Showing results 401 - 500 of 1073

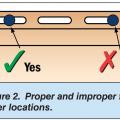

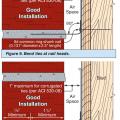

Lay out the rigid foam sheathing joints so they do not align with the window and door edges

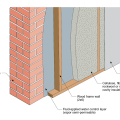

Ledger board, metal brackets, and vertical 2x4s have been installed in preparation for exterior spray foam in this retrofit exterior wall insulation technique

Lifting plates attached to the wall provide good bracing to tighten up SIP panel seams

Light colors have been used on exterior walls and roofs to keep buildings cooler in hot climates for centuries, as shown by this traditional building in Morocco, built in the early 1800s

Limited attic access can make inspections for missing air barriers and insulation challenging

Limited attic access may make it necessary to use a bore scope when inspecting for missing air barriers and insulation in existing buildings.

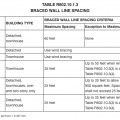

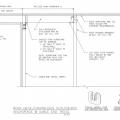

Location of Braced Wall Panels and Braced Wall Lines, Figure R602.10.2.2 in the IRC

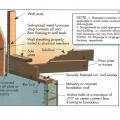

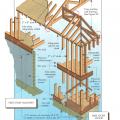

Lower-story wall anchorage to masonry (or concrete) base. Straps properly nailed at wall studs.

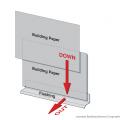

Make sure the beads of caulk are continuous the full length at each SIP panel seam, such as at the wall-roof seam, to maintain air barrier continuity

Manatee County Habitat for Humanity trains its volunteers to construct homes made of construct insulated concrete forms (ICFs).

Many older brick homes are made with unreinforced solid masonry walls that are susceptible to collapse in an earthquake

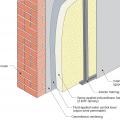

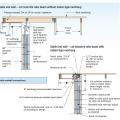

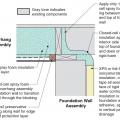

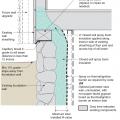

Masonry wall interior retrofit with fluid-applied water control layer and wood-framed wall with cavity insulation (climate zones 1-4 only)

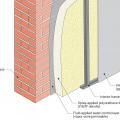

Masonry wall interior retrofit with fluid-applied water control layer, mineral wool rigid foam, and wood or metal stud service cavity (climate zones 1-4 only)

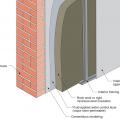

Masonry wall interior retrofit with fluid-applied water control layer, spray foam, and wood or metal stud service cavity

Masonry wall interior retrofit with parge coat, fluid-applied water control layer, mineral wool rigid foam, and wood or metal stud service cavity (climate zones 1-4 only)

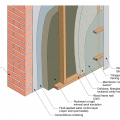

Masonry wall interior retrofit with parge coat, fluid-applied water control layer, rigid mineral wool, wood-framed wall with cavity insulation, smart vapor barrier, and wood or metal service cavity

Masonry wall interior retrofit with parge coat, fluid-applied water control layer, spray foam, and wood or metal stud service cavity

Masonry wall interior retrofit with parge coat, fluid-applied water control layer, wood-framed wall with cavity insulation, smart vapor barrier, and wood or metal service cavity

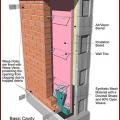

Masonry walls can be insulated with rigid foam insulation attached to the interior face of the concrete block as shown here.

Mineral wool batts are precisely cut to fit around electrical boxes in the wall cavities, preventing cold spots in walls.

Moisture from sprinkler seeped through the concrete block causing water stains and mold inside.

Moisture levels are checked in the blown cellulose insulation before enclosing the walls.

Moisture-resistant plastic and fiber cement exterior trim and cladding are indistinguishable from wood building elements.

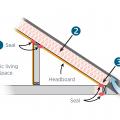

One way to air seal and insulate kneewalls – add insulation and a rigid air barrier along roof line of unconditioned attic space outside kneewall

Over the taped rigid foam board, 2x4 furring strips provide a ventilating air gap and drainage plane under the engineered wood lap siding. The furring strips were attached with structural screws to provide an attachment surface for the siding.

Peel-and-stick panel tape provides added assurance that SIP panel seams will remain airtight

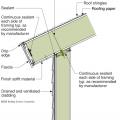

Place first shingle and next section of sidewall flashing over upper edge of diverter

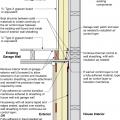

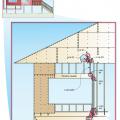

Plan view (from above) showing how the existing garage wall gypsum board is cut away to air-seal the shared wall before adding rigid foam insulation on the garage and exterior walls of the home.

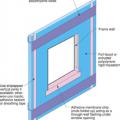

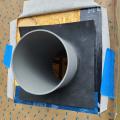

Plan view of electric box installation in exterior wall showing flashing and air sealing details

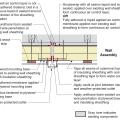

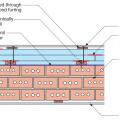

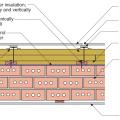

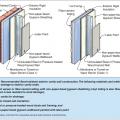

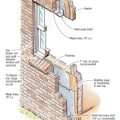

Plan view of exterior masonry brick wall retrofitted with furring strips, three layers of rigid foam insulation staggered and taped at the seams, and 1x4 furring strips to provide a nailing surface and ventilation gap under lap siding

Plan view of exterior masonry brick wall retrofitted with furring strips, three layers of rigid mineral wool insulation staggered and taped at the seams, and topped with metal hat channel providing a ventilation gap surface to nail under the lap siding

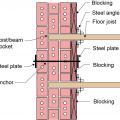

Plan view showing seismic strengthening of brick wall by anchoring the embedded wood floor joists with solid wood blocks attached to the floor joists with steel angles and to the masonry wall with through-wall anchors and steel plates

Polyethylene completely covers the floor of this crawlspace and is attached to the walls and piers as well

Polyethylene is being attached to the crawlspace floor and walls with plywood furring strips

Possible failure scenarios due to house sitting on poorly braced and secured cripple wall

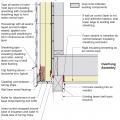

Proper flashing around windows is especially important when the rigid foam serves as the drainage plane in the wall

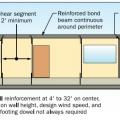

Properly reinforce masonry walls in coastal locations to resist high winds and waves.

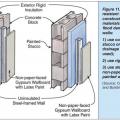

Recommended flood resistant wall construction for concrete block walls with stucco or brick veneer.

Reduce thermal bridging in hot climate zones by using an intersecting exterior wall framing technique as shown here.

Redundant moisture barriers including siding, house wrap, and coated sheathing can help protect walls from excess moisture, while vapor retarders prevent vapor from entering the wall from the house, for example from a bathroom or kitchen.

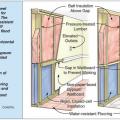

Retrofit of cantilevered foundation wall showing details at the inside corner for installing closed-cell spray foam in the wall and overhanging floor

Retrofit of cantilevered wall showing details at the inside corner for installing air sealing and rigid foam insulation in the wall and overhanging floor

Retrofit of cantilevered wall showing details at the outside corner for installing air sealing and rigid foam insulation in the wall and closed-cell spray foam in the overhanging floor

Retrofit of cantilevered wall with beam showing details at the outside corner for installing air sealing and rigid foam insulation in the wall and overhanging floor

Retrofit of cantilevered wall with beam showing details at the outside corner for installing air sealing and rigid foam insulation plus water control membrane in the wall and overhanging floor

Right – The ties are bent at a 90 degree angle at the nail head and embedded into the mortar joint at least 1.5 inches.

Right - Covered porches protect the south-facing windows and doors of this building from solar heat gain.

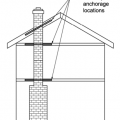

Right - A continuous load path connects the roof and wall framing to the foundation.

Right - A drywall gasket is installed along the top plate before installed drywall.

Right - A floor-to-floor hold down can be installed as a retrofit without removing the siding.

Right - A hand saw is used to remove wall material for a small through-the-wall HRV; 6 of 14.

Right - A hole is drilled into the wall for installation small through-the-wall HRV; 5 of 14.

Right - A small through-the-wall HRV duct is installed in an exterior wall; 7 of 14.

Right - A smart vapor barrier wraps the walls and window frames of this home. Seams are taped to provide an air- and water-resistant barrier.

Right - A termite shield and a sill gasket are installed between the sill plate and the foundation on a raised slab foundation.

Right - An EPDM gasket is installed around an HRV duct installed in an exterior wall; 9 of 14.

Right - Anchorage to increase the wind uplift resistance of outlookers forming the overhang at a gable end truss wall.

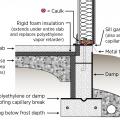

Right - Basement slab with a capillary break of either gravel or a drainage mat.

Right - Below-grade concrete has been properly sealed against moisture and is now having insulation installed.

Right - Braced wall line spacing is correctly calculated for determining wall bracing in accordance with the IRC.

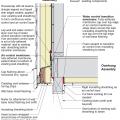

Right - Brick veneer is installed with a 1-inch air space behind the brick, metal flashing and weep holes above and below the windows and at the base of the wall to direct out water that gets behind the brick.

Right - Closed-cell spray foam covers the interior of the foundation wall and wall framing is placed to the inside of the spray foam.

Right - Closed-cell spray foam insulation fills the wall cavities of the exterior walls in this home retrofit

Right - Closed-cell spray foam is installed as a skim coat to provide air tightness to an exterior wall cavity before installing batt or blown cavity insulation.

Right - Closed-cell spray foam is used to retrofit an existing rubble basement foundation wall.

Right - Closed-cell spray foam was applied to the interior of a foundation wall.

Right - Dovetail-shaped plastic mesh is installed to collect mortar droppings at the base of the wall to keep weep holes from being clogged.

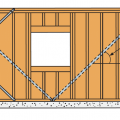

Right - Engineered portal frames are used for wall bracing to resist wind and earthquake loads.

Right - Engineered structural screws are installed to secure a stud to a top and bottom plate for increased hurricane or seismic resistance.