moisture management techniques to keep the basement dry

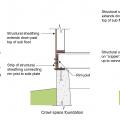

For seismic resistance in basement, crawlspace, and crawlspace “cripple” wall foundations, connect the plywood or OSB sheathing to the wall framing, rim joist, and sill plate and anchor bolt the sill plate to the foundation

ICF bricks are stacked to form hollow walls that are reinforced with steel rebar before the concrete is poured in

Moisture can migrate from below the foundation to the basement wall and insulation cavity in a conventional blanket insulation installation

New Charleston, SC home's first level used as parking, storage, and access space

Right - A continuous layer of rigid foam insulation is installed against the foundation, and the perforated fiberglass insulation blanket is installed over that and covered with a semipermeable facing.

Right - Air barrier is present and installed between the floor system and unconditioned space.

Right - All seams in the HVAC equipment and ductwork are sealed with mastic; because the HVAC equipment is in the garage, it is an air-sealed closet.

Right - Basement with exterior XPS or EPS insulation and insulation under the basement slab.

Right - Below-grade concrete has been properly sealed against moisture and is now having insulation installed.

Right - Closed-cell spray foam covers the interior of the foundation wall and wall framing is placed to the inside of the spray foam.

Right - Closed-cell spray foam is used to retrofit an existing rubble basement foundation wall.

Right - Closed-cell spray foam was applied to the interior of a foundation wall.

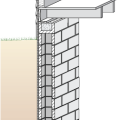

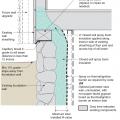

Right - Concrete masonry unit (CMU) basement wall showing exterior insulation and sill detail; above-grade wall has sheathing to the inside of the rigid foam.

Right - Foil-faced polyisocyanurate rigid foam board is tightly installed and sealed against a concrete foundation wall prior to installing fibrous blanket insulation.

Right - Potential locations for basement insulation in new construction, slab insulation should always be underneath, with walls insulated (a) inside, (b) outside, (c) sandwiched inside, or (d) inside and outside of walls.

Right - Poured concrete basement wall showing exterior insulation and sill detail; above-grade wall has sheathing to the inside of the rigid foam.

Right - Poured concrete basement wall showing exterior insulation and sill detail; above-grade wall has sheathing to the outside of the rigid foam.

Right - Precast concrete basement walls come to the site with integrated rigid foam insulation and steel-faced concrete studs.

Right - Reduce condensation risks to blanket insulation by installing perforated vapor retarder covered fiberglass blankets over rigid foam that is air-sealed at all edges; staple the blanket to nailers and top/bottom plates and tape over the seams.

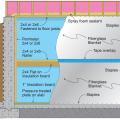

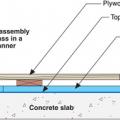

Right - Retrofit of an existing basement slab by adding dimple plastic mat, rigid foam insulation, and a floating subfloor.

Right - Rigid foam board is attached to the interior surface of the basement walls.

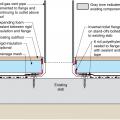

Right - Rigid foam insulation is installed along the exterior edge of an existing foundation slab.

Right - Section view showing how to air-seal and insulate a basement wall with perforated blanket insulation by installing it over air-sealed rigid insulation board to reduce condensation risk in the fiberglass blanket.

Right - The basement foundation is insulated on the exterior and termite shield extends out past the top of the insulation.

Right - The basement walls are wrapped with 3 inches of XPS rigid foam that will be taped at the seams then covered with a dimpled plastic water barrier.

Right - The blanket fiberglass insulation is installed over a continuous layer of rigid foam insulation; the fiberglass is covered with a vapor retarder that is tape sealed at the seams.

Right - The concrete basement wall is insulated on the interior with rigid foam; the footing detail is shown.

Right - The concrete masonry unit (CMU) basement wall has exterior insulation; the footing details include interior and exterior footing drain pipe.

Right - The conditioned basement is insulated on the interior with 1 inch of polyiso R-6.3 rigid insulation.

Right - The existing basement slab is retrofitted by installing a dimple plastic drainage mat, rigid foam insulation, and a floating subfloor.

Right - The poured concrete basement walls are insulated along the inside with 2.5 inches of extruded polystyrene insulation.

Right - This concrete basement wall has exterior rigid insulation and comprehensive moisture management details.

Right - This concrete basement wall is insulated on the interior basement walls with spray foam and under the slab with rigid foam; footing details are shown.

Right - This concrete basement wall is insulated on the interior with rigid insulation; sill details are shown.

Right - This concrete basement wall is insulated on the interior with spray foam insulation; sill detail are shown.

Right - This opening in the foundation wall around this pipe was filled with wire mesh then sealed with spray foam to prevent rodent and insect entry

Right - This poured concrete basement wall is insulated on the exterior and under the slab with rigid insulation; footing details include interior and exterior footing drain pipe.

Right - XPS rigid foam board is tightly installed against a concrete foundation wall and seams are sealed with tape prior to installing fibrous blanket insulation.

Right – A sump pump with a perforated sump pit was installed in the crawlspace slab to reduce water accumulation under the slab

Right – A termite inspection gap is left at the top of the rigid foam board basement wall insulation.

Right – Construction adhesive is applied to the rigid foam panels that will be installed on the interior basement walls.

Right – Foil-faced insulation was added after the crawlspace was dried and sealed by diverting water runoff, sealing off crawlspace windows and vents, and adding sump pumps and exhaust fan ventilation

Right – Foundation drainage mat was installed over the waterproof membrane that covers the sealed crawlspace window

Right – Precast concrete basement walls come to the site with integrated insulation and steel-faced concrete studs.

Right – The basement contains four 5,000-gallon rainwater holding tanks for this home which meets all of its water needs with rainwater.

Right – The basement of this cold-climate home is insulated along interior walls with 2 inches of foil-faced rigid foam; finished basement walls also have a 2x4 interior wall insulated with R-19 blown-in fiberglass insulation and a poly vapor barrier.

Right – The entire first floor and second floor of these modular homes were assembled in the factory and installed on an insulated concrete basement foundation on site.

Right – The insulated concrete forms that are below-grade have a damp-proof coating to prevent moisture seeping into the foundation

Right – The rim joists above the pre-insulated basement walls are sealed and insulated with spray foam to prevent air leakage at this juncture in the building envelope.

Right – The seam between the slab and the foundation wall is sealed with urethane caulk.

Right – The slab is coated with two coats of epoxy paint to minimize moisture transfer through the slab from the ground.

Right – The spacer structure of these ICFs provides supports for attaching the fasteners used to attach the metal studs of the below-grade walls.

Right – This crawlspace window was completely sealed off on the inside and outside with air barrier and water-proof materials and the window well was filled in to an above-grade height to prevent bulk water from entering the crawlspace

Right – Two inches of rigid foam was installed on the ground before pouring the basement floor slab while precast, pre-insulated concrete panels comprise the basement walls.

Right--The polyethylene ground cover for this insulated crawlspace is taped at seams and around posts before the insulation and slab are installed.

Rigid foam insulation and a thin slab were installed over the dirt and gravel of this sealed crawlspace

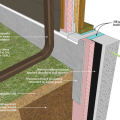

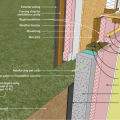

Rigid insulation and water control layers are installed on the exterior of a flat foundation wall; spray foam insulates the rim joist

Spray foam extends down the foundation wall to the slab, which has been retrofitted by adding dimple plastic drainage mat and rigid foam insulation.

Spray foam extends down the inside of the foundation wall to the uninsulated slab; because the wall lacked exterior perimeter drainage, the slab was cut and an interior footing drain was installed.

Spray foam insulation extends down the foundation wall to the slab, which has been retrofitted by cutting the slab to install drainage mat against the wall and a new perimeter footing drain, along with rigid foam plastic above the slab.

The basement is constructed with precast concrete walls lined with R-21.3 foil-faced rigid foam while an R-10 layer of XPS rigid foam covers the ground under the slab.

The basement is half in and half out of the ground with only 4 feet below grade, which allows for full 36-inch-tall windows that are completely above grade.

The basement walls’ interior framing is set in 3 inches from the concrete to allow space for closed-cell foam that is sprayed directly on the concrete, then blown cellulose is added to fill the wall cavity.

The daylight basement walls are made of concrete walls with integrated rigid foam and steel-faced concrete studs.

The existing slab is retrofitted by coating with epoxy paint, then installing rigid foam insulation and a floating subfloor.

The existing slab is retrofitted with epoxy paint, rigid foam insulation, sleepers (furring strips), and subfloor.

The goal of foundation moisture management is to construct the basement, crawlspace, or slab in a way that keeps moisture from getting in in the first place

The rim band connecting the insulated precast concrete basement walls to the floor joists above is spray foamed to provide air-sealing and insulation in this hard-to-seal juncture.

The risk of hydrostatic pressure differences in a flood is reduced when the interior grade of the crawlspace is higher or equal to the exterior grade.

The water heater and other appliances are located above the Base Flood Elevation.

This basement is insulated on the exterior with rigid foam over dampproofing, with granular backfill and footing drains to facilitate drainage away from the foundation, a termite shield to protect from pests, and cellular PVC to protect the rigid foam.

This exterior insulated slab-on-grade monolithic grade beam foundation is protected from pests by termite shield at the sill plate, borate-treated framing, flashing at end of wall insulation, brick veneer over slab-edge insulation, and rock ground cover.

This floor assembly above a vented crawlspace controls vapor and heat transmission by using foil-faced isocyanurate rigid foam insulation installed underneath the floor joists and fiberglass insulation in the floor joist cavities

This house was designed with half of the basement above grade, allowing 36-inch-tall windows for egress and daylight on both sides of the house.

Unvented air-sealed crawlspace is insulated along the perimeter walls with rigid foam

Water-proof materials cover the exterior side of crawlspace windows in a crawlspace retrofit, while foil-faced rigid foams seals and insulates the inside face of the openings

Wrong - Air leakage from the conditioned space to the basement foundation wall can lead to condensation or moisture issues in a conventional blanket insulation installation.

Wrong - Moisture from within the basement foundation wall can migrate into the insulation cavity in a conventional blanket insulation installation.

Wrong - No air barrier is present between the floor system and unconditioned space.

Wrong - Plastic-covered blanket insulation that is installed directly against concrete walls with no rigid foam or closed-cell spray foam covering the concrete could trap moisture coming through the concrete, leading to mold, moisture, and odor problems.

Wrong - The basement blanket insulation is loosely attached to the interior of the basement wall, does not cover the entire wall, is not sealed at the edges, and is not installed over rigid foam that covers the entire surface of the foundation walls.

Wrong - The below-grade concrete does not have the correct construction to be impermeable to moisture because the lumber is untreated and against the concrete that lacks waterproofing.

Wrong - The fiberglass blanket insulation has no perforated vapor retarder, does not cover the entire basement wall, is not sealed at the edges, and is not installed over rigid foam.

Wrong - This plastic-covered blanket insulation is not perforated, does not cover the entire basement wall, is not sealed at the edges, and is not installed over rigid foam.

Wrong – A poorly sealed window and window well allow bulk water to enter the crawlspace from ground that slopes toward the structure

Wrong – The insulated concrete forms at the foundation do not have a damp-proof coating

Wrong – The vapor barrier is not secured to the walls of this crawlspace.

Wrong – This vented crawlspace has standing water because steps were not taken to address site conditions that led to bulk water flow into the crawlspace