Scope

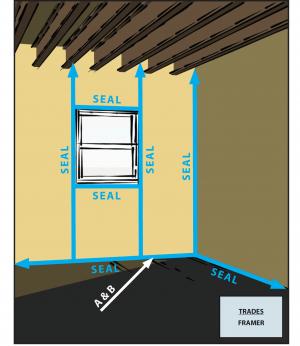

Seal all seams between Structural Insulated Panels (SIPs) with foam and/or tape per manufacturer’s instructions.

- Apply manufacturer-approved sealant inside the joints of all panels and at the sub-floor or foundation connections.

- When applying tape to walls, center it on the joints and provide overlap of tape to meet manufacturer’s specifications.

- When applying tape to roof panels, start from the lowest point of the panel and continue upward.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

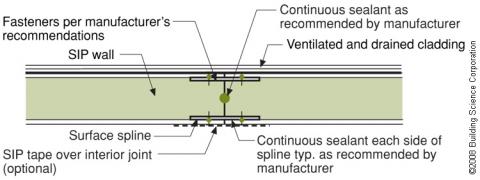

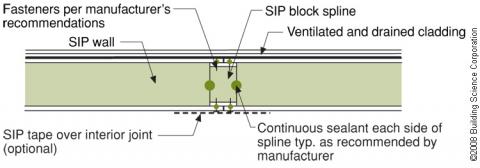

SIPs consist of two layers of plywood or OSB that “sandwich” an inner core of insulating rigid foam. Panels are spliced together using splines, consisting of strips of OSB, SIPs, or 2x4 or 2x6 lumber. The seams where one panel joins another are susceptible to air leakage. To form an air tight bond, spray foam or caulk is applied to the seams before the panels are connected. Many SIP manufacturers will provide the caulk and instructions. The wall-floor, wall-wall, and wall-roof seams can each require as many as six beads of caulk, and the roof ridge seam can require up to 8 beads of caulk.

After caulking, the panels are fit together to assemble the structure. To ensure that joints lock tightly together, a belt winch can be used to pull wall assemblies together; this is especially helpful with larger panels. Before drywalling, the seams can be covered with peel and stick tape as a second layer of protection against air leakage. Before installing drywall is also an ideal time to test the air tightness of the seams with a blower door test and smoke pencil to visually identify the location of any leaks.

Air barrier effectiveness is measured at the whole-house level. High-performance branding programs and the 2009 International Energy Conservation Code (IECC) require that builders meet specified infiltration rates at the whole-house level. See the “compliance” tab for these specified infiltration rates.

For more information on SIP installation, see Structural Insulated Panels.

How to Seal SIP Seams

- Connect the panels with splines. The three most common splines are surface splines, insulated splines, and structural spines (see Figures 1, 2, and 3). To minimize thermal bridging, only use structural splines when needed to carry the structural load. Splines can be installed on one side of the panel in the factory; this can save assembly time at the site.

- Caulk on each side of the spline. Use caulk from the manufacturer, if provided. Follow the caulking schedule required by the SIP manufacturer for the number of beads of caulk to use at each type of seam. Make sure the beads are continuous. Consider using a power caulker; even in a small (1,200 sq. ft.) home, the amount of caulk required can total over 5,000 lineal feet of caulk.

- Assemble the walls and roof. Use a fork lift and crane to place panels. Use lift plates and a belt winch (available from the manufacturer) to pull panels together tightly, if needed (Figure 4).

- Install peel-and-stick tape at panel-to-panel seams and at the ridge and wall-roof interface (See Figure 5).

- Prior to drywalling, conduct a blower door test and use a smoke pencil to ensure that panel seams are tight (Figure 6).

Success

The air tightness of the envelope assembly of a home constructed with structural insulated panels can be easily tested by conducting a whole-house blower test prior to dry wall installation. While the house is depressurized, inspect all panel seams with a smoke stick. An infrared camera may also be helpful in spotting air leakage, if a sufficient temperature difference exists between the outside and the inside of the home.

Climate

No climate-specific information applies.

Training

CAD

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

Sales

Structural Insulated Panels (SIPs) = SIP Thermal Blanket

Structural insulated panels (SIPs) are a sandwich made up of foam insulation glued between two layers of sheathing (e.g., oriented strand board, magnesium oxide board, or drywall). SIP wall and roof panels are produced in a factory and come to the job site clean, dry, straight, and precisely made to the wall dimensions specified in the house plans with precut openings for doors and windows. They assemble quickly, producing a sturdy, well-sealed, well-insulated structure. Because there is minimal to no framing, the foam core provides a nearly continuous thermal blanket around the entire structure so heat transfer through the framing is greatly reduced.