Scope

Air-seal the top, bottom, and sides of a cantilevered floor cavity and ensure that insulation is in full contact with all sides without voids.

- Install a rigid air barrier or other supporting blocking to separate the cantilever from the conditioned space above. Seal all seams, gaps, and holes in the air barrier with caulk or foam.

- Block and seal any open floor joists abutting the cantilever floor cavities.

- Install insulation without misalignments, compressions, gaps, or voids to fill the cantilever floor cavity, making full contact with the top, bottom, and sides of the cantilevered floor cavity

- Cover the bottom of the insulated cantilever floor cavities with a rigid, weather-resistant solid blocking material such as plywood or house siding.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

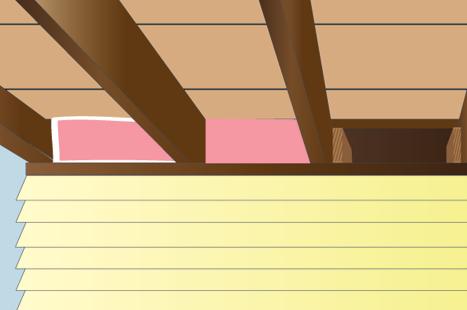

A cantilevered floor is a floor that sticks out past the foundation or supporting wall below. It may be a first- or second-story bump-out, a bay window, or a room over an open porch. Floor joist bays that extend from the building out under the cantilevered floor are sometimes left unsealed and uninsulated by the builder, allowing outside air to flow into the interior space and conditioned air to escape (Figure 1).

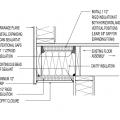

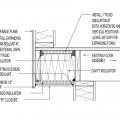

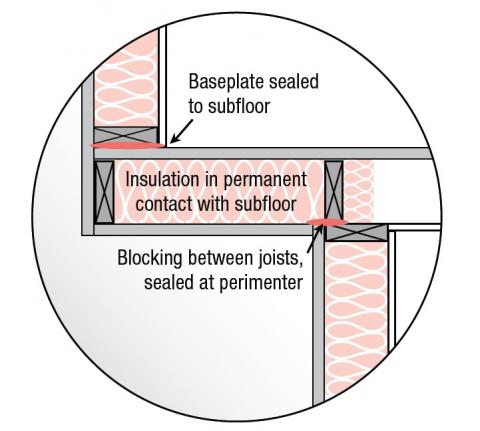

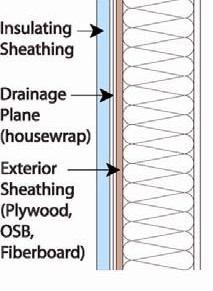

Sometimes cantilevered floors are insulated but not air-sealed. A rigid air barrier (rigid foam insulation, OSB, plywood, or drywall) must be installed across any open floor joist bays to prevent air from blowing through the insulation and rendering it ineffective (Figure 2).

Plywood subflooring above the cantilever should be caulked at the edges and seams. The cantilever floor cavity must be filled with insulation that completely touches the underside of the floor. Insulating foam sheathing and/or house sheathing or siding should be attached to the underside of the cantilever floor joists as a protective covering. Air-sealing and insulation materials may be installed by framers, insulators, and/or siding installers. This task should be included in the contract for the appropriate trade depending on the workflow at specific job sites.

Air barrier effectiveness is measured at the whole-house level. High-performance branding programs and the IECC code require that builders meet specified infiltration rates at the whole house level. See the Compliance Tab for these specified infiltration rates.

Whenever possible, try to avoid running HVAC ducts and plumbing pipes through cantilevered floors. However, when HVAC ducts and/or plumbing pipes must be located in cantilevered floors, ensure that all penetrations are properly air-sealed and that the ducts and/or pipes are well insulated.

How to Air-Seal and Insulate a Cantilevered Floor

Create an air barrier between the interior conditioned space and the cantilever by cutting a rectangle of rigid foam or other rigid air barrier material to fit into each floor joist bay cavity (Figure 3). Make a backstop for the rigid air barrier by tacking furring strips to the joists at the plane with the foundation or house wall.

Figure 3. Rigid foam and caulk are used to seal each joist bay cavity beneath a cantilevered floor. - Insert rigid air barrier pieces into each joist bay, nail in place and caulk to air-seal all four edges of of each piece (Figure 4).

Caulk the subfloor to the floor joists at the perimeter of the cantilevered floor and at any seams in the subfloor (Figure 4 and Figure 5). Seal any wiring or piping holes through perimeter joists or subfloor with caulk or spray foam.

Figure 4. All seams are caulked to completely air-seal the subfloor and joist bay of the cantilever.

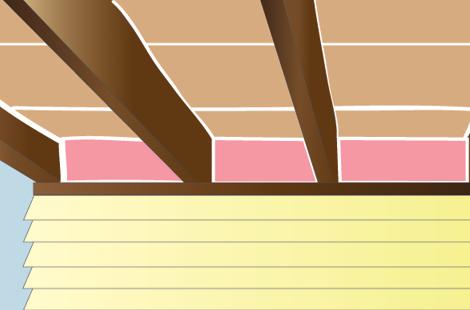

Install unfaced batt insulation in each floor joist bay (Figure 6). Use insulation that will completely fill the cavity; it must be in contact with the top and bottom air barrier (i.e., the subfloor above and rigid sheathing below) with no compressions or voids. Alternatively, insulate each cavity with open- or closed-cell spray foam that is aligned with the underside of the subfloor above. Install to a depth equivalent to the required exterior wall R-value. In cold climates, use closed-cell foam to ensure moisture within the floor is mitigated.

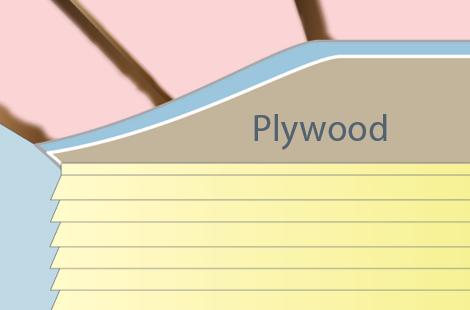

Figure 6. Fill the joist bays of the cantilevered floor with fiberglass batt or spray foam. Cover the underside of the cantilever with rigid foam insulation (Figure 7). Use caulk and fasteners to attach rigid foam to joists and to air-seal at the edges. Tape foam at seams.

Figure 7. Cover the cantilever floor cavity insulation with rigid foam. Cover the rigid foam with siding or with 3/8-inch exterior plywood that is pressure-treated, painted, or primed on all exposed sides (Figure 8).

Figure 8. Cover the rigid foam on the underside of the cantilever with plywood that is pressure-treated, painted, or primed on all exposed sides. - If you have plumbing pipes in the cantilevered floor (not recommended) and live in a cold climate, ensure adequate insulation on the exterior side of the pipes to protect them from freezing. One option is to box in the pipes with a rigid foam box that is caulked to the subfloor to allow warmth from the house to reach the pipes.

Success

Air-sealing of cantilever floor joist bays should be inspected by the site supervisor before the insulation and covering are installed. Blower door testing conducted as part of whole-house energy performance testing may indicate whether air leakage at cantilever floors has been successfully sealed. An infrared camera may also be used to detect air leakage.

Climate

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Training

CAD

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Pacific Northwest National Laboratory

Building Science Corporation, lead for the Building Science Consortium (BSC), a DOE Building America Research Team

Sales

Fully Aligned Air Barriers = Whole-House Draft Barrier

A whole-house draft barrier is a continuous layer of air-tight materials that block air leaks. This barrier can be integrated with other materials to also function as a water barrier, thermal barrier, and vapor barrier. For example, rigid foam insulation can be used to block thermal flow as well as air flow when seams are sealed with tape, caulk, adhesives, or liquid-applied sealants. Some rigid foams have an integrated water control layer as well. Additionally, drywall can serve as an interior air barrier when the seams are taped and spackled, and caulk, spray foam, or gaskets are used to seal around wiring, plumbing, and other penetrations. It also serves as the vapor barrier when finished with paint. Insulation should be in full contact with the air barrier layer.