Scope

Create or modify an air-sealed closet to contain the air handler and the return air plenum. The return air plenum must be air sealed so that the only air that enters the plenum is air coming from the house through the filter-backed grille.

- Form a sealed air barrier of drywall or rigid duct board (sealed on the foil side whether facing in or out) and return air grille(s).

- Where the return plenum is formed by open framing and a plywood platform, install and seal an air barrier (drywall or duct board) to separate the return from adjacent wall cavities.

- Provide a partial door above the return (or a solid door on the side wall) for AHU access.

- If necessary, extend the platform to form a door sill.

- Use a code-approved sealant, for duct board connections, preferably fiberglass mesh embedded in water-based mastic.

- Do not leave open wall cavities in the closet or return air plenum.

- Do not use louvered door returns.

- Do not use a metal or frame air hander stand in a full closet return. If a full closet return (i.e., air handler on stand in closet) is unavoidable, seal all joints, seams, and edges of the closet air barrier (e.g., drywall, floor finish, sub-floor). Install an air barrier, if necessary, to enclose wall cavities and separate the closet from the attic.

- Complete drywall finish at the ceiling of the closet. Seal any gaps around the supply plenum.

See the Building America Solution Center guide on Pre-Retrofit Assessment of Existing Heating and Cooling Systems for more information.

The U.S. Department of Energy’s Standard Work Specifications has additional information on supply plenums and return ducts.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

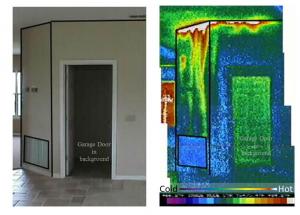

In many homes with a central-forced air system, the air handler unit (AHU) is located in an interior closet or utility room so it appears to be isolated from the outside. However, further investigation often reveals that the AHU is connected to the outside through holes in the walls or flooring behind or beneath the AHU. The AHU is often set on a metal stand and the space beneath is used as a return air plenum, although this space may not be air sealed as a ducted return should be. The return plenum in these situations falls into a nebulous area, an interior space that is very often connected to the exterior or attic of the house through large breaches in the return plenum, the closet, or the room’s air barrier. Figure 1 shows an air handler prior to a system change-out. The open wall cavities are visible inside the return plenum.

The air handler in Figure 1 appears to be on the inside of the house; however, in Figure 2 one can see the holes in the flooring and the wall. Because of these breaches in the air barrier, the air handler is well connected to the attic, the exterior, and the slab plumbing chases.

In many areas of the country, it was (and in some areas still is) customary to leave the air handler closet ceiling open to the attic to allow for combustion and make-up air if gas equipment is installed. Often, when previous retrofits have been carried out where gas equipment was replaced with all electric, the ceiling was left open to the attic. Seal this large breach in the dwelling’s air barrier.

Past and current IECC new construction codes address this potential failing, but replacement codes typically do not require any sealing to be done to these closets or utility/laundry rooms, as they are seen as interior spaces that do not require sealing.

The only place air should be able to enter the return duct system and the furnace or air handling unit is at the return grilles (BSC 2009). It is common for air pressures in the return plenum at the air handler to equal or exceed 0.5 inches water column (125 Pascals). Air leakage problems are often worst at the HVAC furnace or air handler platform.

How to Retrofit an Interior Air Handler Closet at Air Handler Change-out

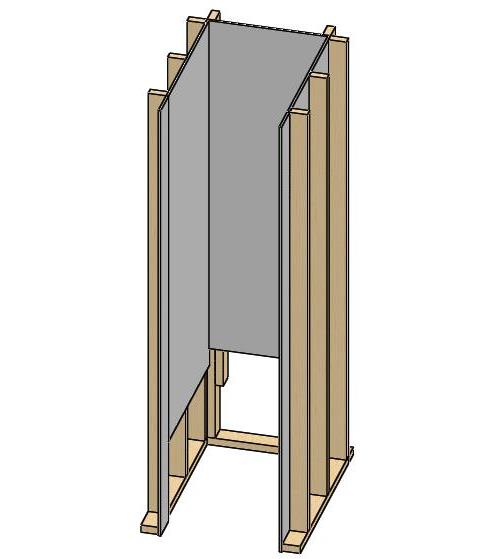

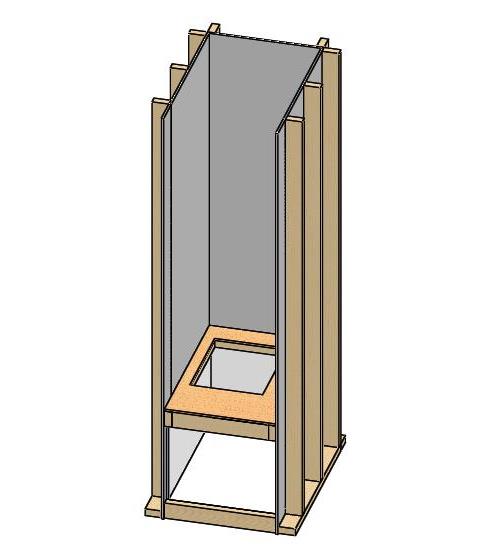

1. Prepare the closet for repair and retrofit to seal the air handler platform (Figures 3 and 4).

- Remove and recycle existing HVAC equipment.

- Repair or replace existing drywall as necessary. If installing new drywall, cover the entire closet, walls, top and bottom plates, and all edges with drywall “mud.”

2. Rough in refrigerant plumbing and electrical. Install framing to support the air handler platform and blocking to create a rough opening for a filter-backed return grille in the wall below the return platform (Figures 5 and 6).

- Determine platform height prior to installation based on the return plenum sizing calculations using ACCA Manuals J and D or equivalent.

- Install a wooden frame for the base of the air handler platform.

- Align the front edge of the platform to facilitate final finish (drywall) of the return grille.

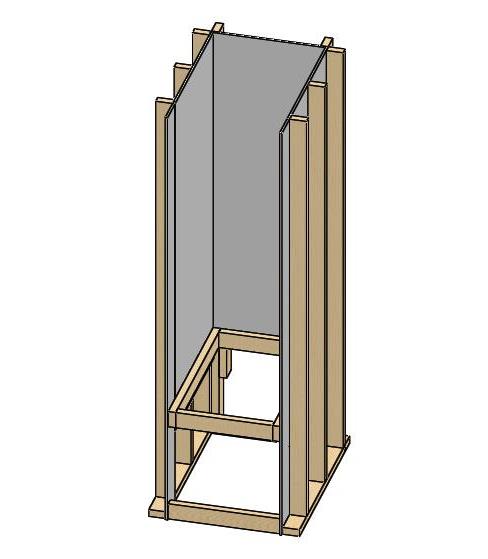

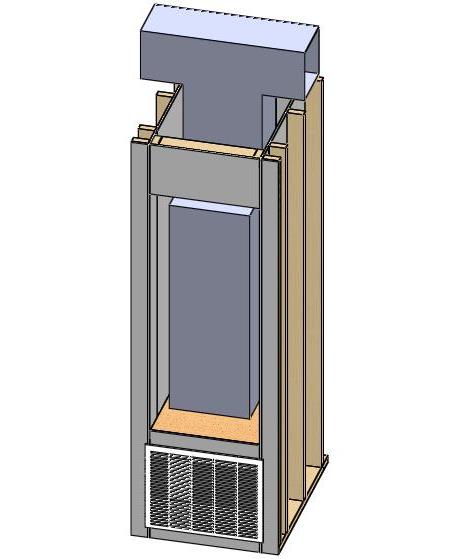

3. Line the sides and bottom, below the platform, of the future return plenum with a code-complaint, air-impermeable material (Figures 7 and 8).

- If the return is truly inside the house, a product with insulating properties (duct board versus drywall) is not necessary; however, HVAC contractors usually perform this work and they are equipped to work with fiberglass duct board.

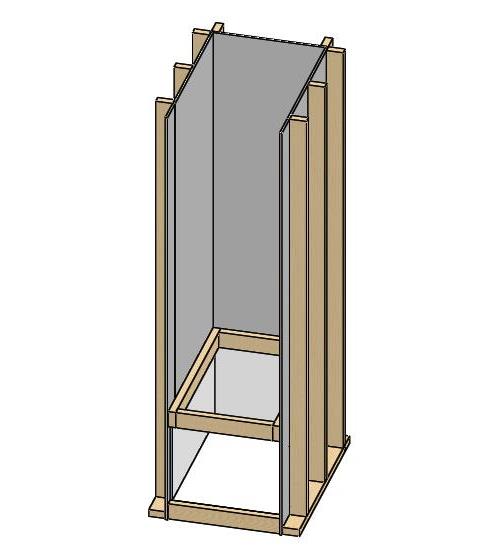

4. Install the air handler support platform (Figures 9 and 10). Fit it snuggly around any refrigerant lines or electrical connections.

5. Seal all joints and seams with a UL-181-approved mastic (Figures 11and 12). Ensure that the edges of the grille opening are well sealed.

6. Install the air handler, filter-backed grille, and supply plenum connection (Figures 13, 14, and 15). Seal the joint between the air handler and the platform. Air seal the ceiling of the closet around the supply plenum. If combustion and make-up air are required, provide it via a local code-approved installation.

7. At finish mechanical:

- Ensure that all four edges of the metal grille frame are sealed to the drywall and return plenum air barrier (e.g., duct board or drywall).

- Provide a threshold and install a partial door above the support platform (Figure 16, image from a different house) or a full door on a side wall (Figure 17, image from a different house) to facilitate air handler access.

Success

Great care must be exercised when encountering naturally aspirated gas appliances inside of the conditioned space (Figure 1). Any changes made to the pressure dynamics of the house can lead to serious and potentially fatal consequences. Work with a home professional certified by the Building Performance Institute (BPI) or Residential Energy Services Network (RESNET) in combustion safety testing to evaluate and devise a combustion safety plan to prevent accidental back drafting of exhaust fumes into the conditioned space before, during, and after renovation. Tests should be conducted to assess air pressure conditions in the combustion air zone where the furnace and/or water heater are located and air pressure differences between the combustion air zone and the occupied areas of the home.

For gas appliances, both new installations and current equipment intended to remain in place post retrofit, ensure specifications, implementation, and installation details are in compliance with 2009 International Fuel Gas Code, Chapter 3, Section 304 for indoor and outdoor combustion air and make-up air. Add permanent openings to the building as needed for compliance as specified in Section 304.6.

Consider conducting a standard RESNET duct airtightness assessment to determine if the return plenum is sealed. RESNET 2016.

Climate

Applicable to all climates. No climate-specific information applies.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Florida Solar Energy Center, lead for the Building America Partnership for Improved Residential Construction (BA-PIRC), a DOE Building America Research Team.

Sales

Ducted Returns =

Comfort systems use fans to push heated and cooled air through ducts into living spaces. Air also needs a way to circulate back to the central comfort system equipment, where it again gets heated or cooled and circulated back to the living spaces. Most homes use centrally located return ducts to capture and return air back to the central comfort system. In contrast, a comfort return system uses separate ducts in each major room to capture and deliver air back to the central comfort system.