Scope

Install a rigid air barrier to separate the porch attic from the conditioned space.

- Install insulation in the exterior wall cavities without misalignments, compressions, gaps, or voids.

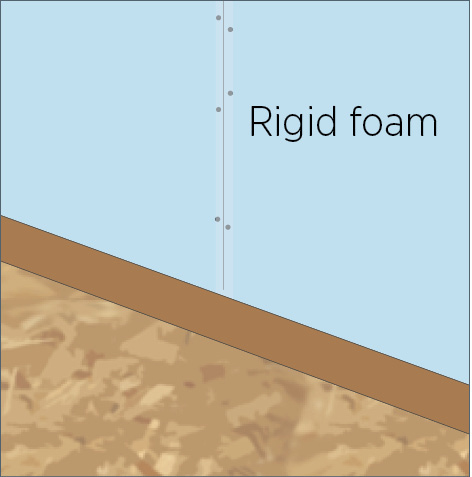

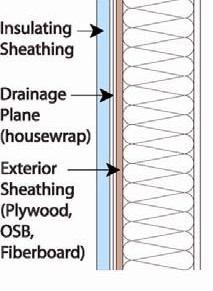

- Install a continuous rigid air barrier on the exterior side of the wall. Rigid air barrier materials could include rigid foam insulation, drywall, plywood, or OSB, among others.

- Seal the air barrier to the framing with a bead of caulk applied to the exterior face of the framing before installing the air barrier. Seal all seams, gaps, and holes in the air barrier with caulk or foam.

- Ensure that the air barrier is continuous and in full contact with the insulation.

- ENERGY STAR requires that an air barrier be installed at the exterior vertical surface of the wall insulation in all climate zones and also that an air barrier be installed at the interior vertical surface in IECC Climate Zones 4-8 (ENERGY STAR).

- If spray foam insulation is used for the wall cavity insulation, the spray foam can serve as the air barrier if it is at least 5.5 inches thick if open-cell or at least 1.5 inches thick if closed-cell spray foam insulation.

- If this wall will not be hidden from view by a porch ceiling, then cover the wall with exterior siding.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

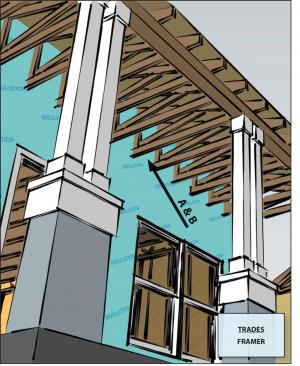

In two-story homes with covered porches, builders may sometimes forget to sheathe the wall area that will be hidden when the porch ceiling is installed, because the porch is framed before the wall sheathing is installed. If there is no exterior sheathing, blown insulation cannot be installed. Even if batt insulation is installed, if there is no exterior sheathing that is caulked in place to serve as an air barrier, the insulation is subject to wind washing from outside air, especially if the porch ceiling is vented or is not air tight.

In one-story homes with vented attics where the ceiling plane of the living space is level with the ceiling plane of the porch, the wall plane between the house attic and the porch attic does not need to be insulated and air sealed. In this case, the ceiling plane of the living space should be air sealed, especially along the top plate of the walls.

In one-story homes with unvented attics, the wall plane between the porch and the house should have a solid, sealed air barrier on the exterior side of the wall cavity and the wall cavity should be filled with insulation that is fully aligned to this air barrier.

The exterior sheathing that is hidden by the porch roof and ceiling can be rigid foam, OSB, plywood, or another rigid sheathing product, and it may be installed by framers or insulators. This task should be included in the contract for the appropriate trade depending on the workflow at the specific job site. Air barrier effectiveness is measured at the whole-house level. High-performance branding programs and the 2009 and 2012 IECC require that builders meet specified infiltration rates at the whole-house level. See the “compliance” tab for these specified infiltration rates.

How to Install a Fully Aligned Air Barrier in a Porch Wall

Install the exterior wall sheathing to extend to or beyond the porch roof rafters or install sheathing from the house attic side after porch roof framing is installed.

Figure 3. Install the exterior wall sheathing to extend to or beyond the porch roof rafters.

- OR -

If the drywall is already installed on the interior side of the wall, install insulation in the wall cavity. Make sure the insulation fully aligns with (is completely touching) the sheathing on the interior side.

Figure 4. Insulate the porch-attic wall making sure the insulation fully aligns with the inside wall sheathing. Apply a thick bead of caulk to the framing that will be covered.

Figure 5. Apply caulk to wall framing. - Cut wall sheathing (e.g., rigid foam insulation, OSB, or plywood) to cover the insulation on the exterior side of the wall cavity.

Nail or screw the sheathing in place over the caulk.

Figure 6. Install rigid insulation or another wall sheathing product. - If there are seams in the sheathing, seal them with caulk or tape.

- Install a porch ceiling or cover the wall sheathing with exterior siding.

Success

A visual inspection should be made by the site supervisor to determine that the wall cavity separating the house from the porch attic is filled with insulation that is in full contact with the interior drywall and that the wall cavity is completely covered with rigid sheathing that is air sealed at all edges to form a continuous air barrier along the exterior wall of the house. Blower door testing, conducted in conjunction with inspection with an infrared camera, may also be useful in detecting air leakage or lack of insulation alignment at the porch wall.

Climate

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Training

CAD

Compliance

Retrofit

SCOPE

Retrofit a wall adjoining an existing porch roof for improved energy efficiency by air sealing and insulating the wall.

- For deep energy retrofits, remove the porch framing, roof, and ceiling from the adjoining exterior wall. Install exterior sheathing, a water control membrane, and insulation then re-install or replace the porch framing. Flash the porch roof-to-wall interface.

- For retrofits in which the porch framing and porch roof remain in place: remove the porch ceiling, inspect for signs of water leakage; repair as needed. Install sheathing between the house and the porch attic. Add cavity insulation, as described in the Scope and Description tabs.

For more information on conditions that may be encountered when working with walls and attics in existing homes, see the assessment guides on walls, windows, and doors and attics.

See the U.S. Department of Energy’s Standard Work Specifications for more on sealing walls to keep out moisture, air, and pests. Follow safe work practices as described in the Standard Work Specifications.

DESCRIPTION

Ideally the exterior sheathing of a house will run continuously along the exterior walls, even where porch framing intersects the exterior wall, such that the porch is completely separated from the conditioned part of the house. However, in existing homes, the porch is sometimes built before exterior sheathing is installed and no sheathing or solid air barrier is put in place to separate the wall from the roof. (See Figure 1 in the Description tab for a graphic representation of this concept.) Insulation is sometimes also lacking in this section of wall.

In deep energy retrofits with ambitious air tightness and energy saving goals, the ideal way to address this issue would be to temporarily remove the porch roof framing adjoining the exterior wall so that sheathing and/or rigid insulation may be added from the exterior prior to re-installing or replacing the porch framing.

If the extensive retrofit involving detachment and re-attachment of the porch roof is impractical, significant improvements to comfort and energy efficiency can still be achieved by air sealing and insulating the wall from the exterior after removing only the porch ceiling to access that section of wall. Although not as effective as disconnecting the framing to make the house’s exterior sheathing and insulation continuous , this approach is often pursued, even in new construction. Figure 1 shows foil-faced rigid insulation and canned spray foam providing an air-sealed barrier between a porch roof and the home’s exterior wall. The rigid foam is taped and foamed to form a continuous air barrier.

How to Retrofit a Wall Adjoining a Porch Roof

For deep energy retrofits:

- Remove the porch framing, roof, and ceiling; or detach and provide temporary support for the porch roof structure if it will be reused.

- Install insulation in the area of the wall that adjoins the porch, if wall cavity insulation is missing or insufficient.

- Install exterior sheathing.

- Install a water control membrane.

- Install a new ledger over the face of the sheathing; provide blocking as needed for structural support.

- Re-install or replace the porch framing.

- Provide flashing at the porch roof-to-wall interface, integrating the drainage plane of the water control membrane of the house with the porch roof.

For retrofits in which the porch framing and porch roof remain in place:

- Remove a large enough section of the porch ceiling nearest the wall to allow space to work on the wall.

- Inspect the existing porch-to-wall interface for signs of water leakage, such as water stains and rot. Remove wet, sagging, or pest-infested insulation. Replace any damaged framing and repair porch roof flashing if needed.

- If insulation is missing or insufficient in the section of wall adjoining the porch, install insulation to fill the wall cavities. Using sprayed polyurethane foam (SPF) insulation will improve the air tightness of the retrofit but batt or blown insulation will also suffice.

- Install caulk on the exterior face of the framing then install sheathing (plywood, OSB, or rigid insulation), as shown in the Description tab. Caulk or tape seams.

- If plywood or OSB is used for the air barrier, consider installing rigid insulation under or over it to improve thermal performance.

- Replace the porch ceiling or cover the wall with exterior siding.

COMPLIANCE

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Pacific Northwest National Laboratory

Steven Winter Associates, Inc., Lead for the Consortium for Advanced Residential Buildings (CARB), a DOE Building America Research Team

Building Science Corporation, lead for the Building Science Consortium (BSC), a DOE Building America Research Team

Sales

Fully Aligned Air Barriers = Whole-House Draft Barrier

A whole-house draft barrier is a continuous layer of air-tight materials that block air leaks. This barrier can be integrated with other materials to also function as a water barrier, thermal barrier, and vapor barrier. For example, rigid foam insulation can be used to block thermal flow as well as air flow when seams are sealed with tape, caulk, adhesives, or liquid-applied sealants. Some rigid foams have an integrated water control layer as well. Additionally, drywall can serve as an interior air barrier when the seams are taped and spackled, and caulk, spray foam, or gaskets are used to seal around wiring, plumbing, and other penetrations. It also serves as the vapor barrier when finished with paint. Insulation should be in full contact with the air barrier layer.