Scope

If located in a potential flood zone, design or retrofit crawlspace foundations to be flood resistant.

- Use a vented, unconditioned crawlspace design rather than a non-vented, conditioned design.

- Ensure foundation footing is deep enough to prevent undermining due to scour.

- Ensure interior grade is higher than or level with exterior grade and exterior grade slopes away from the house.

- Elevate floor assembly.

- Protect service equipment.

- Elevate electrical equipment.

- Build with materials that are moisture, decay, and corrosion resistant.

- Design assemblies to easily dry when they get wet.

- Ensure that floodwaters can enter and exit the crawlspace.

See the Compliance tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

This guide provides information on how to design or retrofit a crawlspace to reduce the risk of damage during a flood event.

See the flood Overview Guide for background information on types of floods, flood mapping, the National Flood Insurance Program (NFIP), and terms used throughout this guide such as Special Flood Hazard Area (SFHA), Zones V, A, and Coastal A, the Flood Insurance Rate Map (FIRM), Base Flood Elevation (BFE), and Design Flood Elevation (DFE). This guide also references topics covered in the flood Design Guide including wet floodproofing, dry floodproofing, and scouring.

Crawlspaces are a common foundation approach in many regions that can experience flood events. Despite their ubiquitous use, they are not recommended in flood-prone areas, particularly in coastal high-hazard areas including SFHA Coastal Zone A or Zone V. Per IRC 2021 Section 322, basements, slab-on-grade foundations, crawlspaces, and any other foundation types other than pilings or columns are not allowed in new construction in these areas. Due to the broad wall area that crawlspace foundations expose to moving floodwaters, they can experience greater lateral forces than pile or column foundations. This broad wall area also causes more disruption of floodwaters, resulting in local scouring which can undermine footings (FEMA P-55 Volume II 2011).

A flood hazard risk assessment should be done prior to design and construction. See the Ensuring Success tab and the Climate tab in this guide for more information on risk assessment and flood mapping.

There are two common crawlspace foundation approaches - the crawlspace is either vented and unconditioned or non-vented and conditioned. Vented crawlspaces are not conditioned and are outside the thermal envelope (i.e., the floor above the crawlspace is insulated; the walls of the crawlspace are not insulated). They are vented to the outside. Non-vented crawlspaces are conditioned and are inside the thermal envelope (i.e., the walls of the crawlspace are insulated). They are sealed to keep outside air out. Note that crawlspaces are not considered occupiable or habitable space, whether vented and unconditioned or non-vented and conditioned.

While neither vented nor non-vented crawlspaces are a recommended foundation type in flood-prone and coastal regions, vented crawlspaces can be designed or retrofitted to resist flood damage through wet floodproofing methods. Non-vented, conditioned crawlspaces, however, should not be used in flood-prone areas. This guide focuses on how to mitigate flood risk for a vented crawlspace.

Crawlspace construction must address structural loads and fire risk and should control water, air, and heat. In flood hazard risk areas, crawlspaces should be designed or retrofitted according to the following parameters:

- The crawlspace is vented and not conditioned and can address applicable structural loads.

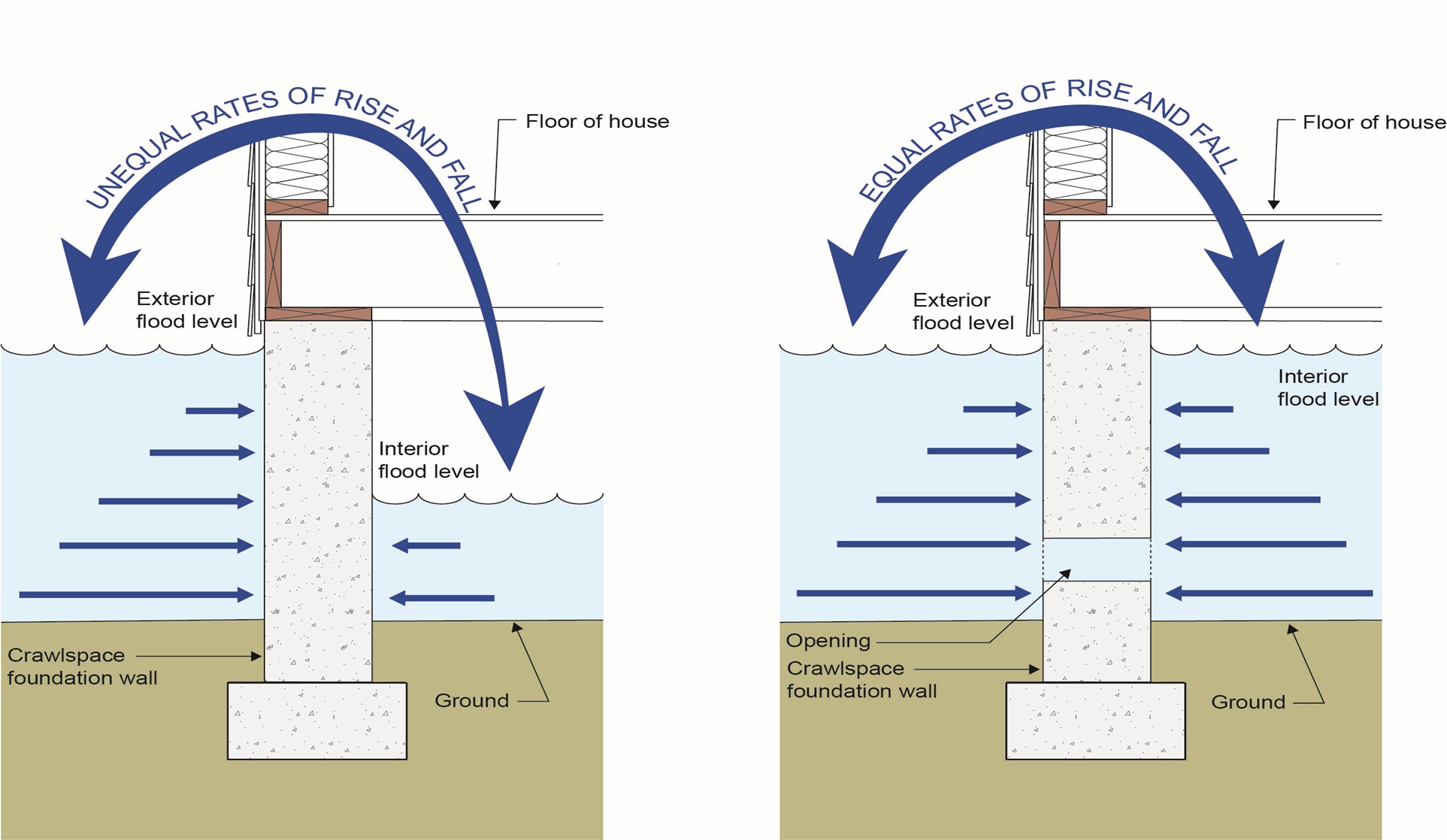

- Floodwater is controlled by ensuring floodwaters can enter and exit the structure (Figure 1).

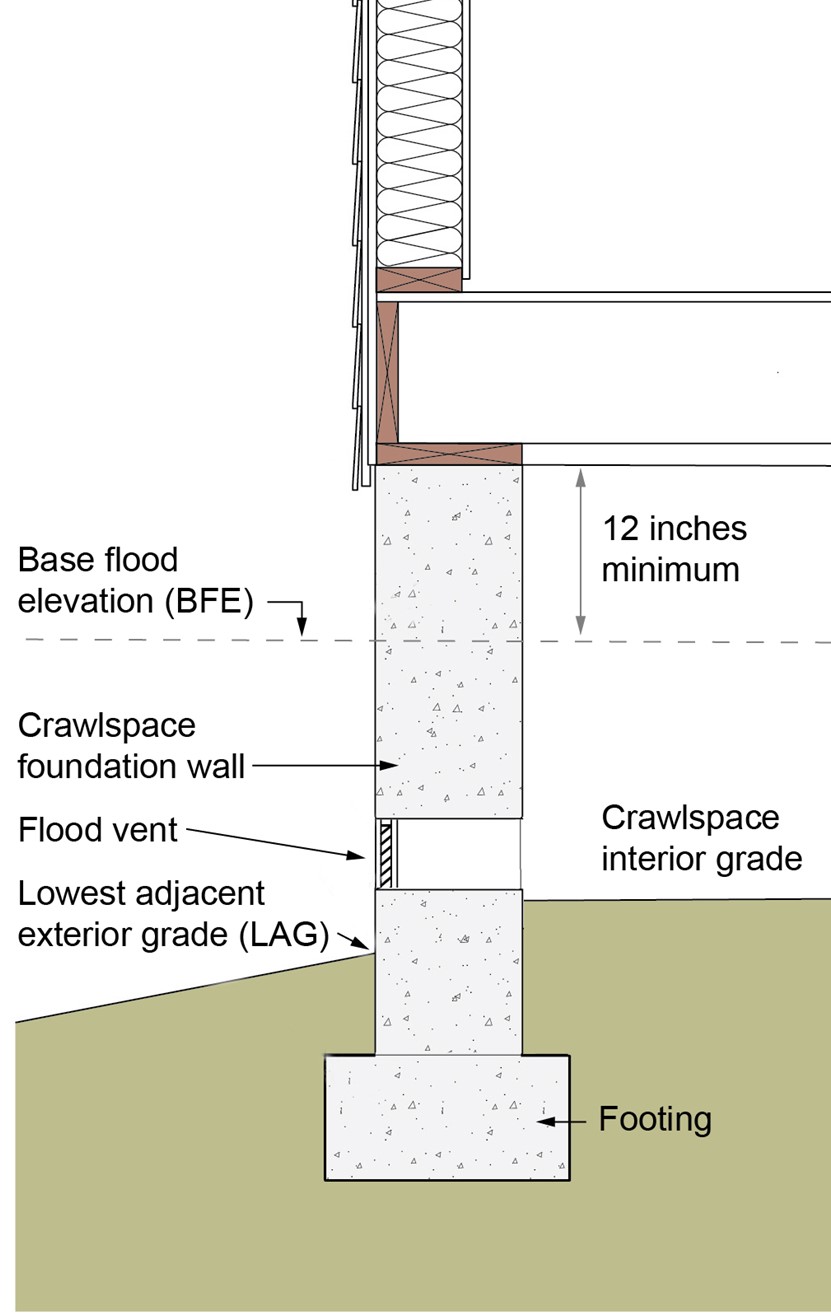

- The floor above the crawlspace is elevated above expected flood levels (Figure 2).

- The interior grade is higher or equal to the exterior grade (Figure 2).

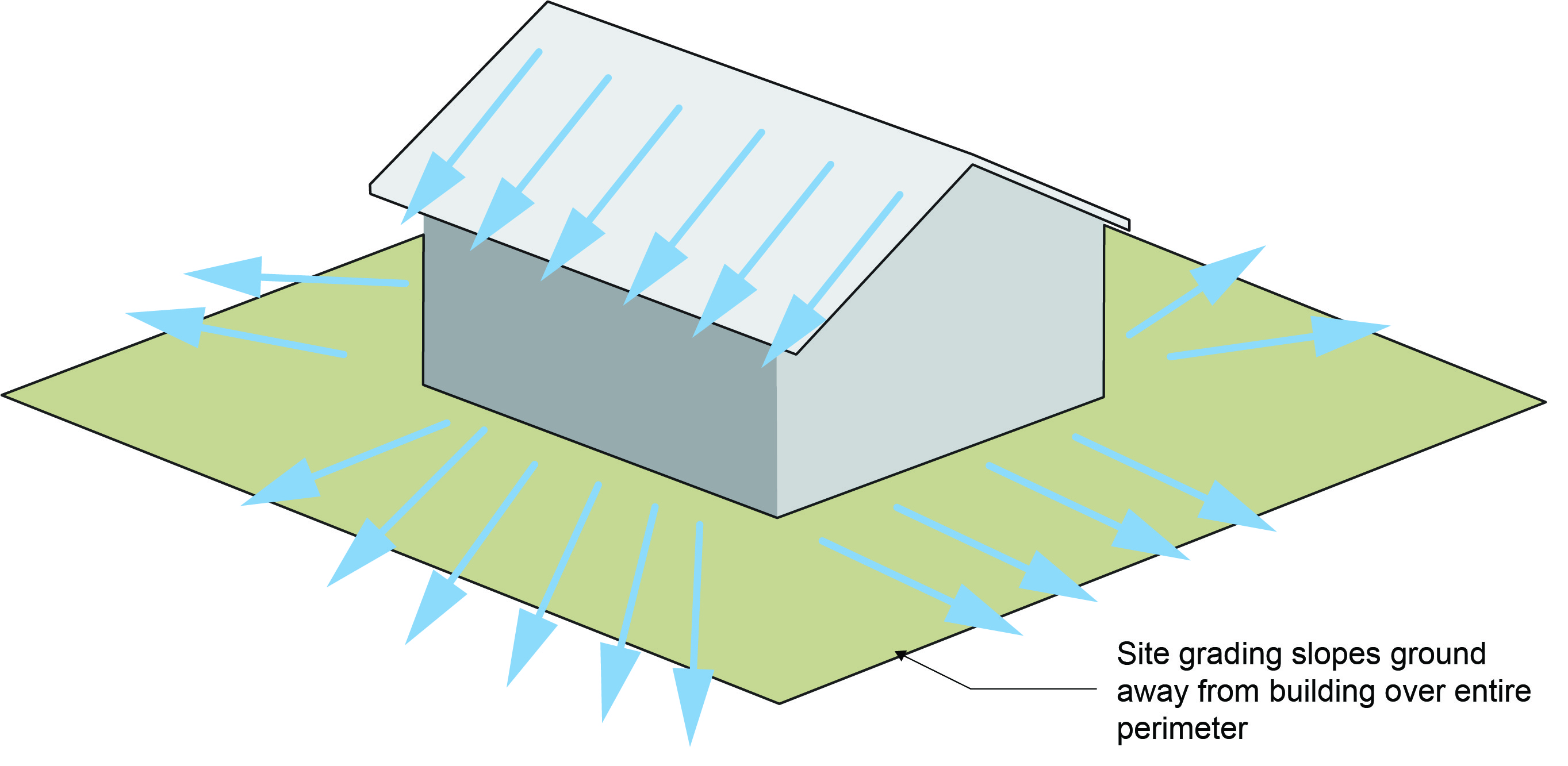

- Site grading slopes away from the building perimeter (Figure 3).

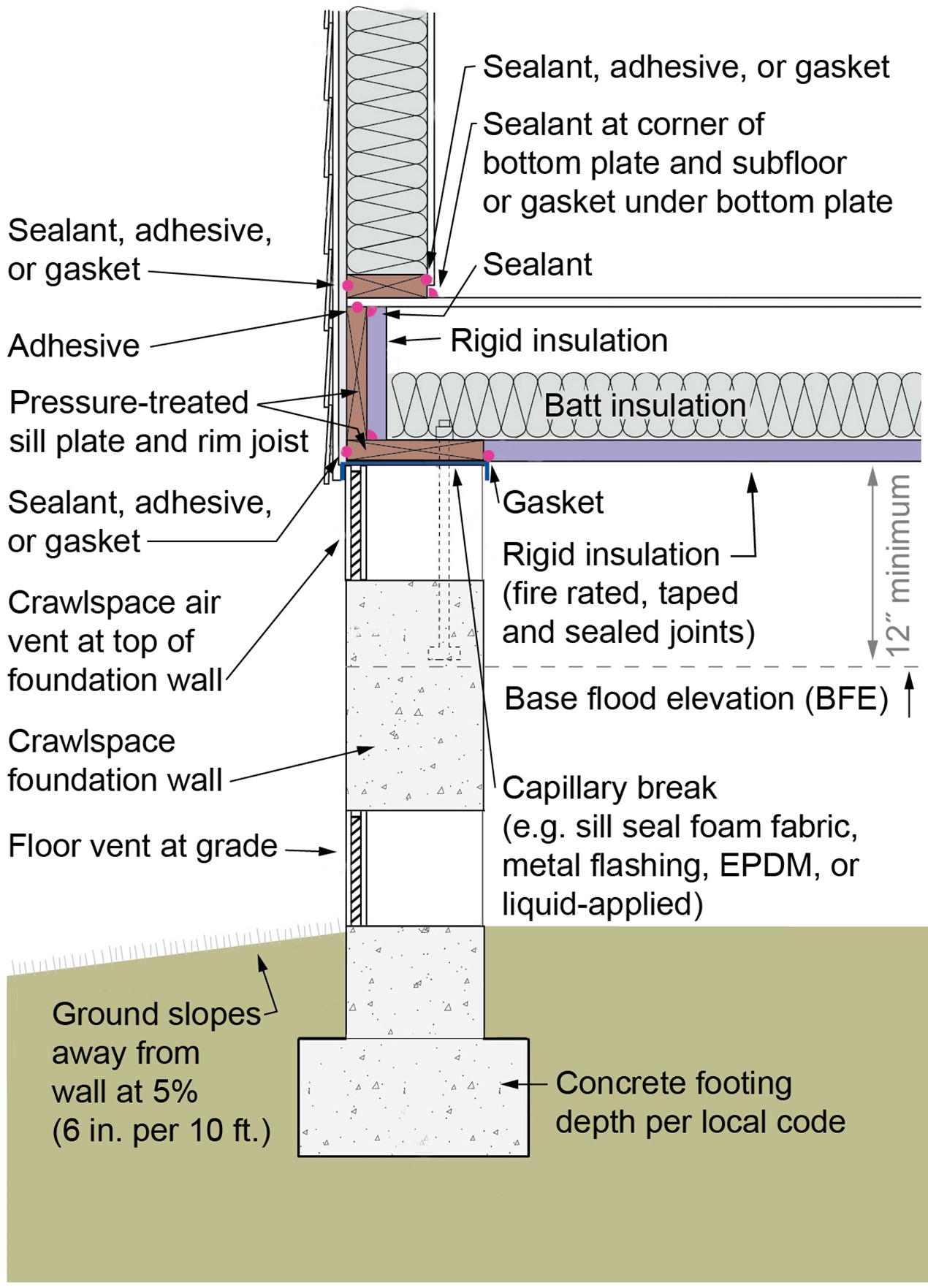

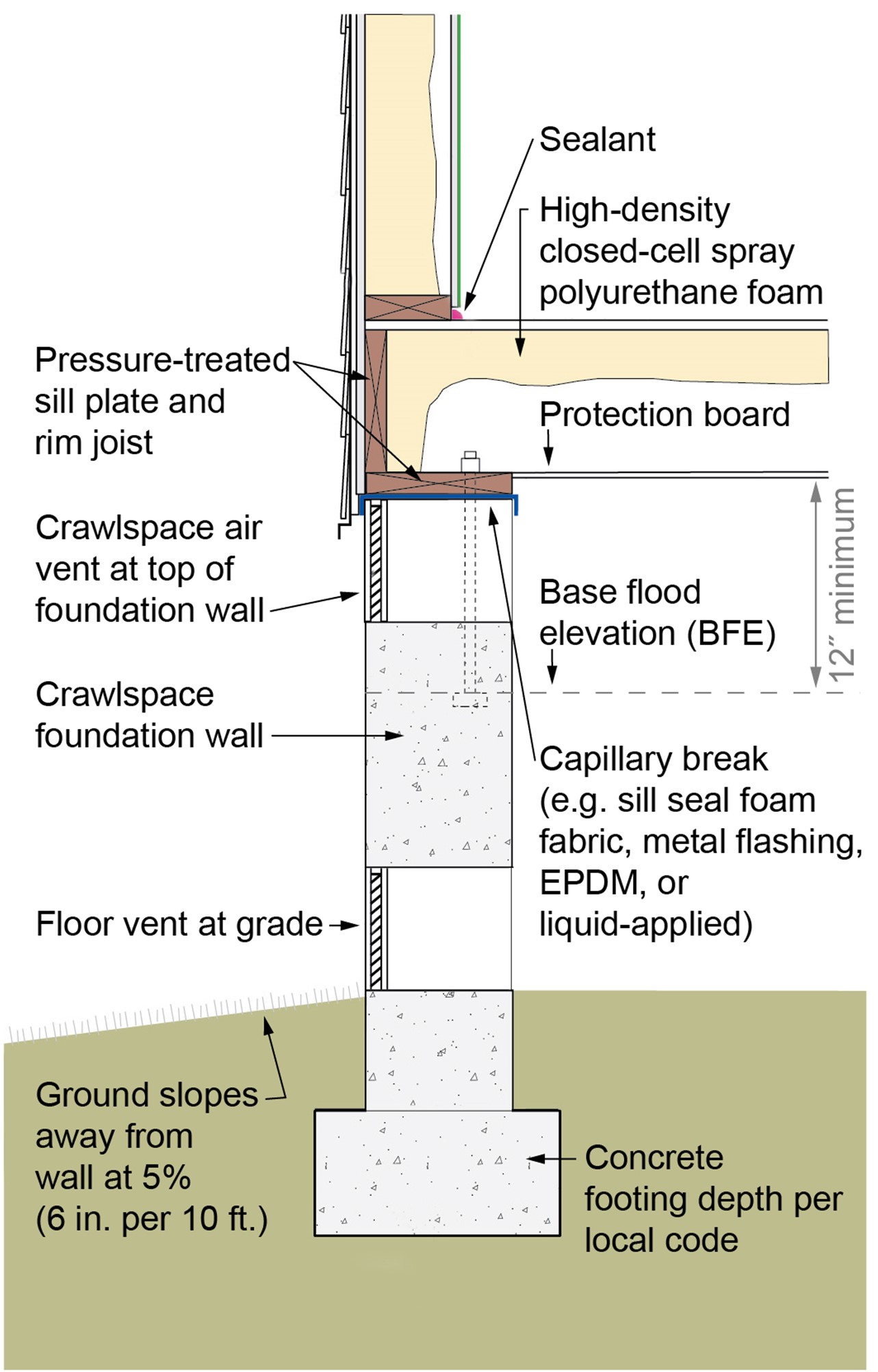

- Thermal efficiency, air sealing, and vapor control are implemented at the floor, sill plate, and rim joist (Figures 4, 5, and 6).

Per IRC 2021 Section 322, floors above crawlspaces should be constructed such that the lowest horizontal structural member is at least 12 inches above the BFE. Raise electrical components such as switches, sockets, circuit breakers, and wiring at least 12 inches above the BFE in order to reduce damage to the electrical system and the chance of fire from short circuits. Plumbing, heating, ventilation, and cooling equipment, including duct work, should also be installed 12 inches or more above the BFE to prevent damage.

Design and construct a crawlspace that controls floodwater by ensuring floodwaters can enter and exit the crawlspace without resulting in hydrostatic pressure differences. Water levels in the crawlspace should rise and fall at the same rate as the water level outside so that hydrostatic pressures are equalized (Figure 1). Openings in the crawlspace wall, or flood vents, can serve this purpose.

Sufficient openings need to be provided to control hydrostatic pressure. Per IRC 2021 Section 322, the total area (size) of all openings serving the crawlspace should be equal to or greater than 1 square inch for every square foot of crawlspace area. A 1,000 square foot crawlspace requires 1,000 square inches of opening. A typical crawlspace foundation vent opening is 16 inches x 8 inches (128 square inches). However, that vent opening typically contains a screen or a louver to control the entry of animals and these screens or louvers can collect debris and block the flow of water. It is recommended that vents used for flood venting have screens or louvers which open completely passively during a flood to allow the water to bypass the screen. If the screens or louvers open completely and provide 128 square inches (net free area) then 8 vent openings would be required. These openings should be distributed over the entire perimeter – 2 per crawlspace wall assuming a square crawlspace foundation. At a minimum, any enclosed area must have at least two openings on different sides of the space. If the installed vents have louvers or screens and do not open completely, only the net free area may be counted when calculating total area of the openings. If a 16 inch x 8 inch vent is installed which has 50% net free area allowing water flow, then the area of that opening would be 64 inches ( (16 x 8) X 50%).

The bottom of each flood vent opening should be located within 12 inches of the level of the interior or exterior grade (whichever is higher).

The risk of hydrostatic pressure differences is reduced where the interior grade is higher or equal to the exterior grade (Figure 2). Ideally, the interior grade would be higher than the exterior grade and the flood vent openings would be located only slightly above interior grade.

Vented crawlspaces typically have air vents to allow air exchange between the inside and outside of the crawlspace. These are often located at or near the top of the crawlspace wall, which does not promote floodwater entry and exit. Many air vents are not appropriate as flood vents, even if located close to grade. Air vents which can be closed off in any manner should not be considered as flood vents. Additionally, air vents generally have fixed pest screens which can become clogged by debris during a flood event, greatly reducing their ability to pass water and relieve hydrostatic pressures.

The exterior grade of the entire perimeter should be sloped to direct water away from the building (Figure 3).

Vented crawlspaces must keep air and vapor out of the crawlspace floor framing. Figure 4 illustrates the use of foil-faced rigid isocyanurate insulation under the floor framing. With this assembly, the framing is kept warm enough to prevent condensation during both winter and summer. The foil facing on the rigid insulation is an exceptional vapor barrier (< 0.1 perm) and addresses vapor drive from below. With the impermeable rigid insulation, even relatively impermeable floor coverings such as vinyl flooring and polyurethane-coated wood flooring will work. The flow of vapor into the assembly (vapor drive) is less than the flow of vapor out of the assembly, even with relatively impermeable floor coverings. The rigid insulation should be installed airtight. The seams should be sealed with foil tape.

Adding fiberglass cavity insulation in conjunction with the impermeable foil-faced rigid foam is a hybrid approach that uses the best qualities of both materials. Note that the optimum location for the airspace is above the cavity insulation because this makes the floors warmer (this same detail works for bedroom floors over garages).

The perimeter of the floor system must be air sealed properly. Figure 5 illustrates the key seams and joints where sealant, adhesive, or gasketing is required to create a continuous air barrier from the rigid foam installed under the floor system to the sill plate, the rim joist, and the wall above. Sill plates and rim joists should be framed out of treated lumber to resist decay.

As an alternative to rigid foam and cavity insulation, closed-cell high-density spray polyurethane foam (ccSPF) can be used to insulate the floor system above a vented crawlspace as shown in Figure 6 . to The spray foam provides the continuous thermal, vapor, and air barrier when connected to the exterior wall control layers. Closed-cell high-density spray foam has a low vapor transmission – less than 1.0 perm – and can be used with most floor finishes.

Pest and insect control is provided by installing a protection board on the underside of the floor joists. Fiber cement boards work well for this purpose (Figure 6). The fiber cement boards should be installed using screws to allow for removal should floodwaters rise above the floor framing level and wet the cavities. If closed-cell high-density spray foam is wetted by floodwater, it will need its exposed surfaces to be cleaned even though it is water resistant.

If rigid foam and cavity insulation are used, a protection board can be installed on the underside of the rigid foam. In the case of cavity wetting, the removal of the protection board, rigid insulation, and cavity insulation facilitates cleaning and decontamination of framing members. The rigid insulation and batt insulation should be considered “sacrificial” if wetted by floodwaters.

Success

A vital step when designing or retrofitting a crawlspace to be flood resistant is to understand the local flood risk. See the Climate tab for information on determining the flood risk for a specific location. For homes within an SFHA, flood resistance should be incorporated into any design or retrofit. If a home is not located in an SFHA, there may still be a chance of flooding. It is up to the discretion of the homeowner as to whether flood resistance measures are worth the investment.

Obtaining an accurate BFE and understanding how high it is above actual grade are key to successful implementation of flood resistance. Unless the lowest non-flood-resistant horizontal member of the house is at least 12 inches above the BFE, it is reasonable to expect that flood damage will occur at some point.

Climate

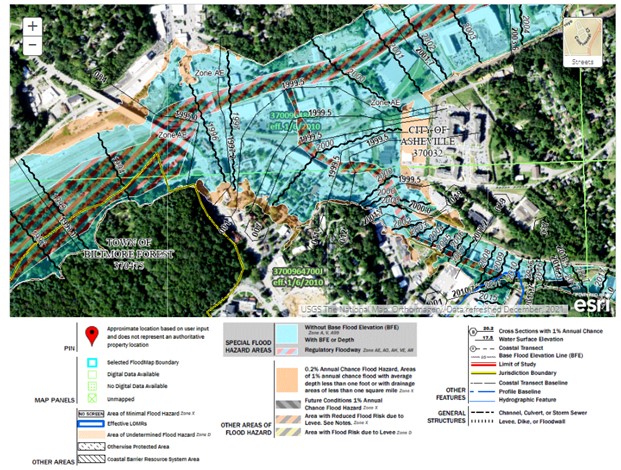

The flood resistance approaches shown in this guide work in all climates. Understanding the flood risk at a particular location, however, is an important first step in designing and retrofitting for flood resistance. Flood hazard risk areas are identified by FEMA as Special Flood Hazard Areas (SFHA) and can be found on Flood Insurance Rate Maps (FIRMs).

FEMA flood maps and related tools and can be found on FEMA’s website.

The National Flood Hazard Layer (NFHL) map is a searchable geospatial database containing current flood hazard information. Using the NFHL Viewer, accessed through FEMA’s website, you can find and print the FIRM for a specific location.

Figure 1 is an example of the flood hazards shown on the NFHL Viewer for a specific location.

Figure 2 provides a closer view of one portion of the map in Figure 1. Note the SFHAs are designated by color and pattern, and the BFEs are designated by wavy black lines.

Training

Compliance

Retrofit

The approach to retrofit is the same as the approach to new design. The same details provided in this guide for new design apply to retrofit. If the bottom of the existing floor system is 12 inches or more above the BFE, then the primary action needed is to ensure floodwaters can enter and exit the crawlspace via flood vents. If the floor system is within 12 inches of the BFE, or lower than the BFE, a few options exist as detailed in FEMA’s Homeowner’s Guide to Retrofitting.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.