Scope

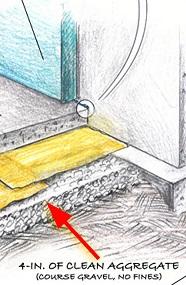

Install a capillary break beneath slab foundations (for example, a slab-on-grade or basement slab foundation) consisting of 4 inches of aggregate stone or 4 inches of sand covered by geotextile matting. Install a vapor barrier over this consisting of

- ≥ 6-mil polyethylene sheeting lapped 6-12 inches with seams sealed, or

- ≥ 1-inch extruded polystyrene rigid foam insulation with joints taped.

Seal the sheeting or foam at the joints with foundation walls and around posts or pipes coming up from the ground to provide a continuous vapor barrier.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Water gets through the foundation of most houses, either through bulk moisture leaks or through a process called capillary action. Once inside, the water can create significant problems for the home, including structural damage, mold, and poor indoor air quality.

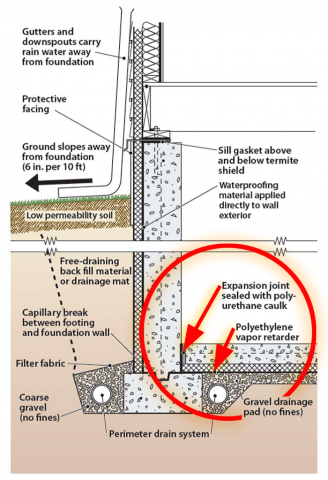

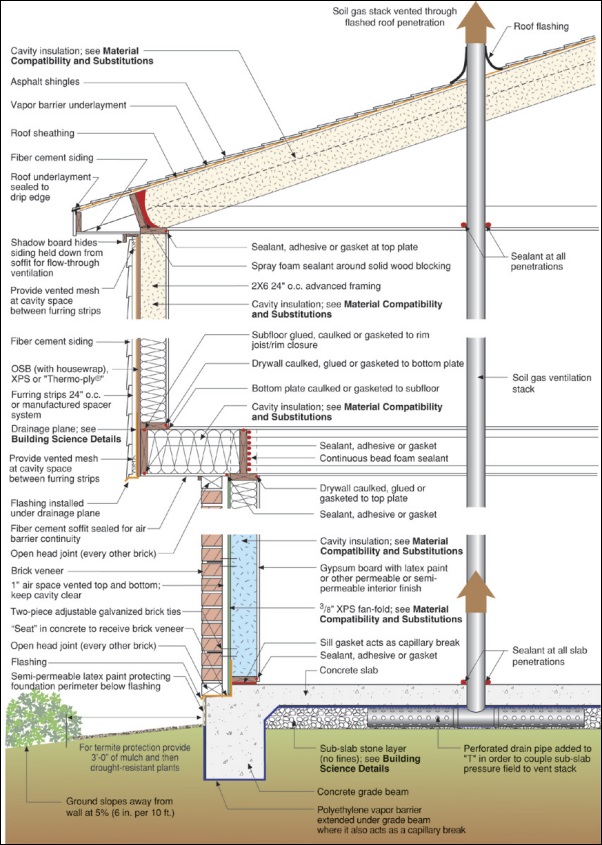

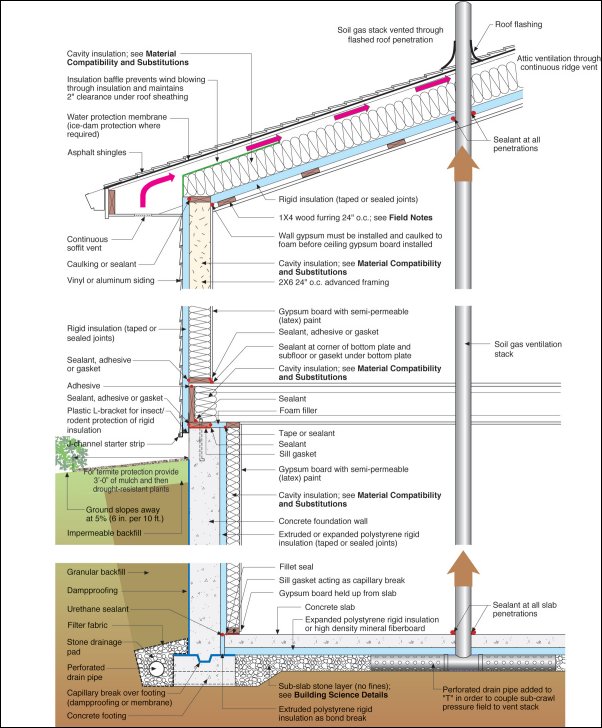

Bulk moisture is the flow of water through holes and cracks and is addressed in the guide Exterior Surface of Below-Grade Walls. Bulk water usually moves with gravity down and through foundation walls if large openings or cracks allow it to flow freely into the building. Capillary action occurs when liquid water wicks into the tiny cracks and open spaces of porous building materials such as masonry block, concrete, or wood (see Figure 1 and Figure 2). Capillary suction enables porous materials like concrete to wick water in any direction, including upwards against gravity, for surprisingly long distances. Capillary action in concrete is theoretically capable of pulling water upward as far as 6 miles (Lsibturek, 2014).

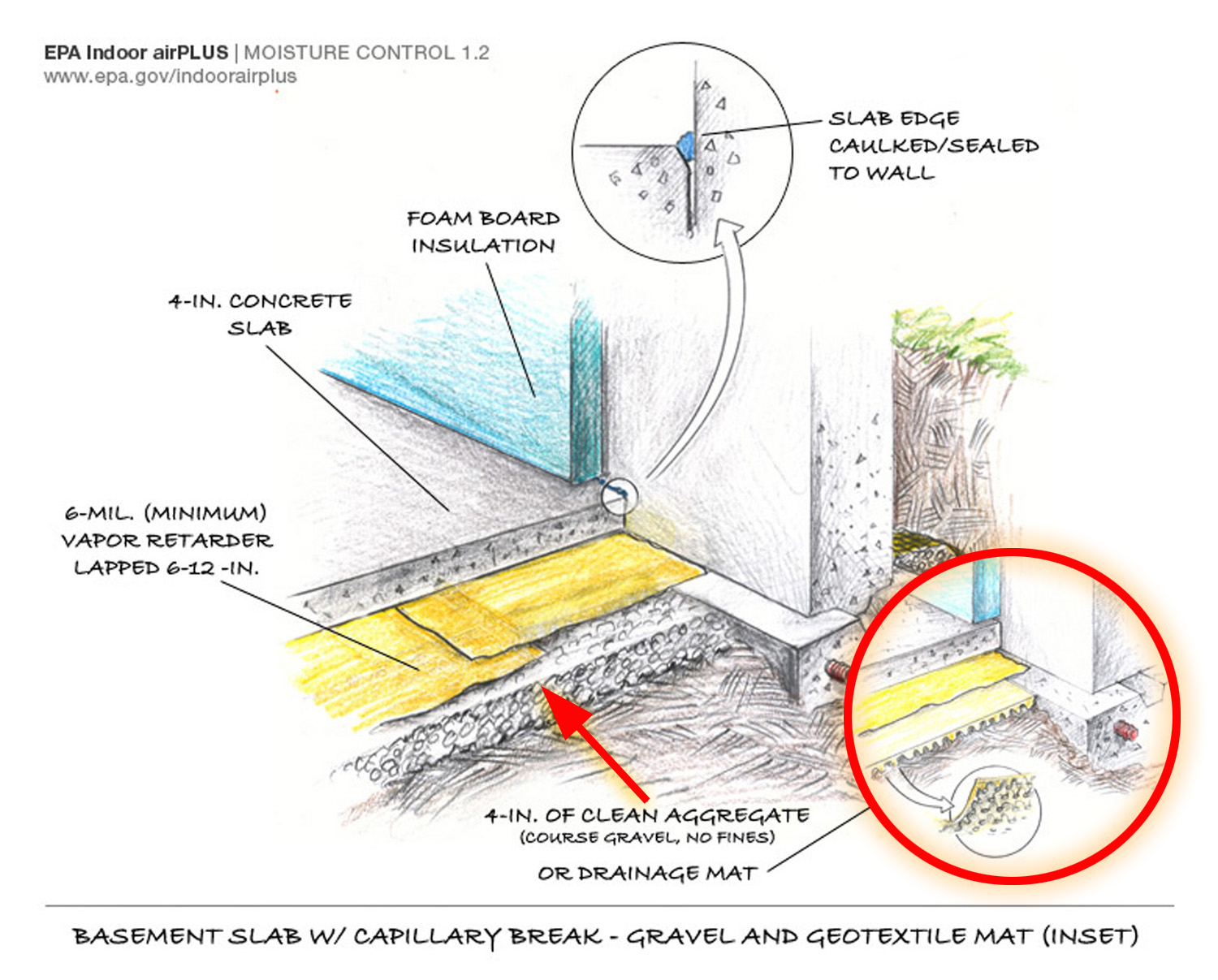

To establish a capillary break that will prevent water from wicking up into the basement or slab-on-grade foundation, the U.S. Environmental Protection Agency’s Indoor airPLUS Construction Specifications recommend builders install a drainage pad of either aggregate or sand and geotextile matting. The large spaces between the individual stones prevent capillary action from occurring. The geotextile matting material, which consists of waffle-like or dimpled high-density plastic sheet or a matrix of plastic wire, also has numerous air gaps that prevent capillary action from occurring. Both options are shown in Figure 3.

This base is then covered with a vapor barrier of either polyethylene sheeting or extruded polystyrene rigid insulation (EPA 2018).

Polyethylene sheeting is used here primarily as a vapor retarder but it also provides a capillary break. Polyethylene is sometimes used as the vapor barrier between the footing and stem wall to prevent “rising damp,” capillary action that can pull moisture up into the footing walls, as shown in Figure 2.

Rigid foam can also be installed, either over the polyethylene sheeting or directly on the aggregate to serve as a vapor barrier. As with the polyethylene sheeting, if the insulation serves as the vapor barrier, the joints between the insulation panels must be taped and sealed, and the concrete slab should be in direct contact with (poured directly on) the insulation or poly sheeting.

Some builders spray closed-cell spray foam directly onto the gravel base to serve as the vapor barrier, while providing an insulation layer under the slab.

How to Install a Capillary Break with Aggregate or Sand and Geotextile Matting

- Level the soil beneath the slab area.

- Install a bed of ½-inch diameter aggregate gravel to a consistent depth of 4 inches.

Or, distribute a 4-inch layer of clean sand evenly across the entire pad area. Lay the geotextile matting in strips across the entire area surface, making sure it is in contact with the foundation edges. - Install radon vent pipe in gravel or sand if desired or required.

- Install a vapor barrier consisting of polyethylene sheeting or polystyrene rigid insulation.

How to Install Polyethylene Sheeting as a Vapor Barrier

- Select at least 6-mil polyethylene sheeting as a minimum thickness.

- Place the polyethylene sheeting over the entire foundation area making sure it touches each perimeter wall (see Figure 3 and Figure 4). The polyethylene can be extended to serve as a capillary break under the footing of a slab-on-grade foundation (as shown in Figure 5) or between the footing and the stem wall (as shown in Figure 6).

- Lay the lengths of sheeting side-by-side and overlap the edges by at least 6 inches.

Tip: Overlap the polyethylene sheets by 12 inches to compensate for uneven cut lines. - Seal the sheets together at the overlap using either a continuous bead of acoustical sealant, butyl rubber, or butyl acrylic caulk, or with tape manufactured to seal or patch polyethylene such as some builder's tapes and tapes used to repair polyethylene greenhouses (EPA 2018).

- Seal around any penetrations through the sheeting such as plumbing or radon mitigation piping.

- Pour the concrete slab directly over the polyethylene (see Figures 5, 6, and 7) or install rigid foam and then pour the concrete slab (see Figure 4).

How to Install Polystyrene Rigid Insulation as a Vapor Barrier

- Lay the polystyrene rigid insulation over the entire foundation area, making sure it touches all perimeter walls. See Figure 8.

- Tape and seal the joints between insulation pieces.

- Tape around all piping that comes through the rigid foam insulation (see Figure 9).

- Pour the concrete slab over the sealed polystyrene insulation.

Success

It is critical that care be taken when installing and working around the polyethylene and/or rigid foam prior to pouring the foundation slab to maintain a complete, well-secured, and unbroken vapor barrier over the aggregate or sand and geotextile matting capillary break.

Climate

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Training

CAD

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

IBACOS, lead for IBACOS, a DOE Building America Research Team

U.S. Environmental Protection Agency

Sales

Foundation Capillary Break over Aggregate = Foundation Floor Water Barrier

Without an effective moisture barrier, water can penetrate the pores of a concrete foundation slab, which can potentially lead to moisture-related issues. To prevent moisture from wicking up into the concrete slab and foundation walls, a water-proof layer is installed under the concrete consisting of 6-mil plastic sheeting overlapped and taped at the seams or soil-contact-rated rigid foam taped at all seams. Under this barrier is a 4-inch layer of gravel to help moisture drain away. In crawlspaces, plastic sheeting should installed over the dirt floor.