Scope

Install emergency or backup cooling and refrigeration to prepare for extreme heat events and power outages.

- Assess capacity and reliability of any existing cooling, refrigeration, and backup power systems.

- Determine whether to provide emergency cooling for the entire house or for just one zone.

- Determine whether to provide backup power for the entire house or for just one zone.

- Reduce cooling energy and power needs of the home by air sealing, insulating, installing efficient windows or storm windows, and shading. This will reduce the required size of the backup power system. See the “Design for Extreme Heat” guide.

- Select emergency cooling type: Mini-split system, window unit, portable A/C unit, portable evaporative cooler, or window unit evaporative cooler.

- Select emergency refrigeration type: Full-size refrigerator/freezer, mini-fridge, ice maker, or deep freezer.

- Select backup power with enough capacity to power cooling, refrigeration, and other critical loads: Standard portable generator, portable inverter generator, permanently installed standby generator, permanently installed battery backup system, portable battery backup, or the battery in an electric vehicle.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

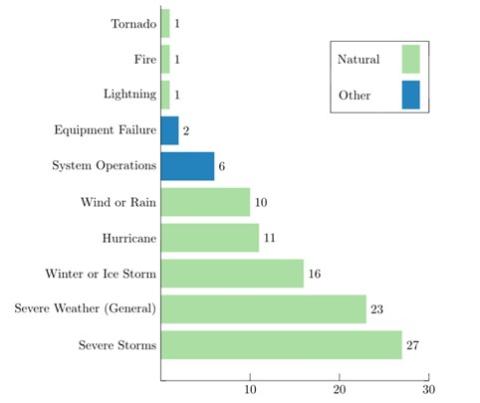

During extreme heat, or any disaster event that occurs during hot weather, space cooling and food refrigeration are vital. Cooling and refrigeration equipment are strained during high heat events, however, and the likelihood of failure increases during these times. Extreme heat puts extra strain on the electricity grid as well, due to increased demand and reduced generating capacity at the power plant (ORNL 2019 ). Other disaster types, such as hurricanes, tornadoes, earthquakes, floods, and wildfires, can physically destroy portions of the grid or equipment serving the home (Figure 1). Any of these disaster types can happen when cooling and refrigeration are needed. Power loss or equipment failure during these events leaves occupants vulnerable to overheating and loss of food and/or medication due to spoilage.

Emergency cooling and refrigeration systems, powered by backup power systems, can mitigate these risks. The requirements for emergency cooling are simply that it can keep occupants cool enough to keep them safe during extreme heat, that it is reliable, and that it has a small enough power draw that it can be comfortably powered by the planned backup power system.

The primary HVAC system for a home can be considered its emergency cooling system if the system is reliable and well-maintained, and if there is a whole-home backup power system large enough to comfortably handle the full load. However, this guide focuses on smaller systems that could be installed as partial backup to the main HVAC system, or as part of an emergency plan for homes without central cooling systems. The systems discussed include window-unit air conditioners, portable room-sized units, and ductless mini-split units. Emergency refrigeration includes small, high-efficiency refrigerators. Backup-power systems include both portable and whole-home generators and batteries.

One emergency strategy is to create a “cool room” or cool zone that could be set up in just one part of the home. The room could be isolated from the rest of the house and provided with a small, dedicated cooling and dehumidifying system. This concept could reduce cost and size of emergency cooling systems as well as backup power systems. See the guide “Creating a Cool Room for Extreme Heat Events” for more information on this concept.

Emergency Cooling Systems

In all non-arid locations, an emergency cooling system should be a standard A/C unit such as a window unit air conditioner, portable A/C unit, or mini-split system. These systems can cool and dehumidify simultaneously. For arid regions, evaporative coolers should be considered due to their lower power draw.

An emergency cooling system must be sized within the capacity limits of the backup power system. The start-up amperage of an emergency cooling system is important since small generators or battery banks can only serve smaller start-up loads. Unless the house has a large solar PV system with a large battery bank or a large generator with ample fuel storage, it is important that a small, efficient cooling system be selected to cool the space. This will enable a standard generator or a modestly sized battery bank to provide effective cooling.

Note that a heat pump can be an alternative to most standard A/C units, whether window units or mini-splits. Heat pumps provide cooling just like A/C units, but they can also provide efficient heating when needed. This can allow for emergency cooling systems to double as emergency heating systems. The added cost for upgrading from A/C-only to a heat pump is usually marginal.

Evaporative Coolers

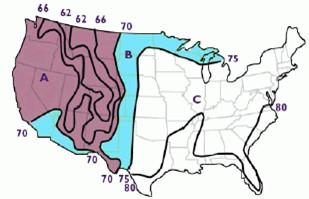

In a dry climate, evaporative coolers can be utilized for low-energy emergency cooling. Options include small battery-powered units (Figure 2), plug-in portable units, and plug-in window units. Permanently installed whole-house units are also available but are beyond the scope of this guide.

Small battery-powered units are appropriate for personal cooling, with the unit blowing directly on the occupant. They cannot be expected to cool an entire room in most situations. Power consumption for these units typically ranges from 7 to 15 watts. These are a viable very-low energy personal cooling option as long as a backup power source is available for recharging.

Plug-in portable units and window units can cool an entire room, appropriate for cooling about 100 ft2 to 2,000 ft2 (or more). These units draw power in the range of about 50 to 500 Watts. Window-mounted units are designed to mount in an existing window (similar to a window A/C unit) and to plug into a standard outlet. The water connection can be via a garden hose or by more permanent plumbing. Plug-in portable units usually have a water reservoir that must be refilled periodically. Plug-in portable units come in sizes appropriate for a single small room, or an entire moderately sized home. Window units typically come in sizes large enough to cool a large room or a moderately sized home.

Portable and window unit evaporative coolers will increase room humidity, making them an inappropriate strategy for many locations in North America. Even in dry climates, some outside air exchange is needed to keep humidity levels down and to allow the unit to continue to provide cooling. Depending on the size of the area being cooled and how well the home is air-sealed, sufficient outside air exchange could be achieved by cracking or opening a window or windows, turning on a bathroom exhaust fan, or simply by the natural air infiltration that occurs through the walls, doors, and windows.

See the Evaporative Cooling Systems guide and the Passive and Low-Energy Cooling guide to learn more about evaporative coolers, including how to select a properly sized unit. The Climate tab provides guidance on where in the U.S. evaporative coolers are appropriate.

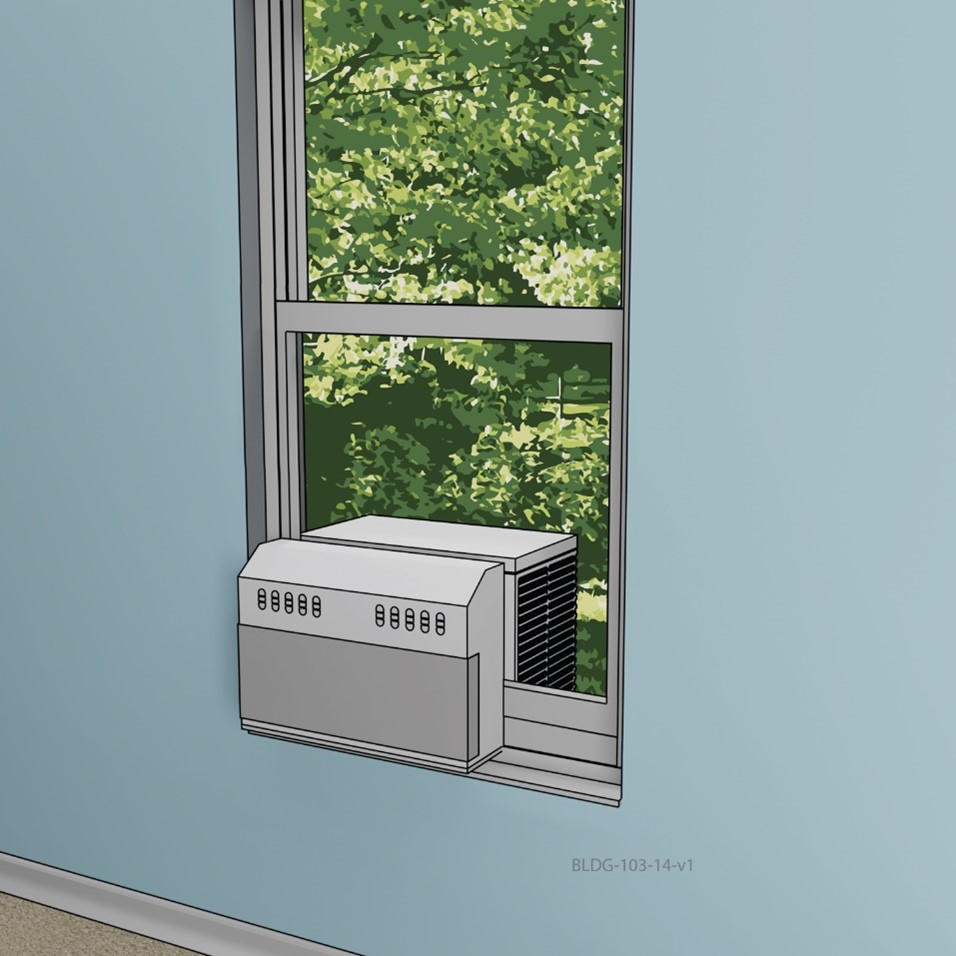

Standard Window Air Conditioners and Heat Pumps

Standard window air conditioners are an older, but proven technology that can serve as an efficient, low-power backup cooling system (Figure 3). Power use tends to be 500 to 1,000 Watts, which is easily provided by a portable generator that is not too heavily loaded with other electrical loads. Cooling capacities are generally in the range of 5,000 – 12,000 Btu/hr. This is enough capacity to cool a large room or rooms, but generally not an entire home. The cost of window units tends to be in the range of $150 to $400.

It is important to shop for efficient window air conditioners for an emergency cooling system to reduce draw on a backup power source. Search for efficient units with the ENERGY STAR label using the ENERGY STAR product database. Typical units have an energy efficiency ratio (EER) of about 10 Btu/Wh, but the most efficient inverter-controlled window air conditioners now have an efficiency of 15 Btu/Wh—nearing that of efficient central systems. These are much more efficient than portable air conditioners and generally cost less as well. When searching for a unit, note that models labeled as 110-Volt, 115-Volt, or 120-Volt can plug into a standard wall or generator outlet, while models labeled for 220 Volts, 230 Volts, or 240 Volts require a special outlet such as those typically used for electric ranges or electric clothes dryers.

It is important to properly locate, seal, and insulate around an installed window air conditioner to obtain best performance. Follow the manufacturer’s guidance on installation, as well as this U.S. DOE guide on properly installing window air conditioning units for efficiency and comfort.

Saddle and U-Shaped Window Air Conditioners and Heat Pumps

Innovations within the window-unit class of cooling systems include saddle and U-shaped units (see Figures 4 and 5). This new generation of window air conditioners and heat pumps makes it possible to still use the window when the unit is in place. Also, because the compressor and its fan are completely outside the window, they tend to be much quieter in operation. Installation of these units can be DIY. Some units use the advanced R-32 refrigerant, which has low global warming potential.

These units are typically inverter-controlled, with outdoor condensers and indoor coils that offer high efficiency (about EER 12 -15 Btu/Wh). Some models can operate on 120-Volt electricity and thus can simply plug into a conventional household outlet or portable generator socket. Their cooling capacities are around 12,000 Btu/hr with a power draw of 400 to 600 Watts when in operation. They cost $500 to $1,200, typically more expensive than standard window units but less expensive than mini-split systems, especially considering installation costs (mini-split systems generally require professional installation).

Saddle and U-shaped inverter-driven window units are also more efficient than most portable air conditioners and are much less awkward in operation and appearance. They are also considerably quieter (~42 dB inside) than a typical room air conditioner, which may be important for sleeping during a prolonged disaster event. They offer many of the advantages of mini-split air conditioners and heat pumps without the costly installation and need for an installer that works with refrigerant.

Mini-Split Air Conditioning and Heat Pump Systems

Mini-split air conditioners and mini-split heat pumps can serve as a backup or emergency cooling system that also can significantly reduce household cooling (and heating) costs during the rest of the year (see Figure 6). These systems are very efficient, very quiet, and have no duct systems like central systems. Ducted systems are associated with efficiency losses of 10% to 30% when the ducts and air handler are located outside the thermal envelope (e.g., in a basement, crawlspace, garage, or vented attic) and how well they are sealed.

The smallest mini-split systems generally provide about 9,000 Btu/hr of cooling at an EER of approximately 18-30 Btu/Wh. A 9,000 Btu/hr model typically has an operating wattage of 350-500 Watts. In very efficient homes with good windows and wall and ceiling insulation, a larger central mini-split system can provide all of the cooling needed. It can then operate as the primary cooling or the emergency cooling system.

Even for less well-insulated homes, a recommended strategy is to install a centrally located mini-split heat pump or air conditioner in the house, which is then used to supplement and offset the operation of a less efficient existing central system. Research has shown that the annual cooling energy can be reduced by 30% or more by using a mini-split system to offset the use of a less efficient central system (Sutherland et al. 2016). It also can instantly become a backup cooling system in the event of a failure of the main cooling system.

Using a mini-split unit as emergency cooling is even more convenient with some modern units which plug in and operate on 115 volts, rather than 220 volts. Many of these operate with Bluetooth remote control from smart phones. Do-it-yourself systems are now available, although professional installation is still recommended.

Mini-split heat pumps typically cost between $800 and $1,500 for the equipment only, but installation can easily double or triple the total cost. When selecting a unit, look for the ENERGY STAR label to ensure energy efficiency, lower operating costs, and less draw on the backup power system. The ENERGY STAR database for mini-split heat pumps is an excellent resource for finding high-efficiency ENERGY STAR-certified models.

See the Ductless (Mini-Split) Heat Pumps guide for more information on these systems.

Portable Air Conditioners

Portable air conditioners are another option for emergency cooling (Figure 7). These are increasingly popular, but are generally of poor efficiency and expensive compared with other options. Portable air conditioners typically have two ducts that must be connected to the outside (often through a window). These ducts are required to exhaust heat from the space. Generally, this results in an awkward appearance and can present a danger for stumbling over hoses. They tend to cost in the range of $500 to $1,500 at the time of writing (2022).

Portable air conditioners typically come in cooling capacities ranging from 3,000 BTU/hr to 10,000 BTU/hr. The most advanced units have inverter-controlled compressors and have EERs up to 10 Btu/Wh. Most units must have condensate collected and periodically dumped or piped to the house exterior or to a drain. Some newer units use the collected water to cool the condenser coil, which is then vented for simpler operation. Some units have battery backup and can operate for 3 to 8 hours depending on mode without site electricity. Power draw tends to be about 400 to 1,000 Watts.

While these units are popular given their portable nature, it is important to point out that they tend to cost more than window units, without any increase in efficiency. They also are not nearly as efficient as mini-split heat pumps, which can produce twice as much cooling for a given amount of input power.

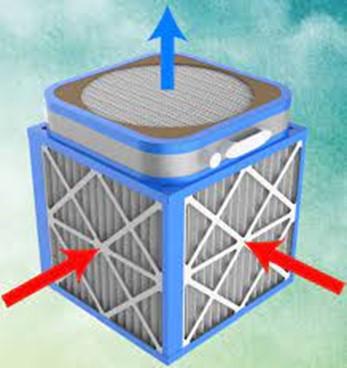

Air Cleaners

Disasters often coincide with poor air quality, especially in the case of extreme heat and wildfires. In such cases, having an emergency air cleaning system could be as important as emergency cooling and refrigeration. As a guard against poor air quality, an interior air filtration system that filters down to 3 microns is recommended. Thoroughly air-sealing the home should also be part of any plan for indoor air quality during an emergency. ENERGY STAR certified air cleaners can be found on the ENERGY STAR product database.

DIY options exist for very effective air cleaners as well. One such option is the Corsi-Rosenthal Box, which gained popularity during the Covid-19 pandemic. As shown in Figure 8 below, these devices are constructed using MERV-13 filters for the walls of the box and a standard box fan as the top of the box.

Cooling System Summary

Evaporative coolers can provide the most cooling for the least amount of energy, but only work in dry climates. In a non-arid climate, the mini-split heat pump option is generally the most efficient for backup cooling but is also the most costly, and will require some advanced planning. Standard window units tend to be the lowest cost option and can maintain reasonable efficiency. U-shaped and saddle window units have higher efficiencies than standard window units, but also higher cost. Portable air conditioners are generally less efficient and more expensive than window units, but they may be desirable due to their portability or lack of a suitable window for window unit installation.

Emergency Refrigeration

Emergency refrigeration not only keeps food and medicine safe, but is an efficient and effective method of keeping people cool when A/C is not available (by drinking cold fluids and ice). Emergency refrigeration consists of smaller, efficient, appropriately sized refrigeration units that can be operated with small generators or building-level battery backup systems. The efficiency of the refrigeration units is important. The daily energy usage can be roughly determined by examining the EnergyGuide label for a particular refrigerator unit and dividing the annual indicated kWh by 365 days/yr (See Figure 9). Note that the energy use of refrigerators is strongly impacted by the surrounding ambient temperature. During extreme summer weather, this can potentially increase daily electricity use by 20% or more.

Perhaps the best advice for emergency refrigeration is to obtain an ENERGY STAR-certified refrigerator of a small size and with the lowest indicated energy use on the EnergyGuide label. These use less energy than older models. Investing in a new refrigerator will pay off on your monthly electric bill as well as make it easier to provide emergency power for operation in the event of power interruption. The ENERGY STAR database of certified refrigerators can help consumers find and select an efficient refrigerator.

Note that the most efficient refrigeration units will often not be the smallest mini-fridge units. For a backup refrigerator, choose a model that uses less than 2 kWh per day. Some available refrigerator models show an estimated consumption of only 1 kWh per day or less. These are ideal for backup or emergency refrigeration.

If the emergency or backup refrigerator is an existing refrigerator, it is recommended that a small portable power meter be used to measure the actual power use of the refrigerator over a period of days. These meters are readily available and simply plug into the wall between the appliance plug and the wall outlet. Note that refrigerators also go through a defrost cycle that can periodically increase power use for several minutes.

If a refrigerator will be powered by a backup power system, it is important to know how many watts the refrigerator uses on start up. A refrigerator’s motor needs much more power to start than it does to run in a continuous fashion. For startup, the motor often needs 100% to 300% more power than the average demand indicated using the listed maximum amperage. For example, a refrigerator with a maximum listed amperage of 3.5 Amps at 120 Volts would have a running wattage of about 420 Watts (3.5 Amps times 120 Volts equals 420 Watts), but may have a startup wattage of 800 Watts. In this case, a 1,500-Watt generator would be sufficient to run your refrigerator. However, older units, or larger refrigerators such as side-by-side units, can require up to 2,000 Watts to start. Operating wattage can be estimated by multiplying the full load amps by 120 V (See Figure 10). Startup wattage can be assumed to be as much as 3 times the resulting value. Startup wattage can be confirmed from the owner’s manual if available.

Reducing Refrigerator Energy Usage

It is possible to reduce a refrigerator’s energy usage through good maintenance and efficient habits. Below are a few ways you can reduce the amount of energy your refrigerator uses.

- Keep the door closed. Avoid keeping the door open for long periods. An open refrigerator door lets cool air out and warm air in, thus increasing the compressor runtime and energy use.

- Adjust temperature set point. The U.S. FDA recommends a setpoint of 40°F or lower in a refrigerator. For energy efficiency, a setting no lower than about 38°F should be considered. If the unit does not indicate a temperature, you can measure it with a refrigerator thermometer and adjust the setting appropriately (See Figure 11).

- Keep coils clean. Refrigerator condenser coils (on the back or under the refrigerator) can pick up dust and grime. When this happens, the refrigerator has to work harder. The impact of fouled refrigerator coils has been measured to be approximately 4%.

- Ensure free airflow for heat rejection. Refrigerators usually rely on free space below, behind, and above the unit to allow air to flow and carry away rejected heat. Restricted airflow will reduce efficiency.

- Place your refrigerator in a cool location out of direct sunlight.

Backup Power Systems

Emergency cooling and refrigeration are useless during a power outage unless they can be powered by a backup power system. Options for emergency backup power systems include standard gas-powered portable generators, inverter-driven gas-powered generators, full-home standby generators, full-home battery backup systems, smaller portable battery systems, and some electric vehicle batteries. These options are further described below and in the guides “Generators for Back-Up Power During Outages” and “PV Battery Storage for Power Outages.”

A primary consideration when choosing what type of system to use is its capacity (Watts, kW, or Amps). The system should be large enough to comfortably power the chosen emergency cooling and refrigeration systems, as well as other critical loads. Table 1 provides a rough guide for the required generator or battery backup capacity to meet loads for emergency refrigeration and cooling.

Table 1. Approximate cooling and refrigeration loads that can be served by different-sized backup power systems (Source: FSEC)

| Generator or Battery Capacity | Potential Refrigeration or Cooling Electrical Loads | Leftover Capacity for Additional Loads |

|---|---|---|

| 1,000-1,500 W | Full-size refrigerator | 700 – 1,200 W |

| 1,500 W-3,000 W | Full-size refrigerator and Small A/C unit (Window unit, mini-split, or portable unit, <1000W) | 700 – 2,000 W |

| 3,000 – 6,000 W | Full-size refrigerator; fans; and window unit, mini-split, or portable AC unit | 2,000-4,000 W |

Generators

There are three classes of generators that are typically utilized for backup power. The smallest and least expensive are standard gasoline-powered portable generators at a cost of $500 to $1,000 (Figure 12). They typically provide 1,000 to 3,000 watts, but greater surge power. Although common and affordable, they tend to be noisy in operation and use more fuel than other generator types—typically about 5 gallons per day. Noise level is more important than one might think. As emergency situations can continue for days, the ability to sleep is vital and generator noise can lead to fatigue of those taking refuge. Standard generators also do not save much fuel in response to reduced or varying loads; they tend to use nearly the same amount of gas whether they are fully loaded with electrical equipment or simply idling with minimal loads being served.

An alternative to a standard generator is an inverter generator. Inverter generators tend to be more expensive than standard generators (typically $1,000-$2,000) but are much quieter in operation and more efficient. They typically provide 1,000 to 6,000 watts. They modify their energy output in dynamic relation to the loads that they are serving. They also tend to use less fuel—often 3 to 4 gallons per day—and adjust gas usage in proportion to the electrical load. They pay direct savings in fuel use when the load on the generator is reduced.

Finally, there are whole-home standby generators that can typically provide 6,000 to 48,000 watts. They tend to be much more expensive, very large (mount on an outdoor pad), and operate on natural gas, propane, or diesel fuel. They generally cost $5,000 - $20,000 to purchase and install but they can operate full-sized air conditioners and large loads. They do have long-term maintenance requirements. Systems using propane or diesel fuel need on-site tanks. These systems are also heavy and require a concrete pad for installation and a proper exhaust manifold and safe venting away from occupied dwellings.

See the Generators for Back-up Power During Outages guide for more information.

Battery Backup Systems

House-level, full battery backup can provide sufficient power for emergency cooling or refrigeration, particularly when matched with solar photovoltaic generation systems (See Figure 13). These systems can provide maximum power up to 10,000 Watts and can typically store 7 kWh to 15 kWh per battery. One or two packs can meet the needs of most homes for a few days. They must be recharged, usually by solar electricity, to maintain stored power.

Battery systems are responsive to the efficiency of the loads they are serving, so reducing the energy used in the home will extend the charge-life of the battery. Full house battery systems typically cost $800 to $1,000/kWh of storage. Installation is complex, including switchover and a communications gateway to monitor performance. Sizing a battery backup system, particularly served by a PV solar electric system, is a very complex topic and is best done by carefully measuring critical loads to be served. See the More tab for a guide on sizing battery systems.

Some electric vehicles are designed such that the car battery can be used to power external devices. An electric vehicle equipped with backup power capability that meets some or the entire home load can be part of an emergency backup power plan. Not all electric vehicle batteries have this capability and it will require installation of extra electrical components in the home.

All of the types of emergency cooling mentioned in this report can be found in DC-powered models. A unit that is powered by DC current has the advantage that it can be powered more efficiently by a battery system than a unit that runs off AC power. When using this strategy, it is important to ensure that the battery backup system has an accessible DC receptacle. A DC-powered air conditioning unit will not be able to plug into a standard receptacle in a typical home’s electrical system.

Smaller battery systems (1-2 kWh) with PV charging can run a refrigerator for many hours. They are not sufficient for emergency cooling systems, however. These units typically cost $1,500 to $4,000.

See the PV Battery Storage for Power Outages guide for more information on battery storage systems.

Additional Considerations

It is important to select efficient cooling and refrigeration appliances to reduce the start-up amperage that must be supplied by the batteries or generator. Efficient equipment will also reduce the capacity of the generators or battery systems needed to successfully supply the emergency cooling of the refrigeration loads. With efficient equipment, inverter generators will need to be refueled less frequently, and batteries will hold a charge for longer. Inefficient electrical loads such as electric resistance water heaters, electric resistance ranges, toaster ovens, and incandescent lighting should be eliminated to create “headroom” for critical cooling and refrigeration loads.

A key point for new construction is that building a home with good windows and ample ceiling and wall insulation will allow a smaller cooling system to provide effective emergency cooling. For existing homes, improving wall and ceiling insulation, providing effective shading, and improving windows can similarly reduce equipment size. These types of efficiency measures will reduce the size of the backup power system needed and will reduce the amount of fuel or solar power required, making the likelihood of surviving a disaster event higher.

Success

The key to success with emergency cooling and refrigeration is to ensure that the equipment slated for emergency service is reliable and has a small enough power draw to be easily served by the backup power system. Success also depends on safe installation and operation of equipment, particularly generators.

Generator Safety

There are significant safety concerns with generators that operate on gasoline or diesel fuel. If used incorrectly, portable generators can pose a serious carbon monoxide hazard. Never locate a generator inside the home. Direct exhaust away from windows, doors, and vents. Do not operate a generator in partially enclosed spaces, even if using fans or opening doors and windows for ventilation. See this guide by OSHA on safely operating portable generators for more information. For whole-home generators that are permanently installed, installation safety and venting should comply with manufacturer recommendations and local building code.

Climate

Emergency cooling is most likely to be needed in the warmer and more disaster-prone areas of the country. Homes located in hot climates (lower-number climate zones in Figure 1) and in areas prone to hurricanes, floods, tornadoes, earthquakes, or wildfires, should seriously consider an emergency cooling plan. Extreme heat, however, can strike in any climate, raising the importance of emergency cooling in all areas of the country. Emergency refrigeration to prevent medication or food spoilage is important in all U.S. climates.

Hotter climates tend to require larger capacity emergency cooling systems unless the decision is made to limit the cooling to a particular zone or room in the house. Given climate change and the temperature increases being observed, past climate is likely not indicative of future climate. Thus, a conservative approach is recommended. Hotter climates may also need backup cooling for longer periods of time in the event of power outage while cooler climates may only need short-term solutions.

The prevailing humidity conditions have a significant impact on what type of emergency cooling systems are feasible. Backup cooling systems in arid climates can use evaporative cooling while more humid geographic locations cannot. Area 'A' in Figure 2 is considered well-suited to evaporative cooling. Area 'B' is considered possible but not ideal for evaporative cooling, and Area 'C' is considered too humid for evaporative cooling to be effective or desirable.

Compliance

Compliance

International Residential Code (IRC)

Air Conditioning Contractors of America (ACCA) Standards

ACCA Manual S - Residential Equipment Selection

ACCA Manual D - Residential Duct Systems

ACCA Manual J - Residential Load Calculation

ACCA Standard 5: HVAC Quality Installation Specification

ACCA Standard 9: HVAC Quality Installation Verification Protocols

Retrofit

The concepts presented in the Description tab and other tabs of this guide are equally applicable in a retrofit situation.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

Evaluation of Mini-Split Heat Pumps as Supplemental and Full System Retrofits in a Hot Humid Climate

The following authors and organizations contributed to the content in this Guide.