Showing results 1 - 48 of 48

An exhaust fan pulls damp air out of a retrofitted sealed crawlspace while drawing in dry air from the living space

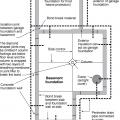

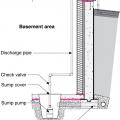

Basement plan showing sump pump location and perimeter drain that empties to the sump pit

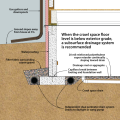

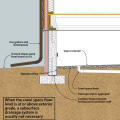

Because the above-grade potions of the wall lack exterior insulation, condensation and even ice form during cold winter conditions

Before sealing and insulating the crawlspace, the windows were sealed, the window wells backfilled, and sumps pumps were installed that discharged to the gutter downspouts

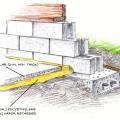

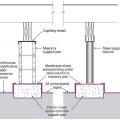

Capillary break at all crawlspace floors using > 6 mil polyethylene sheeting, lapped 6-12 in., and secured in the ground at the perimeter using stakes

Capillary break at all crawlspace floors using ≥ 6 mil polyethylene sheeting, lapped 6-12 in., and lapped up each wall or pier and fastened with furring strips or equivalent

Capillary break at all crawlspace floors using ≥ 6 mil polyethylene sheeting, lapped 6-12 in., and placed beneath a concrete slab

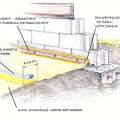

Comprehensive above-grade water management details for a crawlspace foundation include a capillary break over the crawlspace floor, slope the surface grade away, installing gutters that slope away, and capillary break under sill plate.

Comprehensive water management features include a capillary break (≥ 6-mil polyethylene sheeting) at all crawlspace floors

Exterior XPS basement insulation is correctly installed to completely cover the foundation wall

Foil-faced rigid foam and spray foam can be used to insulate a basement on the interior; use good moisture management techniques to keep the basement dry

ICF bricks are stacked to form hollow walls that are reinforced with steel rebar before the concrete is poured in

Right – A sump pump with a perforated sump pit was installed in the crawlspace slab to reduce water accumulation under the slab

Right – Because this home is in a coastal location that may flood the crawlspace is vented and the home is constructed on metal piers.

Right – Foil-faced insulation was added after the crawlspace was dried and sealed by diverting water runoff, sealing off crawlspace windows and vents, and adding sump pumps and exhaust fan ventilation

Right – Foundation drainage mat was installed over the waterproof membrane that covers the sealed crawlspace window

Right – Polyethylene sheeting vapor barrier is installed and sealed to the crawlspace walls with mastic

Right – This crawlspace window was completely sealed off on the inside and outside with air barrier and water-proof materials and the window well was filled in to an above-grade height to prevent bulk water from entering the crawlspace

Right--A heavy polyethylene sheet covers the floor of this crawlspace providing a capillary break and vapor barrier to keep soil gases out of the house.

Right--The polyethylene ground cover for this insulated crawlspace is taped at seams and around posts before the insulation and slab are installed.

The top course of these concrete masonry unit (CMU) crawlspace foundation walls and piers is filled with grout then sprayed with a waterproofing membrane that acts as a capillary break and prevents moisture from migrating into the framing material.

Water-proof materials cover the exterior side of crawlspace windows in a crawlspace retrofit, while foil-faced rigid foams seals and insulates the inside face of the openings

Wrong - A typical vented crawlspace in North Carolina exhibits water leakage, poor drainage, and a low-quality vapor retarder that does not cover all of the ground surface and is not sealed to the walls.

Wrong - The sump pump alone cannot address the water infiltration issues in this crawlspace.

Wrong -The top of the sump pump crock is too high above the crawlspace grade level for any water in the crawl to enter the sump.

Wrong – A poorly sealed window and window well allow bulk water to enter the crawlspace from ground that slopes toward the structure

Wrong – No polyethylene sheeting vapor barrier is installed on the crawlspace floor

Wrong – The polyethylene sheeting vapor barrier is not attached to the piers with mechanical fasteners

Wrong – The vapor barrier is not secured to the walls of this crawlspace.

Wrong – This vented crawlspace has standing water because steps were not taken to address site conditions that led to bulk water flow into the crawlspace