Scope

Completely remove existing windows and replace with new windows. Install the new windows using modern standards and techniques for flashing, water sealing, and air sealing in accordance with ASTM Standard E2112-07, Standard Practice for Installation of Exterior Windows, Doors, and Skylights.

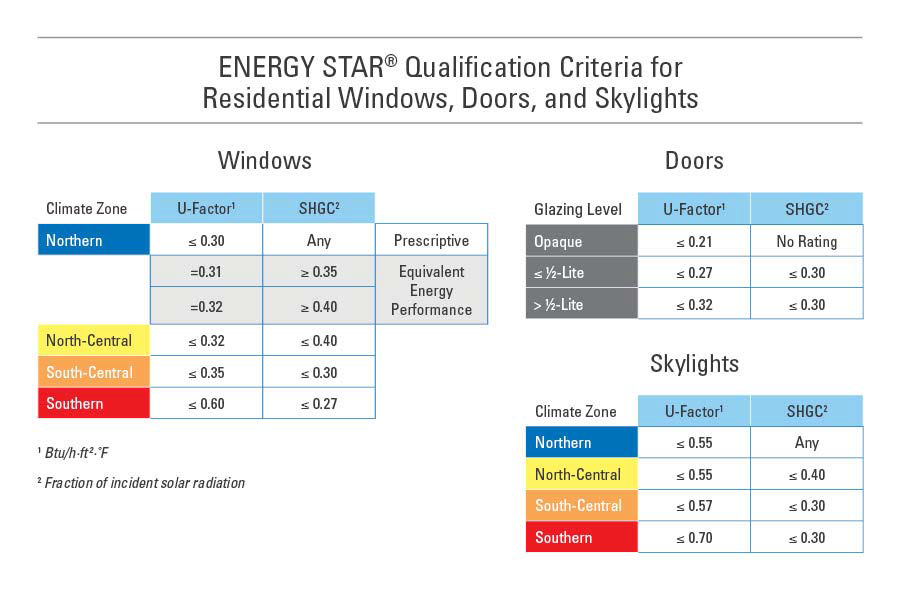

- Select energy-efficient windows that control solar-energy gains and help reduce heating and cooling loads. Maximum U-values of 0.3 or lower are recommended. Windows meeting ENERGY STAR criteria for the appropriate climate are recommended. See Compliance tab for more information.

- Completely remove and dispose of or recycle the window sashes and frame. Remove existing sash weights. Recycle the cast iron weights. Air seal and insulate the sash weight cavities.

- Reconstruct the window rough opening.

- Place the new windows within the window plane as specified in building construction documents. Placement of the window near the siding in walls receiving exterior rigid insulation may require that a frame extension be constructed as shown in the photo.

- As summarized within the Success tab, before beginning this work, inspect the interior and exterior of the building, including each window, to identify impacts and potential risks with completing the work. Diagnose water and air infiltration pathways, and choose strategies most appropriate to address each leak.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Before beginning this work, the window should be assessed as outlined within the Success tab.

The highest performance but most intrusive and expensive option is a complete window replacement. This measure includes not only removal of the existing window sashes, but the entire window frame (back to the rough framing). This often includes the interior and exterior casing and trim as well.

A complete window replacement would most commonly be done in conjunction with a more extensive building renovation project. The projects defined here are replacement 1) as a sole project, 2) in conjunction with a siding replacement, and 3) in conjunction with an exterior insulation retrofit.

Windows are often installed in combinations or bays in many existing homes. The intersections of these window groupings often contain voids that need to be air sealed and insulated.

Window Replacement as Sole Project

The details provided here, are designed so that a future cladding replacement or exterior insulation upgrade can be integrated with the window replacement with only minimal disruption to the window installation details.

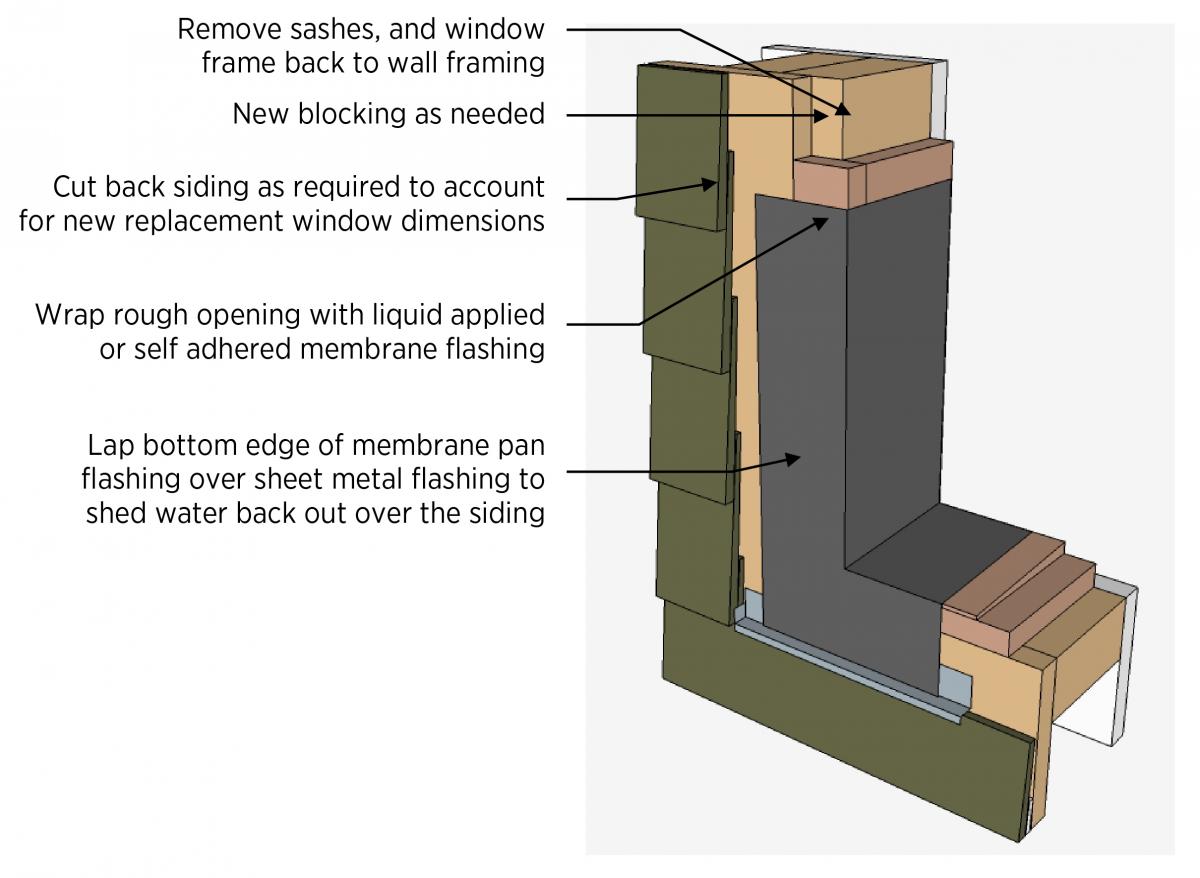

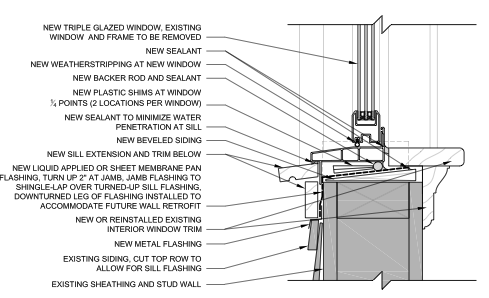

Often the existing rough opening size is not the desired final dimension and additional blocking is added to frame out the rough opening to the correct dimension. The new rough opening is lined on all sides with a liquid applied or self-adhered waterproof membrane. The membrane should extend out a minimum of 4 inches onto the plane of the exterior wall. The membrane will ultimately be covered with exterior window trim. Should a future upgrade to the wall occur at a later date, only the window trim would need to be removed to allow for a tie-in between a new water resistive barrier (WRB) (and potentially an air barrier).

Typically, a certain amount of siding will need to be removed to accommodate the window installation. Trimming back of the siding should be done with care so that damage to underlying elements such as building paper can be avoided if possible. Connecting the window membrane flashings to a building paper or some other WRB is recommended. It may be the case that the wall does not have an existing WRB to connect to. In this case, sealing the membrane flashing directly to the wood sheathing, and providing a metal flashing below the sill to shed water back out over the cladding would be recommended; however, it should be recognized that in doing so a certain amount of risk is accepted by the home owner as the remainder of the wall does not conform to recommended enclosure water management design. In these situations, it may be warranted to examine a full cladding replacement at the same time in order to retrofit the building with a proper WRB.

Window Replacement in Conjunction with a Siding Replacement

If the siding is replaced and a new wall WRB is installed at the same time as the windows, the re-installation details would be the same as current recommended new construction practice. The details would change slightly in that a complete wrapping of the rough opening with a membrane would no longer be needed. Instead, the wall WRB could be wrapped into the rough opening on the sill and jambs, a pan flashing installed at the sill. After the window was installed, the jambs and head would be sealed with a self-adhere membrane flashing and the WRB would be shingle lapped over top of the membrane head flashings.

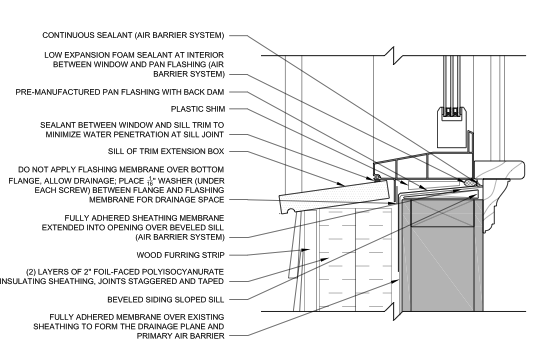

Window Replacement in Conjunction with an Exterior Insulation Retrofit

Window replacement done in conjunction with an exterior insulation retrofit of the building requires some additional consideration for the window installation details. The window can be placed either inboard of the insulation layer (“innie” window) or at the front face of the insulation (“outie” window). The choice of the window placement is often governed by the location of the WRB (or the placement of the WRB may be governed by the desired window placement location).

“Innie” windows are most easily integrated with a WRB that is placed behind the insulation at the plane of the exterior wall sheathing. By contrast, “outie” windows are most easily integrated with a WRB that is placed at the face of the exterior insulation. In either case, the integration of the window flashing with the WRB remains the same.

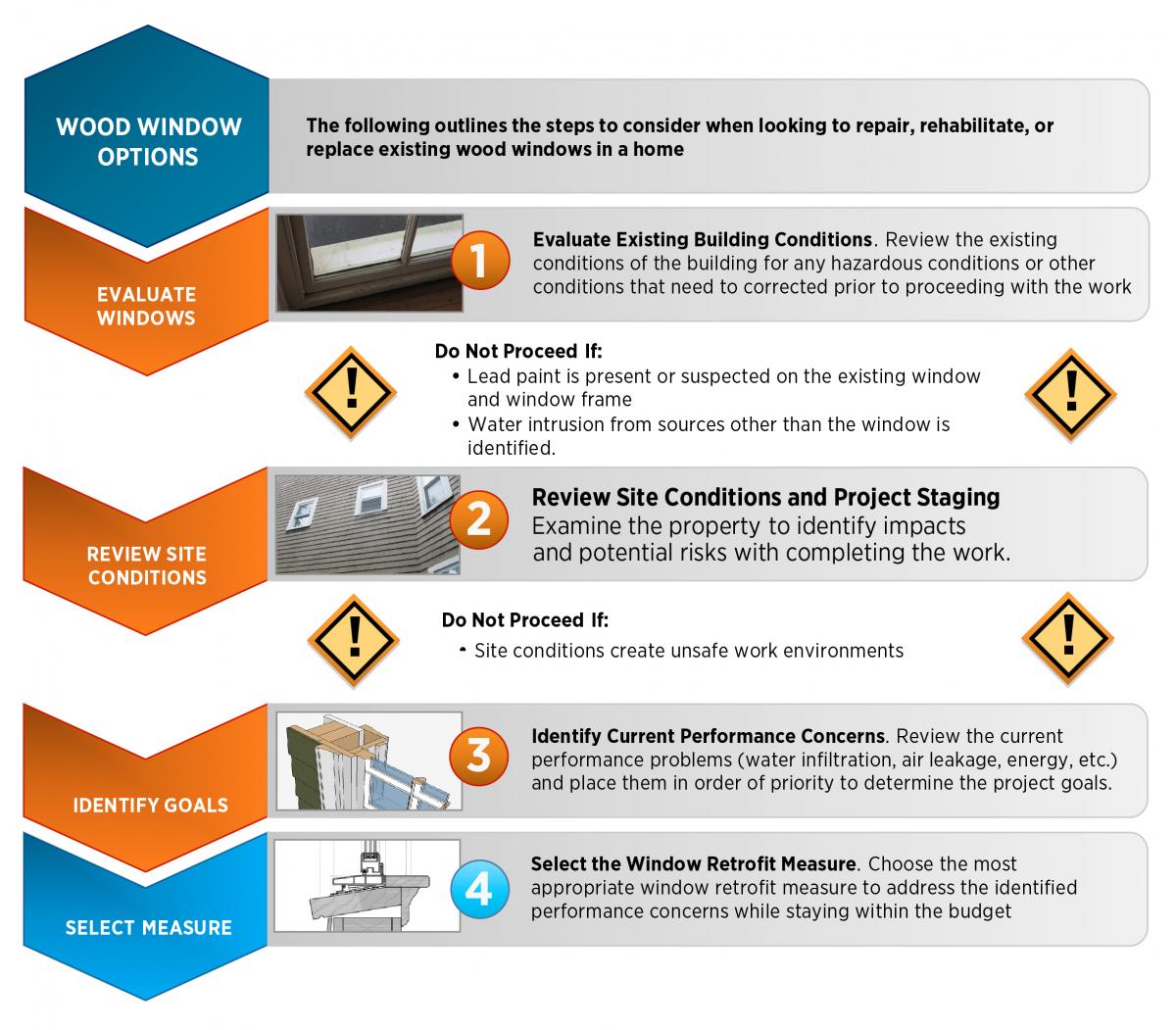

Success

Identifying Risks

Prior to any retrofit work being conducted, it is important that the following conditions of the building systems be reviewed:

- Lead and other hazardous materials

- Site conditions and project staging

- Identification of water infiltration concerns

- Identification of deteriorated or damaged materials

- Identification of user comfort concerns

Contractor/Homeowner Safety

OSHA: Fall Protection (if window work is to be done at height, from the exterior)

Lead and Other Hazardous Materials

Old wood windows and trim are a common location of lead paint in homes. Any work being completed on the window systems should follow all appropriate state and federal laws regarding handling of hazardous materials.

Site conditions and Project Staging

The home and site should be reviewed to identify impacts and potential risks with completing the work.

If the work is to be done for the exterior, scaffolding, lifts, ladders, or other means to access work areas may be needed. Work done at height may require fall protection be used. Proximity to adjacent property or vegetation may limit access or create unsafe work areas. Exterior staged work may also damage existing landscaping or vegetation.

If the work is intended to be completed from the interior, consideration should be given to disruption of the occupant and clearances for moving equipment and materials into and out of the space. With any interior work there is always a chance of damage to interior finishes. Appropriate planning and protection is required.

Identification of Water Infiltration Concerns

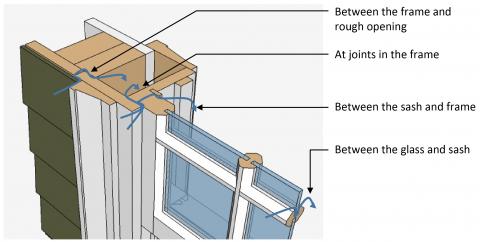

Windows, above all other enclosure systems, are a common location of water infiltration issues. It is important to understand the various pathways for potential water infiltration, and identify current water leakage problems. While the details presented in this document are all intended to improve the moisture performance of the window assemblies, it is not intended to address all possibilities, and is not a replacement for inspection and evaluation of the performance of an individual window. Existing problems should be identified, and the strategy chosen that will be most appropriate to address the concern. Window systems water leaks can be grouped into four general categories (Figure 1 below):

- Between the window frame and rough opening

- Through the joints in the window frame

- Between the window frame and the operable sashes

- Through the joints between the glass and the sash frames

Prior to any work being done, interior and exterior inspection and monitoring of the conditions of the building should be completed. Water staining, peeling paint or wall paper, and staining on trim or floor assemblies below window systems are indications of water infiltration and/or condensation. Leakage between the sashes and the frame and between the glass and the sash is usually marked by water staining on the interior window frame itself. Condensation on the window frames can also lead to staining of the interior finishes. It is important to monitor the questionable area to prevent a false diagnosis of the water management problem being experienced.

Leakage between the window and rough opening or through the joints in the window itself are typically contained within the wall assembly and may go unnoticed, or could manifest as staining and peeling paint below the window or damaged flooring.

Other problems such as water infiltration at the window head may be indications of failed or missing head flashing. However, other problems not associated with the window system may in fact be the cause of the water infiltration. Care must be taken to properly diagnose the infiltration pathway.

If it is a known recurring problem, then the infiltration problem must be addressed prior to or in conjunction with the window retrofit work.

If no obvious signs of water infiltration problems exist and the window elements and connection wall components are in good condition, no additional work may be needed. However, as stated above, water infiltration problems are often concealed within wall cavities with no outward signs. This becomes more of a concern if the window retrofit work is being done in conjunction with the addition of cavity fill insulation. With the addition of insulation to the wall cavities, water infiltration problems that previously may have had sufficient drying ability, may now lead to prolonged moisture accumulation. Prolonged moisture accumulation can lead to material deterioration. If there is suspected leakage, then further investigation, including but not limited to thermal scans, moisture content measurements, and cutting of investigation holes below window assemblies to look for signs of moisture problems would be recommended.

Unless the problem is obvious, it may be prudent to contact someone with experience with diagnosing water infiltration problems prior to proceeding.

Identification of Deteriorated or Damaged Materials

If damage to existing elements is noted, the materials should be removed and replaced as part of the retrofit. Certain elements will be more critical to the proper implementation of the chosen strategy.

The window sill is arguably the most important element of the window assembly, as water will drain downward by gravity either into the wall (e.g., hole through sill) or directly onto the wall (failure of the sill extension). Water that does get into the window assembly must be allowed to drain out, for this reason, the joint below the window frame should not be caulked and any weep holes included in the bottom of the frame by the manufacturer should not be filled in. For all proposed measures in this document excluding complete window replacement, the condition of the sill is critical to the performance of the measure. Cracked or rotting sills need to be replaced prior to any work being done.

The window frame including the exterior casings is the next most critical element. If the casing is deteriorating, its replacement may be warranted. This should not be confused with the exterior trim, which is often installed as a decorative element on top of the casing.

Deteriorating trim may not affect the water management performance of the window however; it may be an indication of other problems and generally creates an aesthetic problem.

Depending on the measure being examined, the condition of the window sashes may or may not be a concern to the performance of the measure taken. For window rehabilitation, sash retrofit, or interior storm retrofit, the condition of the sashes is critical to the performance of the window. For windows with exterior storms, the sashes are more protected from the elements, and the condition is less important from a water management perspective, yet still critical from an energy and condensation resistance perspective. For sash replacement, window insert, or full window replacement, the condition of the sash is irrelevant, as they will be removed. For this reason, windows with severely deteriorated sashes may be better candidates for the latter retrofit measures.

Identification of User Comfort Concerns

As part of the initial review, associated comfort concerns relating to the window systems should be evaluated. Window air leakage is a significant source of occupant comfort problems. Unlike other common enclosure leakage pathways, window air leakage is commonly very direct, resulting in distinct drafts.

Radiation effects from cool glass surfaces are another common comfort problem. This is more difficult to identify, as the tendency is to assume that the discomfort felt when near a window is from air leakage or drafts. This results in some misdiagnosis of the dominant function. A general recommendation is to increase the interior surface temperature of the window system to reduce the radiant heat transfer from the occupant to the window. This is commonly done by adding additional panes of glass (or films) to create an insulating air (or other gas) space between the layers.

Compete Window Replacement

Complete window replacement is most common with more extensive building retrofits, as it generally requires disturbance to both interior as well as exterior finishes. When combined with a more extensive energy retrofit that includes the addition of exterior insulation to the building, it provides the most freedom for design and placement of the window. The windows can be installed in plane with the framing or be pushed towards the exterior to line up more traditionally with the plane of the siding. When walls are also being renovated, windows sizes can be adjusted as necessary or desired.

This work will improve the energy performance of the assembly by reducing air infiltration, as well as thermal conductance through the assembly. Choosing the most efficient windows will improvements in thermal performance and reducing the potential for interior condensation problems on the window system. The ENERGY STAR website provides a listing of the most efficient windows among those that qualify for the ENERGY STAR.

Complete window replacement will affect the interior and exterior appearance of the building. Typically, historic review boards prefer preservation of existing windows. Replacement will be most appropriate in historic properties when rehabilitation is underway for other reasons (such as decay, structural failure, or building expansion) and the renovation is designed to mimic historic features. In homes within historic districts or listed as historic structures, ensure approval from appropriate authorities before proceeding with the project. Approval may require a plan review, public notification, hearings, and a fee. Complete window replacement is not reversible.

Typically, a certain amount of siding will need to be removed to accommodate the window installation. Trimming back of the siding should be done with care so that damage to underlying elements such as building paper can be avoided if possible. Connecting the window membrane flashings to a building paper or some other water resistive barrier (WRB) is recommended. It may be the case that the wall does not have an existing WRB to connect to. In this case, sealing the membrane flashing directly to the wood sheathing, and providing a metal flashing below the sill to shed water back out over the cladding would be recommended, however it should be recognized that in doing so a certain amount of risk is accepted by the home owner as to the remainder of the wall does not conform to recommended enclosure water management design. In these situations, it may be warranted to examine a full cladding replacement at the same time in order to retrofit the building with a proper WRB.

A window selection tool is available at the Efficient Windows Collaborative.

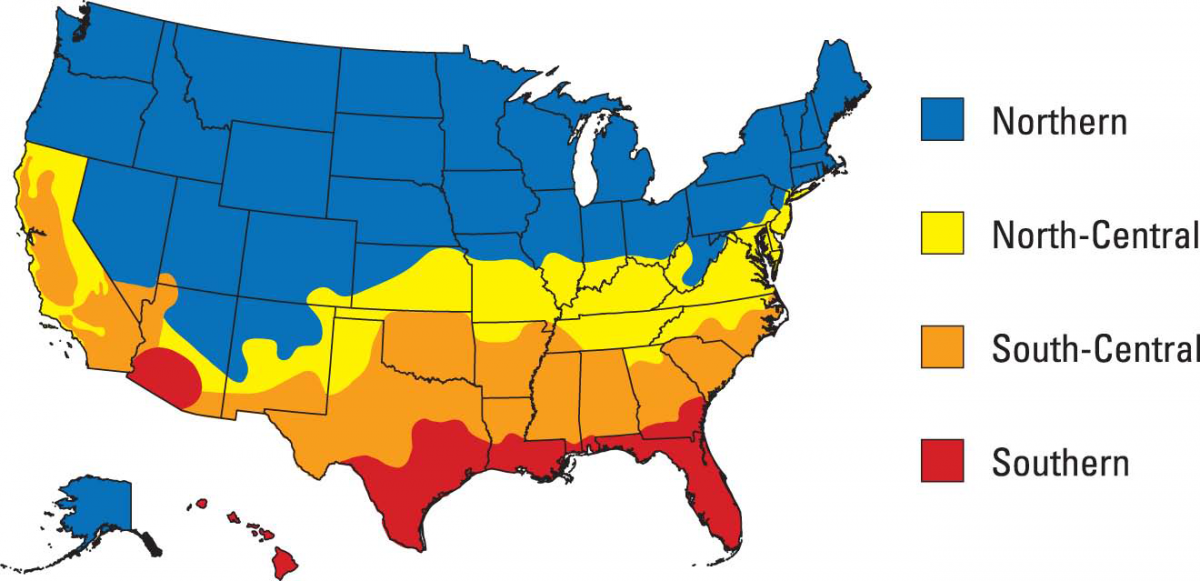

Climate

Use ENERGY STAR's Windows, Doors and Skylights Climate Zone Finder for detailed climate information in your area.

The Efficient Windows Collaborative provides a window selection tool and step-by-step guides to selecting windows for each state.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Building Science Corporation, lead for the Building Science Consortium (BSC), a DOE Building America Research Team

Sales

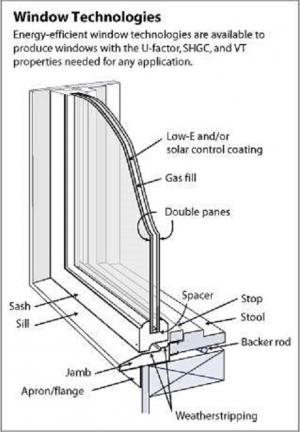

High-Performance Window System = High-Performance Window System

Homes with high-performance window systems are more comfortable and consume less energy than homes with traditional windows. High-efficiency ENERGY STAR-rated windows perform at least 15% better than a standard window and have an insulating value of R-3 or higher. Ultra-efficient windows perform at least 50% better than a standard window and have an insulating value of R-5 or higher. On average, they save homeowners 7% to15% on utility bills. These window systems use a combination of insulating frames and other features to reduce heat loss. They consist of two or three glass panes separated by insulating spacers and installed in insulated frames made of nonconductive wood, fiberglass, or vinyl. The space between the glass layers is filled with a nontoxic gas like argon or krypton that insulates better than air. The glass panes are coated with a low-emissivity coating that reflects sunlight and protects curtains, furniture, and hardwood floors from fading over time.