Showing results 101 - 200 of 354

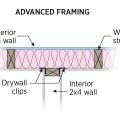

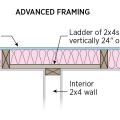

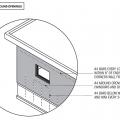

Interior non-load bearing walls are 2x4 studs spaced 24-inchon- center, can have non-structural connectors

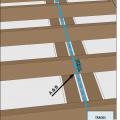

Interior wall attached with top plate metal connector, drywall clips support drywall, plan view

Interior wall attached with top plate metal connector, drywall clips support drywall, side view

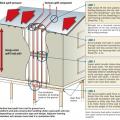

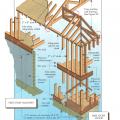

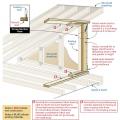

Key connection points for a continuous load path for earthquake and high wind disaster resistance

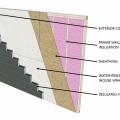

Ladder blocking where exterior walls intersect interior walls provides more space for insulation and reduces thermal bridging.

Ladder blocking where interior and exterior walls intersect uses less wood and provides more room for insulation than stacking studs in the exterior wall to nail the interior wall to.

Ledger board, metal brackets, and vertical 2x4s have been installed in preparation for exterior spray foam in this retrofit exterior wall insulation technique

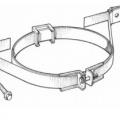

Many hardware stores sell appliance bracing kits to secure the water heater to wall framing with metal straps

Marriage joints between modular home modules at all exterior boundary conditions fully sealed with gasket and foam

Metal Flashing Material Table

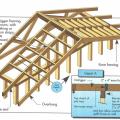

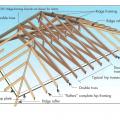

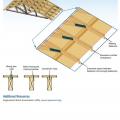

Metal straps tie the roof rafters to the top plate for additional resistance to severe storms.

On top of the ice-and-water shield, the builder installed horizontal beams that were raised 6 inches off the deck to allow room for spray foam insulation.

Open-web floor joists provide space for ducts between the floors of a two-story home.

Permanent options for keeping sun off windows to minimize solar heat gain include permanent overhangs and awnings, frames, and louvers.

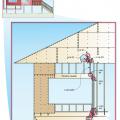

Raised ceiling duct chase installation technique

Reduce thermal bridging in hot climate zones by using an intersecting exterior wall framing technique as shown here.

Right - A continuous load path connects the roof and wall framing to the foundation.

Right - A floor-to-floor hold down can be installed as a retrofit without removing the siding.

Right - Blocking has been installed between the ceiling joists and air sealed in place with canned spray foam to stop air flow beneath the attic knee wall.

Right - Closed-cell spray foam insulation fills the wall cavities of the exterior walls in this home retrofit

Right - Correct angle for installing an engineered structural screw to secure a rafter to a wall for hurricane resistance.

Right - Engineered portal frames are used for wall bracing to resist wind and earthquake loads.

Right - Engineered structural screws are installed to secure a stud to a top and bottom plate for increased hurricane or seismic resistance.

Right - Gasket installed at marriage wall connection prior to assembling modules

Right - Installation steps for the L-bent strap method of bracing a gable end wall

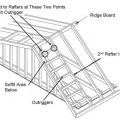

Right - Lookout or outrigger framing for a gable overhang provides two points at each outrigger to add metal connectors to strengthen the overhang against wind uplift.

Right - Metal connectors provide uplift resistance at the rim joist between floors in new construction for a continuous load path.

Right - Metal connectors provide uplift resistance at the stud-to-bottom plate connection in new construction for a continuous load path.

Right - New flashing has been installed to complete the air and water control layers at the window openings of this wall retrofit that includes insulating the wall cavities with spray foam

Right - Raised-heel roof trusses allow more room at the eaves for attic insulation.

Right - Spray foam fills the walls and rim joists to air seal and insulate while caulk seals the framing joints.

Right - The wall framing is connected to roof framing with metal ties for hurricane-resistant construction.

Right - This concrete roof is properly attached and reinforced to withstand hurricane winds.

Right - This roof has a low gable and is secured to the wall framing to resist wind uplift.

Right – A bead of sealant will form an airtight gasket between the top plate and drywall.

Right – A gap separates the two wall layers in this double-stud wall assembly allowing room for insulation to stop thermal bridging between the inner and outer wall

Right – A layer of sealant covers the wood-to-foam layer seams in the insulated header.

Right – An existing gable wall is reinforced with horizontal braces that butt up to the gable end wall and connect back to multiple trusses; retrofit studs make full contact with the wall and the compression blocks and are connected to the horizontal brac

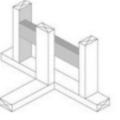

Right – Appropriate use of framing members to support double windows and additional cripples for drywall purposes

Right – Blocking was installed in the walls behind the tub for installation of grab bars.

Right – Engineered open-web floor joists provide space between floors for ducting.

Right – Examples of wall stud to sill plate and foundation and wall rod connectors and brackets.

Right – Examples of wall stud to top plate and stud to rim joist framing connectors and brackets.

Right – Foam gasket is installed on the surface of the framing before plywood sheathing is installed on these factory-constructed wall panels.

Right – Full length 2x6 nailer has been installed to allow space for insulation at wall intersection

Right – Ladder blocking allows the exterior wall to be insulated where intersected by an interior wall.

Right – Open web floor joists can provide a space between floors for HVAC ducting.

Right – Rigid air barrier installed between double-wall assembly. Inside cavity will be insulated

Right – Staggered 2x4s are placed every 12 inches on 2x6 plates, providing a nailing surface on each side of the wall every 24 inches.

Right – Subfloors are installed in a clean, dry, well-lit factory setting for these modular, factory-built homes.

Right – This home is framed with double walls – two 2x4 walls set next to each other then sheathed with OSB on the exterior and netted on the interior face to create an extra-deep wall cavity that can be filled with blown-in insulation.

Right – This hot-humid climate home is constructed with concrete block that is insulated on the inside with rigid foam; the framing is borate-treated lumber; the roof design is a high-wind-resistant hip roof with only one small gable over the entry.

Right – This roof consists of parallel truss chords which allows for cathedral ceilings.

Right – This three studs in this corner are positioned to allow insulation against more of the exterior wall than standard three-stud corners.