Scope

Install a gas-fired tankless hot water heater in a new or existing home to provide domestic hot water that is heated on demand without the standby losses associated with tank storage water heaters.

Equipment Selection

- Determine the required capacity for a gas-fired tankless water heater. Calculate the practical maximum flow rate needed at any one time. Determine the required temperature rise (based on winter time cold water temperature and desired hot water temperature setpoint).

- Select a gas-fired tankless water heater that is able to provide the desired flow rate and temperature rise according to the manufacturer’s specifications. An ENERGY STAR qualifying tankless water heater is encouraged.

Site Validation

- Confirm that the home has sufficient gas supply to allow the installation of the selected tankless water heater without impacting other gas appliances.

- Determine location of water heater. If gas, ensure that required clearances for the equipment and venting are met. If a condensing unit, confirm that a means for removing the condensate is provided that meets local code requirements.

Installation Requirements

- Install the tankless water heater using rust- and corrosion-proof hardware that is compliant with local code requirements and manufacturer recommendations. Ensure unit is level.

- Connect water heater to venting system, gas line, and electricity in a manner compliant with all local codes and manufacturer recommendations. Ensure all required valves, expansion tanks, and piping required for the performance and maintenance of the selected tankless water heater are installed.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Most conventional residential water heaters store hot water in a tank (typically 20-80 gallons). The tank allows a relatively large volume of water to be used in a very short time. After such a large draw, the burner will fire to heat the tank back up to the set point temperature (usually near 120°F). A key drawback of this system is familiar to most people: after a large draw (e.g., a long shower), hot water may not be available until the tank heats up again; this can take 20-30 minutes (or more) in many systems.

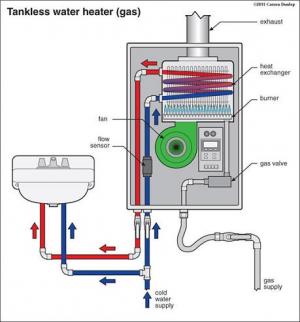

Tankless water heaters (sometimes called instantaneous or on-demand water heaters) do not have large storage tanks (Figure 1). When a hot water tap is turned on, cold water enters the unit from the cold water supply. A sensor detects the water flow and activates a heating device, which raises the water temperature to a preset level. When the water flow from the fixture stops, the heating element shuts off. Tankless water heaters only consume energy when they are on. Because tankless water heaters do not have to keep a large reservoir of water hot, they have almost none of the stand-by losses that tank water heaters have. Thus tankless water heaters can significantly reduce water heating energy use. (IBACOS 2012). Another appealing feature of tankless water heaters is that occupants don’t “run out” of hot water. One can theoretically shower forever because there is no tank to drain. However, there is a limit to the volume of hot water available at any given time. For example, if home occupants try to take two showers, start laundry, and wash dishes at the same time, the delivered hot water may not be as hot as desired.

Tank water heaters have modulating burners or several staged burners that can provide a variable amount of heat depending on the hot water flow rate. Because these burners heat water as it is used, the burners are much larger. Typical burners for residential tank-type water heaters are often 30,000 – 50,000 Btu/h while tankless water heaters typically have burner capacities of 120,000 – 200,000 Btu/h.

Equipment Selection

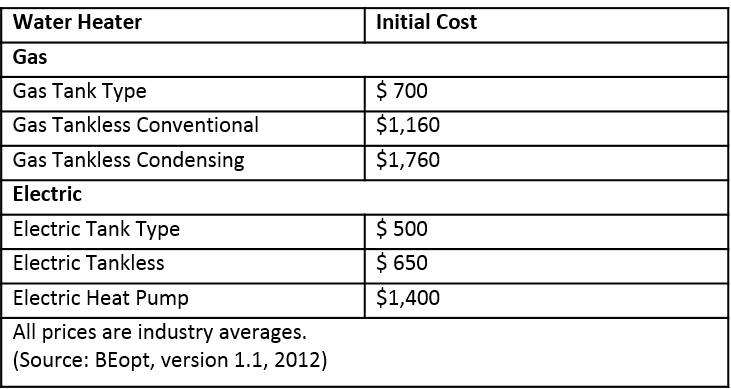

Although the initial installed cost of a tankless water heater can be 1½–2 times as much as that of a tank-type water heater, the tankless water heater costs less annually to operate. Table 1 shows average industry costs for tank, tankless, and condensing tankless gas and electric water heaters (analysis from 2012). Tankless water heaters can cut energy costs by 5%–40% compared to a tank-type water heater using the same fuel type. The efficiency of a water heater is indicated by its energy factor (EF), a value determined by standardized testing. The higher the EF rating, the more efficiently the unit uses energy. As with automobiles, the actual efficiency of the product depends on the operating conditions. The EF for residential gas-fired tank water heaters can be 0.57–0.70. Gas-fired tankless water heaters typically have an EF of 0.82–0.94, depending on whether the unit is a standard or condensing unit (Figure 2).

Electric tankless water heaters can also save energy. However, they provide less hot water flow than gas-fired units. Because of their instantaneous nature, electric versions can create high peak loads for electric utilities. In areas where utilities charge more for electricity at peak times, these systems could be especially expensive for consumers. If natural gas is not available consider the installation of a heat pump water heater. Tankless water heaters are generally considered to last up to 20 years, compared to 10–15 years for tank-type water heaters (IBACOS 2012).

Equipment Sizing

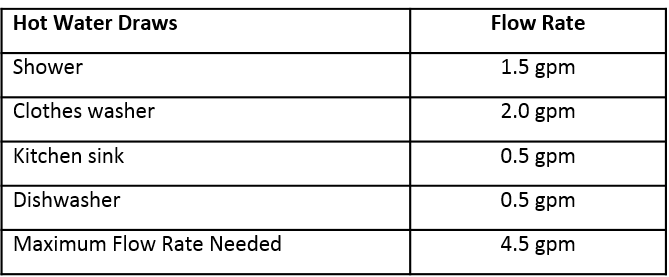

Sizing tankless water heaters is somewhat different than sizing storage water heaters. Sizing is based on the practical maximum flow rate needed at any one time. To determine the maximum flow rate needed, make a list of coincident hot water draws as shown in the example in Table 2.

Note that showerheads may be rated at higher flow rates (e.g., 2 gpm), but in this example it’s assumed that 1.5 gpm of hot water (~120°F) is mixed with colder water to achieve the desired temperature. Flow rates for appliances may be difficult to determine, but many newer, efficient appliances have much lower hot water draws.

Note also in this example that there is one shower shown. A home may have a second (and perhaps third) shower, but it is assumed to be unlikely that all showers, the clothes washer, and the dishwasher will need to be run at the same time.

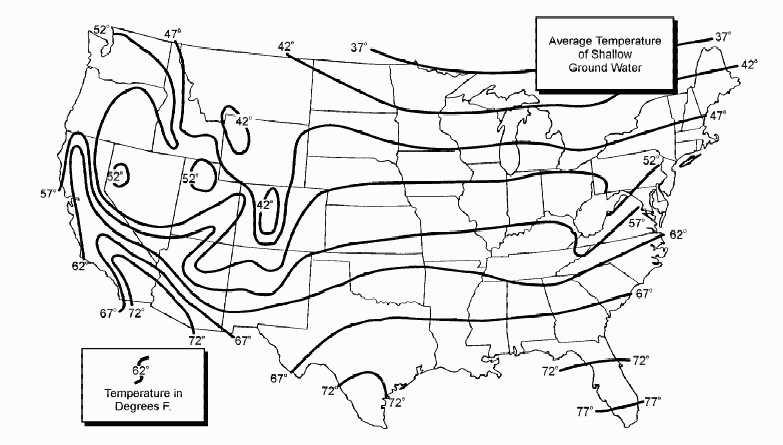

Once you’ve determined the practical maximum flow rate (4.5 gpm in the example above), determine the temperature rise. Typical hot water supply temperatures are near 120°F. The map in Figure 3 shows the average temperature of shallow ground water for different regions of the United States. Use this map (or one similar) to determine typical cold water temperature in your region. For example, in Seattle the average ground water temperature is approximately 52°F. Therefore, the temperature rise to reach 120°F is 68°F, so in this example, one would look for a tankless water heater model that can provide at least 4.5 gpm with a temperature rise of 68°F.

Figure 4 shows an example of a flow rate-versus-temperature rise graph for a tankless water heater model. According to the graph, this water heater model could provide 4.5 gpm at a temperature rise of 68°F so this model would work.

In addition to maximum hot water delivery, also pay attention to minimum hot water flow rates. When washing hands or washing dishes, often flow rates below 0.5 gpm are desired, but not all tankless water heaters can deliver flow rates this low. Minimum flow rates should be listed in the product manufacturer’s literature.

Condensing versus Non Condensing and Venting of Tankless Gas Water Heaters

Condensing gas tankless water heaters are typically vented through a sidewall rather than through the roof. Most fuel-fired tankless water heaters are direct vent and many are sealed combustion. Exhaust gases are blown directly out through a vent in the wall, not up a flue or chimney. Sealed-combustion units are usually configured with two separate vent pipes, one for intake air and one for exhaust air. However, some models will work with concentric intake and exhaust air pipe-within-a-pipe configuration, requiring only one hole through the outside wall. Sealed combustion appliances are strongly recommended in all homes, especially in tight homes where backdrafting is a greater risk.

While using a through-the-wall venting may streamline installation as no venting through the roof is required, this could also complicate installation in existing homes where an old water heater did use a chimney that needs to be sealed off. The ideal location for a tankless gas water heater is on or near an outside wall. In an existing home this may require changing the location of the water heater.

Gas tankless water heaters may be condensing or noncondensing. With any fuel-burning combustion appliance, as the fuel burns, hot gases and steam are produced. In a noncondensing gas water heater, these got emissions (about 300° F) are vented outside. The steam condenses to water vapor when it exits the exhaust pipe. Because the condensate water is corrosive (pH 3-5), the exhaust pipe material must be non-corrosive as well as able to withstand high temperatures; for example, Category 3 stainless steel. About 20% of the heat is exhausted out the vent so noncondensing gas water heaters have efficiencies of about 80. Condensing tankless gas water heaters use a secondary heat exchanger to extract more heat out of the exhaust gases, enabling them to achieve efficiencies of greater than 90%. Because the exhaust gases are cooler (around 100°), condensing units can use less expensive PVC for exhaust venting.

Tankless water heater costs have fallen as the systems have become more popular. However, both equipment and installation costs vary, depending on locale. The hardware itself is generally more expensive than for tank-type heaters. Installation costs, however, can be lower than for gas tank water heaters – especially if the cost of a flue or chimney can be eliminated. Refer to manufacturers’ installation guidelines for specific venting requirements for the selected water heater. Electric tankless water heaters require no venting.

Condensing water heaters are generally the only products that achieve ENERGY STAR certification. Read the product literature or Energy Guide labels to compare efficiencies (Figure 4). Look for the ENERGY STAR label or check the ENERGY STAR website for efficient models.

Gas Piping

Because fuel-fired tankless water heaters have much larger burners, they often require larger gas lines. Depending on what other combustion appliances are installed and pipe length, a tankless water heater might require a ¾-inch branch lines whereas many tank-type water heaters need only ½-inch gas piping. For example, a tankless water heater might require 199,900 BTUs while a typical tank water heater requires 40,000 BTU capacity when operating. Both the main trunk line from the meter to the house and the main branch lines may need to be sized larger than they would for a storage tank water heater to ensure that the pipe lines have enough capacity without too much pressure drop even if all of the gas appliances in the home were operating at the same time. Tankless Water Heating Gas Piping Facts provides a good explanation along with the pipe diameter formula from the National Fuel Gas Code (NFPA 54, ANSI Z223.1, Section 6.4.1).

Scaling and Maintenance

In some installations, especially in areas with hard water, scale can build up on the piping in the heat exchangers. This reduces capacity and efficiency and in extreme situations can cause complete water heater failure. Many manufacturers recommend professional, yearly cleaning of the heat exchanger with a mild acid solution (such as vinegar). To facilitate this, “flush kit” valves should be installed during installation that allow the water heater to be isolated from the rest of the home’s plumbing system. After isolation, a pump can be connected to flush the heat exchanger with the acid solution. Adding these valves during installation is a small cost that can provide much longer and more reliable performance. Of course refer to the installation and owner’s manuals for details about specific products.

Hot Water Distribution and Pipe Insulation

The water distribution system directly affects the delivery time of hot water from a tankless water heater to individual fixtures and appliances. Many older plumbing systems were installed using a trunk and branch piping layout. The remote manifold layout uses several small manifolds to group short pipe runs for the kitchen, bathrooms, and laundry. A homerun distribution system where all hot water uses have their own PEX line running to a large central manifold is the most efficient system to deliver hot water from a tankless water heater (IBACOS 2012). As with any hot water system, insulating the piping can reduce distribution heat loss. In new construction, insulate all hot water lines. In retrofit installations, install insulation on any accessible pipes, such as pipes visible next to the water heater in a basement or mechanical room. Builders who are seeking certification to the DOE Zero Energy Ready Home program must meet the U.S. Environmental Protection Agency’s WaterSense hot water distribution criteria; for more information on hot water distribution efficiency, see the EPA’s WaterSense Homes Specification and EPA’s Guide for Efficient Hot Water Delivery Systems.

Condensate Management

Condensing water heaters have condensate that must be drained or piped away. Refer to manufacturers’ instructions and check with local codes to properly drain and dispose of this condensate, which may acidic. In addition to providing a method to dispose of the condensate, a neutralizing system is recommended, as the condensate is slightly acidic and can damage drain pipes over time. The neutralizing system needs to be properly maintained to be effective.

Hot Water Recirculation and the Cold Water Sandwich Effect

While several manufacturers offer on-demand recirculation systems for tankless water heaters, these solutions have a limitation. The pump shuts off when the desired temperature is met. This means that the burner also shuts down. So, when the faucet is then opened, there is the potential for a small amount of cold water to pass through the water heater before the burner re-ignites. This is commonly-referred to as the “cold-water sandwich effect,” because there is hot water in both ends of the pipe with a small amount of cold water in between that can be an unwelcome surprise for users. The most common way to deal with this issue is to install a small electric storage tank that is maintained at the desired hot water temperature - essentially a hybrid between storage and tankless water heating. This added tank can be as small as 5 or 10 gallons. Some manufacturers have even built this minimal water storage into their tankless water heaters. See the article Why Add a Tank to a Tankless Water Heater? for more information.

How to Install

Follow manufacturer’s instructions.

Include a backup drain pan as a precautionary measure; it can also be used during maintenance to drain the unit.

Success

Gas-fired tankless water heaters produce higher flow rates than electric on-demand heaters. Because of their instantaneous nature, electric versions can create high peak loads for electric utilities. In areas where utilities charge more for electricity at peak times, these systems could be especially expensive for consumers. If natural gas is not available consider the installation of a heat pump water heater.

When furnaces, boilers, and water heaters are installed within the home’s pressure boundary (i.e., within the thermal envelope), this equipment should be direct-vent/sealed-combustion equipment. ENERGY STAR permits non-direct-vented combustion appliances in Climate Zones 1, 2, and 3. If atmospheric-vented furnaces, boilers, or water heaters are installed in a confined space or an air-tight building, two fresh air supply ducts or openings must be installed to provide combustion air in the combustion appliance zone (CAZ) as required by NFPA 54, Sections 5.3.3 and 5.3.4. If the furnace, boiler, or water heater to be installed is atmospheric or mechanically vented and draws its combustion air from the combustion appliance zone, the rater must test the equipment using the Building Performance Institute (BPI 2012) or RESNET-approved procedures for depressurization, spillage, draft pressure, and CO concentration in the ambient air and in the flue. Ambient CO concentration should be < 25 ppm (< 8 ppm is preferred).

Climate

Location of Tankless Water Heater – Indoors or Outdoors

Follow manufacturer guidelines on whether climate conditions in your area are suitable for installing a tankless water heater outdoors. The climate needs to be warm year-round to avoid the potential of water lines freezing, so typically tankless water heaters should only be installed outdoors in climate zones 1 and 2. A number of outdoor tankless water heater models have freeze protection features, but these consume more energy and the plumbing lines leading to and from the outdoor tankless heater need freeze protection (e.g., heat trace) as well.

Equipment Sizing

As mentioned in the Description tab, sizing of tankless water heaters is based on the practical maximum flow rate needed at any one time in a home and the required heat rise of the water (which is dependent on the winter cold water temperature in your home’s location and the hot water setpoint temperature). Refer to the flow rate versus temperature rise graph in the product specification information to determine if the equipment can achieve the desired hot water performance. An example graph is shown in the Description tab.

Cold Climates

In cold climates, in addition to proper sizing, it is critical to use sealed-combustion, direct-vent, or power-vented equipment. It is also critical to make sure that the air intake and exhaust discharge vents are located sufficiently above anticipated snow line. The intake should be sufficiently separated from the exhaust vent to prevent frost buildup on the cold air intake pipe. The exhaust discharge must be sufficiently high so that frozen condensation that may accumulate on the ground will not block the exhaust pipe. Condensate lines should be directed to an indoor drain.

Training

Compliance

Compliance

ENERGY STAR Tankless Gas Water Heaters

International Residential Code (IRC)

International Plumbing Code (IPC)

American National Standards Institute (ANSI) Z21.10.3 / CSA 4.3-2017

National Fire Protection Association (NFPA) 54, American National Standards Institute (ANSI) Z223.1-2018

Retrofit

SCOPE

Install a gas-fired tankless water heater in an existing home.

Follow the installation instructions in the Scope and Description tabs of this guide.

See the U.S. Department of Energy’s Standard Work Specifications for more information on tankless water heaters.

DESCRIPTION

When selecting a tankless water heater, make sure to verify that the unit is sufficiently sized for your hot water needs based on expected temperature rise, total hot water flow (gpm) needs, and gas line capacity.

Gas line

The available size and pressure of the natural gas lines to an existing home may be the determining factor in whether a tankless gas water heater can be installed. Often the gas line from the street needs to be upsized to meet the additional demand of a tankless water heater, along with all other gas appliances that will be served in the home. Most tankless gas water heaters require a minimum ¾-inch gas line from the street and code may require it, while 1/2 –inch line is typically sufficient for tank water heaters and other gas appliances. Many manufacturers now offer tankless gas water heaters that operate with a ½-inch natural gas line feed; however, the heating capacity of these units typically tops out around 150,000 Btuh; also, other factors must be accounted for in determining adequate pipe capacity, including other gas appliances in the home and pipe line lengths (including elbows and Ts). Tankless Water Heating Gas Piping Facts provides a good explanation of pipe sizing issues along with the pipe diameter formula from the National Fuel Gas Code (NFPA 54, ANSI Z223.1, Section 6.4.1).

Electricity

Even natural gas water heaters will require 120 volts AC outlet for the controls, sensors, and electric spark ignition to fire up the unit. If there is a desire to ensure that hot water is still available in a power outage, you can connect the water heater into an uninterrupted power supply (UPS) battery backup like one typically used for computers.

Venting

Tankless water heaters have gained popularity in existing home applications due to their ability to be vented through a sidewall. Exhaust gases are blown directly out through a vent in the wall, not up a flue or chimney. This may streamline installation, but it could also complicate installation in existing homes where an old water heater did use a chimney that needs to be sealed off. The ideal location for a tankless water heater is on or near an outside wall. In an existing home this may require changing the location of the water heater.

Most tankless water heaters are sealed combustion, meaning that combustion air for the burners is brought directly from outdoors and the combustion fumes are exhausted to outdoors without any interaction with the living space air. Sealed combustion appliances are strongly recommended in all homes, new and existing, especially in tight homes, to avoid potential issues related to building pressures and combustion make-up air requirements and to minimize the risk of backdrafting the water heater or other combustion appliances located inside the home.

If you are replacing an existing tank water heater you will likely need to install a new vent pipe. Most older gas water heaters use a standard Category IB vent. High-efficiency direct-vented, sealed-combustion gas water heaters use a PVC or stainless steel vent pipe to vent the exhaust and a second vent pipe to the outside to bring in combustion air.

Check with your local code jurisdiction for specifics on the required distance between the combustion air inlet and the combustion exhaust outlet. A distance of 3 feet is typically required between the inlet and any known sources of contaminants. However, many manufacturers do offer a concentric pipe ventilation option that can minimize the difficult of locating the intake and exhaust. The concentric pipe is likely to have a diameter of 5-inch versus 3-inch for each stand-alone single pipe.

If an existing storage water heater that shares a flue with another heating appliance is being replaced with a tankless water heater that is being vented separately out a sidewall, be aware of an “orphaned flue.” Flues are sized to accommodate the flue gases of all of the appliances they serve, so removing one combustion appliance could reduce the effectiveness of the flue at removing combustion byproducts from the remaining atmospherically vented combustion appliances. Typically the concern for orphaned flues occurs when an older furnace is replaced leaving an orphaned atmospheric-vented water heater that doesn’t generate enough heat for a now-oversized flue. However, it’s possible that changing out the water heater could cause similar problems for an orphaned furnace. Have the installing contractor test the furnace’s draft after removing the water heater from a shared flue.

Condensate Drain

Be aware that high-efficiency condensing tankless water heaters will require a condensate drain line. The condensate may be corrosive and should be disposed of either to the outside or to the sewer, in accordance with local code requirements.

COMPLIANCE

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Steven Winter Associates

Pacific Northwest National Laboratory

Sales

Instantaneous Gas Water Heater (elec. not eff. so excluded) = High-Efficiency Endless Hot Water Heater

High-efficiency endless water heaters are also known as tankless hot water, on-demand water heaters, or instantaneous water heaters. They heat water only as it is needed, without a storage tank. This is so they don’t lose heat through the tank's walls and never run out of hot water. Typically, these water heaters provide hot water at a rate of 2 to 5 gallons per minute. In addition to energy savings, other benefits include small size and longer life expectancy.