Showing results 51 - 100 of 139

Provide a continuous air barrier from the rigid foam below the crawlspace floor joists to the rim joist to the exterior wall above

Right - A technician wraps the foundation piers with a vapor retarder in preparation for laying vapor retarder over the floor of this crawlspace.

Right - After wrapping the posts, a technician lays a vapor retarder over the floor of a crawlspace.

Right - Air barrier is present and installed between the floor system and unconditioned space.

Right - All seams in the HVAC equipment and ductwork are sealed with mastic; because the HVAC equipment is in the garage, it is an air-sealed closet.

Right - An installer uses canned spray foam to air seal joints in an existing subfloor.

Right - Potential locations for crawlspace insulation: vapor sheeting should always cover the floor with insulation (a) outside walls, (b) inside walls, (c) both sides of walls, (d) sandwiched inside walls, or (e) under the first floor.

Right - Spray foam covers the walls and a sealed vapor retarder lines the floor of this unvented crawl space.

Right - Spray foam insulates and air-seals the stone walls of this unvented crawlspace.

Right - Technicians use adhesive when installing the vapor barrier along the walls of this crawlspace.

Right - The butterfly damper of this crawlspace supply register opens when the HVAC fan is running; the damper duct is sealed with mastic and supported by strapping.

Right - The posts and floor of this crawlspace are covered with a heavy sheet of vapor retarder that is sealed to the post, the walls, and at all seams.

Right - The sealed conditioned crawlspace provides a clean, dry, and temperate environment for the home’s supplemental dehumidifier.

Right - the vapor barrier is extended up the sides of the piers in this crawlspace, which is sealed and insulated to house the HVAC ducts.

Right - This crawlspace, which is insulated on the floor, has a complete vapor barrier over the floor and up the walls that is sealed at all seams and termite inspection gap at the top of the vapor retarder.

Right - This unvented crawlspace is insulated along interior walls with rigid foam and air-sealed by covering the floor with vapor retarder that is sealed to the rigid foam which is taped at the seams.

Right - This unvented crawlspace is insulated along the walls and between the floor joists with 2-inch foil-faced polyisocyanurate; a termite inspection gap is visible above of the wall insulation and below the band joist.

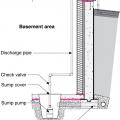

Right – A sump pump with a perforated sump pit was installed in the crawlspace slab to reduce water accumulation under the slab

Right – Air vents near the top of the crawlspace wall are not used as flood vents, and flood vents are installed close to grade

Right – Because this home is in a coastal location that may flood the crawlspace is vented and the home is constructed on metal piers.

Right – Foil-faced insulation was added after the crawlspace was dried and sealed by diverting water runoff, sealing off crawlspace windows and vents, and adding sump pumps and exhaust fan ventilation

Right – Foundation drainage mat was installed over the waterproof membrane that covers the sealed crawlspace window

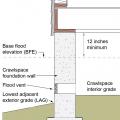

Right – Interior grade is elevated and flood vents are located slightly above interior grade

Right – Polyethylene sheeting vapor barrier is installed and sealed to the crawlspace walls with mastic

Right – Spray foam insulation was sprayed onto the ground and along the sides of the foundation walls and piers of this insulated crawl space.

Right – This crawlspace window was completely sealed off on the inside and outside with air barrier and water-proof materials and the window well was filled in to an above-grade height to prevent bulk water from entering the crawlspace

Right--A heavy polyethylene sheet covers the floor of this crawlspace providing a capillary break and vapor barrier to keep soil gases out of the house.

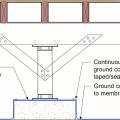

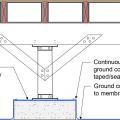

Right--The polyethylene ground cover for this insulated crawlspace is taped at seams and around posts before the insulation and slab are installed.

Rigid foam insulation and a thin slab were installed over the dirt and gravel of this sealed crawlspace

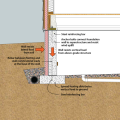

Rigid foam insulation applied to the crawlspace walls, allowing a 3-in. pest control inspection strip at the top

Seal all penetrations through the band joist

Seal the crack between the sill plate and the foundation wall

The floor of the sealed insulated crawlspace is covered with a heavy plastic vapor-barrier sheathing that is taped at all seams and around the foundation piers to prevent water vapor from moving into the crawlspace.

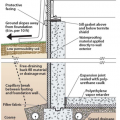

The goal of foundation moisture management is to construct the basement, crawlspace, or slab in a way that keeps moisture from getting in in the first place

The polyethylene ground cover in the crawl space is lapped up sides of piers to posts to provide a continuous air and vapor barrier

The polyethylene ground cover in the crawlspace is continuous at interior posts and piers

The risk of hydrostatic pressure differences in a flood is reduced when the interior grade of the crawlspace is higher or equal to the exterior grade.

The sealed, insulated crawlspace is a clean, dry location to house the main floor heating ducts and also provides bonus storage space.

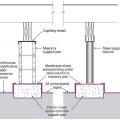

The top course of these concrete masonry unit (CMU) crawlspace foundation walls and piers is filled with grout then sprayed with a waterproofing membrane that acts as a capillary break and prevents moisture from migrating into the framing material.