Scope

Insulate an existing slab floor by adding rigid foam insulation over the slab then installing a floating subfloor as follows:

- Treat any significant or persistent site water management issues that are contributing to basement water management issues first.

- Inspect the existing slab for cracks, holes, and penetrations.

- Clean the slab prior to beginning any repairs or retrofit work.

- Seal the cracks, holes, and penetrations.

- Install negative side vapor barrier.

- Install rigid foam insulation.

- Install sleepers if needed.

- Install a floating subfloor.

For more information, see the U.S. Department of Energy’s Standard Work Specifications regarding slab foundations.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

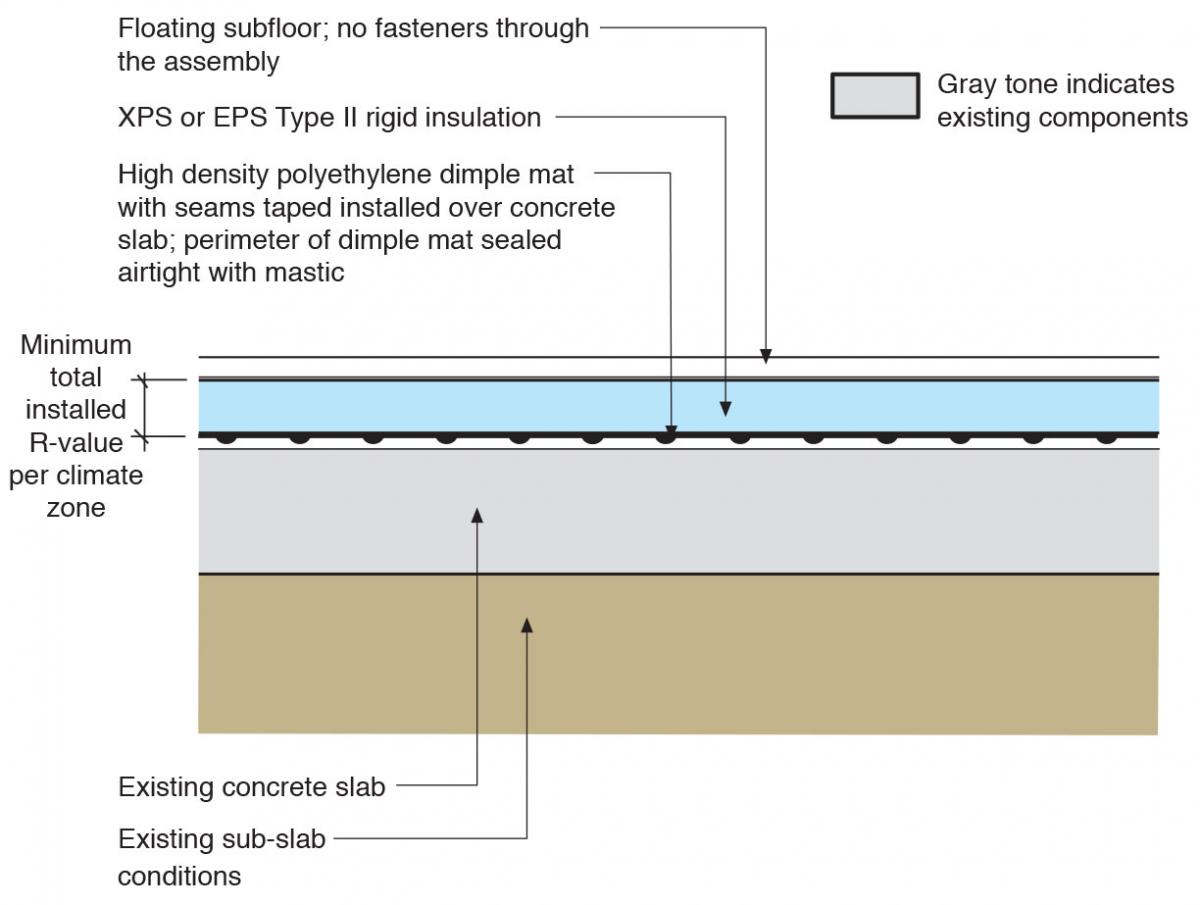

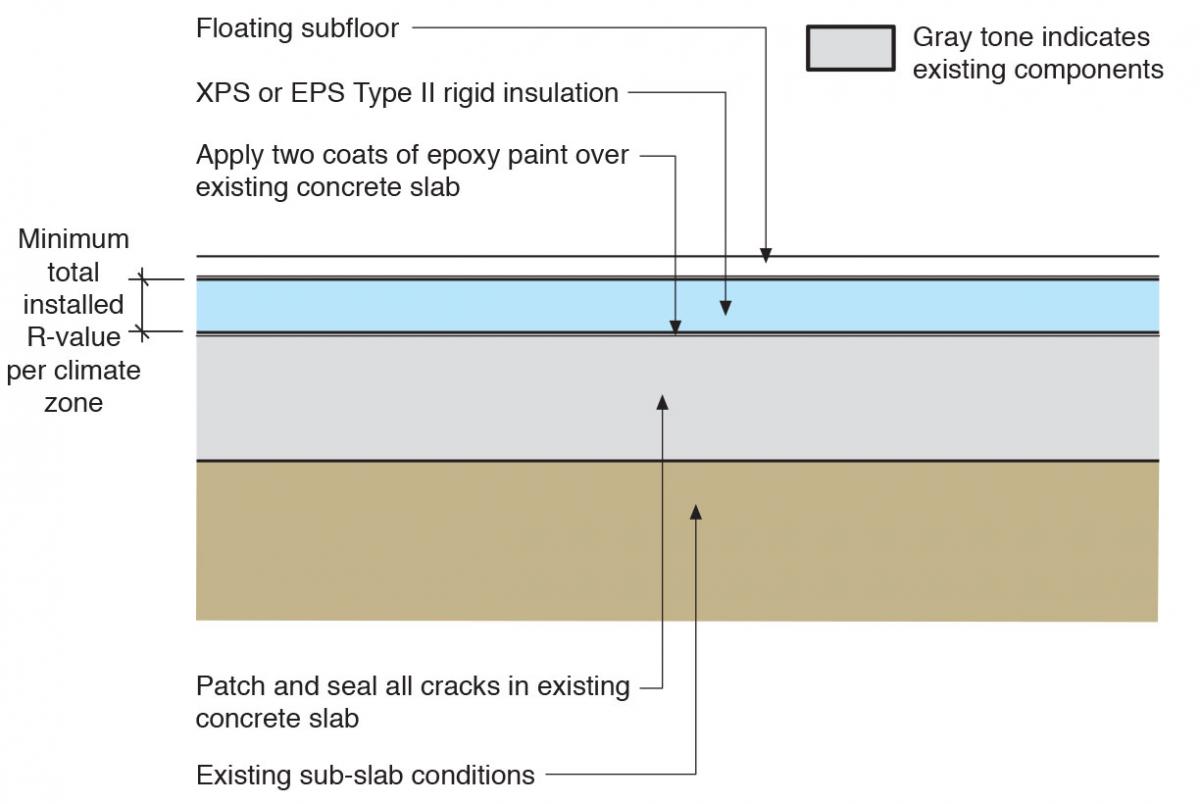

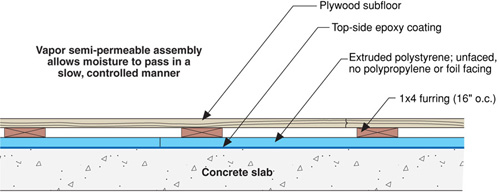

If the existing basement slab is uninsulated, there are two options for adding insulation. One option is to remove the existing slab, excavate below, install insulation, then pour a new slab along with taking other appropriate moisture protection steps. This option is rarely considered feasible due to cost and other considerations. The other option is to install rigid foam insulation and water control measures on top of the existing slab. A floating subfloor is then installed either directly over the rigid foam insulation (Figures 1 and 2) or over furring strips (Figure 3).

When the existing slab is covered with rigid foam insulation, steps must be taken to manage moisture. One option includes providing a water drainage space underneath the insulation to allow water to be drained over the existing slab to a sump or other drainage system. This drainage space is completely isolated from the home by vapor-impermeable and air-impermeable materials. Figure 1 shows rigid insulation installed over an existing slab using polyethylene dimple mat as the drainage layer between the insulation and the existing slab. The other option (Figures 2 and 3) requires installation of a perimeter drain system tied into a sump or other drainage system. For more on sump pump installation, see the guide Drain or Sump Pump Installed in Basements or Crawlspaces.

When performing basement retrofits, consider testing for radon. If radon levels warrant installation of a passive or active radon mitigation system it can be installed before insulation, vapor and water barrier layers are installed over the slab. See the guide Vertical Radon Ventilation Pipe for more information on radon testing and mitigation.

Head height in the basement should be verified prior to beginning retrofit work in order to comply with the current adopted building code, as this retrofit measure will raise the floor height. Where it is not possible to add insulation over the existing basement slab due to insufficient head height in the basement, at a minimum, the slab should be patched and sealed to the foundation wall for soil gas control and epoxy paint should be applied to the surface for moisture transfer control. For more information on this approach see Water Management of Existing Basement Floor.

Insulation with Floating Floor over Existing Slab with Drainage Layer between Insulation and Existing Slab

A drainage mesh or dimple plastic mat is installed over the existing slab then covered with rigid foam and a floating subfloor (see Figure 1). The above-slab drainage layer must be connected to an interior sump pit. The interior sump pit must have an air tight and gasketed cover that is designed to provide the dual function of keeping soil gasses out and preventing ground water from entering the basement. (See the guide Sump Pump Cover Gasket.)

Through-assembly fasteners should not be used because these would puncture the air and vapor control layers and could potentially admit soil gas that is collected in the air space below (in the drainage mesh or dimple mat).

How to Install a Drainage Layer and Insulation with Floating Floor over an Existing Slab

- If significant or persistent water issues exist in the basement, treat those issues prior to sealing the slab.

- Consider testing radon levels in the basement and home prior to the sealing project. If a radon stack is needed, install it before urethane sealant and epoxy paint are applied.

- Inspect the existing slab for cracks, holes, and penetrations. Locate the areas that need to be addressed.

- Remove any debris or dust particles from the slab prior to applying urethane sealant to ensure proper adherence of the sealant.

- Apply a generous and continuous bead of urethane sealant to any cracks, holes, around any penetrations, and at wall-to-slab joints to prevent pest and soil gas (including radon) entry.

- Install a 6-mil polyethylene vapor barrier with seams taped or a high-density polyethylene dimple mat with seams taped (see Figure 1).

- Install rigid foam insulation (XPS or EPS Type II) with seams taped.

- Install a floating subfloor. Do not fasten the subfloor through the floor assembly.

Insulation with Floating Floor Directly Over Existing Slab

Instead of drainage mat, the existing slab can be coated with two coats of epoxy paint, then rigid foam can be installed directly over the epoxy layer (see Figure 2). Use of this slab assembly requires a sub-slab drainage system such as an interior perimeter drain.

How to Install Insulation with Floating Floor Directly over an Existing Slab

- If significant or persistent water issues exist in the basement, treat those issues prior to sealing the slab.

- Consider testing radon levels in the basement and home prior to the sealing project. If a radon stack is needed, install it before urethane sealant and epoxy paint are applied.

- Inspect the existing slab for cracks, holes, and penetrations. Locate the areas that need to be addressed.

- Remove any debris or dust particles from the slab prior to applying urethane sealant to ensure proper adherence of the sealant.

- Apply a generous and continuous bead of urethane sealant to any cracks, holes, around any penetrations, and at wall-to-slab joints to prevent pest and soil gas entry

- Apply two coats of epoxy paint over the existing slab. The area should be clear of dust and debris.

- Install rigid foam insulation (XPS or EPS Type II) with seams taped (see Figure 2).

- Install a floating subfloor. Do not fasten the subfloor through the floor assembly.

Insulation with Sleepers and Floating Floor over Existing Slab with Drainage Layer between Insulation and Existing Slab

A third option is to install unfaced rigid foam over an existing slab that has been coated with epoxy paint, then to install 1x4 sleepers for the plywood subfloor to sit on (see Figure 3). Use of this slab assembly requires a sub-slab drainage system such as an interior perimeter drain.

How to Install Insulation with Sleepers and Floating Floor Directly Over an Existing Slab

- If significant or persistent water issues exist in the basement, treat those issues prior to sealing the slab.

- Consider testing radon levels in the basement and home prior to the sealing project. If a radon stack is needed, install it before urethane sealant and epoxy paint are applied.

- Inspect the existing slab for cracks, holes, and penetrations. Locate the areas that need to be addressed.

- Remove any debris or dust particles from the slab prior to applying urethane sealant to ensure proper adherence of the sealant.

- Apply a generous and continuous bead of urethane sealant to any cracks, holes, around any penetrations, and at wall-to-slab joints to prevent pest and soil gas entry.

- Apply two coats of epoxy paint over the existing slab. The area should be clear of dust and debris.

- Install rigid foam insulation (XPS or EPS Type II) with the seams taped (see Figure 3).

- Install 1x4 furring strips at 16 inches o.c. and attach them to the concrete slab through the rigid foam insulation.

- Install the plywood subfloor. Fasten the subfloor to the furring strips.

Success

Apply urethane sealant and epoxy paint to a clean, dust-free surface.

Visually verify the quality of the sealant application and paint application for continuous adhesion and coverage before proceeding to the next steps.

Seal any penetrations in the slab, such as around sump pumps and plumbing and vent pipes.

Climate

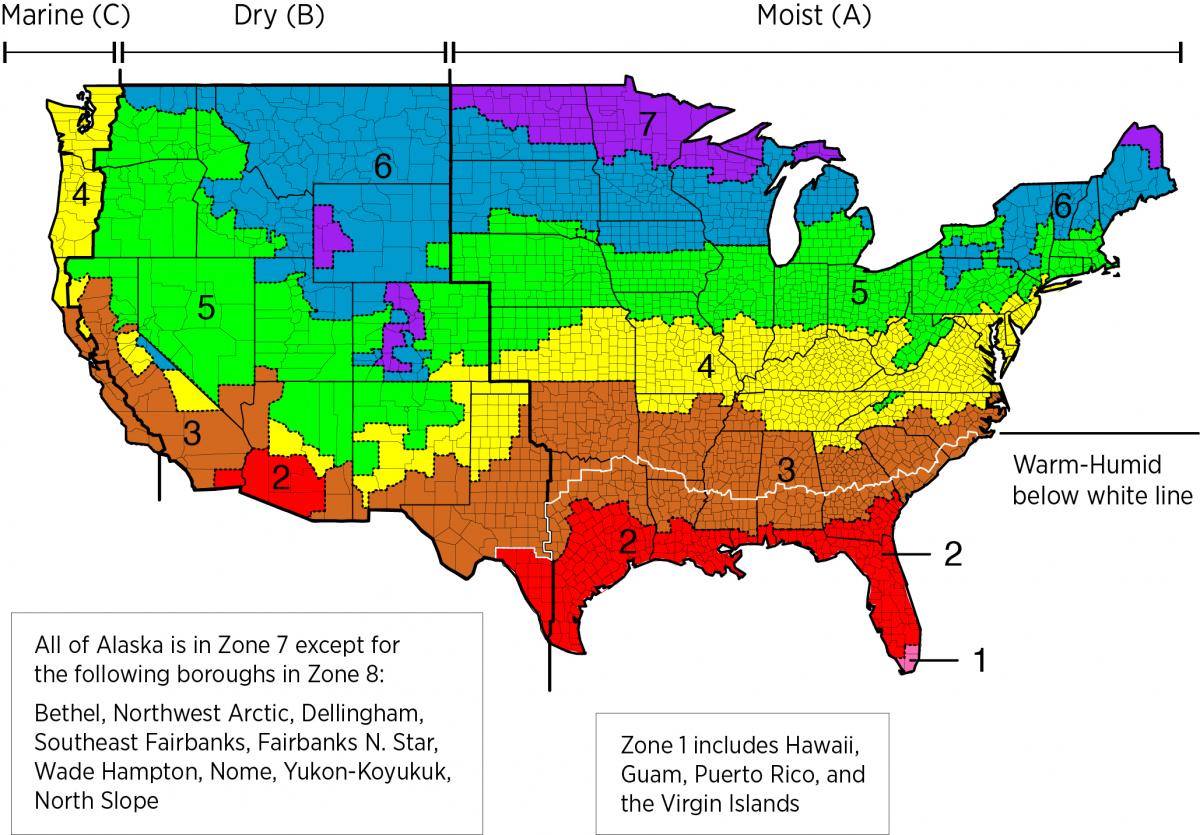

The slab assembly should be designed for a specific hygrothermal region, rain exposure zone, and interior climate.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

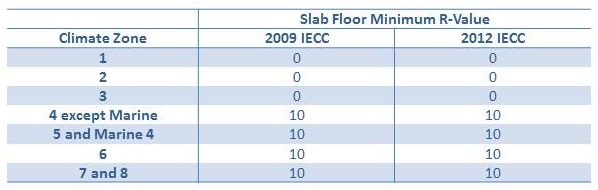

The insulation levels should be based on the minimum requirements for vapor control in the current adopted building code and the minimum requirements for thermal control in the current energy code. Additional insulation can be added above these minimums to create high R-value floor assemblies. The table below provides the minimum thermal resistance (R-value) requirements for slab floors specified in the 2009 IECC (ICC 2009b) and the 2012 IECC (ICC 2012b), based on climate zone.

Table 1. Minimum R-Value Requirements for Slab Insulation. (Source: 2009 IECC and 2012 IECC)

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Building Science Corporation, lead for the Building Science Consortium (BSC), a DOE Building America Research Team

Sales

High-R Foundation Insulation = High-Efficiency or Ultra-Efficient Foundation Insulation

There are two levels of foundation insulation: high-efficiency insulation, which meets the 2015 International Energy Conservation Code, and ultra-efficient insulation, which is 25% more efficient than this national code. Using high-efficiency and ultra-efficient insulation, along with professional installation (e.g., no gaps, voids, compression, or misalignment with air barriers; complete air barriers; and minimal thermal bridging) creates conditioned spaces that require very little heating and cooling, along with, even comfort and quiet throughout the house.