Showing results 1 - 47 of 47

Closed-cell foam is sprayed into roof cavities along the masonry parapet wall to form a continuous air barrier between the wall and the sheathing of the flat roof

Closed-cell spray foam fills the roof joist cavities forming an air barrier between the masonry parapet wall and the roof sheathing

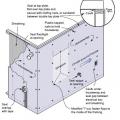

House wrap is sealed at all seams and overlaps flashing to serve as a continuous drainage plane over the exterior walls.

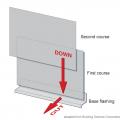

Install all layers of the drainage plane to overlap, not underlap, to direct bulk water down and out of the wall.

New coated OSB roof sheathing is installed over the existing sheathing of the flat roof and taped at the seams to provide a continuous air barrier

Right - House wrap is overlapped “shingle” style to direct moisture down and away from the house; seams will be taped so house wrap serves as both an air and weather barrier.

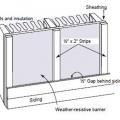

Right - This cedar siding is installed over furring strips which allow an air and drainage gap behind the siding.

Right – The building felt is installed on all exterior walls and provides a complete drainage system

Right – The rigid insulation covers all exterior walls and all seams are taped to provide a complete drainage system

Right – The water-resistant barrier covers the entire house and the seams are taped to provide a complete drainage system

Right – Vertical and horizontal furring strips are installed over a breathable membrane weather resistant barrier to create an air gap and drainage plane behind the wood siding that will be installed next.

Roofing paper protects the top of the new plywood parapet while the base of the parapet is air sealed with spray foam and fibrous insulation is installed in the rafter cavities in this flat roof retrofit

The base of the plywood parapet is air sealed with spray foam and fibrous insulation is installed in the rafter cavities in this flat roof retrofit

The black coating on these walls is a liquid-applied asphalt-based air and moisture barrier.

The windows in this building are connected to the fully adhered water and air control layer using fluid-applied flashing

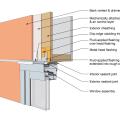

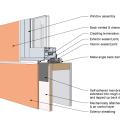

This drawing shows key head details for a window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer

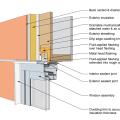

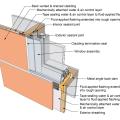

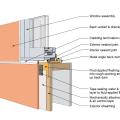

This drawing shows key head details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer

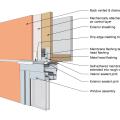

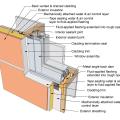

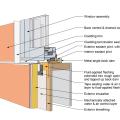

This drawing shows key head details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer and continuous insulation

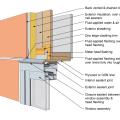

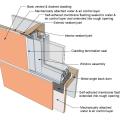

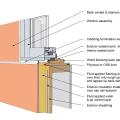

This drawing shows key head details for a window installation using a self-adhered membrane tape flashing on a wall with a mechanically attached water and air control layer

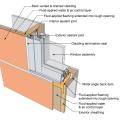

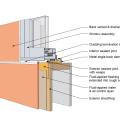

This drawing shows key head details for an “outie” window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer and continuous insulation

This drawing shows key jamb details for a window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer

This drawing shows key jamb details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer

This drawing shows key jamb details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer and continuous insulation

This drawing shows key jamb details for a window installation using a self-adhered membrane tape flashing on a wall with a mechanically attached water and air control layer

This drawing shows key jamb details for an “outie” window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer and continuous insulation

This drawing shows key sill details for a window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer

This drawing shows key sill details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer

This drawing shows key sill details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer and continuous insulation

This drawing shows key sill details for a window installation using a self-adhered membrane tape flashing on a wall with a mechanically attached water and air control layer

This drawing shows key sill details for an “outie” window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer and continuous insulation

This farmhouse was retrofit by removing the existing siding and adding taped insulated sheathing and battens before installing new siding

This house design in the Hot-Humid climate uses a slab foundation, masonry walls, and an Exterior Insulation Finish System (EIFS) cladding.

Windows are installed as “outies” in this wall assembly using a self-adhered membrane water and air control layer with continuous exterior insulation

Wrong – The rigid sheathing seams are not taped and the gaps could cause moisture problems

Wrong – The water-resistant barrier is not complete and the holes and gaps could cause moisture problems

Wrong – There is not a water-resistant barrier installed underneath the exterior finish of the walls