Scope

Design and construct or retrofit roof assemblies to resist wind pressures at roof edges during high-wind events.

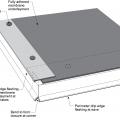

- Install a fully adhered roof membrane over the entire surface area of the roof deck.

- Install code-compliant metal drip edges at eaves and gables/rakes.

- Secure cladding at roof edges.

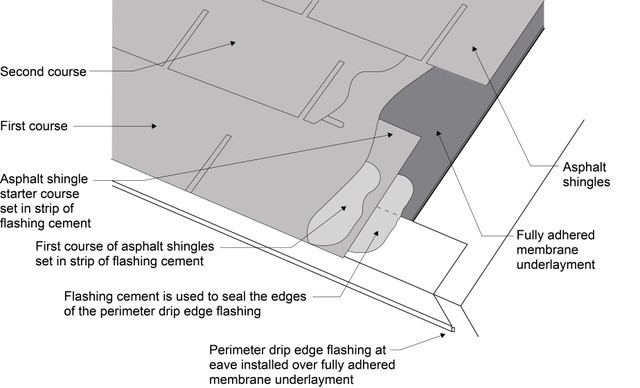

- Install asphalt shingles at eaves over an asphalt shingle starter strip that is adhered to the fully adhered membrane underlayment or the drip edge or both. Set asphalt shingles that are installed at eaves and at gables and rakes in a minimum 8-inch wide strip of flashing cement.

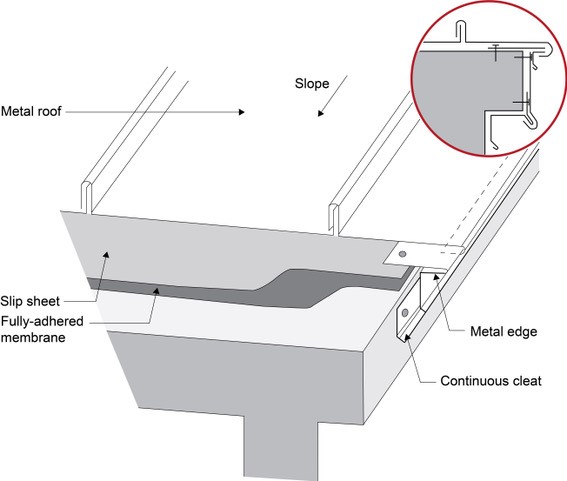

- Install metal roof cladding over a “slip sheet” installed between the metal roof and the fully adhered membrane. Also, use a continuous cleat to mechanically attach the metal roofing.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

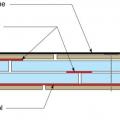

The greatest stress roof assemblies experience in high wind zones is at roof edges. That is where roofs experience the highest positive and negative air pressures. Roof assemblies need to be able to resist the wind pressures that can act on them during high wind events such as hurricanes. In addition to the highest wind pressure differences, roof edges can also experience the greatest rainwater loads. In sloping roofs, all of the rainwater incident on the roof area drains downward to the roof edge.

This guide provides guidance for the construction of roof edges in sloping roof assemblies for residential construction. The guidance is applicable to both new construction and the re-roofing of existing roof assemblies.

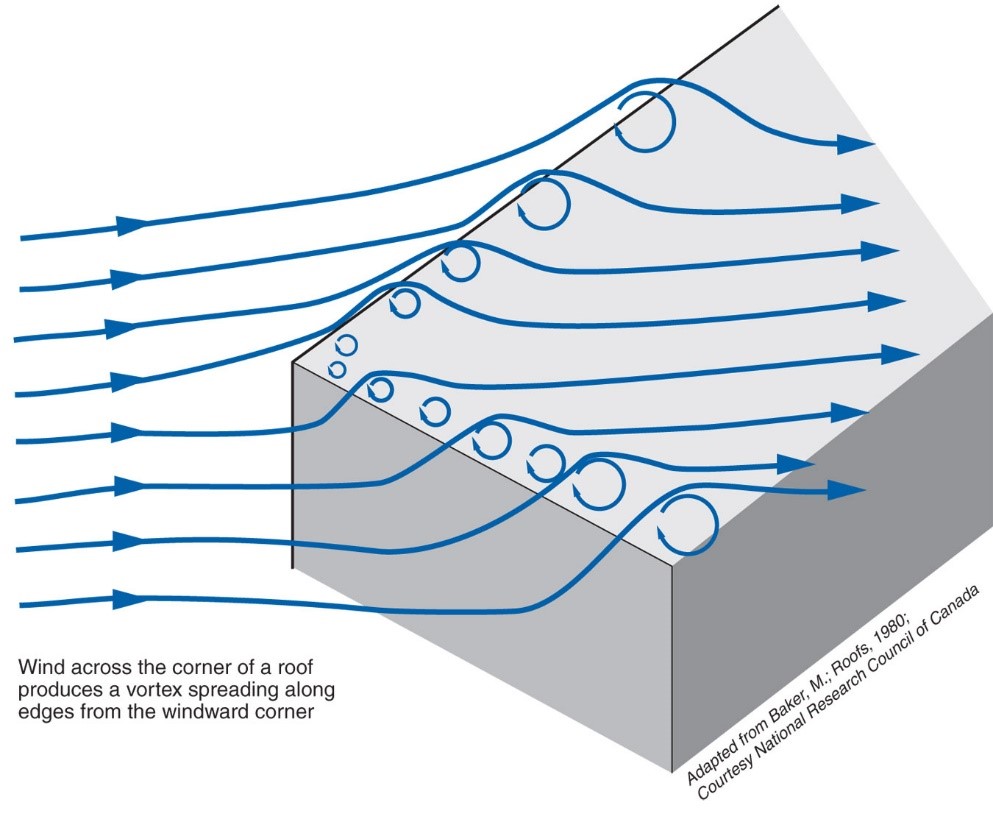

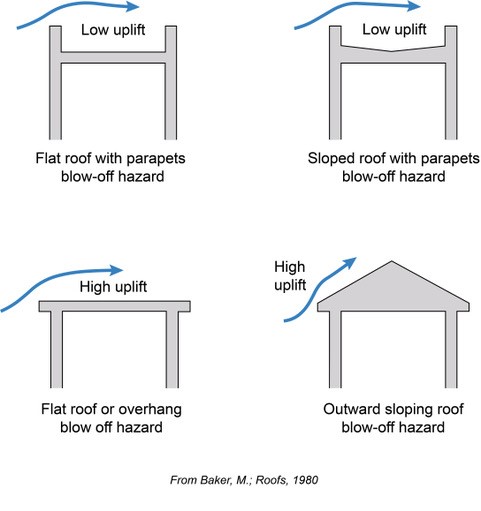

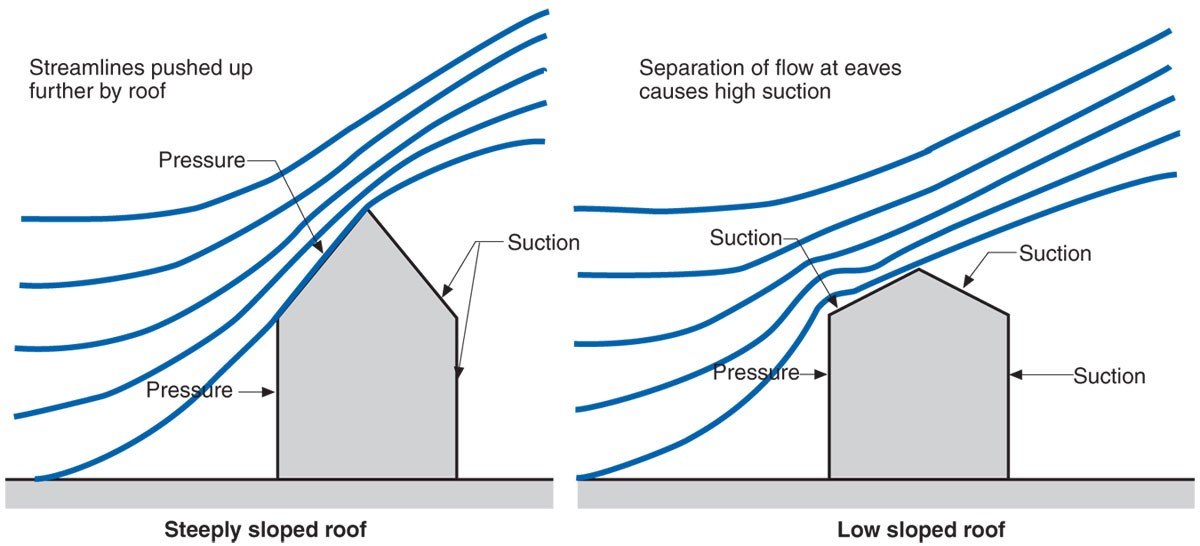

During high-wind events, high localized areas of negative pressure (“suction”) occur above roof edges due to the development of vortices (Figure 1). These pressures become more pronounced with sloping roofs typical of residential construction (Figure 2 and Figure 3). Most roof covering “blow-off” occurs at roof edges for these reasons.

In high-wind zones it is recommended – as a minimum requirement - that a fully adhered roof membrane underlayment be installed at roof eaves and roof rakes. This could be a single-ply membrane such as TPO, EPDM, or PVC, or a built-up modified bitumen, or fluid-applied membrane. Improved performance and reduced risk occurs if a fully adhered roof membrane underlayment is installed over the entire surface area of the roof deck – not just at roof eaves and roof rakes.

If a fully adhered roof membrane is not installed over the entire surface area of the roof deck, and a mechanically fastened underlayment is installed instead, alternative roof deck air sealing and water control requirements are necessary to provide acceptable performance and acceptable risk in high wind zones. Alternative roof deck air sealing and water control requirements can be found in the Insurance Institute for Building and Home Safety (IBHS) Fortified Home Hurricane Technical Summary.

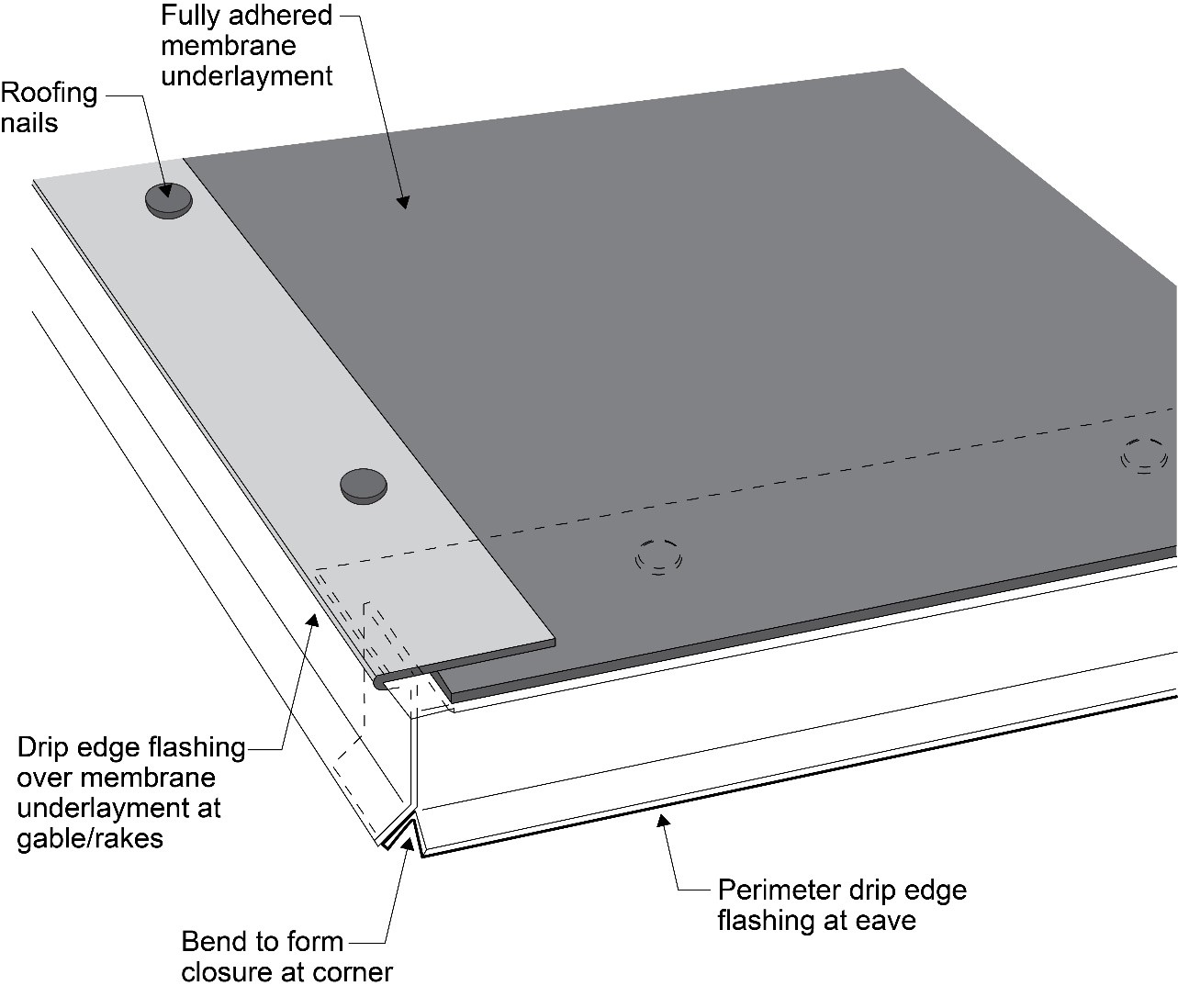

In high-wind zones, it is recommended that drip edges be installed at roof eaves and roof rakes (Figure 4). The following drip edge installation requirements are recommended:

- Code compliant metal drip edges should be installed at eaves and gables or rakes (applicable codes set the minimum gauge required).

- Drip edges should overlap a minimum of 3 inches at joints.

- Eave drip edges should extend a minimum of ½ inch below sheathing and overlap the top of the roof sheathing edge a minimum of 2 inches.

- The drip edge should be mechanically fastened to the roof deck at a maximum spacing of 4 inches and the fasteners should be compatible with the flashing.

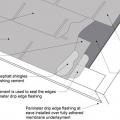

- Drip edges at eaves can be installed over the fully adhered membrane underlayment if flashing cement is used to seal the edges.

- Drip edges at gables or rakes should be installed over the fully adhered membrane underlayment.

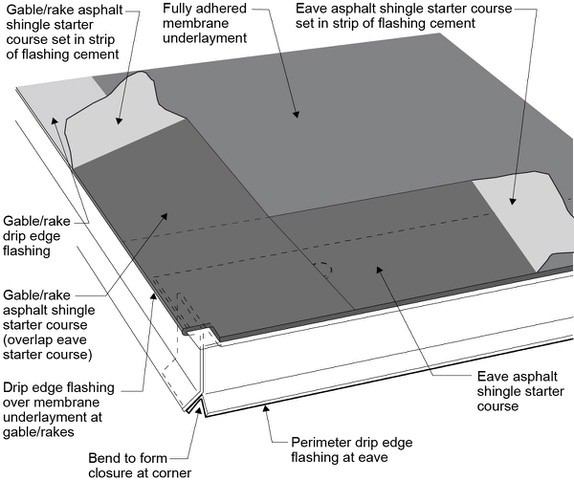

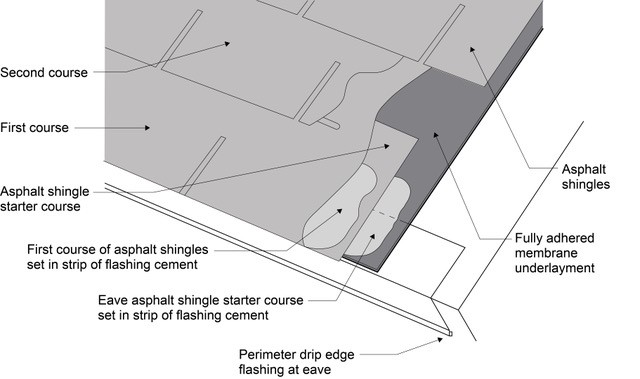

Asphalt shingles that are installed at eaves and gables or rakes should be installed over an asphalt shingle starter strip that is set in a minimum 8-inch-wide strip of flashing cement adhered to the fully adhered membrane underlayment and/or to the drip edge (Figure 5). Asphalt shingle courses are then installed over the starter course (Figure 6).

Where drip edge flashing is installed over the fully adhered membrane at the eaves, flashing cement should be used to seal the upper drip edge of the flashing (Figure 7).

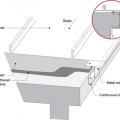

With metal roof assemblies, the approach is modified to include a “slip sheet” (typically a loose laid building paper) between the metal roof and the fully adhered membrane. The function of the “slip sheet” is to account for the significant movement that metal roof assemblies experience due to temperature changes over the course of a day, week, or season. Additionally, a continuous cleat is necessary to mechanically attach the metal roofing (Figure 8).

Success

In high wind zones it is recommended – as a minimum requirement - that a fully adhered roof membrane underlayment be installed at roof eaves and roof rakes.

Asphalt shingles that are installed at eaves should be installed over an asphalt shingle starter strip that is adhered to the fully adhered membrane underlayment, or to the drip edge, or both.

Asphalt shingles that are installed at gables/rakes should be installed set in a minimum 8-inch-wide strip of flashing cement.

Climate

IBHS Fortified Home Hurricane and High Wind Standards

Drip Edge

Drip edge must be installed (at eaves and rakes) with 3-in. laps. Drip edge shall extend ½ in. below sheathing and extend back on the roof a minimum of 2 in. Drip edge at eaves and at gable ends shall be installed over the underlayment. The drip edge shall be mechanically fastened to the roof deck at a maximum of 4 in. on center. Note: For shingle roofs, starter strips must be adhered at the eave and rake. Either embed the starter strip in roofing cement or use self-adhered starter strips

Training

CAD

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Building Science Corporation