Scope

Install new step and kick-out flashing where an existing roof meets an existing wall as part of a roof replacement. It can also be done as a stand-alone retrofit measure or as an exterior wall upgrade. Install and properly integrate flashing at the intersection of an existing wall and roof, as follows:

- Inspect the wall and roof framing to assess existing conditions and develop specific detailing for flashing the intersection of the wall and roof.

- If there is no metal flashing installed at the wall-roof intersection, or if the existing flashing is damaged, improperly installed, or allowing water to damage the wall, remove the siding and any existing flashing to expose at least 8 inches of the wall. Repair any damaged sheathing and framing.

- If the existing sidewall-roof intersection did not include a kick-out flashing, carefully inspect the side wall at the roof eave for possible deterioration from bulk water leakage and repair as needed.

- Install a new adhesive membrane (ice and water protector) and metal step or continuous flashing that is properly integrated into the weather-resistant barrier and wall and roof coverings to provide continuous water, air, vapor, and thermal control layers on the walls and roof.

For more on roof/wall connections, see the U.S. Department of Energy’s Standard Work Specifications.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

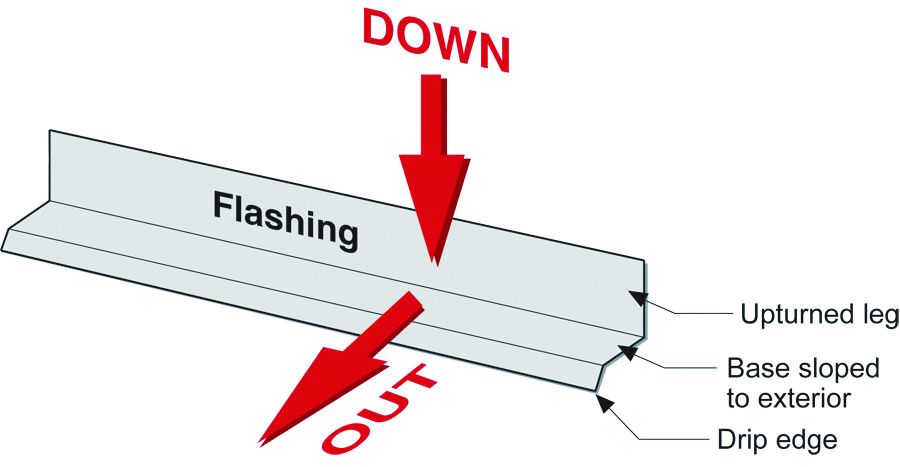

The fundamental principle of water management is to shed water by layering materials in such a way that water is directed down, out, and away from the building. The key to this fundamental principle is drainage. Drainage applies to assemblies such as walls, roofs, and foundations as well as transitions to those assemblies such as lower roofs, porch roofs, decks, balconies, railings, and dormers.

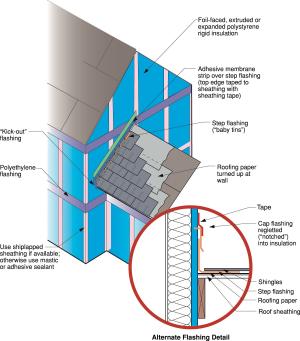

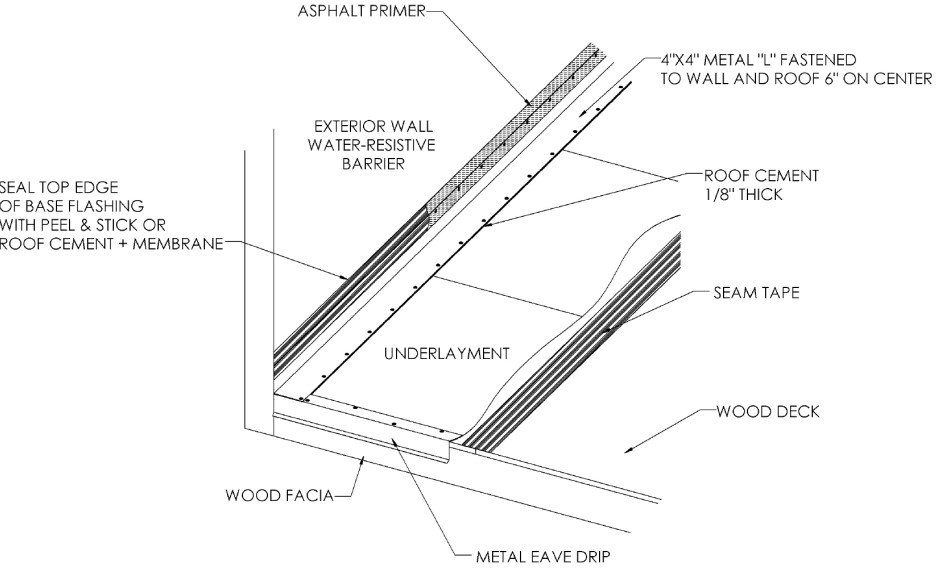

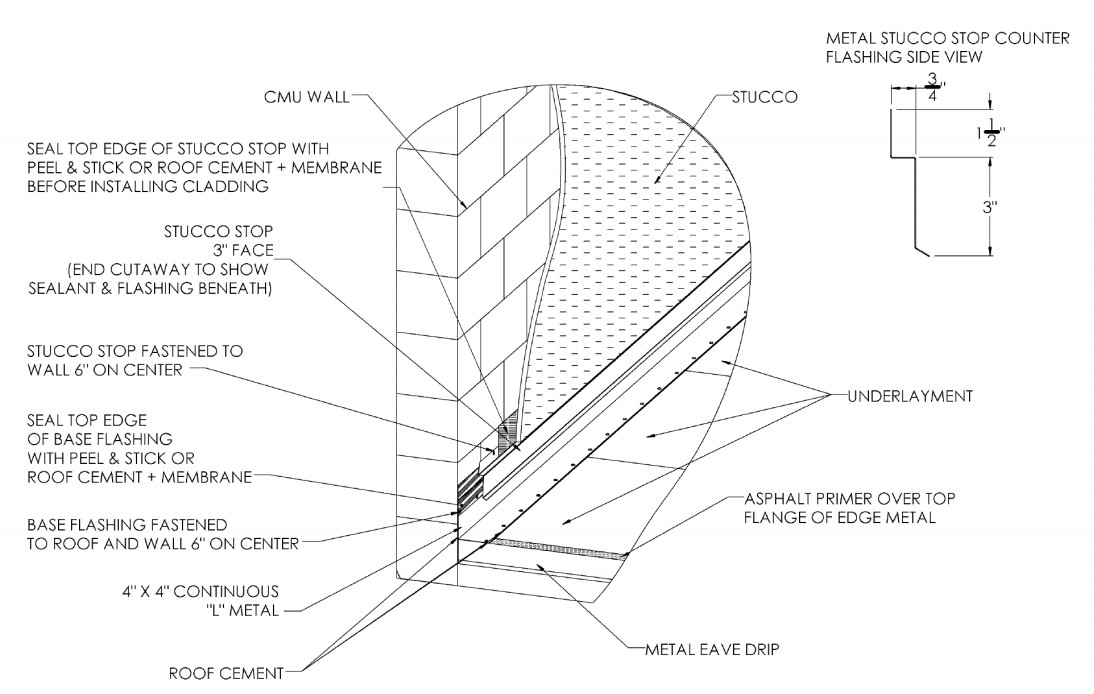

The most elegant expression of the concept of drainage is flashing. Flashing is the most underrated of building enclosure components and arguably one of the most important. Metal flashing and self-adhesive flashing tapes protect vulnerable building components and help direct water down and out of the building (see Figure). Flashing should be integrated with roof and wall drainage planes, such as house wrap or building paper, in a shingle fashion where the top layer of the weather-resistant barrier (WRB) or flashing laps over the bottom layer to prevent water draining behind the bottom layer. These water control details are shown in Figures 4 and 5.

When the roof covering is being replaced on an existing roof, new flashing should be installed at roof-wall intersections. This flashing may also be replaced as a stand-alone retrofit measure or as part of an exterior wall upgrade.

Flashing is required at all roof-wall intersections. Either continuous L-metal flashing or step flashing is used to prevent water intrusion into the wall where a sloped roof intersects a vertical wall. Step flashing is used with shingle roofs; continuous flashing is used with metal and rubber membrane roofs.

The metal flashing pieces are bent at a right angle, with half of the flashing against the wall and the other half interwoven with or underneath the shingles of the abutting roof. The upturned leg of the step flashing is behind the vertical drainage plane (house wrap) on the wall or sealed to it with an adhesive membrane and sheathing tape. Metal flashing must be corrosion-resistant and at least 0.19 inches thick (2018 IRC Section R903.2.1). For asphalt shingle roofs, the IRC requires the base flashing against the vertical sidewall to be continuous or step flashing that is at least 4 inches high against the wall and 4 inches wide above the roofing underlayment (2018 IRC Section R905.2.8.3). Note that step flashing is typically pre-formed individual metal pieces with 5-inch legs (5 inches high by 5 inches wide) and 7 inches long (referred to as 5 by 7 step flashing or base flashing). For metal or rubber membrane roofs, continuous flashing is an alternative to step flashing. The self-adhesive membrane should consist of a material like a butyl or acrylic (meeting AAMA 711). Refer to the manufacturer’s details for installation. See IRC 2018 for the testing requirements for all the materials used. (IRC 2018 Section R903.2 Flashing, Section R905.2.8.3 Sidewall flashing, R908.6 Flashings for reroofing).

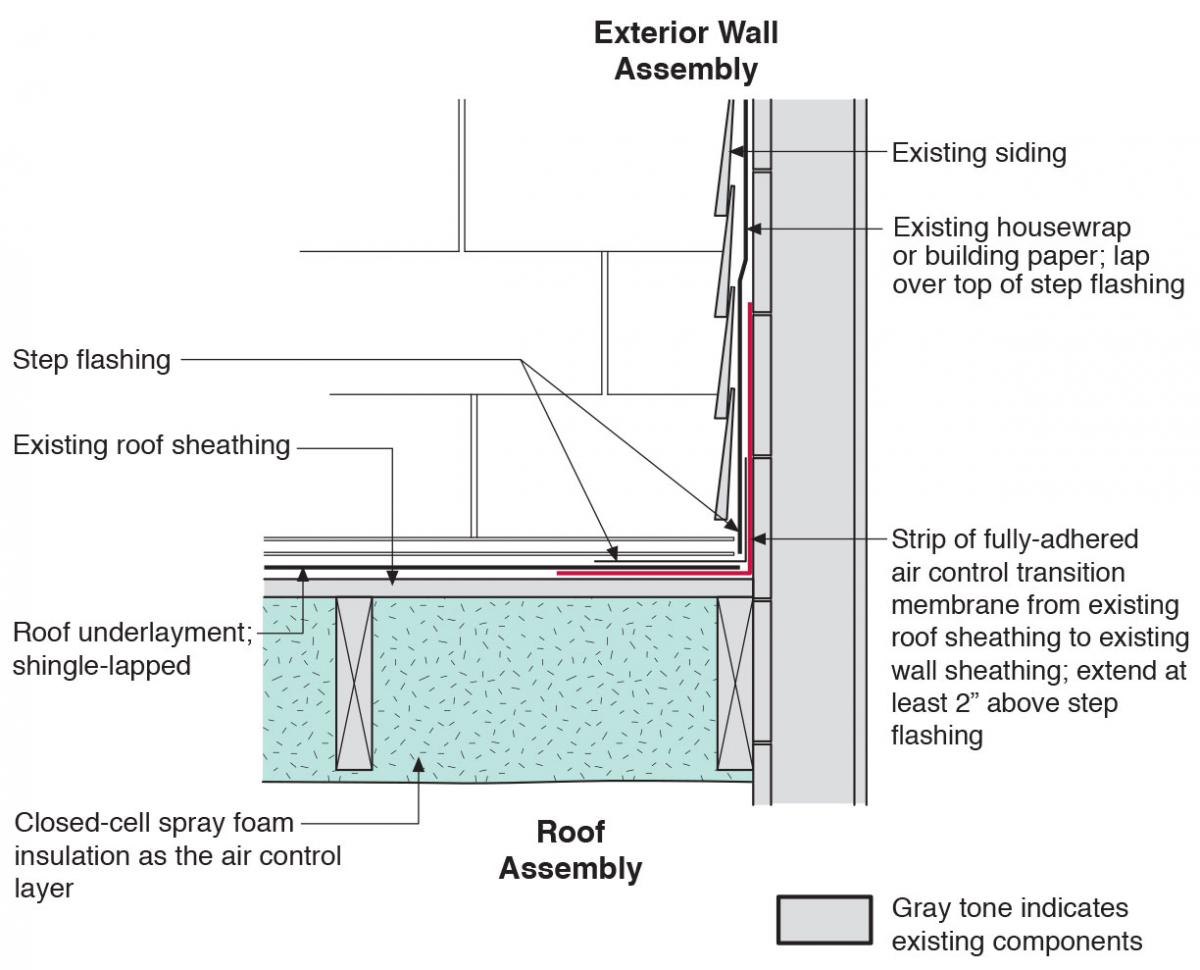

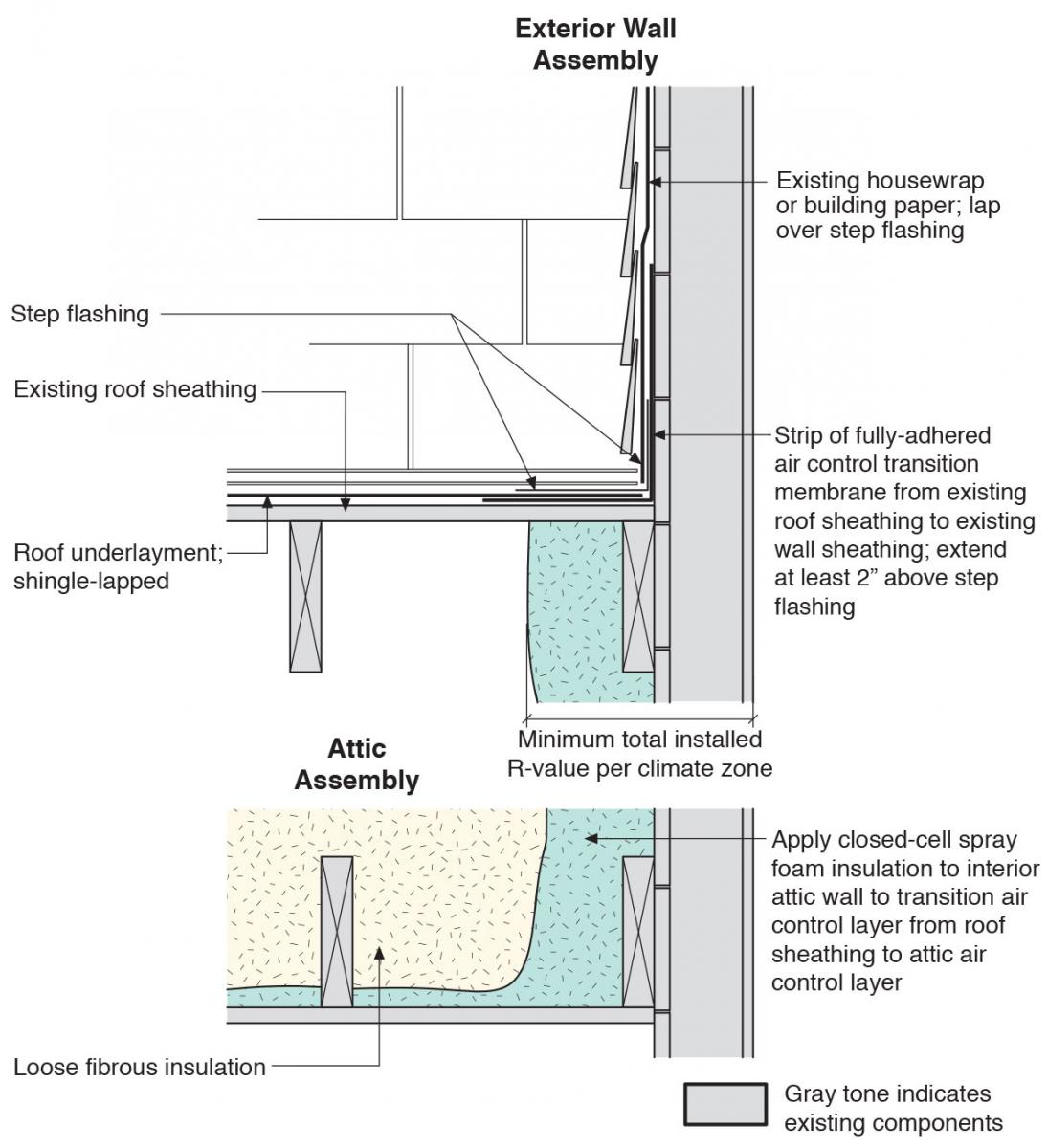

Figures 2 and 3 show a front view of the integration of a new strip of fully adhered air control transition membrane, new step or continuous flashing, new roof underlayment, and new cladding with the existing house wrap and siding. Figure 4 shows continuous L-metal flashing integrated with underlayment at roof-wall intersections. Figure 5 shows flashing at a roof-wall intersection with a CMU wall. Note Figures 4 and 5 are from the Insurance Institute for Building and Home Safety (IBHS) Fortified Home program, which recommends that the metal drip edge be installed over the underlayment on roofs in hurricane and high-wind-prone regions. This is not consistent with shingle-fashion installation of roofing materials generally recommended as a good practice; however, IBHS reports that they have tested this with good results. Counter flashing could be installed to reduce disruption to the flow of rainwater off the roof here. Figures 6 through 11 show the installation of the step and kick-out flashing on a new home but many of the steps are similar.

Installation of kick-out flashing is a critical component of a step or continuous flashing. Kick-out flashing is a piece of flashing at the bottom of a section of the roof that adjoins a wall. It is installed to direct water runoff away from the adjoining wall and usually into a gutter. Kick-out flashing is sometimes fabricated on-site by the roofing contractor; however, seamless plastic flashing pieces specifically molded to serve as kick-out flashing pieces are available. These are sized to handle the larger volumes of water runoff that may be concentrated along the wall in rain storms. For more information, see the guide Step and Kick-out Flashing at Roof-Wall Intersec

How to Install Flashing at the Transition of a Wall to a Lower Roof

- Remove roofing and enough siding on the wall above the roof-wall intersection to expose the existing house wrap or building paper.

- Inspect the structural integrity of the wall and the overhang. Check the framing for any deficiencies, rot, insect damage, etc. Proceed only after needed repairs are performed. Based on the findings, revise the wall and overhang assembly and review specific detailing as needed. Follow the minimum requirements of the current adopted local building code.

- Install a fully adhered air control transition membrane from the existing roof sheathing onto the face of the existing wall sheathing (Figure 6). Extend at least 2 inches above the future step flashing.

- Install the roof underlayment as the water control layer. Extend it to the existing wall and over the transition membrane; the underlayment should wrap up the sidewall at least 8 inches.

- Install new kick-out and step flashing, integrated with shingles as required (Figures 7, 8, 9). Best practice is to install counter flashing, using a self-adhered membrane, over the top edge of the step flashing (Figure 10). Integrate the vertical leg of the step flashing, and counter flashing, with the weather-resistive barrier of the wall. See the guide Step and Kick-out Flashing at Roof-Wall Intersections. Install the new shingles and step flashing over the roof underlayment.

- Lap the existing house wrap or building paper over the top of the step flashing (Figure 11).

- Re-install the siding over the house wrap or building paper. Ensure a minimum 1.5-inch reveal between the bottom of the siding and the shingles of the roof.

Success

Inspect the existing wall and overhang framing and review specific detailing for any deficiencies or water intrusion damage and make any corrections, if necessary.

Ensure the water control layer of the roof and wall assemblies is continuous.

Ensure proper lapping of building layers to shed water away from the wall and overhang assemblies.

Terminate the step flashing with a weather-lapped kick-out flashing.

Climate

Water Management

The IRC does not have additional requirements for roof-wall flashing in hurricane-prone regions or other high-wind areas. Some local jurisdictions may have additional requirements or require specific product approval. Building codes establish minimum requirements, but products must also be installed in accordance with the manufacturer’s instructions. This is important because codes typically do not provide all the detailed information for a durable installation. Assessments by FEMA after hurricanes commonly find that water intrusion and structural building failures are due to improper installation of building components. So, even where the IRC does not require additional measures, proper installation is more critical in hurricane-prone regions.

While typically, all water-protecting components on a roof should be installed shingle fashion, IBHS Fortified does recommend in hurricane and high-wind regions that the drip edge at the roof eaves be installed over, not under, the drip edge.

Cold Climates

In cold climates (zones five and higher), install self-adhered ice and water shield membrane over the roof sheathing at the eaves from the edge of the roof line to at least 2 feet up the roof deck from the interior plane of the exterior wall. (See the guide Heavy Membranes at Eaves in Cold Climates.)

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Kick-Out Flashing, Step Flashing = Roof-Wall Water Deflector

Where roofs intersect walls is a critical point for flashing to prevent water leaks and damage. While wood siding may quickly show evidence of this water intrusion with peeling paint or staining, some wall claddings like fiber cement, vinyl siding, and brick veneer can mask the evidence for years. Roof step flashing must be effectively integrated with diverters known as kick-out flashing to effectively direct water to the gutters and avoid water damage.