Scope

Select and install high-performance windows:

- At a minimum, install windows that are ENERGY STAR rated or that meet or exceed the ENERGY STAR program requirements for windows, doors, and skylights.

- Consider triple-pane and/or ENERGY STAR “Most Efficient” windows.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

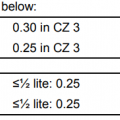

The ENERGY STAR program estimates that installing ENERGY STAR-rated windows rather than standard windows can save homeowners about 6% to 13% on their utility bills while improving a home's thermal comfort. More than 85% of windows sold in the United States today are ENERGY STAR certified. ENERGY STAR windows typically consist of two or three panes of glass in a fiberglass, vinyl, wood, or combination frame (Figure 1). An odorless, colorless, nontoxic inert gas such as argon or krypton fills the space between the panes to provide better insulation than just air. Special low-emissivity (low-e) coatings consisting of a nearly invisible layer of silver applied on one or more surfaces of the glass panes reflect back infrared radiation, to keep heat out in the summer and inside in the winter. These coatings also reflect ultraviolet (UV) rays to minimize fading of furniture and drapes. An insulated spacer keeps the panes of glass the right distance apart; these spacers are made of non-metal insulating materials that also insulate the edges of the glass panes, further reducing heat transfer through the window.

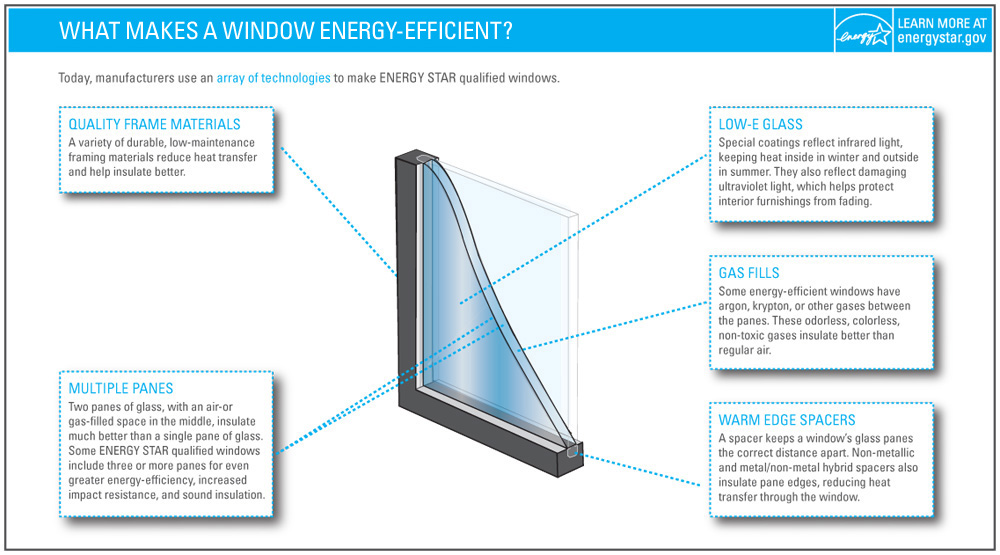

ENERGY STAR window criteria are set by the U.S. Environmental Protection Agency (EPA) based on properties that are independently verified according to procedures established by the National Fenestration Rating Council (NFRC). The NFRC label shows performance ratings in five categories.

- U-Factor measures the rate of heat transfer and tells you how well the window insulates. U-factor values generally range from 0.15 to 1.1 and are measured in Btu/h•ft²•°F. The lower the U-factor, the better the window insulates. A U-factor of 0.20 or lower likely indicates a triple-pane window.

- Solar Heat Gain Coefficient (SHGC) measures the fraction of solar energy transmitted and tells you how well the product blocks heat from incident sunlight. SHGC is measured on a scale of 0 to 1; values typically range from 0.15 to 0.80. The lower the SHGC, the less solar heat the window transmits.

- Visible Transmittance (VT) measures the amount of light the window lets through. VT is measured on a scale of 0 to 1; values generally range from 0.20 to 0.80. The higher the VT, the more light you see.

- Air Leakage (AL) measures the rate at which air passes through joints in a closed window. AL is measured in cubic feet of air passing through one square foot of window area per minute. The lower the AL value, the less air leaks through the window. Most industry standards and building codes require an AL of 0.3 cfm/ft² or less.

- Condensation Resistance measures how well the window resists water build-up on the inner surface of the window. This could result in mold on the window surface. Condensation Resistance is scored on a scale from 0 to 100. The higher the condensation resistance factor, the less build-up the window allows.

The NFRC label is combined with the ENERGY STAR label, which shows the U.S. regions where the labeled window meets ENERGY STAR specifications (Figure 2).

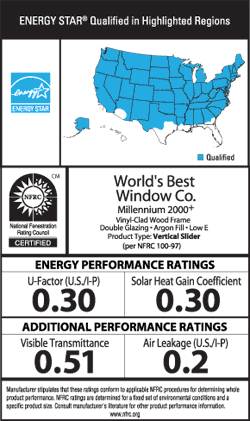

ENERGY STAR establishes U-Factor and SHGC criteria for ENERGY STAR windows based on climate using a climate zone map with four zones (see Figure 3). The criteria show the highest U-factor permissible in each climate zone and the SHGC criteria in each climate zone, with higher SHGCs in colder climates and lower SHGCs in hotter climates. The climate zones shown on this map equate to the climate zones shown in the International Energy Conservation Code (IECC) map, as follows:

- the Southern region = IECC CZ 1 and 2

- the South-Central region = IECC CZ 3

- the North-Central region = IECC CZ 4

- the Northern region = IECC CZ 5, 6, 7, and 8.

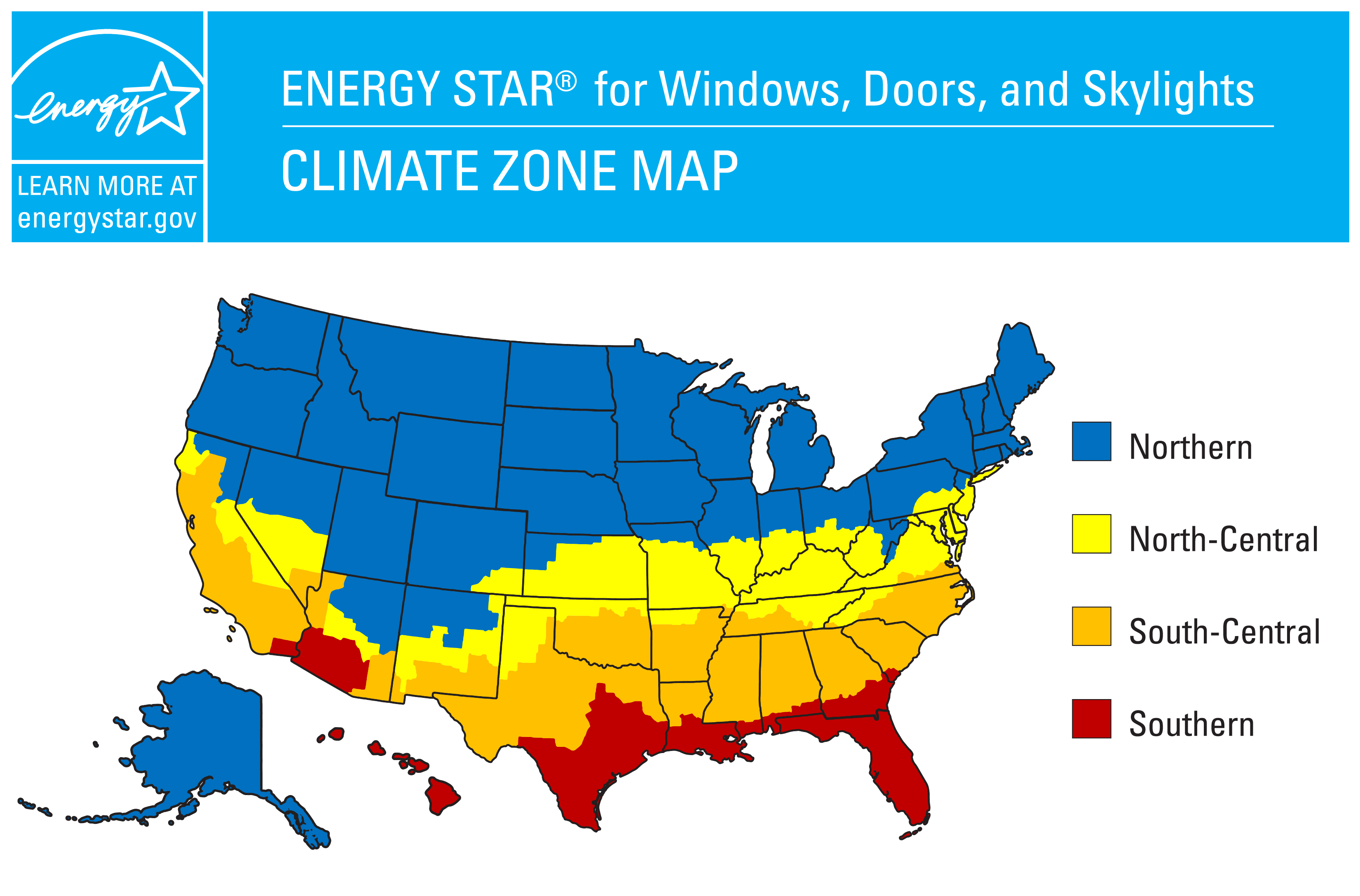

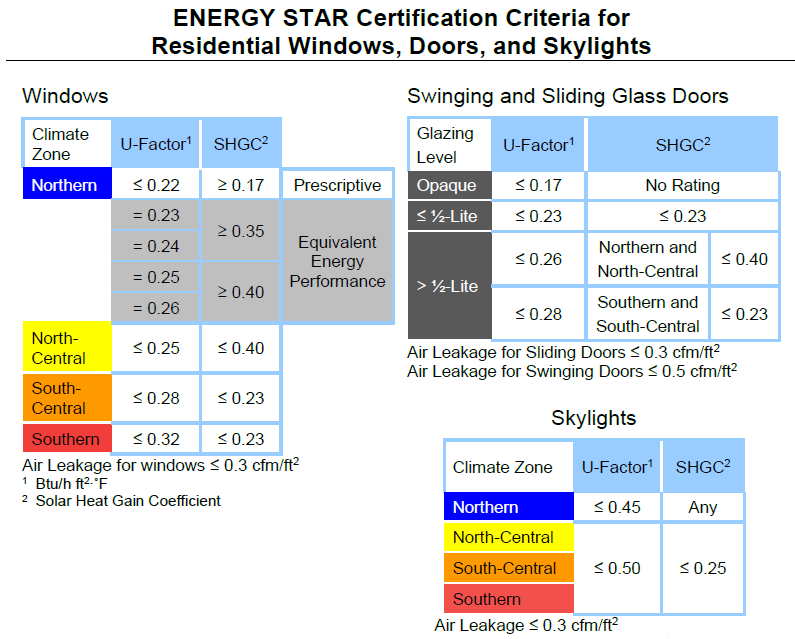

Figure 4 shows the ENERGY STAR Program Requirements for Residential Windows and Skylights, Version 7.0. This version took effect on October 23, 2023. Note that in the northern climate, tradeoffs are allowed between the U and SHGC values.

ENERGY STAR also has a “Most Efficient” program for most of its residential products, including windows. The Most Efficient window criteria requires a U ≤ 0.20, exceeding the performance of the products in any of the four climate zones. These window products are all triple glazed and may be less commonly available, but EPA maintains a web site to search for manufacturers and product lines that meet the Most Efficient criteria.

Financial Incentives

Rebate Incentives

Rebates for windows, skylights, and doors may be available through your local utility company. Check the web site of your local utility and visit the ENERGY STAR Rebate Finder and enter your zip code to see what incentives are available in your area.

Federal Tax Credits

There is also currently a federal tax credit available to tax payers who purchase ENERGY STAR windows and skylights, for 30% of the cost up to $600. Exterior windows or skylights must meet the ENERGY STAR Most Efficient criteria. This tax credit is available through December 31, 2032. Learn more about this tax credit.

Assistance for Low-to-Moderate Income Families

The U.S. Department of Energy (DOE) offers a Weatherization Assistance Program (WAP) available for households with lower incomes that qualify for Supplemental Security Income, Aid to Families with Dependent Children, and other income eligibility criteria. This program includes a home energy assessment and common home improvements such as repairing windows or replacing a few damaged windows – but generally do not replace a whole house full of windows. Some programs also offer storm windows. ENERGY STAR certified storm windows are an affordable option for homes where full window replacement may be difficult, such as lower-income households, low-rise multi-family households, households working with HUD or weatherization programs, or households in historic preservation districts. You can also contact your local electric utility to see if they offer energy-efficiency home upgrades for low-income customers.

How to Purchase and Install ENERGY STAR Windows

- Determine your ENERGY STAR climate zone for the ENERGY STAR window criteria using the ENERGY STAR climate zone finder tool, which bases the climate zone on the county in which the home is located.

- Look for ENERGY STAR-labeled products that meet or exceed the criteria for your climate zone. If ordering from a showroom or building materials supplier, ask for a product that meets the ENERGY STAR criteria in your climate zone. In colder climates, explore the opportunity to go beyond the traditional ENERGY STAR products by specifying Most Efficient products.

- If you are seeking to have your home certified under either the DOE Zero Energy Ready Home program or the ENERGY STAR Single-Family New Homes program, see the Compliance tab for additional window specifications to meet those program criteria.

- Check with local utilities and check the ENERGY STAR website for information about the federal tax credit for ENERGY STAR-rated windows or for other utility rebate programs. For example, in some parts of the country utilities offer substantial rebates for selecting Most Efficient products. Also see the DOE Database of State Incentives for Renewables & Efficiency for information on additional state, federal, and local tax credits and exemptions.

- Follow the manufacturer’s installation instructions when installing the windows to avoid voiding the warranty. Some warranties require that you use an installer certified by the manufacturer.

- Properly install windows to keep air and moisture out. See the guide Fully Flashed Window and Door Openings.

- Properly air seal around window rough openings. See the guide Air Sealing Window and Door Rough Openings.

Success

Look for or request ENERGY STAR-qualifying products when purchasing windows and follow ENERGY STAR criteria to purchase windows appropriate for the climate zone where they will be installed.

Push the envelope by selecting ENERGY STAR Most Efficient products where heating loads dominate. Consider, and design for, triple-pane windows, or consider thin triple-pane windows.

Climate

If you are building to meet an energy-efficiency program certification, refer to that program’s guidance for climate-specific criteria.

To maximize beneficial solar heat gain and minimize unwanted solar heat gain, consider window location and sizing when designing the house. Limit the number of west-facing windows, especially in hot climates, to limit late afternoon glare and solar heat, unless the windows can be properly shaded. This might be through the use of interior or exterior operable shading, including blinds, shades, or solar screens, which may be fixed or manually or electronically operated. Locate south-facing windows under properly sized overhangs or install fixed or removable awnings or pergolas to minimize heat gain from high summer sun and maximize gain from low winter sun. Locating deciduous rather than evergreen shade trees to the south, east, and west will also minimize summer solar gain and allow winter solar gain. Consider selecting different window properties for different sides of the house to maximize beneficial solar gain and minimize unwanted heat gain. Consider how the occupants might use interior or exterior operable shading in conjunction with windows.

In cold climates, consider triple-pane windows both for their energy efficiency and for their ability to minimize condensation on window interiors.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Training

Compliance

Retrofit

Choose ENERGY STAR or ENERGY STAR Most Efficient labeled products when replacing windows.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Pacific Northwest National Laboratory

Stephen Selkowitz

Sales

High-R Window = High-Efficiency Window

There are two levels of window efficiency relative to standard windows: high-efficiency (e.g., ENERGY STAR Certified windows), which perform at least 15% better than standard windows, and ultra-efficient (e.g., most triple-glazed windows) which perform at least 50% better. These windows use a combination of features to reduce heat loss or gain including two or three glass panes separated by insulating spacers, nontoxic gas (e.g., argon or krypton) in the spaces between the glass panes for better thermal resistance, a nearly invisible low-emissivity coating on the glass that keeps heat in during the winter and out in the summer. They also block damaging ultraviolet sunlight (e.g., fading curtains and furniture), and insulate frames.