Scope

In cold climates, install slab edge insulation when retrofitting existing slab-on-grade foundations.

- Remove dirt to fully expose the edges of the existing slab.

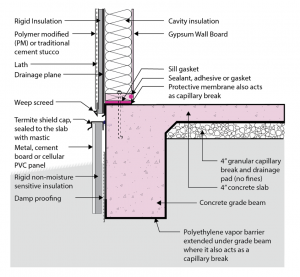

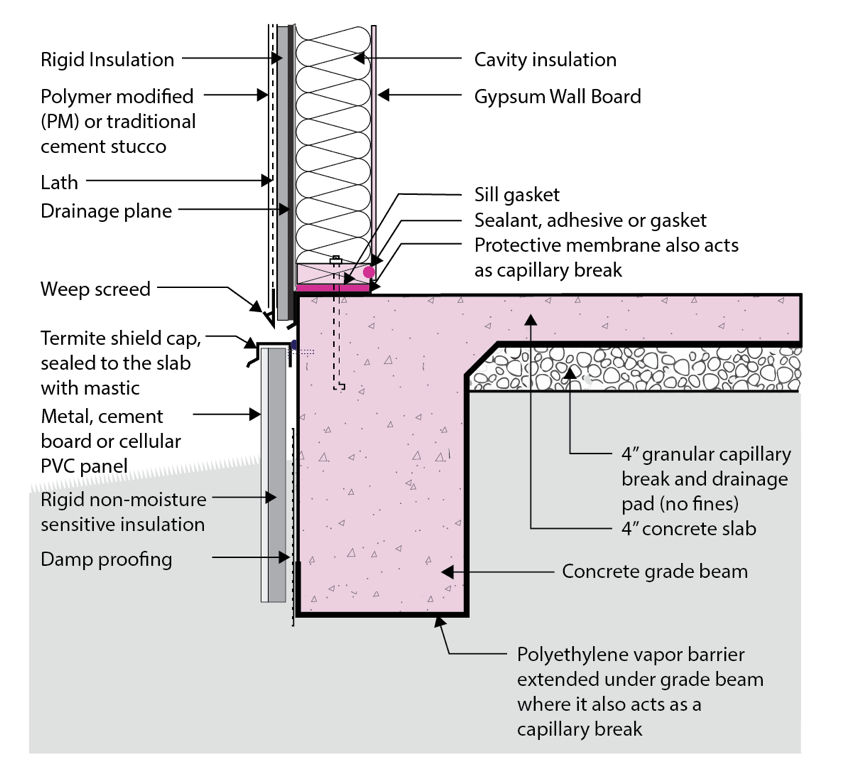

- Clean the exposed slab edge and apply damp proofing as a capillary break.

- Install non-moisture-sensitive rigid foam board insulation (such as extruded polystyrene [XPS] or mineral wool) along the edge of the slab of a slab-on-grade foundation to meet or exceed the insulation R-value required by code.

- Install from the top of the slab down to the depth required by code unless a termite inspection gap is required.

- Install a metal, cement board, or cellular PVC panel to conceal any portion of the insulation left exposed above grade. Note that if cement board is used, it should be a type that is not reinforced with wood fibers, or if it does contain wood fibers, it should be coated with acrylic latex paint on all six sides to protect it from water damage.

- Install a metal cap as an insect guard that conceals the top horizontal edge of both the insulation and the closure panel. Seal the cap to the slab edge with mastic. The metal cap and mastic should be continuous around the building perimeter.

- Replace the backfill, sloping away from the building.

See the U.S. Department of Energy’s Standard Work Specifications, for more on insulating slab foundations as well as information on general safe work practices.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

In climates where the average monthly temperature for the coldest month of the year goes below 45°F, the temperature of the slab perimeter may be below the dew point of the interior air for a significant period of time.

Even when condensation conditions are not present on the slab surface, relatively cool temperatures near an uninsulated slab edge will tend to elevate the local relative humidity. As relative humidity rises, so too does the risk of mold, mildew, fungal growth, dust mites and other pests. This is a particular concern for carpeted slabs as the carpet can provide a medium and cover for these biological risks.

The installation of insulation over the edge of existing foundation slabs reduces the risk of these failures by increasing the temperature of the slab at the building perimeter during winter months and also increases both energy efficiency and thermal comfort. Rigid, non-moisture-sensitive insulations can be installed (extruded polystyrene (XPS) and mineral wool are most common) even over the edges of existing slabs after the building has been completed. This work can be performed by general contractors during new construction or by homeowners looking to improve the comfort and durability of their existing house.

Follow “How to” steps below for retrofitting insulation over existing slabs. For information on insulating slabs of various configurations in new construction, refer to the BASC Solution Center Guide “Slab Edge Insulation.”

How to Insulate an Existing Foundation Slab

- Remove dirt and backfill to fully expose the existing slab edge.

- Clean the exposed slab edge and apply damp proofing as a capillary break.

- Install rigid non-moisture sensitive insulation (extruded polystyrene (XPS) or mineral wool, for example) along the edge of the slab for a slab-on-grade foundation to meet or exceed the insulation R-value required by code.

- Install from the top of the slab down to the depth required by code unless a termite inspection gap is required.

- Install a metal, cement board, or cellular PVC panel to conceal any portion of the insulation left exposed above grade. Note that if cement board is used, it should be a type that is not reinforced with wood fibers, or if it does contain wood fibers, it should be coated with acrylic latex paint on all six sides to protect it from water damage.

- Install a metal cap as an insect guard that conceals the top horizontal edge of both the insulation and the closure panel. Seal the cap to the slab edge with mastic. The metal cap and mastic should be continuous around the building perimeter.

- Replace the backfill, sloping away from the building.

Success

Make every effort to install insulation in such a way that it is in direct contact with the damp-proofed slab edge. This may be difficult if the slab edge is not completely flat. A semi-rigid (but non-moisture sensitive) insulation (such as mineral wool) may be used to better track with the profile of the slab, or you may wish to grind the slab edge to make it smooth. Note, however, that even when drainage mats are used between rigid insulations and concrete walls, the reduction in thermal performance from separating the insulation from the substrate is only about 3%-5%. In most cases, a perfectly flat slab edge is not required to achieve excellent performance. For similar reasons, taping the joints in the insulation is not required, although it may help keep the insulation in place during backfill. Any tape compatible with the insulation may be used (acrylic construction tape is typical).

A thermal camera can be used to evaluate the effectiveness of the insulation at the slab edge from the exterior. A close match between slab temperature and the outdoor air temperature reveals minimal heat loss at the base of the building.

Climate

Slabs in different climate zones require different levels of thermal protection. Refer to the Compliance tab for code requirements.

Note that some local codes include provisions for termite protection. In areas where termite inspection strips are required, the insulation and cover panel should be held down from the top of the slab and the slab edge left exposed along the upper edge. The amount of slab edge to remain exposed is dictated by the local code.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Figure 2. Climate Zone Map from IECC 2021. (Source: 2021 IECC)

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

High-R Foundation Insulation = High-Efficiency or Ultra-Efficient Foundation Insulation

There are two levels of foundation insulation: high-efficiency insulation, which meets the 2015 International Energy Conservation Code, and ultra-efficient insulation, which is 25% more efficient than this national code. Using high-efficiency and ultra-efficient insulation, along with professional installation (e.g., no gaps, voids, compression, or misalignment with air barriers; complete air barriers; and minimal thermal bridging) creates conditioned spaces that require very little heating and cooling, along with, even comfort and quiet throughout the house.