Scope

Install a self-sealing membrane in roof valleys and around penetrations to minimize the possibility of roof leaks.

- Choose a self-sealing membrane such as a bituminous peel-and-stick material or equivalent at all valleys and roof deck penetrations.

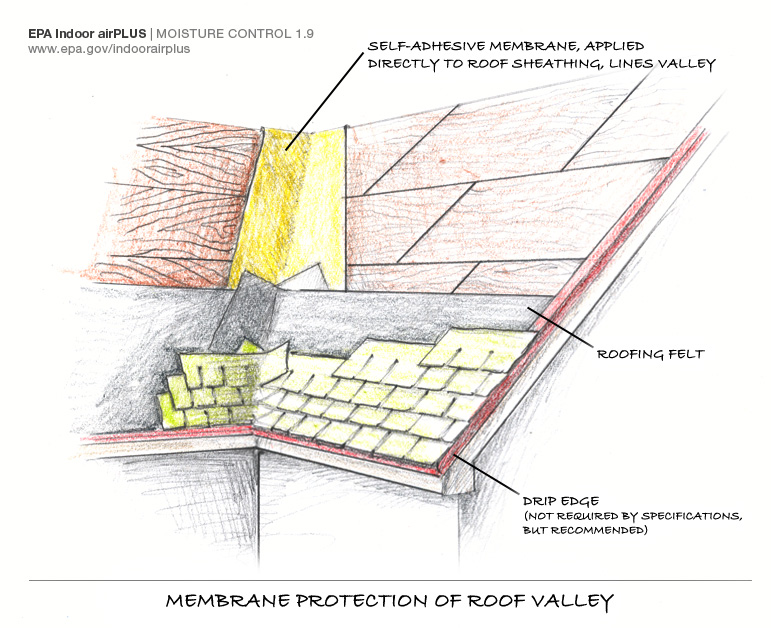

- In valleys, install this layer directly on the roof sheathing surface beneath the roofing felt.

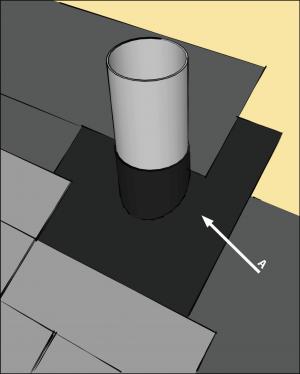

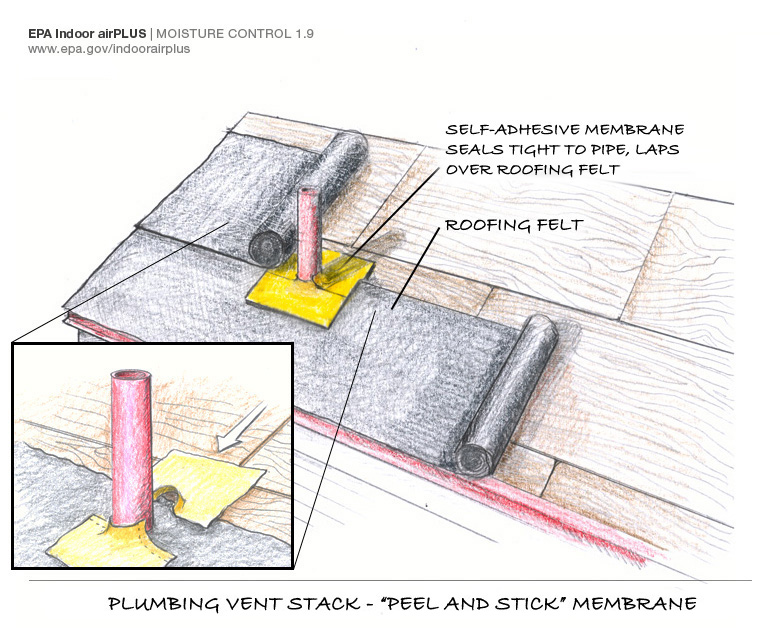

- Around penetrations such as pipes or vents, install one piece to surround the pipe from the down-slope side of the pipe, then install the upslope piece to overlap the upper edge of the down-slope side. Integrate with the roofing underlayment.

- Building code requirements for roof valley flashing vary by roofing material type.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

The roof is the house's primary defense against water intrusion from rain, snow, and ice. This "lid" of the home must be structurally sound and must be designed and constructed to shed water effectively and consistently through all seasons, extreme weather events, and atmospheric conditions. Water that leaks into the house through the roof can quickly damage insulation, create conditions for mold growth and pest invasion, and even set into motion structural rot. Over time even the smallest leak in a roof can result in a significant amount of water damage, and not just in the attic. Once inside the home, water can travel laterally as well as vertically along framing members to cause damage to ceilings, walls, floors, and even basements.

Valleys and penetrations through the roof decking are among the most vulnerable areas for water intrusion. Valleys should be carefully sealed along the entire length. To help prevent water entry at these vulnerable points, install a self-sealing bituminous membrane or the equivalent along all valleys and properly integrate this membrane into the adjoining roofing materials. The self-sealing membrane should also be installed, along with flashing, around all penetrations through the roof, including direct penetrations like plumbing stack vents and structural penetrations like dormer windows and chimneys. Sheathing seams should be sealed with compatible tape.

Most roofing membranes are made of a heavy, flexible bituminous material that has been impregnated with a petroleum-based solution like tar which makes the material waterproof. Most membrane products come with a "peel and stick" adhesive backing. When properly installed, these products provide long-lasting protection from water intrusion. Note: The U.S. Environmental Protection Agency (EPA) uses the phrase "or equivalent" to indicate that a variety of products can be used. Regardless of the product's composition, it must be water impermeable and must durably adhere to the roof deck. Please check with the manufacturer's material classifications and installation instructions to ensure the material you choose will adequately protect the roof from water intrusion (EPA 2011).

Building codes generally do not require a sealed roof deck for new homes or roof replacements, but a sealed roof deck is beneficial in any area and is particularly recommended in hurricane-prone or high-snow-load regions. Sealed roof deck valleys and sealed penetrations are components of a sealed roof deck.

Note: The U.S. Environmental Protection Agency (EPA) uses the phrase "or equivalent" to indicate that a variety of products can be used. Regardless of the product's composition, it must be water impermeable and must durably adhere to the roof deck. Please check with the manufacturer's material classifications and installation instructions to ensure the material you choose will adequately protect the roof from water intrusion.

How to Install Self-Sealing Bituminous Membranes along Valleys of Roof Decks

- Clean the roof deck sheathing along the valley to ensure it is free of loose nails, wires, and debris. Although the membrane is made from a relatively strong material, it can be torn or punctured. Make sure the area is dry and free of oil and dust to ensure the membrane will adhere properly.

- Measure the length of the valley to be covered.

- Cut the self-sealing bituminous membrane to length. For extremely long valleys, cut the material into shorter, more manageable lengths.

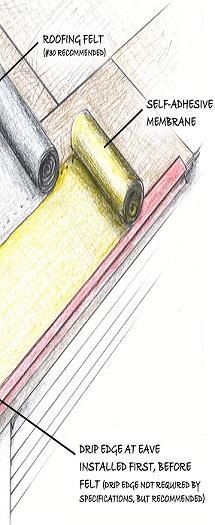

- Install metal drip if required or desired for wildfire and hurricane resistance. Install self-adhering bituminous membrane along the roof eave as required by code or desired to reduce the risk of water damage from ice dams.

- Install the membrane directly on the roof sheathing material (typically OSB). Apply from the lowest point to the highest, overlapping membrane sections by 6 inches in a shingle fashion to allow water to flow unobstructed down the length of the valley. The membrane must be straight and centered with the valley line.

- Installation note: Some peel-and-stick membrane products come with a lengthwise split along the protective backing that can give you a guideline for centering the product while you peel and install it along first one side of the valley and then the other.

- Make sure the membrane lays flat with no gaps, creases, or folds. Secure the material in place with a heavy roller.

- Install the membrane and continue with the installation of the roof cladding. (See Figure 2. Fasteners should not be located within 6 inches of the valley center.)

- If installing shingle roof cladding, metal valleys are recommended over woven or abutted shingle cladding in valleys.

How to Install Self-Sealing Bituminous Membranes Around Direct Penetrations in the Roof

- Clean the roofing area after the pipe or vent has been installed through the roofing deck. Make sure the roof deck around the penetration is free of loose nails, wires, debris, dust, oil, or water.

- Starting at the eave side of the roof below the penetration, install the underlayment (roofing felt) up to the penetration.

- Measure the area to be covered and cut a piece of membrane to fit around the lower half of the penetration, allowing for at least 6 inches of membrane on each side and below the penetration. See Figure 3.

- Install the self-adhesive membrane so that it seals tight around the pipe and laps over the roofing felt, as shown in Figure 3. Use a heavy hand roller to secure it in place. Some manufacturers require that a primer be applied before the membrane is installed, particularly during cold weather or damp conditions.

- Measure and cut a piece of membrane to fit around the upper side of the pipe. A flexible-type membrane-like flashing tape is ideal for flashing around pipes. Install so that it seals tightly around the pipe and the edges overlap the top edge of the first piece of membrane, as shown in Figure 3.

- Continue installing underlayment above the penetration to overlap this membrane.

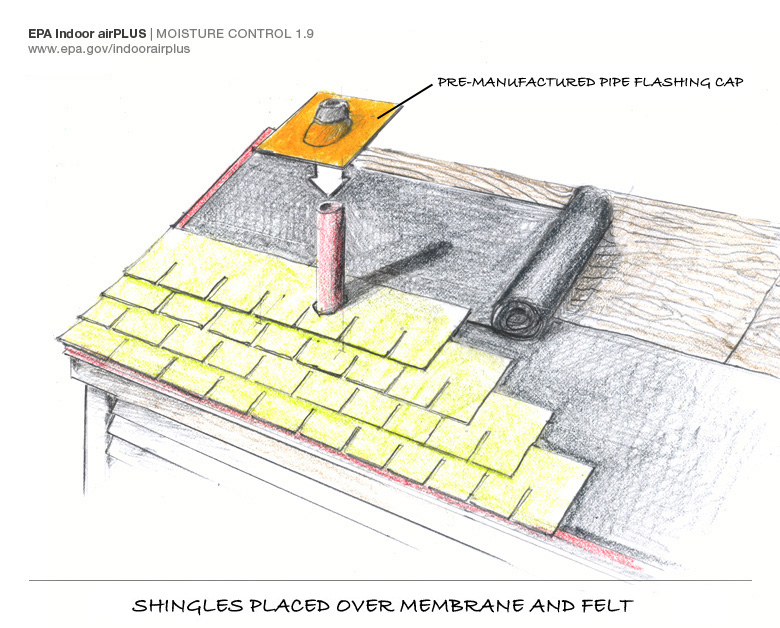

- Install shingles or roofing material up to the penetration.

- Install a pre-manufactured pipe flashing over the pipe and shingles, as shown in Figure 4 and Figure 5.

- Continue installing shingles above the pipe to cover the top edge of the flashing.

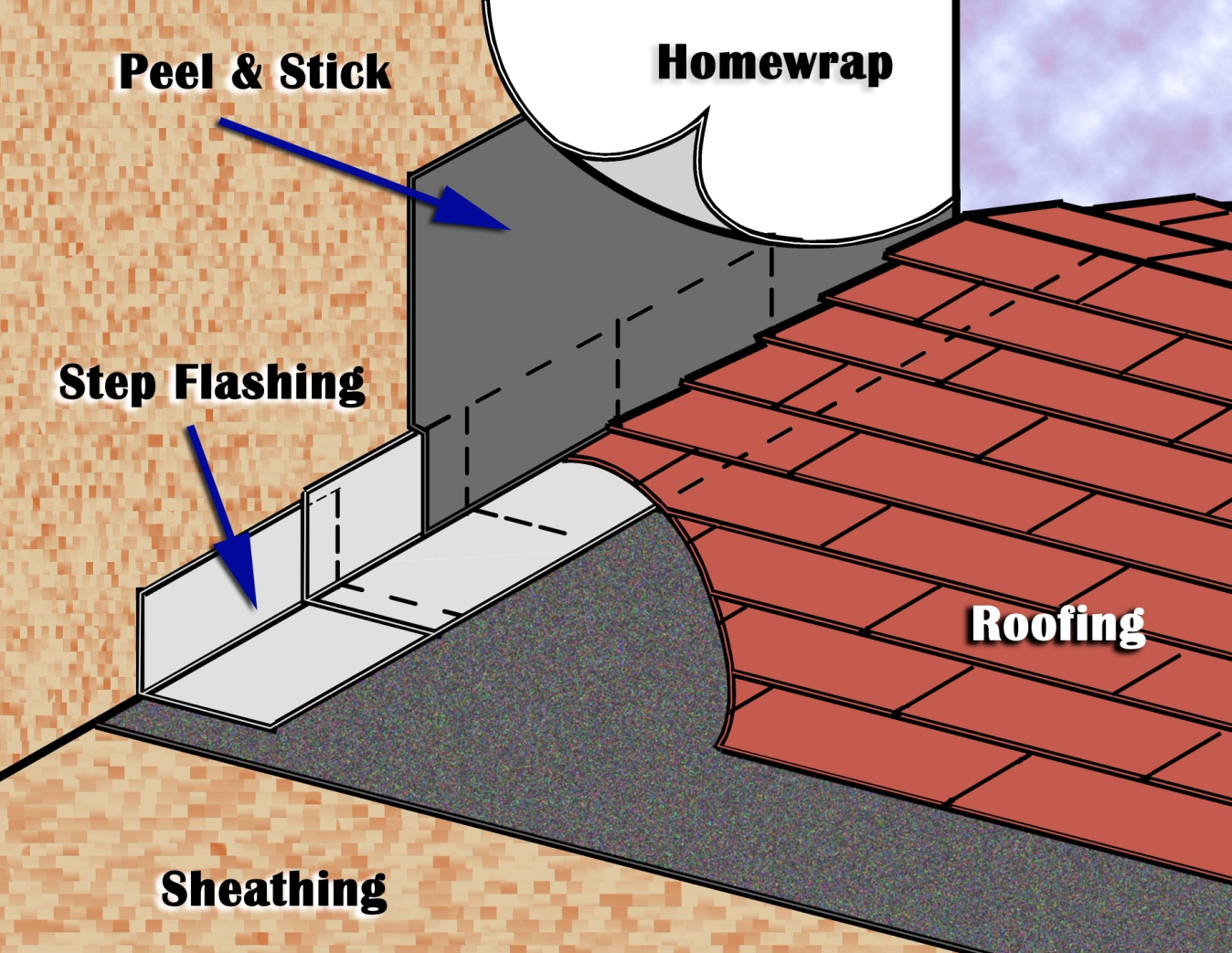

How to Seal Around Structural Penetrations and Roof-Wall Junctures

- Clean the roofing area after the dormer or other structure has been installed through the roofing deck. Make sure the roof deck around the structure is free of loose nails, wires, debris, dust, oil, or water.

- Install underlayment to lap up the vertical wall at least 8 inches and secure it in place. Alternatively, install the underlayment to the vertical wall and install a self-adhesive membrane over the underlayment and up the wall at least 8 inches.

- Install the step flashing and kick-out flashing and secure them in place.

- Apply self-adhesive membrane material directly over the vertical rise of the step flashing and up the side of the penetration.

- Install the WRB material over the peel and stick, securing it in place and attaching it to the membrane with tape.

- Continue installing the roofing material.

- Alternately, the self-adhering membrane can be installed prior to the step flashing as described in the guide Step and Kick-Out Flashing at Roof-Wall Intersections. Apply to the roof deck and lap up the side wall, install metal step flashing, cover the top of metal flashing with self-adhesive tape flashing, and install house wrap and siding over tape flashing.

Success

To ensure that the roof valleys and penetrations are well sealed, the area must be cleaned prior to the installation of the self-adhesive bituminous membrane. Only a complete seal will help keep water from finding its way through the valley and entering the house. Also, once applied, the membrane must be rolled flat so that no folds or creases are present.

Climate

Hurricane-Prone Regions

Roofing and wall cladding are more likely to be damaged or lost in hurricane-prone regions and other high-wind areas, leaving flashing and underlayment exposed and more susceptible to wind and water intrusion. Proper installation of flashing and sealing products is even more important in these areas to protect against storm damage.

The IRC does not have additional requirements for roof-wall flashing in hurricane-prone regions or other high-wind areas. Some local jurisdictions may have additional requirements or require specific product approval. Building codes establish minimum requirements, but products must also be installed in accordance with the manufacturer’s instructions. This is important because codes typically do not provide all the detailed information for a durable installation. Assessments by FEMA after hurricanes commonly find that water intrusion and structural building failures are due to improper installation of building components. So, even where the IRC does not require additional measures, proper installation is more critical in hurricane-prone regions.

The Insurance Institute for Business and Home Safety® (IBHS) offers guidance, best practices, and voluntary construction standards and programs for building in disaster-prone areas, including hurricanes and other high-wind zones. The IBHS FORTIFIED Roof program includes options for sealed roof decks. IBHS also provides specific guidance for flashing, including roof valley flashing.

Sealing the roof deck at valleys and penetrations and proper sealing of the roof deck using self-adhesive membrane and underlayment can significantly prevent water infiltration through the roofs during hurricanes when the primary roofing is damaged. See the Hurricane Technical Summary for New Construction by the IBHS Fortified Home program for all of the methods that can be adopted for sealing roof decks.

High Snow Load Regions

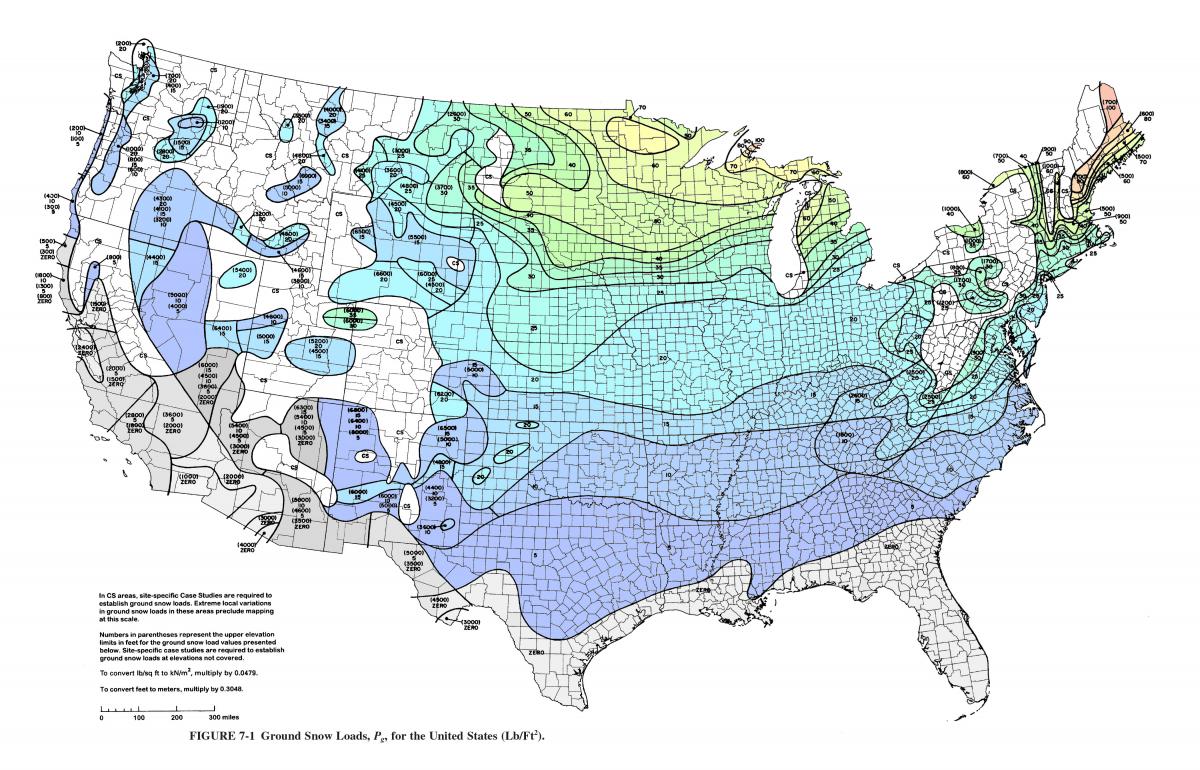

In areas with deep or sustained snow cover (Figure 1), extra protection of roof valleys, as shown in this guide, is recommended. Because roof valleys are difficult to ventilate, they are more prone to heat accumulation and, therefore, snow melt, which can contribute to ice dam formation and subsequent water leakage.

Training

CAD

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Heavy Membrane Valley/Eave = Roof Water Barrier

Valleys and penetrations through the roof decking are some of the areas of the roof most vulnerable to leaks. A peel-and-stick bituminous membrane is installed for protection at these critical locations, including all roof valleys, roof-to-wall transitions, and roof edges to minimize ice dam damage in cold climates. Metal or plastic flashing is usually installed along with the membrane at wall intersections. Flashing is also installed around chimneys, vent stacks, and any other roof penetrations. Some builders install peel-and-stick membrane or a paint-on damp-proofing over the whole roof.