Scope

In areas with no access to a network of fire hydrants and no reliable alternative water source such as an on-site pond, lake, or swimming pool; installing a cistern on the homeowner’s property can provide supplemental water supply for firefighters or indoor sprinkler systems for suppression of house fires due to a wildfire or a fire that starts within the home. Cisterns may be installed because they are required by local code or desired as a best practice by the homeowner.

- Determine proper siting of the cistern where access to the cistern and turnaround space for firefighting trucks are available.

- Determine whether to site the cistern above ground or below ground based on space availability, excavation budget, tank materials, freeze protection concerns, and aesthetics.

- Select appropriate tank materials and construction method: common tank materials include fiberglass reinforced plastic, corrugated steel, welded steel, precast concrete, or poured-in-place concrete.

- Ensure cistern capacity is sized to meet any minimum water supply requirements.

- Provide and maintain access to the cistern drafting connection for firefighters; access should include turnaround space for fire engines.

- Provide access for homeowner maintenance of the cistern and inform the homeowner of any required recurring maintenance.

- Where a reliable alternative water source exists on the property, such as a year-round pond, lake, or swimming pool, consider installing a dry hydrant with piping into that water supply for cost savings instead of installing a traditional cistern.

See the Compliance tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

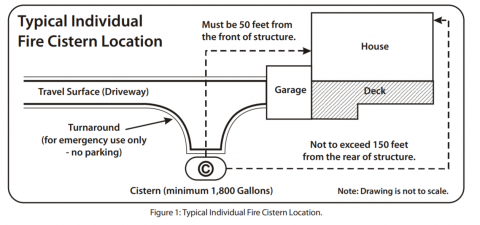

Homes built in high-risk fire hazard areas, such as those located in the wildland-urban interface (WUI), pose several challenges for fire protection services in case of a wildfire or structural ignition from within. Homes in remote areas are generally located long distances from the nearest fire department and may be surrounded by difficult terrain for fire engines and water tender trucks, which leads to increased response time (Figure 1). In addition, these homes often have limited access to water for fire protection. Infrastructure for urban and suburban areas typically includes a network of fire hydrants that enables easy access to municipal water for firefighters in the event of a fire. However, many remote areas are not on municipal water lines and do not have similar fire protection infrastructure.

Three important actions that homeowners in wildland areas can take to increase the survivability of their homes in the event of a wildfire or structural fire from within are to 1) create and maintain defensible space (zones with minimal vegetation and other fire fuels around the outside of the home, see the Solution Center “Defensible Space” guide), 2) ensure ease of access to and egress from the property for firefighters, and 3) ensure firefighters have access to an emergency supply of water on or near the property, via a cistern, swimming pool, dedicated well, or manmade or natural pond. This guide discusses cisterns for use by firefighters (Figure 2). Cisterns can also be used as a source of water for indoor sprinkler systems and the same tank can serve both purposes; indoor sprinkler systems are discussed in the guide “Indoor Sprinklers for Fire Suppression.”

Experienced wildland firefighters have noted that, even if a water supply is provided for fire suppression, the likelihood that a home can be saved in the event of a structure fire is directly related to the response time of the fire department. With house fires in urban and suburban areas, the strategy used by firefighters is to get to the house as quickly as possible (generally within 2 to 5 minutes of receiving the call) to attack the fire aggressively and keep it at a room-and-contents level. If the crew can reach the home within that short window of time, there is a strong likelihood they can save the home. Homes located in the wildland-urban interface present some realities that must be recognized. Response times from the fire department are longer, likely 10 to 15 minutes depending on distance and available resources. Getting adequate resources to a home in the WUI quickly is a challenge for all fire departments, whether staffed with paid fire fighters or volunteers. Ten to 15 minutes is enough time to allow a fire to become established and spread throughout the home, making it unsalvageable. Fire crews responding to a structure fire in a WUI or remote location might count the house as unsalvageable by the time they reach it, depending on the situation, and will use the cistern, tank, or other available water sources to prevent the fire from spreading to surrounding structures or vegetation and starting a wildfire (PNNL 2021).

A cistern can be helpful in saving a home in the event of an approaching wildfire, especially if the home is deemed otherwise saveable by firefighting crews because defensible space has been created around the home ahead of time by the homeowner and because there is easy turnaround space near the home for fire engines. The fire crew will do all in its power to prevent the home from catching fire by using the cistern water, in addition to any water brought to the site in their trucks, for wildland fire suppression and structure protection (for example, wetting down the outside of the home with water or foam). But if a fire gets established in the house, with the winds generated during a wildland fire, there would not be enough water to put out the structure fire. The structure would be deemed lost and any water available would be used for other purposes (PNNL 2021). For context, the NFPA recommends a minimum cistern tank size of 2,000 gallons. At the lowest suggested flow rate of 250 gallons per minute, the cistern will be emptied in 8 minutes.

During a wildland fire, cisterns are most likely to be used as a communal water source. The firefighting crews will fill their tanks from the cistern or other available site water sources to use wherever needed to suppress the wildfire to protect this home and others in the area (PNNL 2021).

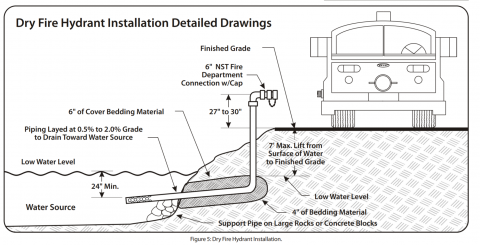

Emergency water sources could include manmade bodies of water such as swimming pools, wells, or cisterns, or natural water supplies such as ponds or creeks. Where natural sources are used, reliability of the water supply should be considered. Ponds and streams are subject to drought, freezing, and seasonal variations in water levels that may render the source unavailable. When the property has access to natural water supplies that are reliable year-round, homeowners may choose to install a dry hydrant – a non-pressurized permanent pipe assembly installed in the water source that allows for withdrawal of water through suction. Dry hydrants installed in natural water supplies provide a cost-effective solution for establishing an emergency firefighting water supply for a home. The water intake end of the pipe should be equipped with a screen to filter out debris. A schematic of a dry hydrant installed in a natural water source from the Boulder County Land Use Department is shown in Figure 3. An image of a dry hydrant installed in a pond is shown in Figure 4. If no dry hydrant is installed, firefighting pump trucks may draw from open ponds by means of a pipe or hose that the firefighters bring to the site.

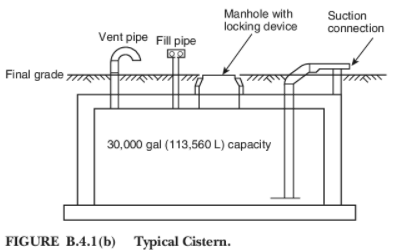

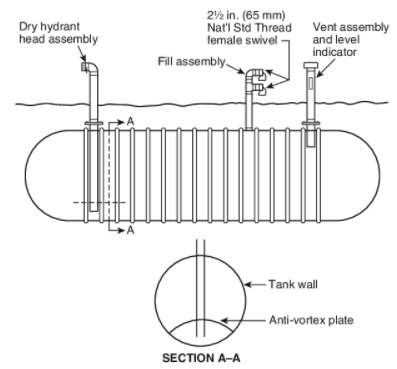

For homes located in areas where no reliable natural water supply or municipal piped water supply exists, homeowners may choose to install a private cistern as a dedicated, reliable, year-round emergency water supply for firefighters to use in the event of a fire (Figure 5). Cisterns are typically constructed of concrete, fiberglass reinforced plastic (FRP), or steel. They can be buried underground or elevated aboveground; however, environmental factors such as freezing temperatures, exposure to ultraviolet radiation, exposure to fire, wind load, and lightning protection should be considered for aboveground cisterns. Underground cisterns are protected from these environmental factors and can be located below the frost level so tank heating is not needed. Typically, a cistern is outfitted with fill and vent pipes, a level indicator, and a hydrant (hose receptacle) that meets the local fire department’s specifications. These tanks are non-pressurized and do not use pumps. In the event of a fire, the fire engine will use onboard pumps to draft water from the cistern.

The tank is typically filled from the homeowner’s well. It could also be filled from a separate well, from a rainwater collection system, or from recycled “grey water” from the home’s sinks and showers. Fire suppression tanks are not typically used as a domestic potable water supply. If they are, specific filtration systems may be required and a system may need to be installed that to prevent the water level in the tank from getting below the minimum needed for fire suppression.

Cistern Construction and Siting

Cisterns for fire suppression are often constructed of concrete, fiberglass reinforced plastic, or steel; they can be built on site or shipped to the site premade. For underground cisterns, the ground must be excavated first, which can add considerably to the cost. Underground cisterns that are made on site of poured concrete are versatile because they can be custom made to any size or shape but they are typically more expensive to construct than precast concrete or fiberglass-reinforced plastic tanks. For all underground tanks, costs for excavation should be considered in the project budget. The National Fire Protection Association’s NFPA 22, Standard for Water Tanks for Private Fire Protection, Chapter 11. 5, outlines design considerations and protection requirements for underground tanks, such as resistance to earth pressure, resistance to movement due to high levels of groundwater, and protection against traffic above the cistern. Figures 6 and 7 show diagrams from NFPA 1142 for typical concrete and fiberglass-reinforced plastic underground cisterns.

Aboveground cisterns are typically made of fiberglass-reinforced plastic, corrugated steel, or welded steel. Fiberglass reinforced plastic tanks are shipped as one piece; however, larger fiberglass reinforced plastic tanks may also be shipped in multiple pieces and assembled on site using manufacturer-approved adhesives. Corrugated steel tanks are typically shipped in multiple pieces and assembled on site. Welded steel tanks can be shipped in pieces and welded on site, or can be shipped pre welded, depending on the size of the tank. Aboveground cisterns are typically installed on concrete foundations per manufacturer requirements or NFPA 22 Chapter 12. Required protection for aboveground tanks is outlined in NFPA 22 Chapter 11.6. For aboveground tanks, freeze protection is a primary concern. Water in the tank should be kept above 42°F as required in NFPA 22 Chapter 16. NFPA 22 Chapter 16 also outlines recommended heating methods such as gravity circulation, steam-heated radiators, immersed steam coils, water recirculating heat exchangers, or electric immersion heaters. Figure 8 shows two images of the same welded steel tank with several primary features identified.

As outlined in NFPA 22 Chapter 11.7, cisterns used for fire protection should be outfitted with a dry hydrant assembly, a liquid level indicator, an accessible method for filling the tank, and a vent that prevents against tank pressurization during filling or creation of a vacuum during water draft. In addition, an antivortex plate assembly should be installed on the suction drop tube in the tank as outlined in NFPA 22 Chapter 14.2. Some fire districts may require an access hatch for inspection, maintenance, or testing.

Fire Engine Access and Hose Connection Requirements

The cistern will typically contain a 4-inch pipe with a coupling that the fire department can use to connect the hard-suction hose from the fire engine to draw water from the cistern for firefighting. This connection is called a drafting connection or fire department connection (FDC). The connection has a shutoff (gate) valve and a suitable thread type for the local fire department. This is typically a threaded male connector that comes with a matching plastic or brass cap with chain. One common connection is the National Hose Thread, abbreviated “NH” or “NST” which comes in various sizes. The most common are the 4.5-inch or 2.5-inch NH/NST. Contact the local fire department to verify specifications for their drafting connection. Having the wrong thread type will require the use of adaptors by the fire department or could make the cistern unusable.

The cistern should be located such that the fire engine can have easy access with either sufficient space for a firetruck to turn around or a circular driveway. Ideally, the lane to the house should have space for two-way traffic.

Providing ease of access and egress to the cistern and home, space for emergency vehicles to turn around, and defensible space around the main structures on the property will increase the likelihood that firefighters will work to protect the home during a wildfire. Figure 9 shows a typical siting of a fire suppression cistern on a residential lot; however, different fire districts may have different requirements. Some fire districts may also publish requirements on emergency vehicle turnarounds.

Minimum Required Water Volume

One consideration when purchasing or constructing a fire cistern is its capacity. The National Fire Protection Association (NFPA) provides a guideline for calculating minimum required water volume, based on a property’s size and flammability, in NFPA 1142, Standard on Water Supplies for Suburban and Rural Fire Fighting. Prior to calculating the minimum water supply, a site survey should be performed to obtain the following pieces of information about the structure: 1) dimensions (length, width, height, and attic height), 2) occupancy hazard classification, 3) construction classification, and 4) exposure hazards, if any. The absolute minimum water supply for a structure with no exposure hazards is 2,000 gallons.

Formula for Calculating Water Supply for Structure with No Exposure Hazards (1)

The formula for calculating the minimum water supply for a structure with no exposure hazards is noted in NFPA 1142 as:

WSmin = VStot / OHC (CC)

Where:

- WSmin = minimum water supply in gallons

- VStot = total volume of the structure in ft3

- OHC = occupancy hazard classification number

- CC = construction classification number.

Formula for Calculating Water Supply for Structure with Exposure Hazards (2)

A structure is considered to have an exposure hazard if:

- It is greater than 100 ft2 and is within 50 ft of another structure.

- The structure, regardless of size, is classified with an NFPA occupancy hazard classification number of 3 or 4 and is within 50 ft of another structure.

Some examples of exposure hazards on a residential property are barns, garages, large sheds, or mother-in-law units within 50 ft of the home. The absolute minimum water supply for a structure with exposure hazards is 3,000 gallons.

The formula for calculating minimum water supply for a structure with exposure hazards is noted in NFPA 1142 as:

WSmin = 1.5 × VStot / OHC (CC)

Where:

- WSmin = minimum water supply in gal

- VStot = total volume of structure in ft3

- OHC = occupancy hazard classification number

- CC = construction classification number.

As noted in NFPA 1142, the minimum requirements are subject to increase by the fire authority having jurisdiction, to compensate for conditions on the property such as:

- Limited fire department resources

- Extended fire department response time or distance

- Potential for delayed discovery of the fire

- Limited access

- Hazardous vegetation

- Structural attachments, such as decks and porches

- Unusual terrain

- Special uses and unusual occupancies.

Determining Total Volume of the Structure

Classifying Occupancy Hazard

The Occupancy Hazard Classification (OHC) number is a series of numbers ranging between 3 and 7 that are used to calculate minimum water supply requirements. On the occupancy hazard classification scale, 3 represents the most severe hazard and 7 represents the lightest hazard. NFPA 1142 Chapter 5.2 provides examples of buildings that fall in the range of occupancy hazard classifications. In the standard, occupancies that contain large quantities of combustible materials, such as sawmills, die casting, and plastic processing plants fall into OHC 3. Buildings where the quantity and combustibility of materials are low, such as apartments, hotels, and hospitals fall into OHC 7. Homes are typically classified as light hazard occupancies (OHC 7), but a site survey should be completed to confirm the home doesn’t have any features that would increase the occupancy hazard classification number.

Classifying Construction Type for Determining Water Volume

Classifying the type of construction is important for determining the minimum volume of water required for fire-fighting purposes because it identifies the flammability of the building components and the home’s susceptibility to ignition during a fire event. The construction classification (CC) number is defined in NFPA 1142 Chapter 6 and can be either 0.5, 0.75, 1.0, or 1.5, depending on the fire-resistivity of the building materials, where higher numbers correspond with more flammable construction. Buildings made of noncombustible material such as brick with all structural members fireproofed might be given a CC number of 0.5, whereas a wood-frame building might be given a CC number of 1.5. NFPA 1142 Chapter 6.2 sets the maximum CC for a dwelling at 1.0, even if it is a wood-framed structure, although a site survey should be completed to confirm the house doesn’t have any construction that would increase the construction classification number.

Sample Calculation for Determining Water Volume

The National Fire Protection Association provides a sample calculation for a residential dwelling in Annex H of NFPA 1142:

- Ground floor 50 ft x 24 ft

- Two 8-ft stories

- A pitched roof, 8 ft from attic floor to ridgepole

- Wood frame (Type V) construction.

Assuming the home has no exposure hazards, the correct formula for calculating minimum water supply is Equation (1):

WSmin = VStot / OHC (CC)

The correct formula for calculating total volume of the structure (VStot) is Equation (4) because the home has a pitched roof and attic space, so:

VStot = (50ft × 24ft) × (16ft + 128ft) = 24,000ft3

For a home, the occupancy hazard classification number is typically 7 and the construction classification number is typically 1.0. The resulting minimum water supply calculation is:

WSmin = 24,000 / 7 (1.0) = 3,429 gallons

The minimum water supply is 3,429 gallons in this example.

Water Delivery Rate

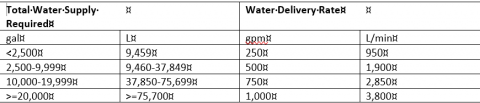

For the firefighting system to be effective, all components of the cistern and attached piping should be sized to accommodate the minimum water delivery rate. The water delivery rate is the rate at which the water is drawn from the cistern when in use by the fire department. Water delivery rates are determined by the required water supply and tabulated in NFPA 1142 Table 4.6.1 as given here in Table 1. Although the table specifies a minimum water delivery rate of 250 gallons per minute when the total water supply required is less than 2,500 gallons, NFPA 1142 Annex A requires a minimum water delivery rate of 1,000 gallons per minute for one- and two-family dwellings under 5,000 ft2. However, NFPA 1142 also allows a 25% reduction in water delivery rate for homes without other structures within 30 ft and a 50% reduction in water delivery rate for homes equipped with an NFPA 13D-compliant automatic fire sprinkler system. (See the guide Indoor Sprinklers for Fire Protection)

Success

Consult with your local or state fire agency or fire management specialist about codes, requirements, standards, and inspections related to water storage for fire protection or dry hydrants in your location. Work with your local fire department to learn about requirements for proper access to the cistern and hydrant and what fittings should be installed to permit connection to the fire apparatus. The local fire department will note the location of the cistern in their pre-plans for wildland fires.

Climate

The U.S. Forest Service offers a website with interactive maps and charts to help communities explore wildfire risk in their location. Houses built in wildland-urban interfaces in hot and dry climates are especially susceptible to wildfire events and may benefit from the installation of a cistern for fire protection.

Specific wildfire risks vary by region and are dependent on topography, native vegetation, building styles, and the quality of state and local building codes. The Insurance institute for Business and Home Safety® (IBHS) provides regional guides that offer region-specific guidance, best practices, and voluntary standards for wildfire resistance.

Contact the local forestry agency or fire department to learn more about the specific wildfire risks where you are building.

Training

Compliance

Compliance

Consult the local or state fire agency or qualified fire management specialist about codes, requirements, and standards related to cisterns for fire protection.

International Wildland-Urban Interface Code (IWUIC)

NFPA 1142 – Standard on Water Supplies for Suburban and Rural Fire Fighting

NFPA 22 – Standard for Water Tanks for Private Fire Protection

Retrofit

Information provided for new homes in this guide also applies to existing homes where homeowners wish to add a cistern for fire suppression.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.