Showing results 1 - 50 of 50

A paint-on flashing is used around the windows and doors for seamless water protection.

A piece of siding is used as sill extension and to provide slope in the opening for the window, which is deeper because exterior rigid foam has been added

Before installing the windows, the window rough openings are sealed with a liquid-applied flashing that provides a seamless moisture and air barrier to protect the wall from water intrusion.

Proper flashing around windows is especially important when the rigid foam serves as the drainage plane in the wall

Right - Corners of window are protected with draining house wrap that laps onto the sides of the window trim, paint-on flashing at window trim corners, and self-adhered flashing to reinforce corners.

Right - Tape flashing keeps moisture out around and below the window; extra tape reinforces the corners to prevent tearing of the house wrap and to keep water out of this critical juncture.

Right – A flexible flashing product is installed around the corners of the window sill before installing the windows.

Right – A metal flashing was installed behind the first row of siding above the windows to guide water over the trim.

Right – The flashing is properly installed to create a complete drainage system with continuous rigid insulation sheathing/siding

Right – There is flashing installed along the top of the window and the water-resistant barrier is layered over to create a complete drainage system

Right – Windows are installed and flashed in the factory for these modular homes.

The fluid-applied asphalt coating provides a weather-resistant, moisture resistant layer around the house, serving as a continuous drainage plane and flashing for window and door openings.

The tape window flashing here is integrated with the roller-applied weather-resistant barrier.

The windows in this building are connected to the fully adhered water and air control layer using fluid-applied flashing

This drawing shows key head details for a window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer

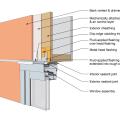

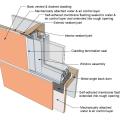

This drawing shows key head details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer

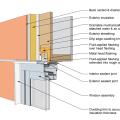

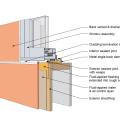

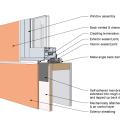

This drawing shows key head details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer and continuous insulation

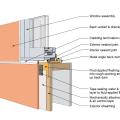

This drawing shows key head details for a window installation using a self-adhered membrane tape flashing on a wall with a mechanically attached water and air control layer

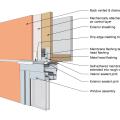

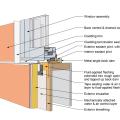

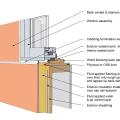

This drawing shows key head details for an “outie” window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer and continuous insulation

This drawing shows key jamb details for a window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer

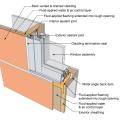

This drawing shows key jamb details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer

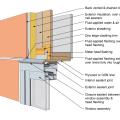

This drawing shows key jamb details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer and continuous insulation

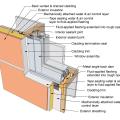

This drawing shows key jamb details for a window installation using a self-adhered membrane tape flashing on a wall with a mechanically attached water and air control layer

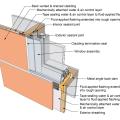

This drawing shows key jamb details for an “outie” window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer and continuous insulation

This drawing shows key sill details for a window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer

This drawing shows key sill details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer

This drawing shows key sill details for a window installation using a fluid-applied flashing on a wall with a mechanically attached water and air control layer and continuous insulation

This drawing shows key sill details for a window installation using a self-adhered membrane tape flashing on a wall with a mechanically attached water and air control layer

This drawing shows key sill details for an “outie” window installation using a fluid-applied flashing on a wall with a fluid-applied water and air control layer and continuous insulation

Windows are installed as “outies” in this wall assembly using a self-adhered membrane water and air control layer with continuous exterior insulation

Wrong - House wrap was poorly installed, seams were not taped, and flashing tape was not installed around windows.

Wrong - House wrap and flashing tape are poorly installed allowing water to get into the gaps behind flashing tape.

Wrong - House wrap tape is not fully adhered at seam and flashing tape is missing from window head, jamb, and corner above window.

Wrong - Stucco has rotted and cracked above a window because of water damage due to lack of proper flashing and drainage.

Wrong - There is no step flashing along the base of the gable and the right window is missing sill trim.

Wrong - Water has gotten behind the paint, possibly due to lack of window flashing, leading to blistering.

Wrong - Window is missing pan flashing under sill and tape flashing at jamb end sill.

Wrong – The corners are not properly flashed, leaving a vulnerable area in the drainage system