Showing results 1 - 211 of 211

A liquid-applied water barrier covers the walls, serving as a drainage plane, air and vapor barrier, and secondary window flashing beneath the rigid foam that will be installed next.

A paint-on flashing is used around the windows and doors for seamless water protection.

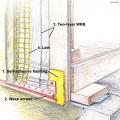

A piece of siding is used as sill extension and to provide slope in the opening for the window, which is deeper because exterior rigid foam has been added

Apply self-adhesive flashing over top edge of the wall flashing, diverter, and housewrap

Before installing the windows, the window rough openings are sealed with a liquid-applied flashing that provides a seamless moisture and air barrier to protect the wall from water intrusion.

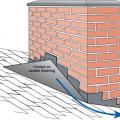

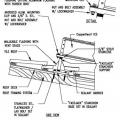

Chimneys and roof valleys are flashed with metal flashing that is integrated with roof shingles.

Clean taping areas and install 3" tape on vertical joint of upper insulation overlapping the horizontal joint

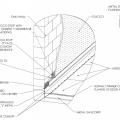

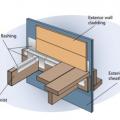

Continuous L-metal flashing integrated with underlayment at roof-wall intersections

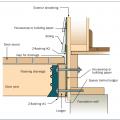

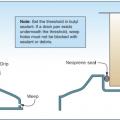

Drip flashing at the door head and drip flashing with hook at the head help to keep out wind-driven rain.

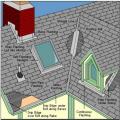

Duct/pipe penetration with metal cap flashing and wood blocking for trim attachment

Existing wall-to-lower roof transition retrofitted with a new strip of fully adhered air control transition membrane, new step flashing, new roof underlayment, and new cladding

Existing wall-to-lower roof transition with a new strip of fully adhered air control transition membrane, new step flashing, new roof underlayment, and new cladding – view from eave

Existing wall-to-lower roof with attic transition with a new strip of fully adhered air control transition membrane, new step flashing, new roof underlayment, and new cladding – view from eave

Expanded polystyrene insulation is installed with joints taped and lath attached in preparation for the application of stucco

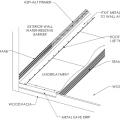

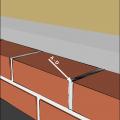

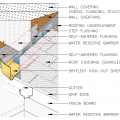

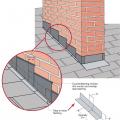

Flashing at bottom of exterior walls with weep holes included for masonry veneer and weep screed for stucco cladding systems, or equivalent drainage system

Flashing at bottom of exterior walls with weep holes included for masonry veneer and weep screed for stucco cladding systems, or equivalent drainage system

Flashing at bottom of exterior walls with weep holes included for masonry veneer and weep screed for stucco cladding systems, or equivalent drainage system

Flashing covers the bottom edge of this wall sheathing then housewrap is layered over the top edge of the flashing.

Flashing is installed above the foundation wall before installing the siding. Seams in sheathing are sealed with tape and caulk, while nail holes are sealed with caulk.

Furring strips provide drainage gap behind lap siding; screen is added at bottom and top to prevent entry of insects and wildfire embers.

Heavy metal flashing protects the deck timbers and separates them from the wall at the wall-deck connection which is vulnerable to both ember entrapment and water damage.

Holes in the exterior walls are flashed and flashing is integrated with housewrap before installing rigid mineral wool insulation.

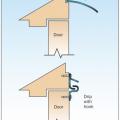

Improper flashing can allow rain water into walls, causing significant damage

Install shingle starter strip then kick-out diverter; attach to roof deck but not sidewall

Integrate pre-formed vent pipe flashing, shingle-fashion, with roofing underlayment and shingles

Kickout diverter flashing keeps bulk water from the roof from overflowing the gutter and continuously wetting the siding material.

Metal cap flashing is installed over the roof parapet and extends down over the roofing membrane

Missing step flashing and kickout flashing caused rotting of wall and roof sheathing, fascia, framing, and plywood cover below the eave at this complicated roof juncture.

Place first shingle and next section of sidewall flashing over upper edge of diverter

Plan view of duct or pipe penetration through exterior wall showing flashing and air sealing details

Plan view of electric box installation in exterior wall showing flashing and air sealing details

Proper flashing around windows is especially important when the rigid foam serves as the drainage plane in the wall

Right - A second layer of flashing tape is applied over the EPDM gasket and first layer of tape at sides and top around the duct; 14 of 14.

Right - After installing the EPDM gasket around the HRV duct, first the lower edge, then the sides of the gasket are taped; 11 of 14.

Right - After installing the EPDM gasket around the HRV duct, first the lower edge, then the sides, then the top of the gasket are taped; 12 of 14.

Right - After installing the EPDM gasket around the HRV duct, the lower edge of the gasket is taped first before taping the other edges of the gasket; 10 of 14.

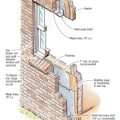

Right - Brick veneer is installed with a 1-inch air space behind the brick, metal flashing and weep holes above and below the windows and at the base of the wall to direct out water that gets behind the brick.

Right - Corners of window are protected with draining house wrap that laps onto the sides of the window trim, paint-on flashing at window trim corners, and self-adhered flashing to reinforce corners.

Right - Counterflashing tops a layer of step flashing which comes down above the asphalt shingle and a layer of L-shaped base flashing which comes down and extends below the shingle; the base flashing is adhered to the roof underlayment with mastic, shown

Right - External outlet wall penetration is flashed with tape that is properly layered with house wrap.

Right - House wrap is lapped back over first layer of flashing tape, then a second layer of flashing tape is applied to the sides around the duct; 13 of 14.

Right - Metal drip edge flashing is installed above hose bib and top of metal flashing is taped to wall.

Right - Painter's tape is used to hold back house wrap while flashing layers are completed around the electric outlet.

Right - Peel and stick flashing and flashing tape seal a plumbing pipe that penetrates an exterior wall.

Right - Permeable rigid mineral wool insulation and appropriate water-management flashing details are integrated with new rigid foam siding to keep water away from the sill beam above the foundation wall

Right - Pieces of metal flashing are installed under each tile course along the valley centerline to prevent debris accumulation between and below concrete roof tiles.

Right - Seams in coated sheathing and joints around window are properly sealed and flashed with tape and all nail holes are covered with paint-on sealant.

Right - Step flashing along a chimney is integrated in a layered manner with asphalt shingle roofing and topped with counterflashing that is embedded into brick mortar joint above

Right - Tape flashing keeps moisture out around and below the window; extra tape reinforces the corners to prevent tearing of the house wrap and to keep water out of this critical juncture.

Right - The duct shows redundant sealing including the caulk, tape, and flashing

Right - The house wrap is properly flashed and taped, and all penetrations are properly flashed.

Right - The pipe penetration is properly flashed and furring strips are installed on each side in preparation for installing cladding

Right - The water and air control layers are properly integrated around the hose bib

Right - This duct penetration is properly flashed and integrated with the taped, foil-faced foam sheathing layer, which serves as the air and water barrier

Right – A chimney cricket is installed and flashed to direct rainwater around the chimney

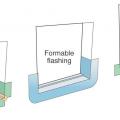

Right – A flexible flashing product is installed around the corners of the window sill before installing the windows.

Right – A metal flashing was installed behind the first row of siding above the windows to guide water over the trim.

Right – A paint-on flashing was applied to the window frames of this ICF house before installing the windows.

Right – All penetrations through the roof decking are sealed with paint-on flashing.

Right – Deck flashing protects the deck-to-wall connection from water and burning embers.

Right – Flashing is installed around chimney, skylight, vents, dormers, in valleys and at eaves

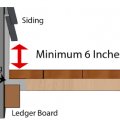

Right – Metal flashing is installed between the deck boards and house wall with the top of the flashing extending up behind the siding and the bottom of the flashing extending out and down over the ledger board

Right – The base of the wall is water proofed and the seam between the base of the wall and the sidewalk is air sealed.

Right – The flashing is properly installed to create a complete drainage system with continuous rigid insulation sheathing/siding

Right – The framing around the window is thoroughly flashed with liquid flashing.

Right – The hard metal ducts are located in conditioned space between floor joists and all seams are sealed with approved metal tape.

Right – The water-resistant barrier is layered over the step flashing to provide a complete drainage system

Right – There is flashing installed along the top of the window and the water-resistant barrier is layered over to create a complete drainage system

Right – There is flashing installed at the bottom of the wall to create a satisfactory drainage system

Right – Two-thirds of acrylic tape is offset above the joint and over and above the fasteners

Right – two-thirds of the blue butyl flashing tape is above the sheathing seam; the top edge of the butyl flashing tape is covered with clear sheathing tape that is also offset so two-thirds is above the top edge of the butyl flashing.

Right – Windows are installed and flashed in the factory for these modular homes.

Right: Brick veneer is flashed correctly with weep holes and a fine mesh screen is installed to prevent pest entry.

Right: Flashing the butt joints in lap siding installations is a better practice than relying on caulk to seal the joints.

Right: This vent was correctly flashed providing proper waterproofing detailing for this siding penetration.

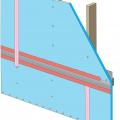

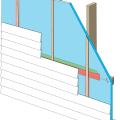

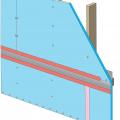

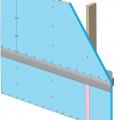

Rigid foam insulation can serve as the drainage plane when all seams are taped. Furring strips provide an air gap behind the cladding.

Section view of duct or pipe penetration through exterior wall showing flashing and air sealing details

Section view of electric box installation in exterior wall showing flashing and air sealing details

Spray foam adhesive provides an extra water resistant layer to the joints and seams on the inside of attics.

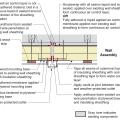

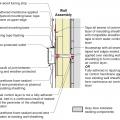

Step 1. Apply roof underlayment over roof deck and up the sidewall over the rigid foam insulation

Step 2. Install shingle starter strip then kick-out diverter as first piece of step flashing.

Step 3. Place the first shingle and the next section of sidewall flashing over upper edge of diverter

Step 4. Install remaining sidewall flashing, appropriate counter flashing, and shingles

Step 5. Apply self-adhesive flashing over top edge of the wall flashing, diverter, and rigid foam insulation

Step and kick-out flashing at all roof-wall intersections extending ≥ 4 in. on wall surface above roof deck and integrated with drainage plane above

Strips of roofing membrane are used to flash around a skylight on a flat roof retrofit

Tape the joint between the top insulation sheet and the Z-flashing with 2" wide tape to improve air tightness

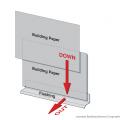

The “down” and “out” approach to flashing – metal flashing directs water down and out of building assemblies

The blocking is completely flashed with roofing membrane before the PV rack hardware is attached on a flat roof

The fluid-applied asphalt coating provides a weather-resistant, moisture resistant layer around the house, serving as a continuous drainage plane and flashing for window and door openings.

The home is sheathed with rigid foam insulation and all seams and holes are taped to provide a continuous air barrier.

The ICF foundation wall of this home is covered with metal flashing before the siding is installed.

The retrofitted flat roof has PV panels and walking mats installed over the roofing membrane

The rough openings for the windows are flashed with a paint-on flashing product then the windows are installed and additional flashing tape is installed over the flashing. Nail holes are sealed with caulk.

The sheathing has rotted because there was not a sufficient drainage gap behind the stucco cladding

The tape window flashing here is integrated with the roller-applied weather-resistant barrier.

The water-resistant barrier, weep screed, and stucco lathe are not properly layered

The water-resistant barrier, weep screed, and stucco lathe are properly layered and will create a complete drainage system

The weep holes are spaced at the correct distance to provide a complete drainage system

The windows in this building are connected to the fully adhered water and air control layer using fluid-applied flashing

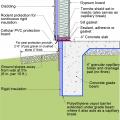

This basement is insulated on the exterior with rigid foam over dampproofing, with granular backfill and footing drains to facilitate drainage away from the foundation, a termite shield to protect from pests, and cellular PVC to protect the rigid foam.

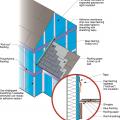

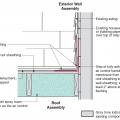

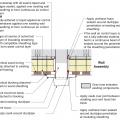

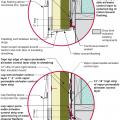

This drawing shows key head details for a window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer

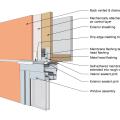

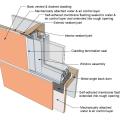

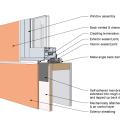

This drawing shows key head details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer

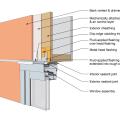

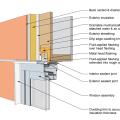

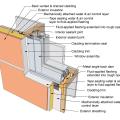

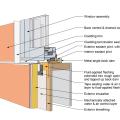

This drawing shows key head details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer and continuous insulation

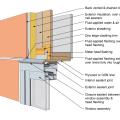

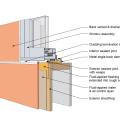

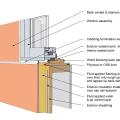

This drawing shows key head details for a window installation using a self-adhered membrane tape flashing on a wall with a mechanically attached water and air control layer

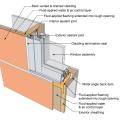

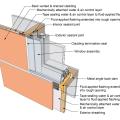

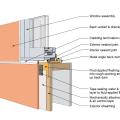

This drawing shows key head details for an “outie” window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer and continuous insulation

This drawing shows key jamb details for a window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer

This drawing shows key jamb details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer

This drawing shows key jamb details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer and continuous insulation

This drawing shows key jamb details for a window installation using a self-adhered membrane tape flashing on a wall with a mechanically attached water and air control layer

This drawing shows key jamb details for an “outie” window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer and continuous insulation

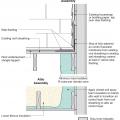

This drawing shows key sill details for a window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer

This drawing shows key sill details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer

This drawing shows key sill details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer and continuous insulation

This drawing shows key sill details for a window installation using a self-adhered membrane tape flashing on a wall with a mechanically attached water and air control layer

This drawing shows key sill details for an “outie” window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer and continuous insulation

This exterior insulated slab-on-grade monolithic grade beam foundation is protected from pests by termite shield at the sill plate, borate-treated framing, flashing at end of wall insulation, brick veneer over slab-edge insulation, and rock ground cover.

This exterior wall retrofit permits drying to the exterior of a sill plate installed on an untreated flat foundation wall

This exterior wall retrofit permits drying to the exterior of a sill plate installed on an untreated irregular foundation wall

This farmhouse was retrofit by removing the existing siding and adding taped insulated sheathing and battens before installing new siding

This house design in the Hot-Humid climate uses a slab foundation, masonry walls, and an Exterior Insulation Finish System (EIFS) cladding.

Threshold Sweep Flashing protects the door and helps to keep out wind-driven rain.

Two types of paint-on flashing (green and red) are installed on the walls and around the windows, over the coated sheathing which is taped at the seams.

Weep holes: Rope inserted in the head joist between bricks will allow water to weep out of the base of the wall assembly

Windows are installed as “outies” in this wall assembly using a self-adhered membrane water and air control layer with continuous exterior insulation

Wrong - House wrap was poorly installed, seams were not taped, and flashing tape was not installed around windows.

Wrong - House wrap and flashing tape are poorly installed allowing water to get into the gaps behind flashing tape.

Wrong - House wrap tape is not fully adhered at seam and flashing tape is missing from window head, jamb, and corner above window.

Wrong - House wrap was not properly cut and adhered where the roof meets the wall so water is likely to get behind the house wrap.

Wrong - House wrap was poorly cut at wall interface and not taped leaving wood exposed and vulnerable to water entry.

Wrong - Metal flashing is bent and poorly installed and tape flashing is missing.

Wrong - Missing kick-out flashing to divert rainwater runoff away from the house and into the gutter where the roof meets the wall has caused discoloration of the stucco and water damage behind the stucco by the front porch and the second-story window.

Wrong - Missing kick-out flashing to divert rainwater runoff into the gutter where the roof meets the wall has caused discoloration and water damage behind the stucco next to this second-story window.

Wrong - Roof is missing metal drip edge to cover the edge of OSB roof decking, roof underlayment should be trimmed back, and asphalt shingles are poorly installed.

Wrong - Roof-wall juncture lacks metal flashing and is poorly designed, thus encouraging water entry.

Wrong - Step flashing is missing where the gable meets roof and the valley flashing is incorrectly on top of rather than under shingles.

Wrong - Stucco has rotted and cracked above a window because of water damage due to lack of proper flashing and drainage.

Wrong - The gutter is missing kick-out flashing causing wall and window damage beneath it.

Wrong - The siding on the chimney is rotten because there is no metal step flashing at the base of the chimney.

Wrong - There is no step flashing along the base of the gable and the right window is missing sill trim.

Wrong - Through-wall flashing has not been installed at brick wall intervals and house wrap is missing.

Wrong - Vent hole has no cover or screening and is poorly sealed and flashed to siding.

Wrong - Vent hole has no cover or screening and is poorly sealed and flashed to siding.

Wrong - Water has gotten behind the paint, possibly due to lack of window flashing, leading to blistering.

Wrong - Window is missing pan flashing under sill and tape flashing at jamb end sill.

Wrong - Wiring holes are not sealed and possible missing flashing around windows is allowing water into walls and causing paint to peel.

Wrong – The corners are not properly flashed, leaving a vulnerable area in the drainage system

Wrong – The flashing of the roof-wall juncture was installed above the roof shingles instead of below the roof shingles; also no kickout flashing was installed.

Wrong – The flashing tape was not installed with a roller to completely adhere it to the OSB sheathing surface.

Wrong – the water-resistant barrier is layered underneath the step flashing, which could allow water to get behind the step flashing and into the wall.

Wrong – There is no flashing installed at the bottom of the exterior walls to create a drainage system

Wrong – There is no flashing installed at the bottom of the exterior walls to create a drainage system