Scope

Install boiler controls in multifamily buildings per the manufacturer’s instructions. The controls should be installed by qualified contractors.

- Conform to applicable local codes for minimum temperature requirements during day and night time.

- Consult with the building manager regarding indoor air temperature targets and history before altering boiler control settings.

- If the building has a history of overheating, then alter boiler control settings (such as indoor temperature control set points and nighttime setbacks) to maximize comfort and energy savings.

- Measure indoor air temperatures in a sample of apartments for a brief period of time. Based on these temperature data, re-adjust boiler settings.

- Perform this task during the coldest part of the heating season.

- It may need to be adjusted during milder winter conditions.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

In multifamily housing, with hydronic heat provided by central boilers, the capability of a boiler controller to adjust the boiler and/or supply water temperature according to inputs such as outdoor and indoor temperatures as well as controller settings is important for achieving energy savings and comfort. Boiler controls can significantly reduce heating costs in multifamily housing. A recent study supported by DOE’s Building America program showed averaged utility bill reductions of 19% when central boilers in three apartment buildings were retrofit by adding boiler controls (Hydronic Heating Retrofits for Low-Rise Multifamily Buildings: Boiler Control Replacement and Monitoring).

Leading control strategies include the following.

Outdoor Reset

Outdoor reset control (ORC) is a popular type of multifamily boiler control strategy with variants for both steam and hot water heating. ORC has existed for perhaps as long as 50 years. It has been more prevalent in multifamily buildings, but is now becoming more common in single-family residential systems, in part because of legislation that went into effect in 2012 requiring improved boiler controls. ORC is one way to meet the requirements.

The basic concept behind ORC is that the amount of heat delivered to the building should vary in proportion to the outdoor temperature. For hot water systems, this takes the form of varying the supply water temperature from the boiler. For steam-heated buildings, this takes the form of varying the duration of the steam cycle (number of minutes per hour that steam is provided to heat emitters). In mild weather, proportionally lower water temperatures and less steam runtime allow heating systems with ORC to limit overheating and reduce fuel consumption. Lower water temperatures also reduce distribution losses from hydronic systems.

Multifamily hot water space heating systems can have multiple boilers, circulation loops, pumps, and valves. Reset control can be integrated with these components to achieve the desired supply temperature to the building.

The underlying logic behind ORC is shown in the reset curve or ratio. It specifies the variation of water temperature (boiler, system supply, system return, or other) with outdoor temperature. The steeper the curve (greater the slope’s magnitude), the sharper the drop in water temperature with each degree rise in outdoor temperature. The reset ratio is usually linear (but some control manufacturers use proprietary non-linear algorithms). In addition to adjusting the slope of the reset curve, the reset curve can be offset up or down depending on the heat loss characteristics of the building and to implement a setback such as for night time, or vacation mode in single-family homes.

One caveat with lowering water temperature is that many boilers, especially older ones, are not designed to accept return water temperatures below 120-130oF for extended periods of time. Risks of lower-temperature return water include possible condensation of corrosive flue gasses that can corrode the heat exchanger over time.

Condensing boilers, on the other hand, are well suited to accept low return water temperatures, and therefore take maximum advantage of ORC, because they are designed with materials that can withstand these conditions without deterioration. Other strategies such as mixing valves or injection pumps can maintain high return water temperature by recirculating some supply water or injecting controlled amounts of boiler water into the boiler return.

In addition, water temperature can be adjusted separately for night time and daytime; however, energy savings from this setback strategy are not proven. A sample outdoor reset control curve is given below where WWSD is “warm weather shut down” (i.e., above this temperature no heat is provided).

Indoor Temperature Cutoff

In this control strategy, which is overlaid on top of outdoor reset control, several temperature sensors are installed in apartments to measure indoor air temperature. If the average temperature of these apartments exceeds a predefined limit, the controller turns the boiler off to reduce overheating.

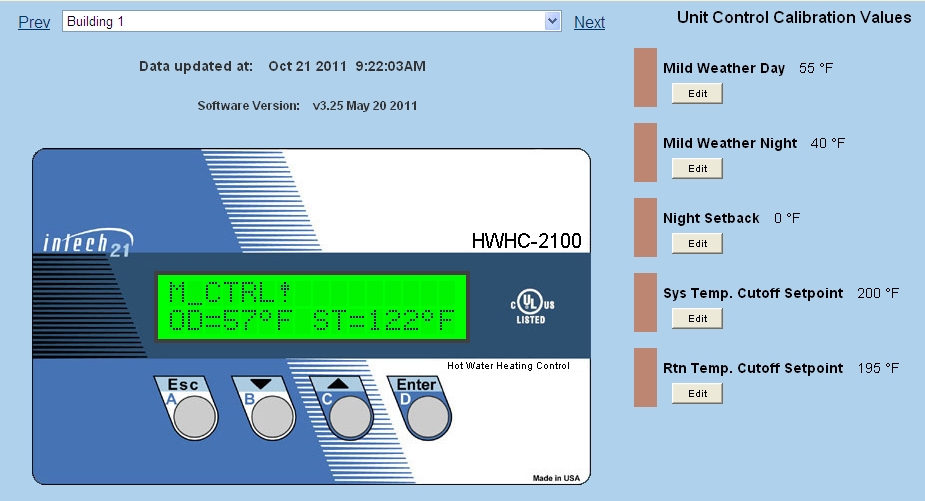

Boiler controllers can often communicate with an offsite server that stores logged temperature and boiler operation data and makes these historical data available on a website. The web-based system may allow remote operation and modification of the control parameters. If apartment temperature sensors are included, then it can provide real-time access to these data so that building operators can ensure the legally required minimum heating temperature is provided to each apartment, without resorting to a large safety factor, which wastes energy by maintaining the water temperature at excessively high temperatures. Access to these data can also assist in diagnosing heating system problems and addressing tenant complaints.

Issues

One risk of systems using apartment temperatures is that tenants using supplemental heating (or cooling) could affect temperature sensor readings inadvertently or intentionally in an effort to obtain more (or less) heat. However, the averaging of all apartment temperatures minimizes the impact any one apartment can have on the system.

Materials

A typical boiler control system will include all equipment, materials, and manuals necessary for its use, including the controller, outdoor temperature sensor, and for systems with indoor cutoff, indoor temperature sensors, pipe temperature sensors, a wireless receiver and networking devices. If mixing valves are also to be controlled, an additional controller and sensors will be required. Other measures discussed under “Ensuring Success” will require additional components.

Who Does the Work

Local codes may require a licensed boiler contractor to perform this work.

Metrics

The data collected from the boiler controller or utility bills can be used to calculate energy savings by comparing periods when the controller is operated with and without selected features.

Success

Because altering boiler control settings require special skills, it must be performed by a qualified contractor. Manufacturer installation instructions must be followed. The following measures are important for health and safety and performance issues.

Health and Safety:

Manufacturer's Instructions. Equipment manufacturer's instructions should be followed.

Electrical Hazards. Potentially hazardous voltages exist in control cabinets and electrically actuated control components. These components should be handled only by qualified electrical or instrumentation service people.

Hot Surfaces. Many hot surfaces exist in a boiler area and even non-heated surfaces can become uncomfortably warm; therefore, care must be exercised to prevent burns and other thermal hazards when near the boiler.

Performance issues. Indoor air temperatures in a sample of apartments should be measured for a short period of time (a few days to a week) to verify the performance of control settings and to quantify changes. Based on these temperature readings, boiler settings should be readjusted. The contractor should preferably perform this task during the coldest part of the heating season, but may need to revisit the setting during milder winter conditions.

Other opportunities. While working in the boiler room, other opportunities for improvements to the heating system performance and safety should be considered, including pipe insulation, combustion safety testing, and boiler tuning and cleaning. Also, consider adding mixing valves or injection pumps to the system to enable resetting to lower supply temperatures than the boiler alone can be reset to.

Climate

Boiler control settings are dependent on the climate characteristics and heat loss of the building. The colder the climate, the more potential there is for energy savings; however, mild climates can experience significant savings as well if existing controllers are poorly adjusted.

Compliance

Compliance

Local ordinances often require residential property owners to provide functioning heating systems that are capable of heating habitable spaces to minimum temperatures delineated in the ordinance for day and night.

Retrofit

SCOPE

Adding boiler controls is a cost-effective measure for improving energy efficiency and comfort in existing multifamily buildings with central boiler heating systems. Updated boiler controllers for apartment buildings have been shown to cut energy use by 19% with a payback of less than three years (Levy Partnership 2014).

See the other tabs in this guide including the Scope and Description tabs for installation guidance.

For more information about steam boiler pressure operating controls, see the U.S. Department of Energy’s Standard Work Specifications.

For safety when working in basements, see the Pre-Retrofit Assessment of Crawlspaces and Basements. For safety considerations when working with combustion appliances, see the Pre-Retrofit Assessment of Combustion Appliances.

COMPLIANCE

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

The Levy Partnership, Inc., lead for the ARIES Collaborative, a DOE Building America Research Team