Showing results 2401 - 2500 of 4973

Right - Potential locations for crawlspace insulation: vapor sheeting should always cover the floor with insulation (a) outside walls, (b) inside walls, (c) both sides of walls, (d) sandwiched inside walls, or (e) under the first floor.

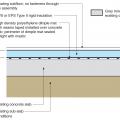

Right - Potential locations for slab-on-grade stem insulation in new construction: slab insulation should always be underneath, with stem walls insulated (a) inside, (b) outside, (c) not at all, or (d) outside with underground extension to repel moisture.

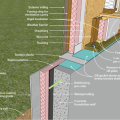

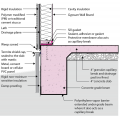

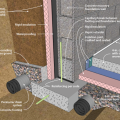

Right - Poured concrete basement wall showing exterior insulation and sill detail; above-grade wall has sheathing to the inside of the rigid foam.

Right - Poured concrete basement wall showing exterior insulation and sill detail; above-grade wall has sheathing to the outside of the rigid foam.

Right - Precast concrete basement walls come to the site with integrated rigid foam insulation and steel-faced concrete studs.

Right - Pressure reducing valves installed outside the home reduce water pressure before water is distributed to fixtures.

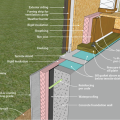

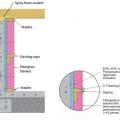

Right - Prevent condensation in fibrous insulation-filled basement wall cavities by installing rigid or spray foam between the frame wall and the concrete foundation wall and by not installing a Class I vapor retarder over the framed wall.

Right - Provide passive ventilation in hot climates by installing wind chases and vents.

Right - Raised-heel roof trusses allow more room at the eaves for attic insulation.

Right - Raised-heel trusses increase the roof height above the eaves allowing more space for insulation above exterior wall top plates; exterior wall sheathing extends up to keep wind from soffit vents from disrupting insulation.

Right - Reduce condensation risks to blanket insulation by installing perforated vapor retarder covered fiberglass blankets over rigid foam that is air-sealed at all edges; staple the blanket to nailers and top/bottom plates and tape over the seams.

Right - Retrofit of an existing basement slab by adding dimple plastic mat, rigid foam insulation, and a floating subfloor.

Right - Rigid foam board is attached to the interior surface of the basement walls.

Right - Rigid foam insulation is installed along the exterior edge of an existing foundation slab.

Right - Rigid foam insulation is taped at seams and installed over a drainage pad of aggregate to serve as a capillary break under the basement slab.

Right - Rigid foam is installed over a waterproofing membrane that has been applied to the basement foundation walls.

Right - Rigid foam slab edge insulation is installed along the exterior edge of a monolithic slab foundation.

Right - Roofs with simple geometries are less susceptible to ignition from wind-borne embers getting lodged on the roof in a wildfire.

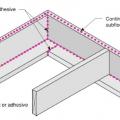

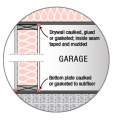

Right - Sealant is installed at the top and bottom plates of a gypsum covered wall separating a garage from the conditioned space of the home.

Right - Seam-sealing flashing tape is installed with roller to fully adhere to the OSB.

Right - Seams in coated sheathing and joints around window are properly sealed and flashed with tape and all nail holes are covered with paint-on sealant.

Right - Section view showing how to air-seal and insulate a basement wall with perforated blanket insulation by installing it over air-sealed rigid insulation board to reduce condensation risk in the fiberglass blanket.

Right - Skylights can add natural light in rooms with limited wall space and if openable can provide desirable ventilation, especially when located at the top of stair wells.

Right - Skylights provide natural light while maintaining privacy in a narrow second-story bedroom.

Right - Solar photovoltaic panels are installed on the highest parts of the roof to avoid being shaded by other parts of the house.

Right - Spray foam covers the walls and a sealed vapor retarder lines the floor of this unvented crawl space.

Right - Spray foam fills the walls and rim joists to air seal and insulate while caulk seals the framing joints.

Right - Spray foam insulates and air-seals the stone walls of this unvented crawlspace.

Right - Spray foam insulates the attic eave between the attic floor and the SIP roof panel.

Right - Spray foam insulation air-seals the ceiling-to-drywall seams at the wall top plate.

Right - Spray foam insulation has been sprayed onto the underside of the sloped roof and the gable end wall to provide a sealed, insulated attic for housing the HVAC ducts

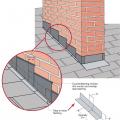

Right - Step flashing along a chimney is integrated in a layered manner with asphalt shingle roofing and topped with counterflashing that is embedded into brick mortar joint above

Right - Straps are spaced close enough together to provide adequate support of the flex duct

Right - Tape flashing keeps moisture out around and below the window; extra tape reinforces the corners to prevent tearing of the house wrap and to keep water out of this critical juncture.

Right - Technicians use adhesive when installing the vapor barrier along the walls of this crawlspace.

Right - The advanced controls in a programmable thermostat can be used to improve the efficiency of the home’s HVAC system.

Right - The air control membrane installed over the roof sheathing is continuous. It connects to the air control of the wall around the entire perimeter without interruption. The roof overhangs have been cut off to make this connection continuous

Right - The air handler for this geothermal heat pump is located in conditioned space.

Right - The attic access panel is insulated and weather stripped and a dam is built to hold back the blown attic floor insulation

Right - The automated ventilation system has a sensor built in switch that can detect indoor air pollution; if it senses a rise in humidity, VOCs, smoke, carbon dioxide, or small particulates, the system will turn on the nearest fan to eliminate pollution

Right - The basement foundation is insulated on the exterior and termite shield extends out past the top of the insulation.

Right - The basement walls are wrapped with 3 inches of XPS rigid foam that will be taped at the seams then covered with a dimpled plastic water barrier.

Right - The blanket fiberglass insulation is installed over a continuous layer of rigid foam insulation; the fiberglass is covered with a vapor retarder that is tape sealed at the seams.

Right - The butterfly damper of this crawlspace supply register opens when the HVAC fan is running; the damper duct is sealed with mastic and supported by strapping.

Right - The ceiling above the garage is air-sealed and insulated with spray foam.

Right - The ceiling above the garage is insulated and air-sealed with open-cell spray foam to keep garage fumes out of the living space above.

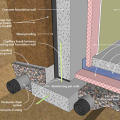

Right - The concrete basement wall is insulated on the interior with rigid foam; the footing detail is shown.

Right - The concrete masonry unit (CMU) basement wall has exterior insulation; the footing details include interior and exterior footing drain pipe.

Right - The conditioned basement is insulated on the interior with 1 inch of polyiso R-6.3 rigid insulation.

Right - The corrosion-resistant metal siding on this tiny house is fire resistant.

Right - The duct shows redundant sealing including the caulk, tape, and flashing

Right - The electronics for this home’s smart home system, including a Wi-Fi router, and controls for lighting, HVAC, security, energy production and tracking are housed together with the electrical panel and HVAC equipment in the home’s utility room.

Right - The energy recovery ventilator ducts supply filtered outside air to multiple locations in the home and continuously exhaust stale air to provide clean, balanced ventilation.

Right - The exhaust duct has been mechanically fastened and sealed with mastic.

Right - The exhaust vent duct terminates to the outdoors with a vent cover that has been properly caulked and covered with a metal pest screen.

Right - The existing basement slab is retrofitted by installing a dimple plastic drainage mat, rigid foam insulation, and a floating subfloor.

Right - The garage roof is correctly oriented for the home’s solar shingle system.

Right - The geothermal heat pump provides hot water for radiant floor heating, domestic hot water, and the air handler for space conditioning upstairs.

Right - The high-efficiency wood stove is located on an interior wall in this home to provide a secondary heating source in cold climates.

Right - The home’s ground source heat pump preheats water for the air source heat pump water heater.

Right - The home’s high-efficiency gas boiler provides domestic hot water as well as in-floor radiant heat, while a high-efficiency heat pump provides cooling and a secondary source of heating.

Right - The house wrap is properly flashed and taped, and all penetrations are properly flashed.

Right - The HVAC ducts are located in conditioned space in a dropped hallway ceiling with very short duct runs for more efficient delivery.

Right - The kitchen exhaust duct termination is integrated aesthetically and functionally with the exterior cladding; however, the opening should be screened to keep out pests.

Right - The pipe penetration is properly flashed and furring strips are installed on each side in preparation for installing cladding

Right - The posts and floor of this crawlspace are covered with a heavy sheet of vapor retarder that is sealed to the post, the walls, and at all seams.

Right - The poured concrete basement walls are insulated along the inside with 2.5 inches of extruded polystyrene insulation.

Right - The precast insulated concrete walls of the basement provide a conditioned space for the high-efficiency (18 SEER, 9.5 HSPF) air-source heat pump, with its variable-speed fan, five-stage compressor, and MERV 11 filter.

Right - The rigid metal HVAC ducting is installed between the floor joists rather than in an unconditioned attic or crawl space to minimize heat loss.

Right - The sealed conditioned crawlspace provides a clean, dry, and temperate environment for the home’s supplemental dehumidifier.

Right - The seams in the OSB sheathing are sealed with a sprayer-applied sealant.

Right - The service penetration in the waterproofing membrane is well-sealed, and there is a drainage mat acting as a protective layer on the interior of the soldier piles and wood lagging.

Right - The service penetrations through the structural slab in this garage plenum are air sealed.

Right - The simple rectangular design of this home provides a large expanse of roof for solar panels.

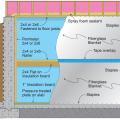

Right - The slab-on-grade foundation is insulated with two layers (R-20) of XPS foam under the-slab and R-10 on the exterior of the stem walls.

Right - The underside of the attic roof deck is insulated with open-cell spray foam to provide an insulated space for HVAC equipment.

Right - the vapor barrier is extended up the sides of the piers in this crawlspace, which is sealed and insulated to house the HVAC ducts.

Right - The wall framing is connected to roof framing with metal ties for hurricane-resistant construction.

Right - The wall top plates are sealed with foam before installing insulation on the ceiling deck.

Right - The water and air control layers are properly integrated around the hose bib

Right - These attic knee walls are insulated with rigid foam and sealed with spray foam to form a continuous air barrier at the gable end of this cathedral ceiling.

Right - These homes have hurricane shutters to protect against high winds and to provide solar control.

Right - These interior solar screens help control glare and solar heat gain while maintaining view to the outside.

Right - These inverters convert the power from the home’s 6.8-kW of photovoltaic panels from DC to AC for connection to the grid; the inverters can also be connected to batteries for backup power storage.

Right - These raised heel roof trusses provide 16 inches of space over the outer walls for full insulation coverage at the attic perimeter.

Right - These removeable awnings provide ample shade to windows and patio space, reducing heat gain to the home.

Right - These retractable awnings provide shade to this outdoor living space and reduce heat gain and glare within the home.

Right - These roof insulation panels are installed in multiple layers with joints offset both vertically and horizontally. The plywood nail base fastened to the roof framing holds the insulation layers together snuggly thus minimizing gaps