Scope

Insulate a floor over unconditioned space with conditioned space above (such as a cantilevered floor, the second floor overhang of a garrison colonial house, the underside of a projecting bay, the ceiling of an inset porch, or the ceiling of a vented crawlspace) by adding insulation and air sealing as follows:

- Inspect the overhanging floor framing to verify existing conditions and develop specific detailing for insulating the overhanging area.

- Provide four control layers that are continuous between the overhanging floor and wall assemblies: water, air, vapor, and thermal.

- Install insulation to levels that meet or exceed the thermal requirements of the current adopted building and energy codes.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Cantilevered floors and floors over unconditioned space in existing homes are frequently found to be uninsulated and not air sealed, causing cold (or hot) areas in the rooms above these floors. Configurations where these overhangs occur include the second-floor overhang of a garrison colonial style house, the underside of a projecting bay, the ceiling of an inset porch, or the ceiling of a vented crawlspace with conditioned space above. There are several methods for air sealing and insulating these types of building configurations. Regardless of which method is used, any seams in the “ceiling” of the cantilever framing cavities should be air sealed before the cavities are insulated and any open floor joist bays that extend from the cantilever into the home must be blocked with some solid blocking material such as rigid foam or plywood and air sealed at the edges. For more information about air sealing cantilevered floors see the guide Cantilevered Floor.

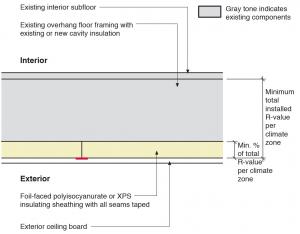

Rigid Insulation below Framing and Cavity Insulation, Finish Material to Underside of Overhang

Figure 1 shows an assembly that is typical for a porch ceiling under a second-story room or the overhang of the second floor of a garrison colonial style home. Any existing finishing material such as plywood is removed from the underside of the overhang framing to minimize the change in elevation of the overhang. The framing cavities are then filled with batt or blown fibrous insulation and rigid foam is attached to the bottoms of the framing joists. Seams in the rigid foam are sealed with tape and a new finish material is installed to cover the rigid foam. This finish material might be fiber cement or engineered wood siding or painted plywood or OSB.

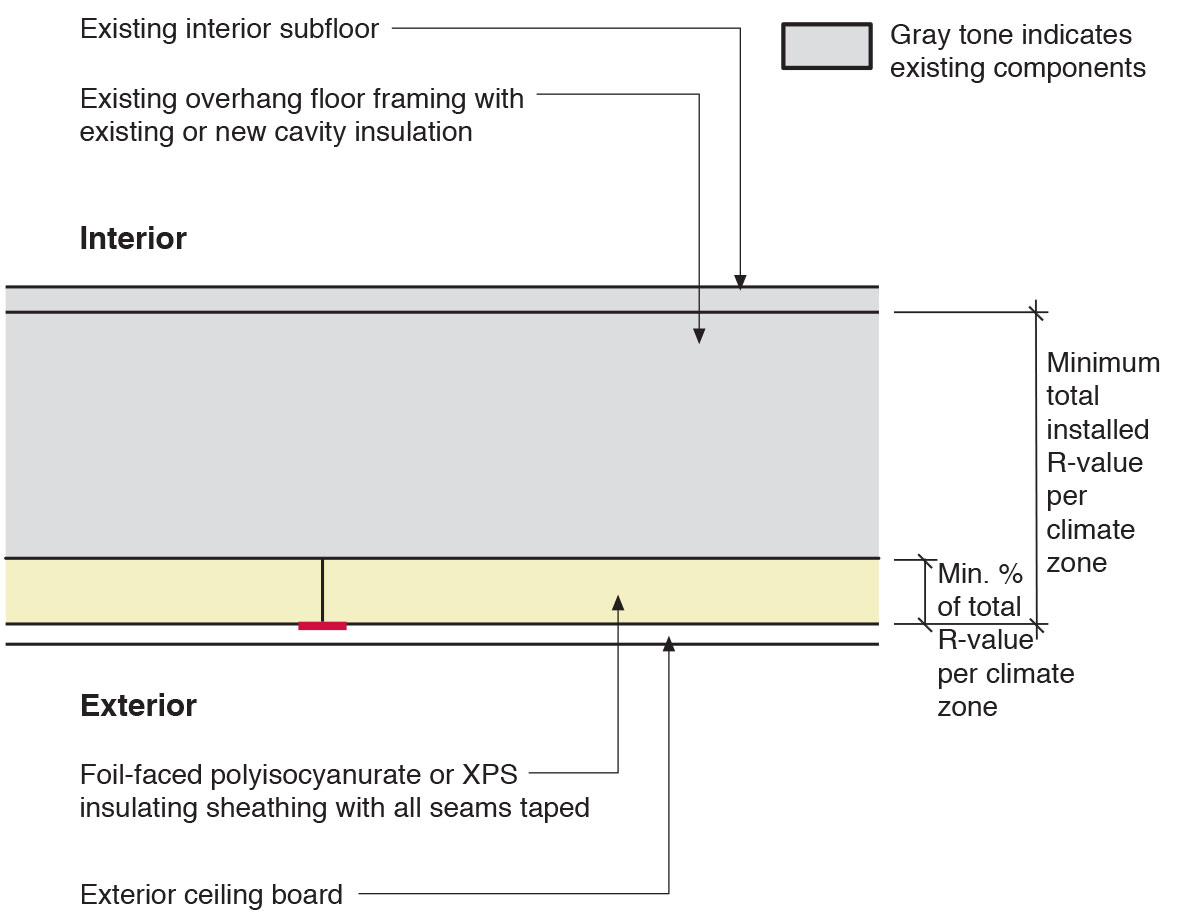

Closed-Cell Spray Foam Insulation in Cavities and Encapsulating Framing

The approach shown in Figure 2 is typical under a first-floor bay or for a vented crawlspace with conditioned space above. The framing is encapsulated with spray foam to decouple the framing from the ground or crawlspace thermal and moisture conditions. The standoffs may be replaced with 2x2 furring if needed for attaching the protection layer (e.g., cement board).

How to Insulate an Overhanging Floor Above Unconditioned Space

- Inspect the structural integrity of the overhanging floor. Check the framing for any deficiencies, rot, insect damage, etc. Proceed only after needed repairs are performed. Based on the findings, revise the floor assembly and review specific detailing as needed. Follow the minimum requirements of the current adopted building and energy codes.

- Air seal the joist cavities of the overhanging floor. Block any open bay that extend into the home’s conditioned space, for example that connect to the space between the first and second floors. Use a solid blocking material to block the bays and air seal around edges as described in the guide Cantilevered Floor.

- Install either loose-fill, batt, or spray foam insulation in the ceiling cavities, then install polyisocyanurate or XPS insulating sheathing to the underside of the framing. Tape the seams of the insulating sheathing to create a robust air control layer, as shown in Figure 1 and Figure 3. ALTERNATELY, install closed-cell spray foam insulation in the cavities and encapsulate the framing, as shown in Figure 2 and Figure 4.

- Install a protective layer of cement board or plywood over the insulating sheathing. ALTERNATELY, apply intumescent coating or other thermal ignition barrier over spray foam if required by code. To protect the spray foam from rodents and/or birds, attach blocking to the existing framing and attach a protective layer of cement board or plywood as shown in Figure 5.

Success

No information at this time.

Climate

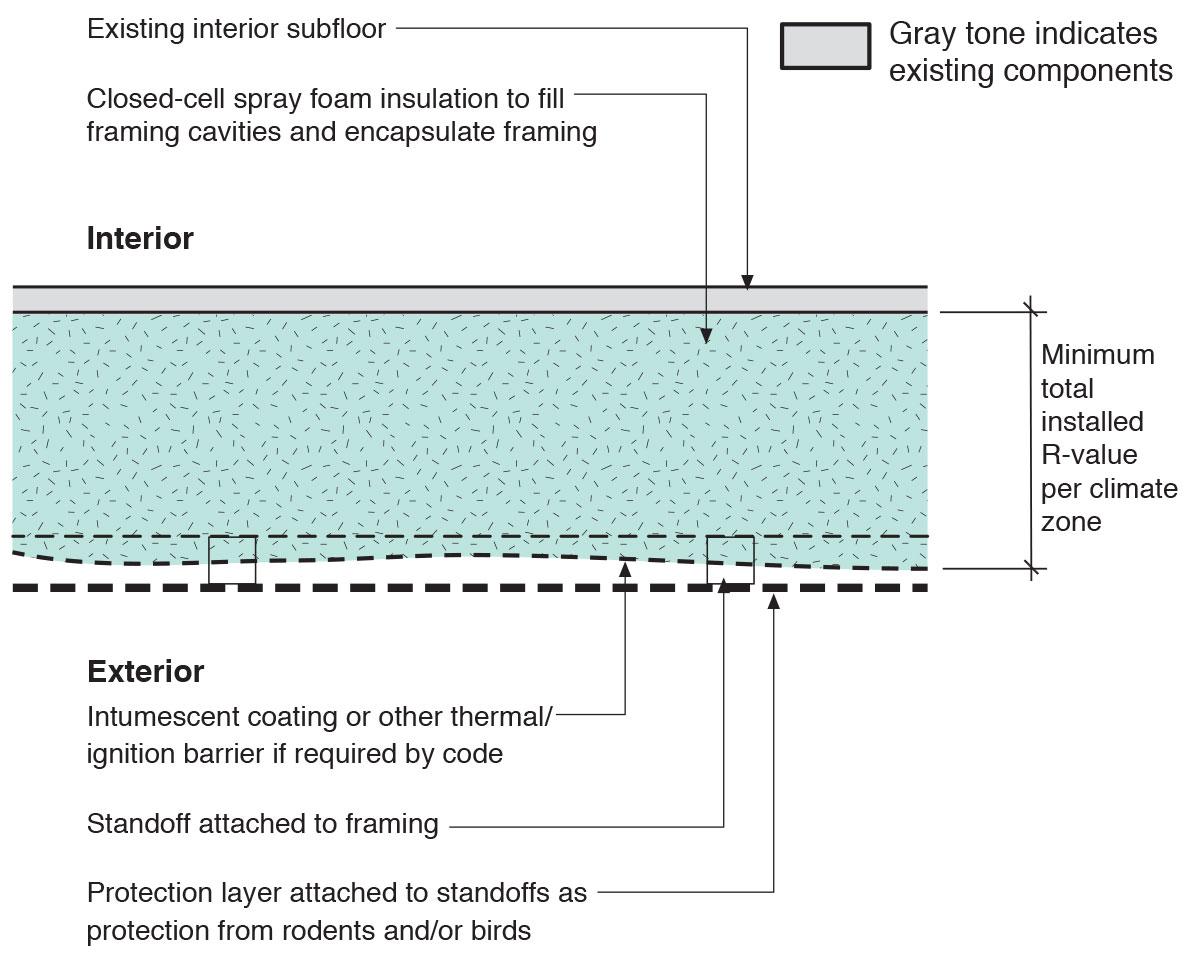

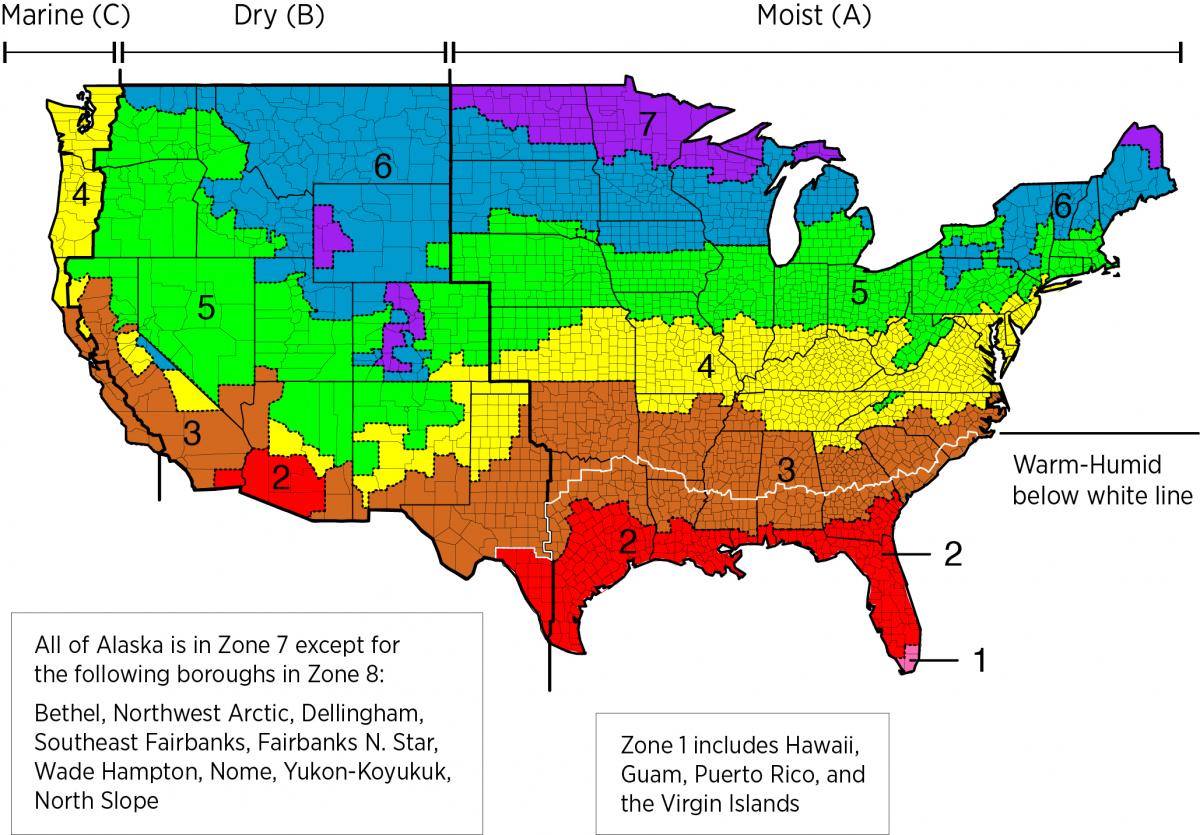

The floor assembly should be designed for a specific hygrothermal region, rain exposure zone, and interior climate.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Figure 1. Climate Zone Map from IECC 2009, 12, 15, and 18. (Source: 2012 IECC)

Figure 2. Climate Zone Map from IECC 2021. (Source: 2021 IECC)

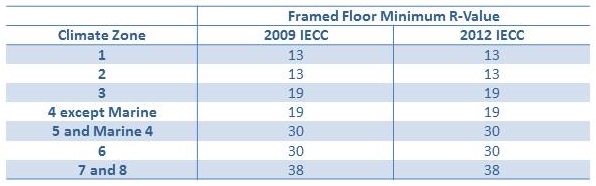

The insulation levels should be based on the minimum requirements for vapor control in the current adopted building code and the minimum requirements for thermal control in the current energy code. (See Table R601.3.1 Class III Vapor Retarders of the 2009 IRC (ICC 2009a) and Table R702.7.1 Class III Vapor Retarders of the 2012 IRC (ICC 2009b). Additional insulation can be added above these minimums to create high R-Value floor assemblies. The table below provides the minimum thermal resistance (R-value) requirements for framed floors specified in the 2009 IECC (ICC 2009b) and the 2012 IECC (ICC 2012b), based on climate zone.

Table 1. Framed Floor R-Value Requirements in the 2009 and 2012 IECC. (Source: 2009 IECC and 2012 IECC)

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Building Science Corporation, lead for the Building Science Consortium (BSC), a DOE Building America Research Team

Sales

High-R Floor Insulation = High-Efficiency or Ultra-Efficient Floor Insulation

There are two levels of floor insulation: high-efficiency insulation, which meets the 2015 International Energy Conservation Code, and ultra-efficient insulation, which is 25% more efficient than this national code. Using high-efficiency and ultra-efficient insulation along with professional installation (e.g., no gaps, voids, compression, or misalignment with air barriers; complete air barriers; and minimal thermal bridging) creates conditioned spaces that require very little heating and cooling, along with even comfort and quiet throughout the house.