Showing results 1 - 50 of 55

A moisture meter verifies that the moisture of the framing is below the recommended 18%.

An uninsulated (or existing insulated) basement slab is retrofitted to reduce moisture transmission by sealing with epoxy paint.

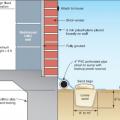

Brick wall assembly for a hot-humid climate with no Class I vapor retarder and with an air gap (drained cavity) to dissipate vapor driven into the wall by the sun.

Cement board (shown in dark grey) is installed behind an installed tub and shower surround.

Do not install carpet in areas that are likely to get wet, such as bathrooms, kitchens, entry ways, or laundry rooms.

Do not install lumber, plywood, or other building materials that show visible signs of water damage or mold.

ICF bricks are stacked to form hollow walls that are reinforced with steel rebar before the concrete is poured in

Right – Moisture-resistant backing material has been used above and behind the tub enclosure.

Right – Two-thirds of acrylic tape is offset above the joint and over and above the fasteners

Right – two-thirds of the blue butyl flashing tape is above the sheathing seam; the top edge of the butyl flashing tape is covered with clear sheathing tape that is also offset so two-thirds is above the top edge of the butyl flashing.

Right: All joints in the rigid foam are taped to keep stucco out of joints for even drying. Mesh tape (shown here) is used with expanded polystyrene (EPS); acrylic sheathing tape or self-adhered membrane is used with XPS

The board in the center of this photograph shows blue stain (not lumber mold), a discoloration of the wood caused by a fungus affecting the living tree, which did not harm the structural integrity of the wood.

The windows in this building are connected to the fully adhered water and air control layer using fluid-applied flashing

This drawing shows key head details for a window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer

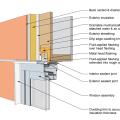

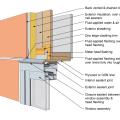

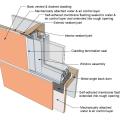

This drawing shows key head details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer

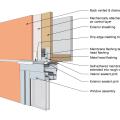

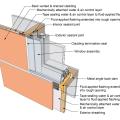

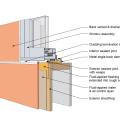

This drawing shows key head details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer and continuous insulation

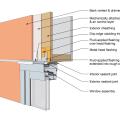

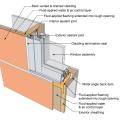

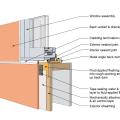

This drawing shows key head details for a window installation using a self-adhered membrane tape flashing on a wall with a mechanically attached water and air control layer

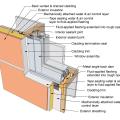

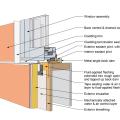

This drawing shows key head details for an “outie” window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer and continuous insulation

This drawing shows key jamb details for a window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer

This drawing shows key jamb details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer

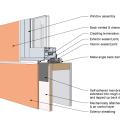

This drawing shows key jamb details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer and continuous insulation

This drawing shows key jamb details for a window installation using a self-adhered membrane tape flashing on a wall with a mechanically attached water and air control layer

This drawing shows key jamb details for an “outie” window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer and continuous insulation

This drawing shows key sill details for a window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer

This drawing shows key sill details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer

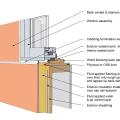

This drawing shows key sill details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer and continuous insulation

This drawing shows key sill details for a window installation using a self-adhered membrane tape flashing on a wall with a mechanically attached water and air control layer

This drawing shows key sill details for an “outie” window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer and continuous insulation

Windows are installed as “outies” in this wall assembly using a self-adhered membrane water and air control layer with continuous exterior insulation

Wrong – Building materials are being stored outdoors with no protection from weather