Scope

Seal seams and holes in the air handler or furnace cabinet of central forced air HVAC systems to prevent the loss of conditioned air.

- Select an air handler with a manufacturer’s designation showing that air leakage is ≤2% of the design air flow rate.

- Use mastic, mastic plus embedded fiberglass mesh fabric, or UL 181A or B tape to seal all cabinet seams and junctures between the air handler or furnace cabinet and the evaporator coil cabinet, the supply plenum and the return plenum.

- Use putty around all conduit and wiring holes.

- Use UL-approved gaskets to seal cabinet doors and access panels.

- Seal all unused conduit knockouts with UL-listed tape or mastic.

- Seal all fixed seams in the cabinets and all seams between the cabinet and the supply or return plenums with mastic or mastic and fiberglass mesh fabric.

- Use a sealing putty to seal the inside of the high-voltage wire conduit termination point in the air handler after the wiring has been installed.

- Check the insulation inside the air handler where the conduit enters. If the insulation has been compromised, repair it with approved spray glue and additional insulation.

- Use a duct blower tester to test the airtightness of the air handler/furnace cabinet and ducts. Verify that the duct system meets code or program airtightness requirements.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Many homes are equipped with central forced air systems that rely on ducts to transport heated or cooled air from a furnace or heat pump to the rest of the home. If the ducts are leaky, they can be a source of energy loss through loss of heated or cooled air, poor HVAC performance through loss of air pressure in the ducts, and comfort problems. Air leakage problems can be worst at the HVAC furnace or air handler cabinet, where air pressures are highest. Cabinet seams, holes, and junctions should be sealed to prevent air leakage. The only place air should be able to leave the supply duct system and the furnace or air handling unit is at the supply registers. The only place air should be able to enter the return duct system and the furnace or air handling unit is at the return grilles (Building Science Corporation 2009).

In high-performance homes, all HVAC equipment, including the furnace or heat pump air handler and any ducts, should be located within the thermal envelope of the home. When the air handler is located within the conditioned space, it is tempting to think that sealing the cabinet is not that important because conditioned air will leak into the home rather than being lost to an attic or crawlspace. However, sealing cabinet air leaks is still very important for maximizing the performance of the HVAC equipment because it helps to ensure maximum air flow to the ducts. In a central forced air system, the highest air pressures are experienced at the air handler, with pressures increasing the closer one gets to the air handler fan. It is common for air pressures in the supply and return plenum at the air handler to equal or exceed 0.5-inches water column (125 Pascals). Therefore, it is critical to seal up the knockouts, seams, and slots in the air handler cabinet.

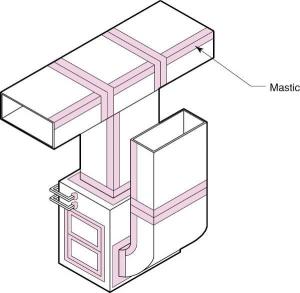

Gas- or oil-fired furnaces are often equipped with an add-on refrigerant coil (called the evaporator coil) to provide cooling during the summer months (Figure 1). The connection between the evaporator coil cabinet and the furnace cabinet is likely the highest point of pressure in the system and can be a large source of leakage if care is not taken to properly seal this juncture during installation. Refrigerant coil cabinets do not always fit directly on top of the furnace; many coil cabinets have a larger footprint than the furnace so the seam between the two boxes is uneven. The coil cabinet should be sealed to the furnace using mastic or an Underwriters Laboratories (UL) 181 approved foil tape. For larger gaps (greater than 3/8 inch) mastic and fiberglass mesh tape should be used.

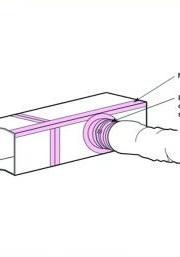

Air handlers (Figure 2), furnaces, and evaporator coil cabinets come from the factory with holes in the form of knockouts, penetrations, and slots for installing piping and wiring. These holes are there for ease of installation and service. However, when installation is completed, any unused holes should be sealed, along with gaps around wiring and piping. Holes where the condensate line and refrigerant lines penetrate the evaporator coil cabinet will be the next highest pressure point, and depending on the model may be a point of negative pressure. Seal around these lines with non-hardening putty. Use non-hardening putty to seal around pipes, tubing, and conduit penetrations in the air handler cabinet as well. This putty comes in strips, slugs, and cords (see Figure 3) and does not dry out, but remains pliable so it can be removed and reapplied. Seal unused electrical and piping knockouts with mastic.

The third point of high (negative) pressure is the area of the cabinet that houses the indoor blower fan. With respect to indoor air quality, this may be considered the most concerning area for air leakage, especially if the furnace is located in a garage or any other area where chemicals are stored or where there is exposure to carbon monoxide. Any seams or unused holes should be sealed with mastic.

The connections with the supply and return plenums are additional areas that experience high pressures. These seams and other cabinet seams should be sealed with mastic, mastic and fiberglass mesh tape, or UL-approved tape.

There are some penetrations in a furnace cabinet that are not considered leakage points. The furnace in Figure 1 is a condensing gas furnace. The penetrations for the condensate line for the condensing gas furnace, vent pipes, gas line, and high voltage wiring (not shown) are not connected to the conditioned air stream and therefore are not areas of concern for leakage.

Regarding cabinet panels that must be periodically removed for routine maintenance of the HVAC equipment, some HVAC technicians suggest using cloth-backed duct tape to seal the panel seams because it is easy to remove or cut through.

How to Air Seal the HVAC Cabinet

- Install the furnace or air handler and all associated ducting within the conditioned space of the home. Select an air handler with a manufacturer’s designation showing that air leakage is no more than 2% of the design air flow rate when tested in accordance with ASHRAE 193 (per 2012 IECC R403.2.2.1).

- Use Underwriters Laboratory (UL) approved gaskets, mastic, mastic plus embedded fiberglass mesh fabric, or UL 181A or B tape to seal all cabinet seams and junctures between the air handler or furnace cabinet and the evaporator coil cabinet, the supply plenum and the return plenum.

- Use putty around all conduit and wiring holes.

- Seal all unused conduit knockouts with UL-listed tape or mastic. Seal all fixed seams in the cabinets and all seams between the cabinet and the supply or return plenums with mastic or mastic and fiberglass mesh fabric.

- Use a sealing putty to seal the inside of the high-voltage wire conduit termination point in the air handler after the wiring has been installed.

- Check the insulation inside the air handler where the conduit enters. If the insulation has been compromised, repair it with approved spray glue and additional insulation.

- Use a duct blower tester to test the airtightness of the air handler/furnace cabinet and ducts. Verify that the duct system meets code or program airtightness requirements.

Success

Install the air handler within the conditioned space of the home.

Seal all seams and holes in the air handler cabinet.

Test the airtightness of the cabinets and ducts with a duct blower test. Verify that the duct system meets code or program airtightness requirements.

Climate

No climate specific information applies.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Tight Duct Sealing =

As conditioned air flows from heating and cooling equipment to the spaces where people live, excessive leaks compromise comfort, health, and durability while increasing energy costs. This is because conditioned air escapes ducts supplying heating and cooling, and potentially contaminated air is pulled into the ducts, returning air to the heating and cooling equipment. Professionally sealed comfort delivery systems are significantly air-tight at all seams and connections. Sealing helps conditioned air get where it is needed, at the correct temperature, without pulling in contaminants from crawlspaces and attics.