Showing results 1 - 21 of 21

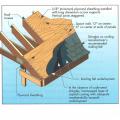

Composition shingle roofing system showing sheathing and hot-mopped underlayment

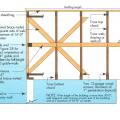

Improper continuous load path design lacking bracing results in the failure of gable end walls under high wind conditions.

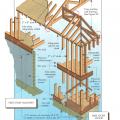

Right - A continuous load path connects the roof and wall framing to the foundation.

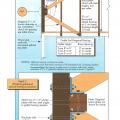

Right – Foam gasket is installed on the surface of the framing before plywood sheathing is installed on these factory-constructed wall panels.

Right – Wood-to-sheathing joints are caulked so the sheathing can provide an air barrier for the home.

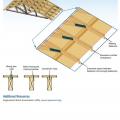

Spray foam adhesive provides an extra water resistant layer to the joints and seams on the inside of attics.

Strengthen an existing roof by applying two-part spray-applied polyurethane foam adhesive to all sheathing and framing joints from the underside of the roof

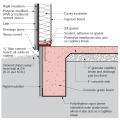

Stucco is installed over rigid insulation, which is installed over a drainage plane consisting of a drainage gap and building wrap layer over the sheathing

The exterior walls of this home consist of two wall cavities: a 2x6 wall with plywood sheathing plus 8-inch I-joists sheathed with engineered wood; both cavities are dense-packed with cellulose for R-60 total.

These factory-built walls consist of 9.5-inch I-studs sheathed with coated OSB, faced with OSB, and dense-packed with cellulose; a second interior surface of drywall is added to provide a 1.5-inch cavity for electrical wiring.

When condensation forms on the interior side of wall sheathing and is not able to dry out, it can lead to mold growth and rotting of wall sheathing and framing

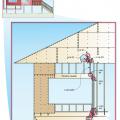

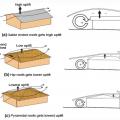

Wind path and uplift force for a gabled roof, a hip roof, and a pyramidal (another variant of a hip) roof design

Wrong - Lack of a weather-resistant barrier allowed water to get behind the siding and rot the framing in this corner rim joist area.