Scope

Retrofit an exterior wall and/or attic to provide continuous air sealing as follows:

- Connect the top of the wall air control layer to the perimeter of the roof/ceiling assembly air control layer and add insulation at this critical juncture to ensure continuity of the air control layer and a consistent thermal control layer.

- Inspect the roof and wall framing to verify existing conditions and develop specific detailing for treating the eave area.

- Verify that roof cladding, underlayment, and eave flashing provide adequate protection from rain water. Repair if needed.

- Install exterior and interior (framing cavity) insulation to levels that meet or exceed the current adopted building and energy codes.

Improvements to the air sealing at the attic-wall transition area can be made as a stand-alone retrofit project, as part of an upgrade to the attic insulation, as part of an effort to convert a vented attic to an unvented conditioned attic, as part of an exterior wall retrofit, or in preparation for an exterior wall retrofit.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Where the roof meets the wall is a common source of air leakage in older homes. The transition of air control is both critical and difficult at this roof-wall intersection. Continuous air control at the top of the building is critical to performance because the difference between interior and exterior air pressure during the heating season tends to be the greatest at the top of the building in the attic. This pressure difference, called the stack effect, is the driving force behind air leakage (see BSD-014: Air Flow Control in Buildings). This air barrier connection is crucial both for unvented attics, where the connection is to the sloped roof air barrier/insulation plane, and vented attics, where the connection is to the ceiling plane at the floor of the attic.

Implementing uninterrupted air control is complicated by the geometry of the roof overhang, by the transition of the air control layer from one component to another, and by the roof framing (protruding rafter tails). Effective continuity of the air control layer relies on both (a) understanding the airtight connections needed between the wall and roof/ceiling assembly and (b) careful implementation and workmanship of these connections.

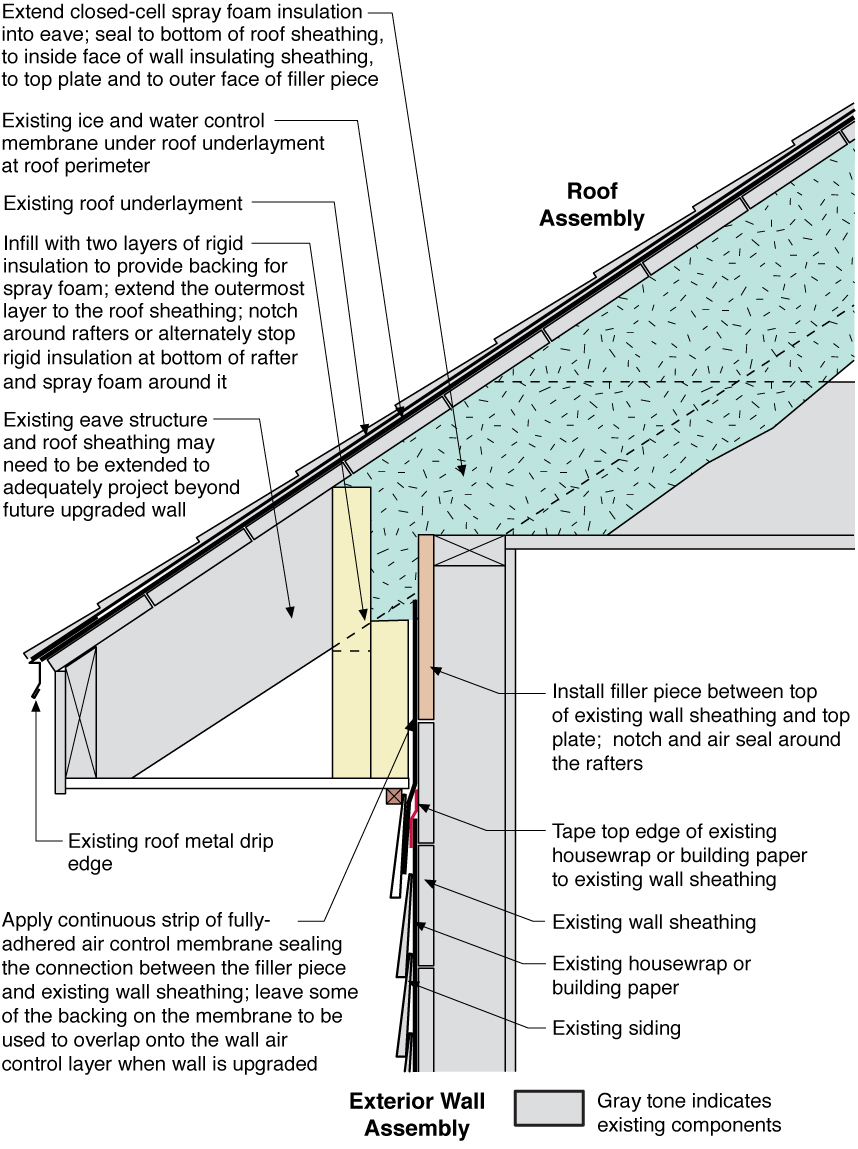

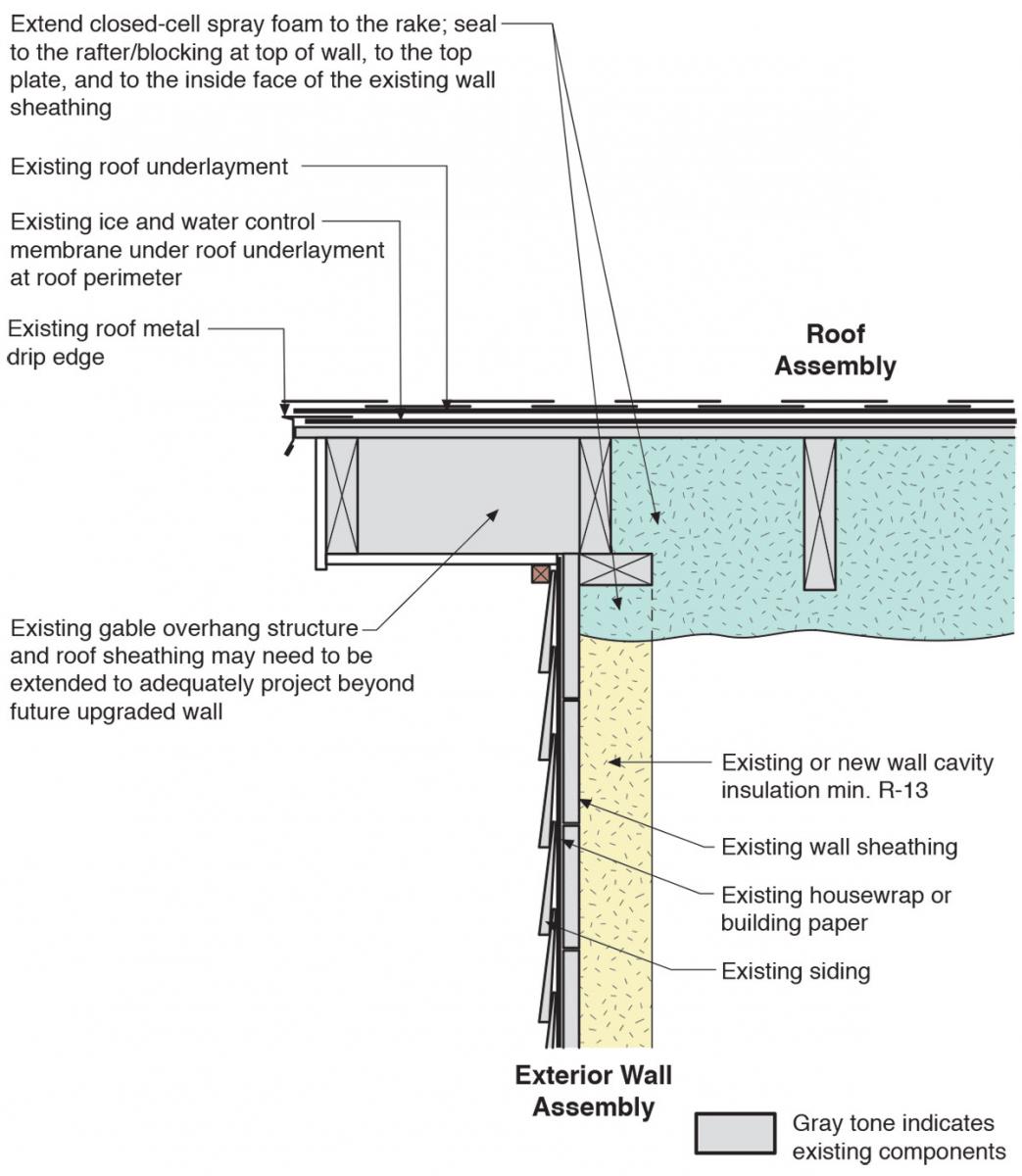

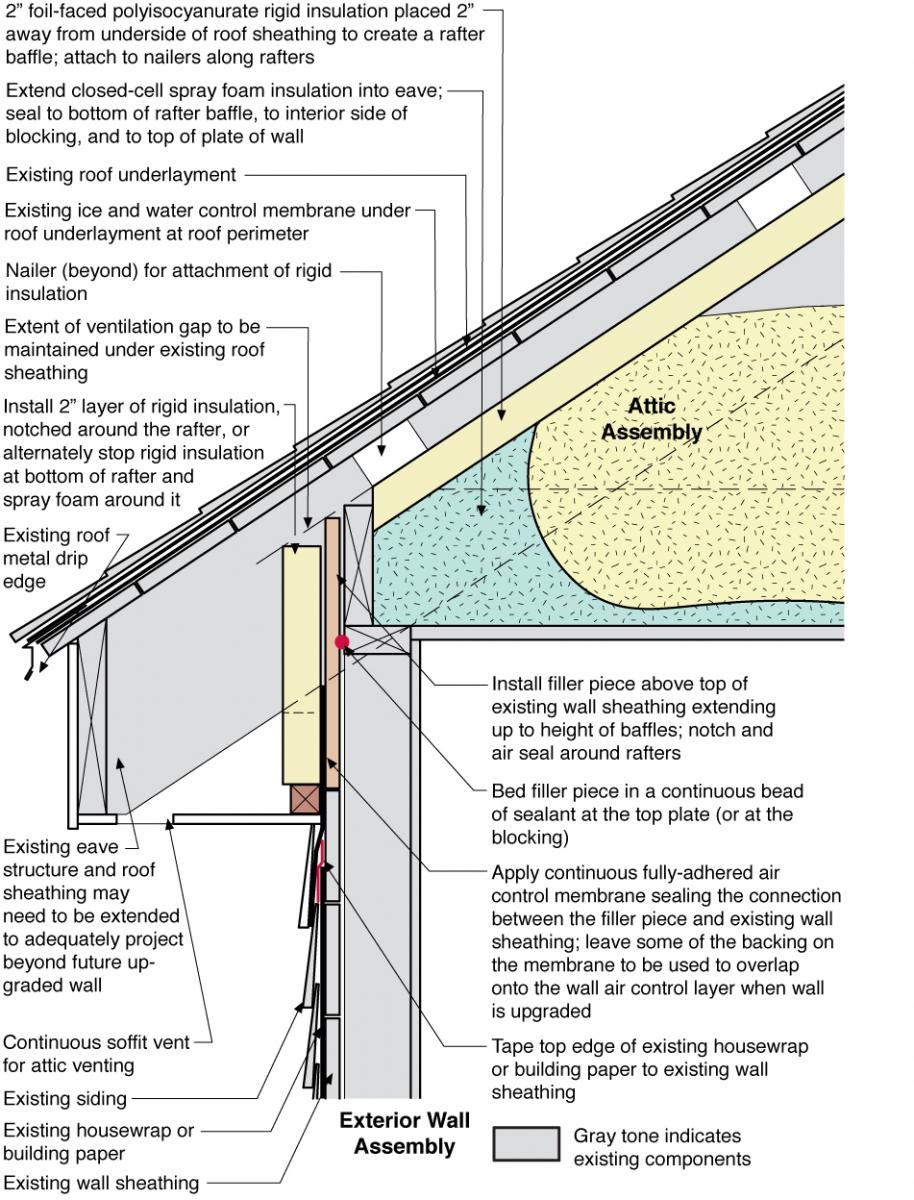

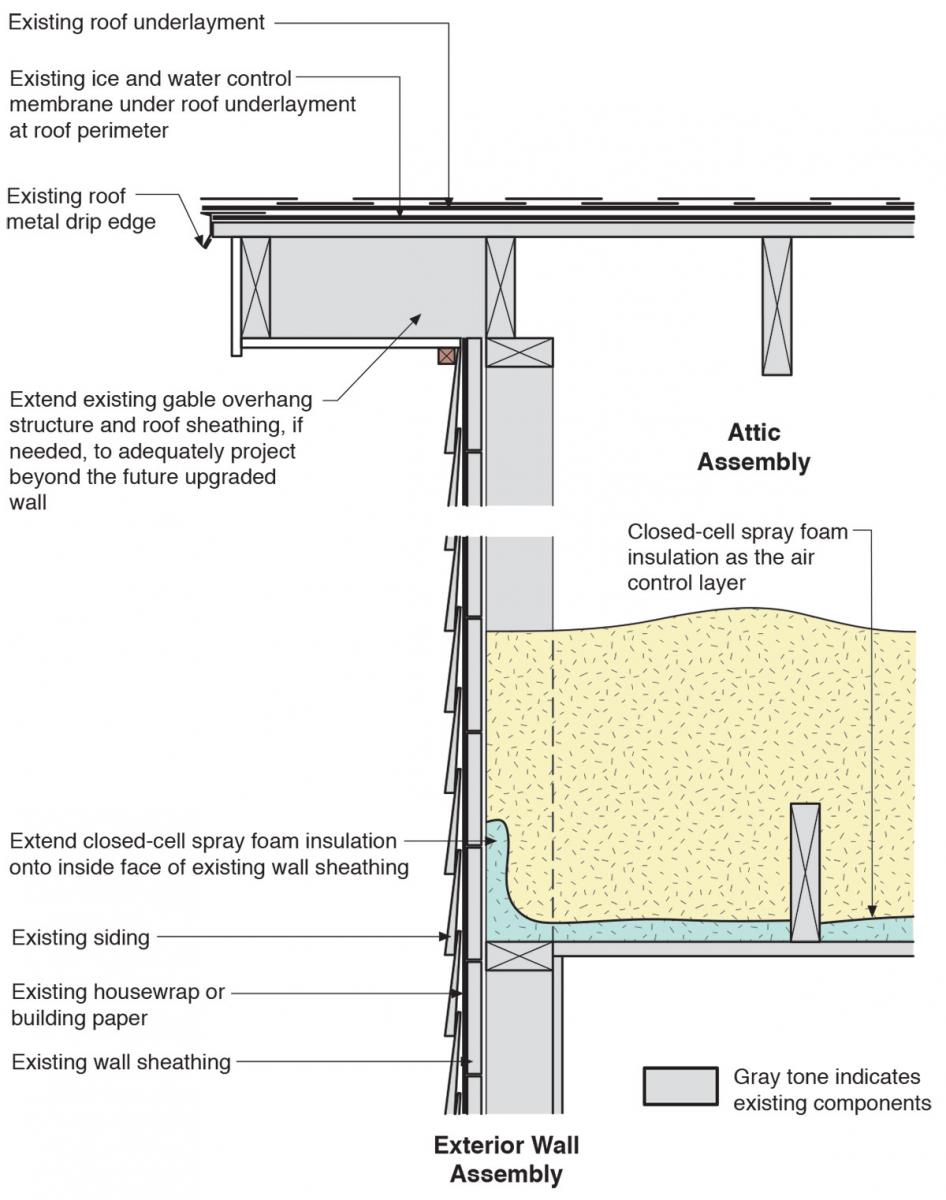

There are several ways to minimize air leakage at the attic eaves depending on whether the attic is vented or unvented and/or sloped. Figures 1 and 2 show an unvented roof assembly with closed-cell spray foam insulation at the underside of the roof deck. At the eave (Figure 1), a filler sheathing piece is installed at the top of the wall (in line with the existing board sheathing), with a continuous strip of fully adhered air control membrane lapped onto the existing wall air control layer. Two strips of rigid foam insulation are installed at the top of the wall, tight up against the roof eave, as backing for closed-cell spray foam. The outermost layer is extended up to the roof sheathing (notched around the rafters); alternately, the rigid foam insulation strips can be terminated at the bottom of the rafters and spray foam insulation installed around the framing. At the rake (Figure 2), attic closed-cell spray foam insulation is extended to the rake edge, and sealed to the rafter/blocking at the top of the wall, to the top plate, and to the inside face of the existing wall sheathing. No work is done on the exterior with this detail. For more information on insulating the underside of an existing home’s roof deck with spray foam, see the guide Below Deck Spray Foam Insulation for Existing Roofs.

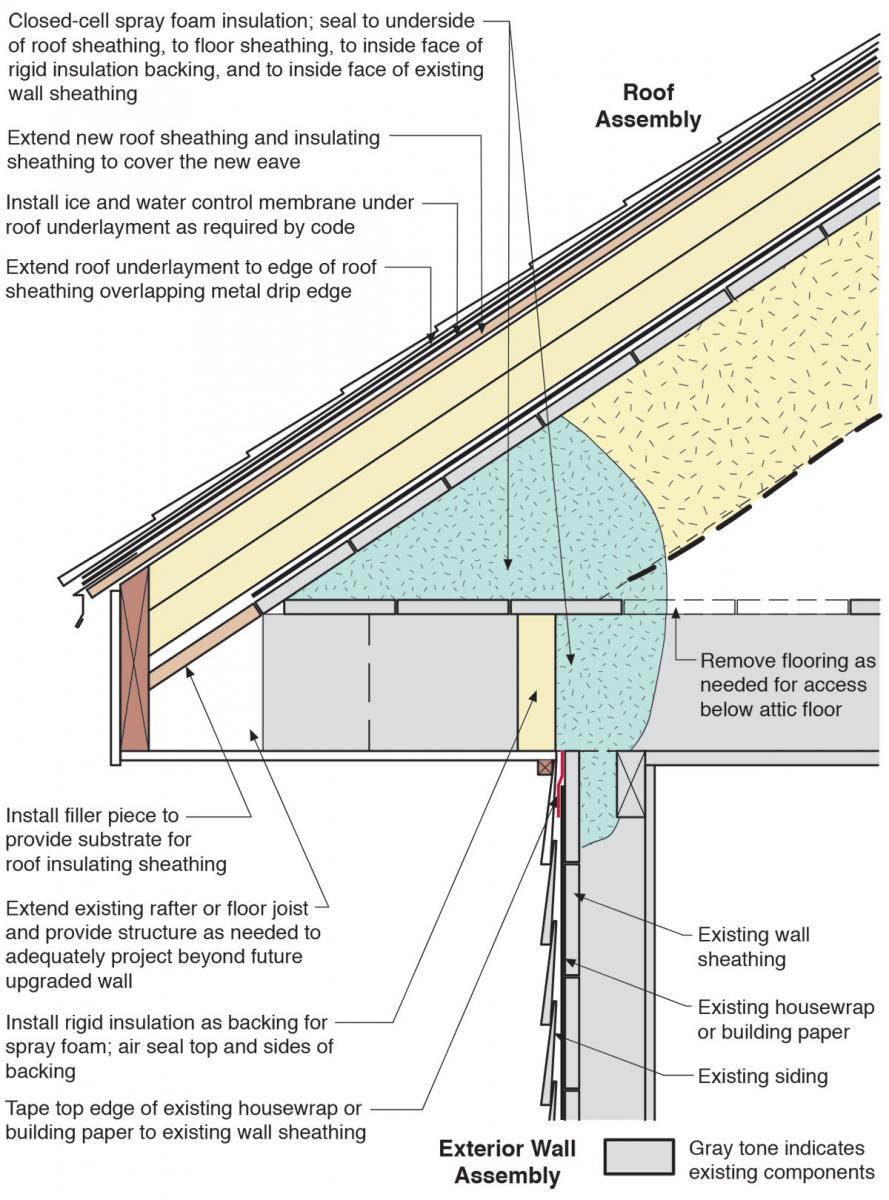

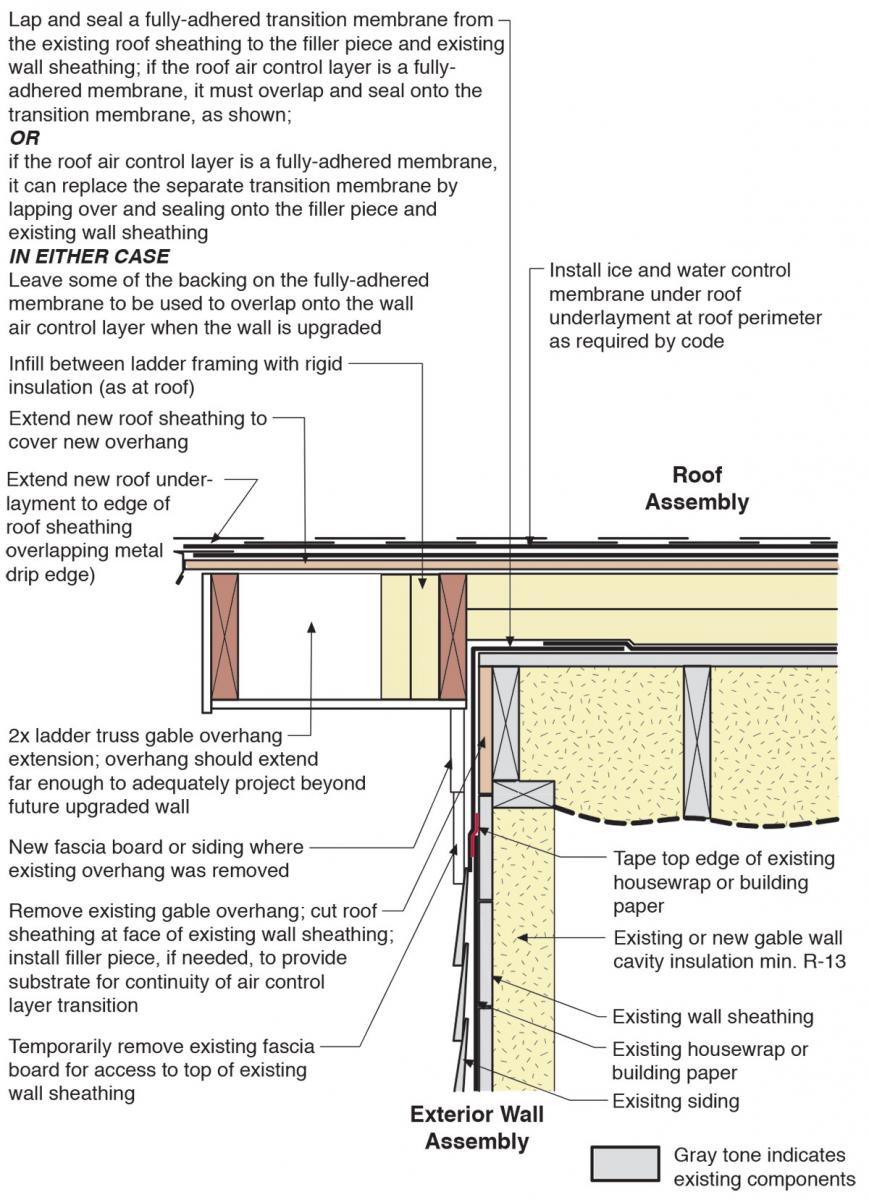

Figures 3 and 4 illustrate an unvented roof assembly retrofitted with exterior insulating sheathing and insulation installed to the underside of the roof deck. For more information on this roof insulation approach see the guide Above Deck Rigid Foam Insulation for Existing Roofs. At the eave (Figure 3), the top edge of the existing house wrap or building paper is taped to the sheathing with sheathing tape. A strip of rigid foam is installed in line with the floor joists as backing for spray foam. Closed-cell spray foam insulation then makes air barrier connections from (a) the underside of the roof sheathing to (b) the floor sheathing to (c) inside the face of the rigid insulation backing to (d) the inside face of existing wall sheathing. At the rake (Figure 4), a filler piece of sheathing is installed at the top of the wall. The top edge of the existing house wrap or building paper is taped to the sheathing; the wall air control layer is connected to the roof air control layer using a strip of fully adhered transition membrane.

Figures 5 and 6 show a vented roof assembly retrofitted with closed-cell spray foam and blown fibrous insulation installed at the attic floor and a rigid insulation rafter baffle attached to nailers under the rafters. At the eave (Figure 5), a sheathing filler piece is installed at the top of the wall (in line with the existing wall sheathing); it is bedded in sealant at the wall top plate, to provide an air barrier connection. The filler piece then receives a continuous strip of fully adhered air control membrane lapped onto the existing wall air control layer. To provide additional insulation at the wall-roof connection, a strip of rigid foam insulation is installed at the top of the wall and notched around the rafters. Alternately, the rigid foam insulation strips can be terminated at the bottom of the rafters, and spray foam insulation can be installed around the framing. In the roof assembly at the rake (Figure 6), the attic insulation is extended onto the inside face of the existing wall sheathing and no work is done on the exterior. For more information on retrofitting the attic insulation by adding spray foam above the ceiling deck, see the guide Spray Foam Insulation Applied to Existing Attic Floor.

If the retrofit project includes (or will include in the future) the installation of rigid foam sheathing on the exterior walls, an extension of the overhangs at the eaves and/or rakes may be needed, because the upgraded walls will be thicker than standard construction. If this extension lowers the elevation of the soffit at the eaves, it may conflict with the existing window head heights or head trim. This needs to be taken into account during planning for the overall renovation.

How to Air Seal and Insulate at Roof Eaves

- Inspect the integrity of the roof system (roofing membrane or shingles). If water damage or active leaks are found, d. do not proceed until repairs are performed.

- Inspect the structural integrity of the roof. Check the roof framing for any deficiencies, rot, insect damage, etc. Do not proceed until repairs are performed. Based on the findings, revise the roof assembly and review specific detailing as needed. Follow the minimum requirements of the current local building code regarding the wood roof framing construction.

- Install a filler piece of wall sheathing at the top of the wall, above the existing board sheathing; and notched to fit around and between the rafters; air seal around the edges. Install rigid foam insulation strip(s) tight up against the roof eave and notch around the rafters. Alternately, terminate the strips at the bottom of the rafters and spray foam around them (see Figure 1 and Figure 5). If the attic has floor boards, as shown in Figure 3, remove flooring at the eaves, block the openings between the ceiling joists with rigid foam. Use the rigid foam as a backer for spray foam installed to air seal and insulate the ceiling joist bays and the eaves.

- Install a continuous fully adhered air control membrane to seal the connection between the filler piece and existing wall sheathing. Lap the membrane onto the existing wall air control layer (see Figure 1 and 5). Alternately, tape the top edge of the existing house wrap or building paper with sheathing tape to the existing wall sheathing to provide an adequate air control layer (see Figure 3).

- Install closed-cell spray foam at the underside of the roof sheathing and extend into the eave (see Figure 1 and 3). Alternately, install closed-cell spray foam at the attic floor, at the bottom of the rafter baffle, and extend into the eave (see Figure 5). The area should be free of debris and dust prior to spraying for adequate adhesion.

Success

Inspect the existing roof framing and the roofing membrane or shingles for any deficiencies and make any corrections if necessary.

If the retrofit project includes (or will include in the future) the installation of rigid foam sheathing on the exterior walls, an extension of the overhangs at the eaves and/or rakes may be needed, because the retrofit walls will be thicker than standard construction. If this extension lowers the elevation of the soffit at the eaves, it may conflict with the existing window head heights or head trim. This needs to be taken into account during planning for the overall retrofit.

Apply spray foam insulation to a clean surface to ensure proper adhesion. The R-value of the spray foam insulation in the eave should be equivalent to the R-value of the wall insulation to control ice dams.

Climate

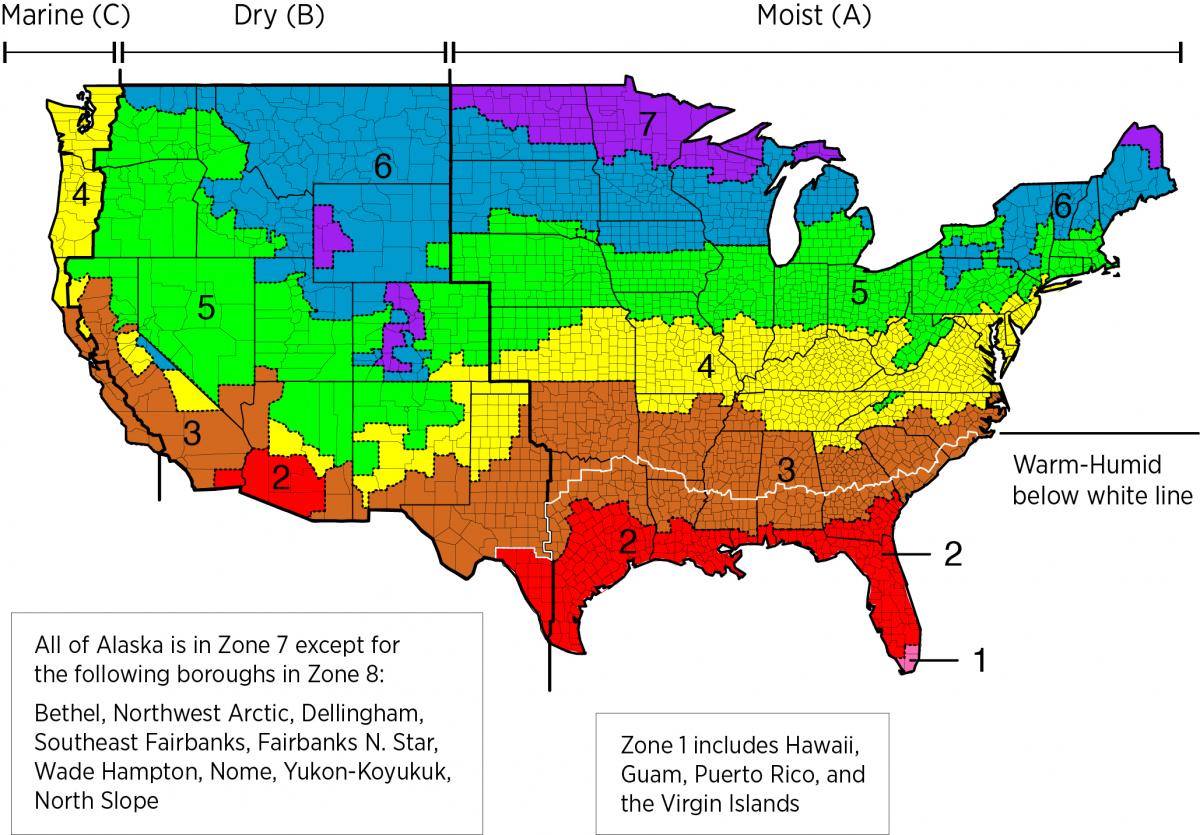

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Figure 1. Climate Zone Map from IECC 2009, 12, 15, and 18. (Source: 2012 IECC)

Figure 2. Climate Zone Map from IECC 2021. (Source: 2021 IECC)

Water Management

In cold climates (zones 5 and higher), install self-adhered membrane over the roof sheathing at the eaves from the edge of the roof line to > 2 feet up the roof deck from the interior plane of the exterior wall. (See the guide WM.3.4: Heavy Membranes at Eaves in Cold Climates.)

Thermal Enclosure

The roof assembly should be designed for a specific hygrothermal region, rain exposure zone, and interior climate. The climate zones are shown on the map below, which is taken from Figure C301.1 of the 2012 IECC.

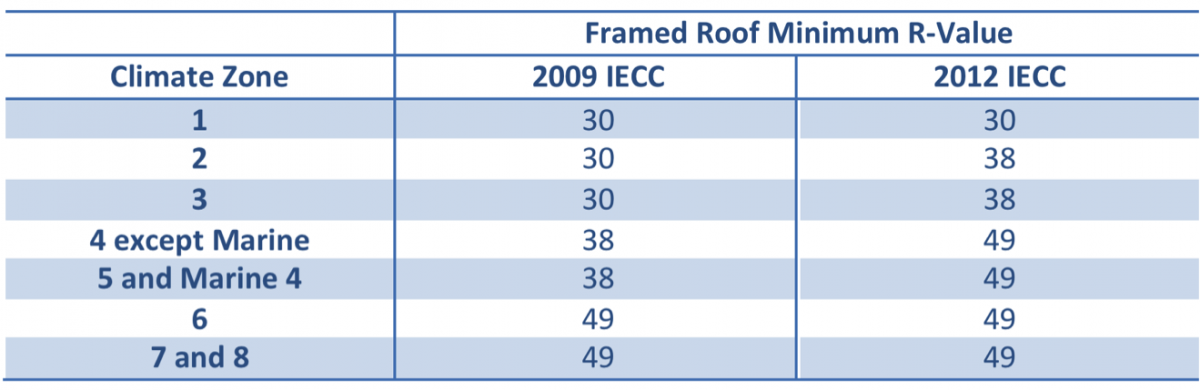

The design should be based on the minimum requirements for the currently adopted building code and energy code, respectively. Table 1 provides the minimum thermal resistance (R-value) requirements specified in the 2009 IECC (ICC 2009b) and the 2012 IECC (ICC 2012b) based on climate zone for roof assemblies.

Table 1. Attic Insulation Requirements in the 2009 and 2012 IECC. (Source: 2009 IECC and 2012 IECC)

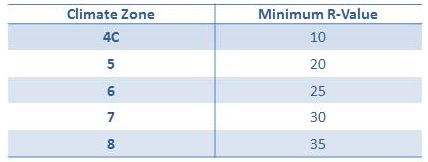

If an unvented roof design is selected, using a hybrid of air-impermeable insulation (rigid foam or spray foam) and fibrous fill (air-permeable insulation), it is vital to maintain a sufficient ratio between the two to control condensation. In colder climate zones, the amount of air-impermeable insulation needed to maintain the sheathing temperature increases. Table 2 provides information on minimum levels of air-impermeable insulation for condensation control specified in Table R806.4 Insulation for Condensation Control of the 2009 IRC (ICC 2009a) and Table R806.5 Insulation for Condensation Control of the 2012 IRC (2012a).

Table 2. Insulation required for Condensation Control in the 2009 and 2012 IRC. (Source: 2009 IRC and 2012 IRC)

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Tight Air Sealed Home = Comprehensive Draft Protection

Poorly air-sealed homes are less comfortable and cost more to maintain because they provide a pathway for drafts, cold spots, moisture, and insects into the home. Comprehensive draft protection includes a continuous air barrier around the whole house along with caulking and sealing in all holes and cracks. This includes around wiring, plumbing, ducts, and flues; where wall framing meets flooring; around windows; where drywall meets top plates and sill plates; where rim joists meet foundation walls and subfloors; etc. Spray foam insulation can be used at rim joists, floors above unconditioned space, and in attics to insulate and air seal at the same time.