Scope

Vent clothes dryers directly to the outdoors, except for ventless dryers equipped with a condensate drain.

- Use smooth metal ducting ≤ 35 feet in calculated length, supported ≤ every 12 feet.

- Locate duct terminus ≥ 3 feet from other openings.

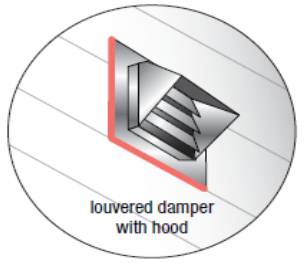

- At the terminating end of the exhaust duct (at the exterior wall), install a louvered backdraft damper with a hood.

- Don't cover the end of the duct with screening.

- Install per manufacturer's instructions and local code.

- Do not use devices that remove lint and bring the heat back into the home. This adds unwanted moisture to the house.

- Do not exhaust dryers within 10 feet of the AC condenser, which could contribute to poor HVAC operations.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Clothes dryers vent about a gallon of water for each typical load of laundry. If this vent empties into a crawlspace, attic, or other building cavity, the potential for moisture-related damage is significant (see the Training tab). Clothes dryers must vent directly to the outside using approved exhaust duct. Vinyl, nylon, and foil ducts are not recommended and if used will void the warranty of most dryers (Cranor 2005). These spiral duct designs often trap lint, which can clog the duct, requiring the dryer to work harder and longer to dry clothes and also causing it to increase dryer temperature. Not only is a poorly exhausting dryer less efficient, it can also be a fire hazard due to the flammability of the collected lint (NFPA 2013). The use of PVC pipe for dryer exhaust ducts is also not allowed per all standards and specifications.

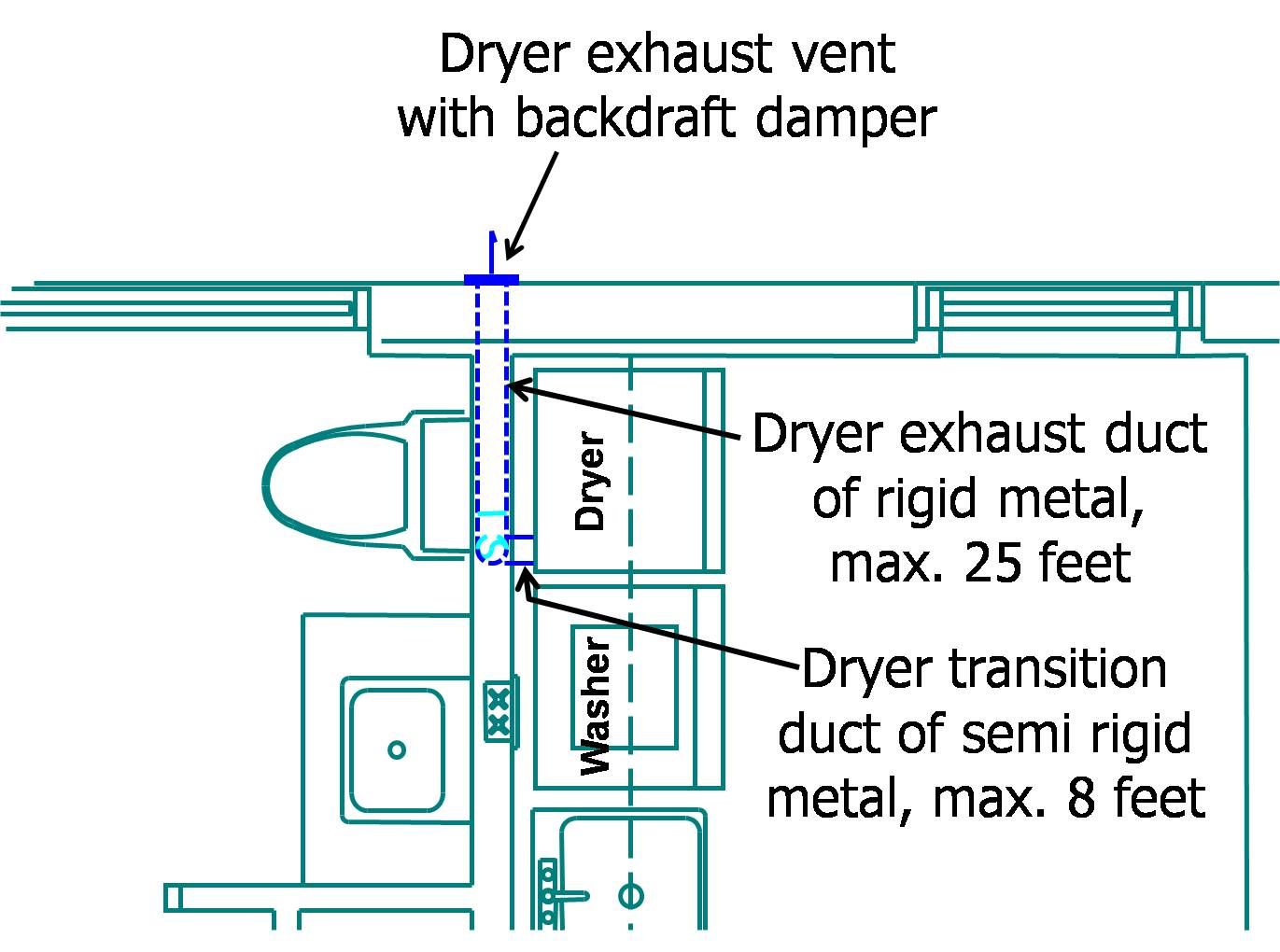

Per the requirements of the International Residential Code, Section M1502 (2009-2021 IRC), the clothes dryer exhaust duct should be a rigid or semi-rigid metal duct made of galvanized steel or galvanized aluminum with a smooth interior finish and a duct diameter of 4 inches. Short, straight, horizontal duct runs are the most effective. Runs should be horizontal with a slight downward angle if at all possible to allow any condensation from water vapor in the exhaust air to drain. The duct length from the wall to the outlet terminal should be no more than 35 feet, including equivalent length for any fittings. Or, follow the duct length recommendations specified by the manufacturer (2009-2018 IRC M1502, see Compliance tab). The duct should be secured in place and supported at 12-foot intervals. Avoid sags in the duct. See the IRC for calculating duct length, taking into account duct diameter and bends in the duct.

The transition duct (the visible piece of duct connecting the dryer to the wall) can be up to 8 feet and should be listed in accordance with UL 2158A; there are some semi-rigid metal transition duct products that are UL listed. The ducts should be joined with clamps or foil tape. Screws or similar fasteners that can protrude into the inside of the duct and catch lint must not be used. The exhaust duct should terminate outside the building at least 3 feet from any building opening and at least 10 feet from an AC or heat pump condenser. The duct termination should be fitted with a closeable gravity or automatic damper. A louvered damper is more effective than a single hinged door. No screen should be installed in the duct terminus (IRC M1502.3, see Compliance tab).

When the clothes dryer is not installed at the time of occupancy, the exhaust duct opening inside the home should be capped or plugged and marked as “dryer duct, future use.” If the dryer duct is run through walls where nails or screws from finish carpentry or other work are likely to penetrate the ducting then protective steel sheet metal plates (≥ 1.6mm) should be installed on the finished face of framing members where there is less than 1.25 inches between the duct and the finished face of the framing (2009-2018 IRC M1502).

When installing the interior duct terminus in the laundry area inside the home, consider using a telescoping rigid metal transition duct or installing an inset box in the wall where the dryer will be located to allow space in the wall cavity for the connecting duct to come up from the floor to the port on the back of the dryer. This inset allows the connecting duct to be straight and not be crushed or looped behind the dryer in ways that severely restrict air flow and can cause a fire hazard from trapped lint. There are several commercially available products or this inset can be constructed on site with 2x4 blocking, drywall, and tape and mud to air seal the seams (Bailes 2010).

How to Install Dryer Exhaust Duct

- Install a rigid metal (aluminum or galvanized steel) exhaust duct connecting the transition duct to the exhaust duct outlet terminal. The exhaust duct should be rigid metal 4 inches in diameter and no more than 35 feet in length or as specified by the duct manufacturer. This length should be decreased by 2.5 feet for every 45-degree bend the duct makes and 5 feet for every 90-degree bend the duct makes. Any joints should be installed in the direction of air flow.

- Support the duct at least every 12 feet, and at all joints. Avoid sags. Air seal any joints with foil tape.

- At the interior wall, connect the exhaust duct to a transition duct that connects directly to the dryer. The transition duct should be UL-2158A listed and should be no longer than 8 feet. Short, direct, semi-rigid metal transition duct is preferred. The ducts should be joined with clamps or foil tape, not screws or similar fasteners that can protrude into the inside of the duct and trap lint.

- Locate the exhaust terminal at least 3 feet from any door or window and away from the fresh air intake of a high-efficiency furnace, water heater, or any other HVAC intake. It should also be located away from air conditioning or heat pump condensing units installed outside. Avoid terminating the duct at the roof. If possible, locate the exhaust terminal so that the exhaust duct will run horizontally with a slightly downward slope (1/4 inch per foot) to reduce the possibility that condensation will accumulate (Cranor 2005).

- At the terminating end of the exhaust duct (at the exterior wall), install a backdraft damper. The hood opening should point down and should be at least 12 inches above the ground (Cranor 2005). A louvered damper is more effective than a single hinged door. No screen should be installed in the duct terminus. Flash and caulk the exterior wall penetration.

- Insulate ducts in unconditioned spaces, especially in cold climates, to avoid condensation.

Recommendations for the Home Owner

Homeowner education is important for the long-term safe operation of a clothes dryer. Consider providing the homeowner with the following recommendations (from InterNACHI).

- Always use a lint filter or screen.

- Clean the lint filter before or after each load of laundry.

- Remove any visible lint within the dryer.

- At least once a year, have a professional technician clean the dryer exhaust duct.

- Gas dryers should be cleaned and serviced regularly by a professional.

- Follow the manufacturer’s operating instructions and don’t overload the dryer. Also, don't attempt to dry soaking wet laundry that hasn't been wrung out or gone through a washing machine's spin cycle to remove excess moisture.

- Turn off the dryer when leaving home and before going to bed.

- Install a fire extinguisher in the laundry area.

- Install a smoke alarm in the laundry area.

- Install a CO alarm in the laundry area for a gas dryer.

Success

Verify with a visual inspection that the clothes dryer vents directly to the outdoors or is a ventless dryer equipped with a condensate drain.

Because clothes dryers exhaust air from the home, if other atmospherically vented combustion appliances are located in the same room as the clothes dryer, the room or combustion appliance zone where these appliances are located should be tested to ensure that enough makeup air is present so that those combustion appliances will not backdraft. Backdrafting could occur for example if a clothes dryer and an atmospherically drafted water heater are located in the same room and there is not enough makeup air provided to the room to compensate for air exhausted when all exhausting appliances are operating at the same time. If the room becomes depressurized, exhaust byproducts could be pulled back into the room rather than exiting up the flue. In the worse case situation, flame rollout could occur where the flame from the water heater's burner is pulled into the room, which could cause damage to the water heater and potentially spread fire to other objects in the room. For information on combustion appliance zone testing, see the guide Pre-Retrofit Assessment of Combustion Appliances or Combustion Appliance Zone (CAZ) Testing. If backdrafting conditions are found to exist, a fresh air intake should be provided to the room where the combustion appliances are located. Additional options include replacing the venting clothes dryer with a ventless dryer and/or replacing atmospherically vented combustion appliances with closed-combustion, direct-vent appliances.

Climate

No climate specific information applies.

Training

Compliance

Retrofit

SCOPE

For ducted (noncondensing) clothes dryers, inspect and repair the dryer exhaust duct to improve safety and performance.

- Inspect the dryer exhaust duct for lint build up.

- Clean the exhaust duct.

- Replace ducting with smooth metal duct at least 4 inches in diameter if needed.

- If the duct is excessively long and/or is routed upward vertically, reroute to a shorter and/or more horizontal position or install an in-line booster fan to improve airflow.

See the U.S. Department of Energy’s Standard Work Specifications for more on safe clothes dryer venting.

DESCRIPTION

Poorly performing clothes dryers are a common source of service calls to appliance repair shops. When complaints include issues such as the clothes are too damp, it’s taking too long to dry, the clothes are getting too hot, or there’s a burning smell, then the source of the problems may not be the dryer at all but may actually lie with the exhaust duct. A clothes dryer pulls in air from the room in which it is located, heats that air, and then exhausts it to the outdoors via an exhaust duct. The dryer relies on good airflow to dry the clothes. Water vapor from the drying clothes is pushed out the exhaust duct, often carrying a considerable amount of lint with it. Short, straight, horizontal, smooth metal-surfaced exhaust ducts provide the best performance. Excessive length, upward angles, kinks, narrow ducts or transitions, and nonsmooth surfaces can all increase resistance in the duct, reducing air flow and contributing to lint build up which overtime can decrease or completely block the airflow. In response, some clothes dryers will quit working but some clothes dryers will continue to heat up in an attempt to dry the clothes. This will cause the clothing to become very hot and it may cause the clothing, or lint stuck in the vent, to catch on fire.

The clothes dryer exhaust duct should be inspected in response to clothes dryer complaints; it should also be inspected and cleaned periodically. Inspections often reveal crushed, kinked, or clogged ducts. Detach the exhaust vent and inspect both the transition hose from the dryer to the wall or floor and the exhaust duct from the interior wall or floor to the exterior wall. There are cleaning kits available to clean the exhaust duct. Vacuum out the transition hose from the dryer to the wall. Replace damaged ducts. Replace ducts made of vinyl, nylon, or foil. If used, they will void the warranty of most dryers. Spiral-duct designs often trap lint and should not be used. The use of PVC pipe for dryer exhaust ducts is also not allowed by modern building standards.

If the exhaust duct is excessively long, has several bends, or is angled upward, for example through the roof, determine if it is possible to reroute the duct via a shorter, straighter, and/or horizontal route to the outside. If the duct route must be long or upward angled, consider installing an inline booster fan. See the Training tab for examples.

If the dryer is in a location where the transition duct is getting kinked or crushed, consider installing a wall inset to provide more space for the transition duct. See the Description tab.

Inspect the duct terminus at the exterior wall. The terminus should be covered with a hooded, louvered gravity damper. If the opening is covered with a screen (see Training tab), remove and replace it with a louvered damper. If the opening is covered with a single flap damper, consider replacing it with a louvered damper.

See the Description tab for a list of recommendations to provide to the homeowner for continued safe dryer operation.

COMPLIANCE

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.