Scope

Properly install all water-using fixtures, equipment, and appliances such that there are no leaks detected from the hot water delivery system, toilets/urinals, sink faucets, showerheads, or from other fixtures or appliances.

For homes seeking certification through EPA's WaterSense program, compliance for toilets shall be verified through visual assessment and by conducting a dye tablet test in each toilet to ensure the flapper is not leaking.

For all other water-using fixtures, compliance shall be verified through pressure-loss testing on all water supplies and visual inspection.

See the Compliance tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

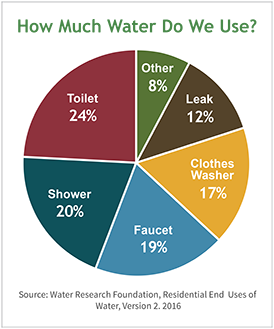

An American home can waste, on average, more than 10,000 gallons of water every year due to running toilets, dripping faucets, and other household leaks (Figure 1).

Likely sources of leaks include:

- Pipes and fittings running between the utility’s water main and the foundation of the home.

- All connection points in the hot water delivery system.

- Toilet angle valves and connections.

- Toilet flapper valves.

- Hot/cold water connection hoses and valves at kitchen and bathroom faucets (Figure 2).

- Shower arm and showerhead threaded connections (Figure 3).

- Shower diverter in bath/shower combinations (Figure 4).

- Connections and valves to dishwashers, clothes washers, refrigerator ice machines, evaporative air conditioners, water softeners, and drinking water treatment systems, if installed (Figures 5 and 6).

Builders who are seeking to certify a home through the U.S. Environmental Protection Agency's WaterSense program must verify that the home does not leak. The verification procedure, which is conducted by a third-party verifier, is described in the Ensuring Success tab.

Leak detection devices are not required to be installed in an EPA WaterSense® labeled home. However, many devices and systems are commercially available to detect leaks in residential plumbing systems at predetermined locations (e.g., clothes washers, dishwashers, toilets, water heaters, sinks, and pipes that may freeze). Some devices automatically shut off the water supply to the house or to the specific appliance to reduce water loss through leaks or ruptures. Other devices may sound a loud alarm for early water leak detection. Most of these devices have components that are battery operated and therefore require homeowner maintenance to ensure performance. If operating correctly, devices that automatically shut off the water may significantly reduce the amount of water loss through leaks and ruptures. They may also serve as a selling feature of the house due to their potential to reduce or prevent property damage caused by flooding.

Installing water meters at each single-family home, if not provided by the municipality, is another way for homeowners to check for leaks. Water meters can indicate that a leak exists if flow is detected when all water fixtures are turned off. Residents could also benefit from the installation of a water meter by obtaining a more accurate account of water use for utility billing purposes.

Success

To determine if there are any leaks in the home, EPA WaterSense verifiers will conduct a pressure-loss test.

Pressure-loss testing in single-family homes includes the following:

- For homes with only one water supply to the home, the verifier will attach a pressure gauge to an outside faucet, take a reading, and then shut off the municipal water supply to the house. After several minutes, the verifier will determine if the pressure has dropped. A loss of pressure indicates an unseen leak.

- For homes with more than one water supply or without an outdoor faucet, verifiers will attach a pressure gauge to the cold water faucet for the washing machine hookup or other cold water faucet and take the pressure reading.

- For homes with a separate water supply for irrigation (e.g., reclaimed water), the verifier will check both the outdoor and indoor water supplies for leaks using the approach described above.

All leaks must be fixed before a home can be certified and receive the WaterSense® label certificate.

Conducting a pressure-loss test on homes in multi-family buildings will vary based on the plumbing system design. Homes that are supplied through a single line with a shut-off can be tested at any point of use within the home. If the home is supplied by multiple supply lines, the verifier will need to coordinate with the builder to ensure that all individual supply systems are tested.

During the verification, the verifier will check for leaks at all visible water supply connections and valves for water-using fixtures, appliances, and equipment. To check for toilet leaks from the flapper valve, the inspector will remove the tank lid and add some food coloring or a dye tablet to the tank. After about 5 minutes, if the water in the toilet bowl is colored, the flapper valve is leaking. Flush immediately upon completing the experiment and check to make sure the tank and bowl are both clear of the coloring to avoid any staining.

If possible, the builder can fix any identified leaks while the verifier is still at the home, and those areas can be immediately re-verified. Some leaks, such as those from irrigation systems, may be more difficult to immediately fix and may require re-verification at a later date.

Climate

No climate specific information applies.

Training

Compliance

Retrofit

SCOPE

DOE’s Standard Work Specifications describes practices to complete whole-house energy upgrades safely without injury or hazardous exposure in the section on Global Worker Safety. The Standard Work Specifications also addresses water leaks and leak detection.

DESCRIPTION

In existing homes, repairing leaks may involve cutting into walls or other finished surfaces. If cutting through plaster and wood lath surfaces, additional care will be required to minimize crumbling of the plaster. High-speed cutting tools, such as powered multi-tools or an angle grinder with a diamond blade, can assist in making clean cuts through the plaster and lath (but will create a considerable amount of dust. A vacuum operating next to the tool while cutting can capture some dust. Another trick is to apply a sealing compound to the back side of the lathe, if it is accessible, prior to cutting to minimize flexing. Masking tape may be applied to the lines to be cut to help hold lathe together. Wetting may also help reduce dust generation.

Existing surfaces may be finished with paint containing lead, especially in homes built before 1978. Old plaster may contain asbestos. The following assessment guide contains information on hazardous materials: Pre-Pre-Retrofit Assessment of Hazardous Materials.

Any penetrations through exterior walls, or floors, or ceilings that abut nonconditioned space must be sealed. See the guides on air sealing electrical wiring and plumbing penetrations. Other guides are also available that cover other air sealing strategies. Use “Search” to find specific topics, such as garage walls, ceilings, and others.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Water Efficient Indoor =

Water is an increasingly precious commodity. Choices in fixtures, appliances, and even design can help conserve this vital resource.