Scope

The EPA WaterSense Home Specification does not have mandatory requirements for water softeners. However, if installed, these systems may contribute to the mandatory 30% efficiency requirement. Refer to the specific WaterSense Approved Certification Method (WACM) for specific requirements.

The following are recommendations and best practices:

If a water softener is installed, it should be a demand-initiated regeneration system that is water- and salt-efficient.

All self-regenerating water softeners shall be certified to meet the most current standards for NSF International/ANSI 44 Residential Cation Exchange Water Softeners, including the voluntary efficiency rating standards in Section 7 – Mandatory Testing for Elective Claims for efficiency rated systems, which states that water softeners shall:

- Be a demand-initiated regeneration system (i.e., it must use a flow meter or water hardness sensor to initiate regeneration; devices that use time clock-initiated regeneration [fixed time schedule] do not qualify for the efficiency rating).

- Have a rated salt efficiency of not less than 3,350 grains of total hardness exchange per pound of salt, based on sodium chloride (NaCl) equivalency (477 grams of total hardness exchange per kilogram of salt).

- Not generate more than 5.0 gallons of water per 1,000 grains of hardness removed during the service cycle (18.9 liters per 64.8 grams of total hardness removed).

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Water softeners are common household appliances found in regions of the country where hard water (or water that contains a lot of dissolved calcium or magnesium) is prevalent. Hard water can cause scales to form on the inside of pipes, water heaters, and other appliances and equipment. Scales do not conduct heat well and can reduce the flow of water through pipes. Hard water also reduce soap's ability to lather and reacts with the soap to form a sticky coating on skin.

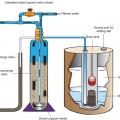

Hard water can be managed by softening or filtering the water. Water softeners are often used due to the high costs associated with filtration. The calcium and magnesium ions in the water are replaced with univalent hydrogen, sodium, or potassium ions (i.e., cation exchange). To achieve the ion replacement, the water in the house runs through a bed of small plastic beads or through a chemical matrix called zeolite. The zeolite is covered with hydrogen, sodium, or potassium ions. As the water flows past the hydrogen, sodium, or potassium ions, they swap places with the calcium and magnesium ions. Eventually, the zeolite contains nothing but calcium and magnesium, and at this point it stops softening the water. It is then time to regenerate the zeolite. Regeneration involves soaking the zeolite in a stream of concentrated brine, usually of sodium chloride or potassium chloride, or acid solution. The strong brine displaces all of the calcium and magnesium that has built up in the zeolite and replaces it with hydrogen, sodium, or potassium. The remaining brine plus all of the calcium and magnesium are flushed out through a drain pipe.

While the volume of water consumed by these fixtures during the regeneration phase has decreased significantly in recent years, water softeners still generate and discharge a significant volume of wastewater. To minimize the water consumption of these fixtures and reduce the amount of salt discharged into septic and sewer systems, the NSF/ANSI 44–Residential Water Softener Testing Standard and the Water Quality Association’s WQA S-100 Residential Water Softener Testing Standard include a voluntary set of requirements for efficiency-rated (ER) residential cation exchange water softeners. (These two standards are essentially identical. Therefore, a residential cation exchange water softener can be certified to either standard.)

All residential cation exchange water softeners sold in the United States must be certified to the general requirements of NSF/ANSI 44 (or WQA S-100). The voluntary efficiency requirements found in Section 7 of NSF/ANSI 44 are for manufacturers looking to differentiate and market their products as water- and sodium-efficient. Under Section 7, an ER system must meet the following criteria:

- Be a demand-initiated regeneration (DIR) system. In other words, it must use a flow meter or water hardness sensor to initiate regeneration. Devices that use time clock-initiated regeneration (fixed time schedule) do not qualify for the efficiency rating. Softeners that use time clock-initiated regeneration automatically regenerate on a fixed time schedule set by the user (typically every four days to weekly). This can result in unnecessary regeneration during times of reduced use and waste large volumes of water.

- Have a rated salt efficiency of not less than 3,350 grains of total hardness exchange per pound of salt, based on NaCl equivalency (477 grams of total hardness exchange per kilogram of salt).

- Not generate more than 5.0 gallons of water per 1,000 grains of hardness removed during the service cycle (18.9 liters per 64.8 grams of total hardness removed).

Most manufacturers indicate on the product packaging and literature that their product meets the NSF/ANSI 44 Residential Cation Exchange Water Softeners Efficiency Rating. In addition, the following organizations that independently certify water softeners to the NSF/ANSI standards maintain a listing of products that meet the voluntary efficiency rating:

Success

For homes seeking certification through the U.S. Environmental Protection Agency's WaterSense program, the WaterSense verifier will verify through the manufacturer’s product specification sheet or product manual that the softener has been certified to meet NSF/ANSI 44 Residential Cation Exchange Water Softeners, including the voluntary efficiency rating standards in Section 7.

Climate

This guide is relevant to locations with hard water.

Training

Retrofit

SCOPE

See the U.S. Department of Energy’s Standard Work Specifications (SWS) for more on water softening. DOE’s Standard Work Specifications describe practices to complete whole-house energy upgrades safely without injury or hazardous exposure in the section on Global Worker Safety.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Water Efficient Appliances =

Look for ENERGY STAR-certified appliances when buying clothes washers or dish-washers. ENERGY STAR-certified clothes washers uses about 25% less energy and 40% less water than regular washers. An ENERGY STAR dish washer will save, on average, 1,600 gallons of water over its lifetime compared to a dishwasher built before 1994. Energy savings result from reduced hot water consumption.