Showing results 401 - 500 of 898

Right - Foil-faced polyisocyanurate rigid foam board is tightly installed and sealed against a concrete foundation wall prior to installing fibrous blanket insulation.

Right - Foil-faced polyisocyanurate rigid foam is attached to the existing exterior wall with vertical wood furring strips

Right - Furring strips were installed with blocking to allow adequate room for 4 inches of mineral wool.

Right - Ladder blocking allows insulation to be installed in exterior walls at interior-exterior wall intersections.

Right - Mineral Wool insulation is installed on the exterior of wall with furring strips.

Right - Mold- and water-resistant fiber glass insulating sheathing is installed after panelized walls are assembled on site.

Right - New flashing has been installed to complete the air and water control layers at the window openings of this wall retrofit that includes insulating the wall cavities with spray foam

Right - Open-cell polyurethane spray foam to R-28 on underside of roof turns new attic into conditioned space for HVAC.

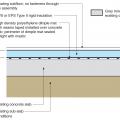

Right - Potential locations for basement insulation in new construction, slab insulation should always be underneath, with walls insulated (a) inside, (b) outside, (c) sandwiched inside, or (d) inside and outside of walls.

Right - Potential locations for crawlspace insulation: vapor sheeting should always cover the floor with insulation (a) outside walls, (b) inside walls, (c) both sides of walls, (d) sandwiched inside walls, or (e) under the first floor.

Right - Potential locations for slab-on-grade stem insulation in new construction: slab insulation should always be underneath, with stem walls insulated (a) inside, (b) outside, (c) not at all, or (d) outside with underground extension to repel moisture.

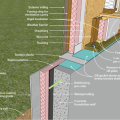

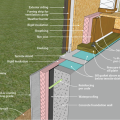

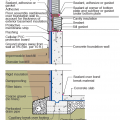

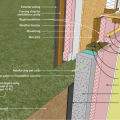

Right - Poured concrete basement wall showing exterior insulation and sill detail; above-grade wall has sheathing to the inside of the rigid foam.

Right - Poured concrete basement wall showing exterior insulation and sill detail; above-grade wall has sheathing to the outside of the rigid foam.

Right - Precast concrete basement walls come to the site with integrated rigid foam insulation and steel-faced concrete studs.

Right - Raised-heel roof trusses allow more room at the eaves for attic insulation.

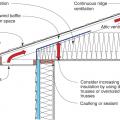

Right - Raised-heel trusses increase the roof height above the eaves allowing more space for insulation above exterior wall top plates; exterior wall sheathing extends up to keep wind from soffit vents from disrupting insulation.

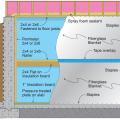

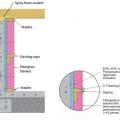

Right - Reduce condensation risks to blanket insulation by installing perforated vapor retarder covered fiberglass blankets over rigid foam that is air-sealed at all edges; staple the blanket to nailers and top/bottom plates and tape over the seams.

Right - Retrofit of an existing basement slab by adding dimple plastic mat, rigid foam insulation, and a floating subfloor.

Right - Rigid foam board is attached to the interior surface of the basement walls.

Right - Rigid foam insulation is installed along the exterior edge of an existing foundation slab.

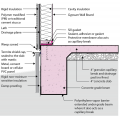

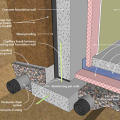

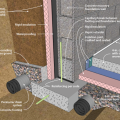

Right - Rigid foam is installed over a waterproofing membrane that has been applied to the basement foundation walls.

Right - Rigid foam slab edge insulation is installed along the exterior edge of a monolithic slab foundation.

Right - Section view showing how to air-seal and insulate a basement wall with perforated blanket insulation by installing it over air-sealed rigid insulation board to reduce condensation risk in the fiberglass blanket.

Right - Spray foam fills the walls and rim joists to air seal and insulate while caulk seals the framing joints.

Right - Spray foam insulates and air-seals the stone walls of this unvented crawlspace.

Right - Spray foam insulates the attic eave between the attic floor and the SIP roof panel.

Right - Spray foam insulation air-seals the ceiling-to-drywall seams at the wall top plate.

Right - Spray foam insulation has been sprayed onto the underside of the sloped roof and the gable end wall to provide a sealed, insulated attic for housing the HVAC ducts

Right - The attic access panel is insulated and weather stripped and a dam is built to hold back the blown attic floor insulation

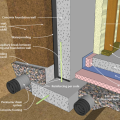

Right - The basement foundation is insulated on the exterior and termite shield extends out past the top of the insulation.

Right - The basement walls are wrapped with 3 inches of XPS rigid foam that will be taped at the seams then covered with a dimpled plastic water barrier.

Right - The blanket fiberglass insulation is installed over a continuous layer of rigid foam insulation; the fiberglass is covered with a vapor retarder that is tape sealed at the seams.

Right - The ceiling above the garage is insulated and air-sealed with open-cell spray foam to keep garage fumes out of the living space above.

Right - The concrete basement wall is insulated on the interior with rigid foam; the footing detail is shown.

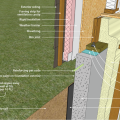

Right - The concrete masonry unit (CMU) basement wall has exterior insulation; the footing details include interior and exterior footing drain pipe.

Right - The conditioned basement is insulated on the interior with 1 inch of polyiso R-6.3 rigid insulation.

Right - The energy recovery ventilator ducts supply filtered outside air to multiple locations in the home and continuously exhaust stale air to provide clean, balanced ventilation.

Right - The existing basement slab is retrofitted by installing a dimple plastic drainage mat, rigid foam insulation, and a floating subfloor.

Right - The poured concrete basement walls are insulated along the inside with 2.5 inches of extruded polystyrene insulation.

Right - The rigid metal HVAC ducting is installed between the floor joists rather than in an unconditioned attic or crawl space to minimize heat loss.

Right - The slab-on-grade foundation is insulated with two layers (R-20) of XPS foam under the-slab and R-10 on the exterior of the stem walls.

Right - The underside of the attic roof deck is insulated with open-cell spray foam to provide an insulated space for HVAC equipment.

Right - The wall top plates are sealed with foam before installing insulation on the ceiling deck.

Right - These attic knee walls are insulated with rigid foam and sealed with spray foam to form a continuous air barrier at the gable end of this cathedral ceiling.

Right - These raised heel roof trusses provide 16 inches of space over the outer walls for full insulation coverage at the attic perimeter.

Right - These roof insulation panels are installed in multiple layers with joints offset both vertically and horizontally. The plywood nail base fastened to the roof framing holds the insulation layers together snuggly thus minimizing gaps

Right - This concrete basement wall has exterior rigid insulation and comprehensive moisture management details.

Right - This concrete basement wall is insulated on the interior basement walls with spray foam and under the slab with rigid foam; footing details are shown.

Right - This concrete basement wall is insulated on the interior with rigid insulation; sill details are shown.

Right - This concrete basement wall is insulated on the interior with spray foam insulation; sill detail are shown.

Right - This foil-faced polyisocyanurate rigid foam is installed on an existing exterior wall and the seams are taped so the rigid foam can serve as a water control layer

Right - This heated garage plenum is insulated along the bottom of the plenum space.

Right - This heated garage plenum is insulated and has an opening to access the interior, allowing for repairs and maintenance.

Right - This high-thermal-mass home uses masonry construction to naturally regulate temperatures inside the house

Right - This new sealed attic has 5.5 inches (R-20) of spray foam insulation along the underside of the roof deck providing a conditioned attic space for the heating and cooling ducts.

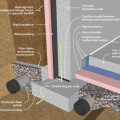

Right - This poured concrete basement wall is insulated on the exterior and under the slab with rigid insulation; footing details include interior and exterior footing drain pipe.

Right - This rigid insulation is correctly installed in a level layer over aggregate; the seams will be taped

Right - This unvented crawlspace is insulated along interior walls with rigid foam and air-sealed by covering the floor with vapor retarder that is sealed to the rigid foam which is taped at the seams.

Right - This unvented crawlspace is insulated along the walls and between the floor joists with 2-inch foil-faced polyisocyanurate; a termite inspection gap is visible above of the wall insulation and below the band joist.

Right - Workers installed rigid foam on the floor and the sill plates of these pre-cast, pre-insulated concrete wall panels to provide a continuous layer of insulation under and around the not-yet-poured basement floor slab.

Right - XPS foam insulation is attached to the existing exterior wall with wood furring strips that serve as a nail base for the siding and are installed vertically to allow for drainage and drying behind the siding

Right - XPS rigid foam board is tightly installed against a concrete foundation wall and seams are sealed with tape prior to installing fibrous blanket insulation.

Right – Attic access hatch has been properly insulated by attaching a fiberglass batt, gasketed, and opening has blocking

Right – 11-inch ICFs provide R-50 of wall insulation from the footing to the roof on this cold-climate home.

Right – A 1-inch layer of XPS rigid foam covers the 2x6 wall studs and is topped by ½-inch-thick plywood sheathing, which is covered with draining house wrap and serves as a nailing surface for siding and trim.

Right – A termite inspection gap is left at the top of the rigid foam board basement wall insulation.

Right – After installing the insulated concrete foundation wall panels, the builder installed underslab rigid foam, which was topped by 4 inches of crushed rock then the poured slab.

Right – All insulated sheathing boards are installed according to the manufacturer’s recommended fastening schedule and taping specifications

Right – All supply ducts in this home were located in conditioned space; any return ducts that were located in the attic were insulated with closed-cell spray foam and buried in the blown-in attic insulation to prevent air leakage and heat loss.

Right – an instructor shows a student how to cut batt insulation around wiring rather than compressing the batt behind the wiring.

Right – An insulated space is provided in the home’s attic to house the HVAC equipment.

Right – Attic access door has foam and rubber weatherstripping installed that remains in contact when closed.

Right – Batt insulation provides additional insulation for the home’s main duct chase.

Right – Battens were installed above the cork insulation to provide a ventilating layer between the insulation and the roof sheathing on this “hot roof” design.

Right – Blocking has been installed around the perimeter of this attic access to prevent insulation falling into the house

Right – Closed-cell polyurethane foam is sprayed on the underside of the roof deck to provide structural connections and seal seams in the sheathing to increase wind resistance

Right – Construction adhesive is applied to the rigid foam panels that will be installed on the interior basement walls.

Right – Even house wrap is installed in the factory for these modular homes where each floor is factory assembled.

Right – Fiberglass batt insulation fills the walls while the floor joists above are insulated with spray foam insulation to both insulate and air seal this transition space.

Right – Full length 2x6 nailer has been installed to allow space for insulation at wall intersection

Right – Furring strips provide a drainage and ventilation gap between the siding and the cork insulation.

Right – Furring strips provide a drainage gap between the rigid foam and the siding.

Right – Furring strips were installed to provide a 3/8-inch drainage plane over the rigid foam and under the fiber cement lap siding.

Right – Housewrap was properly shingled and taped on this wall assembly which places the housewrap beneath the rigid foam sheathing; wall cavities will be filled with spray foam.

Right – Insulated concrete forms (ICFs) provide the insulated stem wall for the slab-on-grade foundation for this SIP house.

Right – Insulation installed to correct depth and will be aligned with air barrier