Scope

Test heating and cooling duct distribution systems for air leakage using a testing protocol approved by Residential Energy Services Network (RESNET) (RESNET 2013). This testing is typically done by a home energy rater certified by RESNET.

- Conduct the testing at either rough-in (after the air handler and ducts have been installed and sealed but before drywall or flooring and registers are installed) or at final (after the air handler and ducts, drywall and flooring, and registers have been installed).

- If there is more than one system in the home, assess leakage on a per-system, rather than per-home, basis.

- Either visually inspect or duct blower test ventilation ducts (e.g., ducts used for a separately ducted ERV or HRV system).

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Central forced air heating and cooling systems use ducts to distribute the hot and cold air. If these ducts have loose connections where sections of duct connect to each other or to duct boots or trunk lines or the air handler, air can leak through the cracks. Leaky ducts can be a major source of energy loss and comfort problems, and can contribute to moisture problems, especially when the ducts run through unconditioned space such as a vented attic or crawlspace.

Building codes such as the International Residential Code (IRC 2015) and the International Energy Conservation Code (2015 IECC), and energy-efficiency programs like ENERGY STAR Single-Family New Homes require that if a home’s HVAC system includes a duct distribution system, the ducts must be tested for air leakage. Duct leakage is measured and documented by a certified home energy rater using a testing protocol approved by the Residential Energy Services Network, Inc. (RESNET). The accepted protocols are found in RESNET's Mortgage Industry National Home Energy Rating Systems Standards, Chapter 8, Section 803.3 (RESNET 2013).

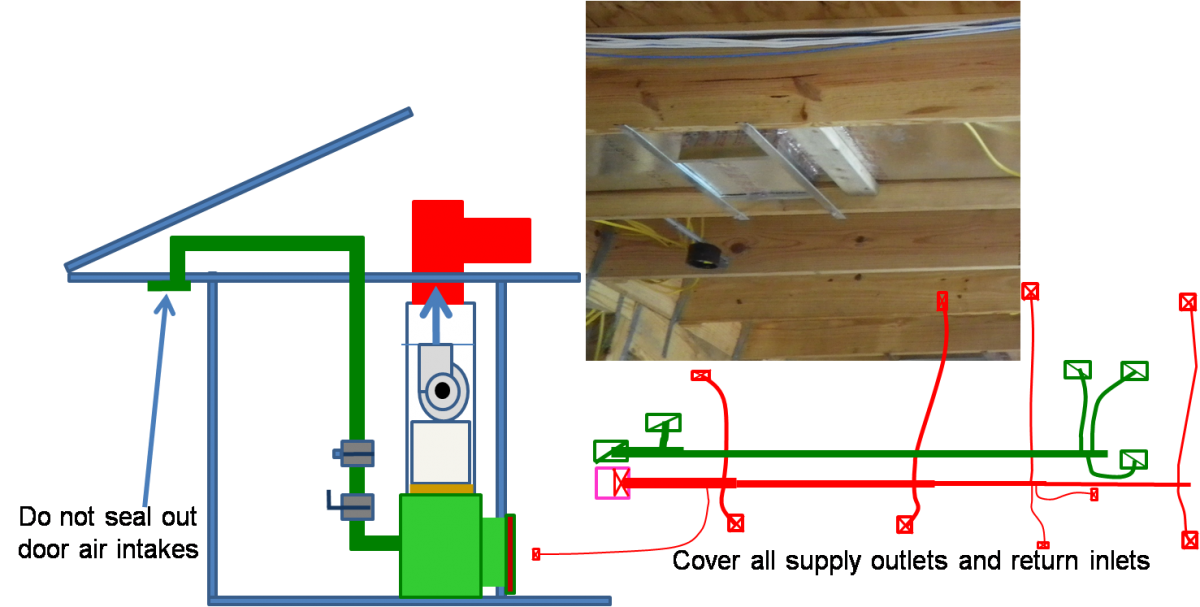

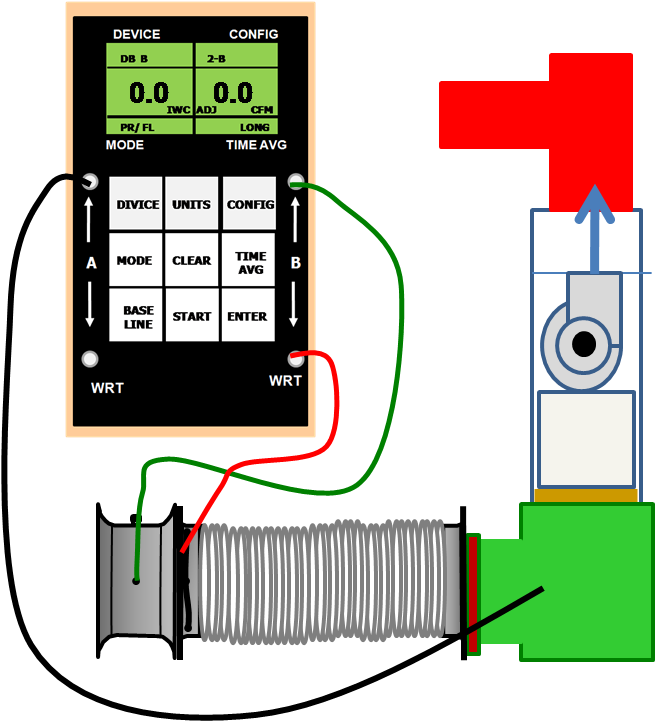

As required by RESNET standards, the test is performed using a duct tester, such as the Minneapolis Duct Blaster or the Retrotec Duct Tester. The duct tester consists of three components: a calibrated fan that is used to either pressurize or depressurize the duct, a device called a manometer that is used to measure pressures, and supplies such as cardboard and tape or adhesive plastic sheeting to seal off the supply and return registers during the test (See Figure 1). The fan and manometer are used together to pressurize or depressurize the duct system to 25 pascals (0.10 inch water column [IN WC]) (RESNET Standards). Once at 25 pascals pressure, the air flow through the duct tester is read in cubic feet of air flow per minute at 25 pascals; this measurement is abbreviated as CFM 25.

Duct leakage testing should be performed after all components of the system have been installed, including the air handler, the ductwork, and the register boxes or duct boots.

Two types of tests are performed: total duct leakage and leakage to the outdoors:

The "duct leakage to the outdoors" test measures only duct leakage outside of the home’s air barrier, i.e., leakage to the outdoors, for example, into an unconditioned attic or crawlspace. The “total” duct leakage test measures how much air leakage there is for all of the ductwork connected to the HVAC system, including ducts located both outdoors and indoors.

According to ENERGY STAR Single-Family New Homes (Version 3, Rev 11), for ducts in unconditioned spaces such as unconditioned vented attics or crawlspaces, both tests should be conducted. When all ducts are located inside conditioned spaces, only the "total" duct leakage test needs to be conducted if certain conditions exist. Testing of duct leakage to the outdoors can be waived in accordance with the 2nd or 3rd alternative of ANSI / RESNET / ICC Std. 301, Table 4.2.2 (1), footnote (w). Alternatively, testing of duct leakage to outdoors can be waived in accordance with Section 5.5.2 of ANSI / RESNET / ICC Std. 380 if total duct leakage, at rough-in or final, is ≤ 4 CFM25 per 100 sq. ft. of conditioned floor area or 40 CFM25, whichever is larger. For ENERGY STAR criteria on testing of duct leakage to the outdoors, see Duct Leakage to Outdoors.

ENERGY STAR (Version 3, Rev 11) allows total duct leakage to be tested at either rough-in or final. “Rough-in” is when the air handler and ducts have been installed and sealed but before drywall or flooring and registers are installed. (This includes cabinets (e.g., kitchen, bath, multimedia) or ductwork that connect duct boots to toe-kick registers.) “Final” is after the air handler and ducts, drywall and flooring, and registers have been installed. If testing is conducted at final, registers installed over carpets are permitted to be removed and the face of the duct boot temporarily sealed during testing.The Rater should also visually verify that the ductboots have been durably sealed to the subfloor (using duct mastic or caulk) to prevent leakage during normal operation. If testing is done at final, this visual check can be done then. If testing is done during rough-in, the rater must return after the drywall has been installed to visually confirm that the duct boot is sealed to the drywall. If the ductblaster leakage testing is done at final, ducts should be visually inspected at rough-in to look for any obvious gaps or misses in duct mastic so those can be corrected before drywalling. Some raters will also recommend that the ducts be tested at rough-in with a low-CFM smoke machine connected to one of the ducts and the other registers closed off so that the HVAC contractor can clearly see and fix any leaks in the ducts.

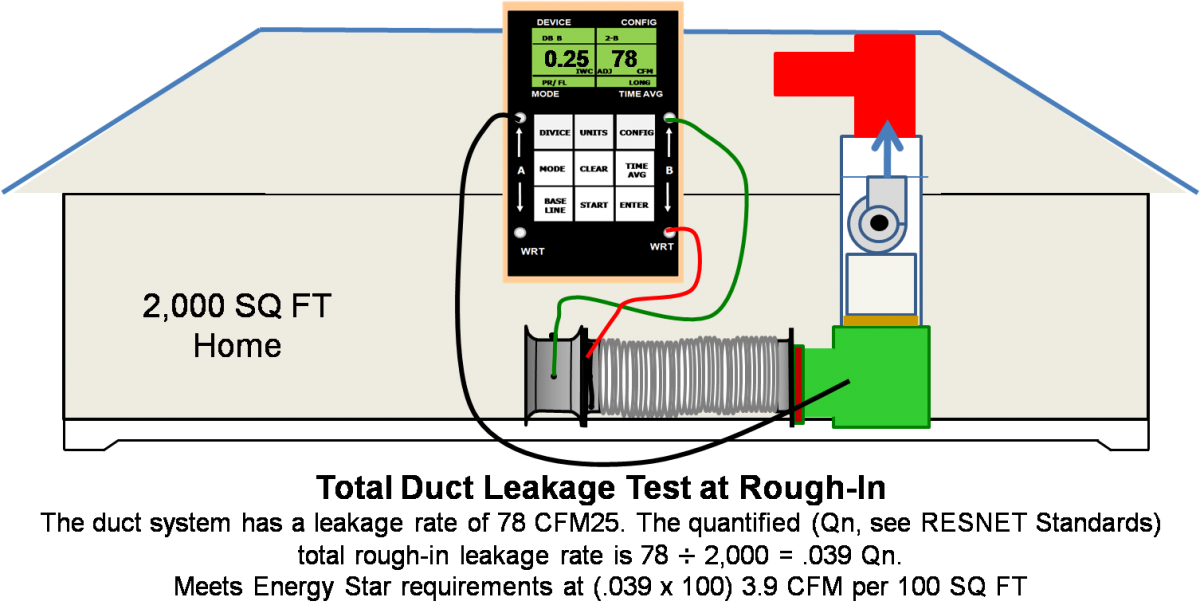

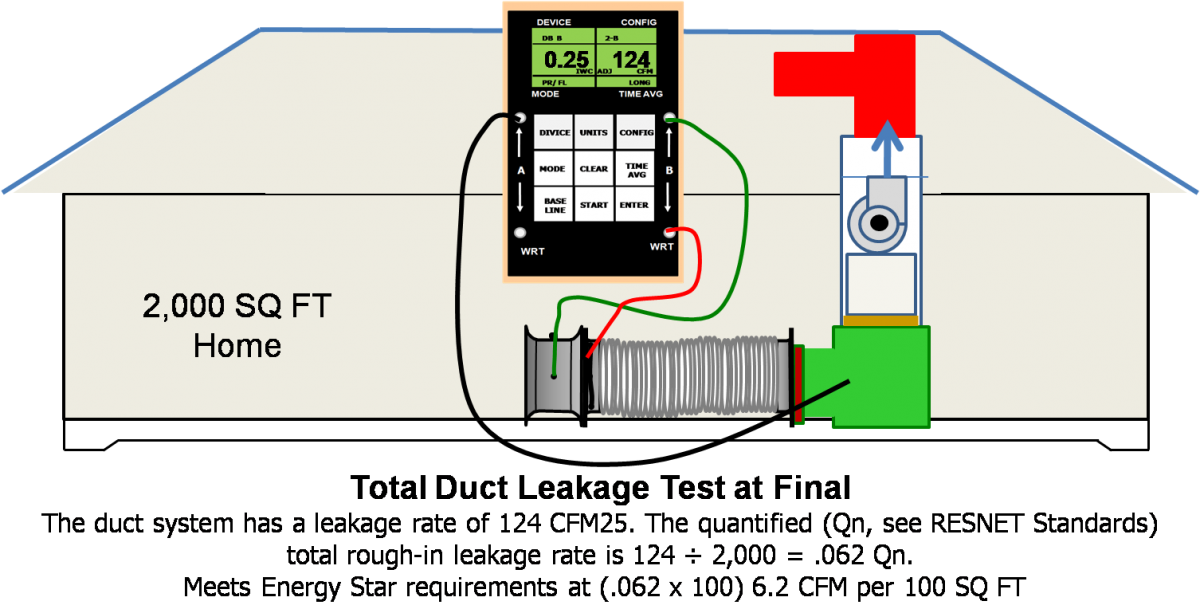

The ENERGY STAR Version 3 Rev 11 air leakage criteria specify that duct air leakage must be ≤ 4 CFM25 per 100 ft2 of conditioned floor area or ≤ 40 CFM25, whichever is greater, at rough-in or ≤ 8 CFM25 per 100 ft2 of conditioned floor area or ≤ 80 CFM25, whichever is greater, at final.

There are pros and cons to either method. Some builders prefer to test for duct leakage at rough-in when the ducts are easier to access in case additional air sealing needs to be done. Some builders, especially those who install ducts in the attic, prefer to wait until final to test the ducts because the ducts are likely to get moved about by other trades in the meantime and ducts will still be accessible.

One might question why duct leakage needs to be tested at all if the ducts and air handler are located inside conditioned space. High-performance homes are homes built tight using materials that greatly retard heat transfer through conduction, convection, and radiation. As a result, high-performance homes require smaller HVAC systems. For example, 20 years ago, a 2,000-ft2 home required a 4- or 5-ton air conditioner for cooling. That same house built to today's building code would only require a two-ton unit. This downsizing results in energy and cost savings. However, ducts are sized to an air handler capacity at 350 to 450 CFM per ton. If the system size is cut in half, the air flow velocity is also cut in half. Therefore, the conditioned air stays in the ducts longer and thus it is even more important that the ducts are well insulated and not leaking in order for the conditioned air to be delivered to where it is needed.

Leakage limits are assessed on a per-system, rather than per-home, basis. So, for example, if a home has two furnaces, duct leakage must be measured in each system and compared to the square footage that the system conditions. Each system must meet the “total” and “outdoors” leakage requirements to qualify for the ENERGY STAR program.

How to Test "Total" Duct Leakage at Rough-In or Final

- For duct testing at rough-in, perform the test before drywall and finished flooring are installed, and after the air handler, ducts, and duct boots (register boxes) are installed. For duct testing at final, perform the test after the air handler, ducts and duct boots, drywall or finished flooring, and registers are installed. Connect the duct tester by attaching the duct that comes connected to the calibrated fan to a return duct grill with suitable tape (Figure 1). If conducting the test at rough-in, if there are any cabinets that connect duct boots to toe-kick registers, they do not need to be installed. If testing ducts at final, visually inspect the ducts prior to drywalling, to fix any obvious areas of leakage. A smoke test could also be conducted at this time to assist in making corrections before drywalling.

- Temporarily seal shut all of the other supply and return duct registers using cardboard and tape or removable adhesive plastic (Figures 2 and 3).

- Set up the duct tester to either pressurize or depressurize the duct system (follow manufacturer’s instructions). Set up the manometer to display pressure and air flow according to the manufacturer’s instructions.

- Connect the "input" on the pressure side of the manometer to the return (the black tube in Figure 4).

- Turn on the fan to pressurize (or depressurize) the ductwork to 25 pascals relative to the house. Leave at least one door or window open between the building and outside to prevent changes in building pressure due to the operation of the duct tester.

- Once a steady 25 pascals of pressure is reached in the duct system, note the manometer reading for CFM. The amount of air flow needed to maintain 25 pascals of pressure is the amount of air escaping through the leaks in the duct system, indicated in cubic feet per minute.

- Reconnect the input (black tube in Figure 4) to a supply duct in a part of the house that is some distance from the return. Repeat steps 5 and 6. Record the duct leakage.

- Add the two duct leakage measurements together and divide by two. This will give the most accurate duct leakage measurement for total duct leakage. See the examples in Figures 5 and 6.)

- If duct leakage is too high, use a theatrical smoke machine to illustrate duct leakage locations to the HVAC contractor.

- The air handler unit can be sealed with UL-listed foil mastic tape to reduce air leakage.

Success

After ducts are installed and before drywall is installed, the duct system should be visually inspected by a HERS rater to ensure that all duct connections are properly fastened and sealed, preferably with mastic. The rater should also visually inspect at rough-in that ducts are fully insulated (to R-8 for supply ducts and R-6 for returns and other ducts) along the length, including all connections, and that the insulation is not compressed by tight strapping, by framing members, or by excessive bending.

If duct leakage is tested at rough-in, a HERS rater should confirm and document that total duct leakage is the greater of ≤ 4 CFM 25 per 100 ft2 of conditioned floor area or ≤ 40 CFM25 using a RESNET-approved testing protocol and should verify with a visual inspection that duct boots are sealed to finish surfaces at final.

If duct leakage is tested at final, the HERS rater or builder may perform an optional, additional duct blaster test prior to drywall installation or make use of a theatrical smoke machine to look for air leaks so they can be sealed before drywalling.

Climate

No climate specific information applies.

Training

Compliance

Retrofit

The information provided for testing duct leakage in new homes applies to testing duct leakage in existing homes as well.

For more on duct sealing, see the U.S. Department of Energy’s Standard Work Specifications.

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

HVAC System Diagnostics (New or Existing Homes) = Certified Comfort System

Even good installers can miss things. Once the home’s comfort system has been installed, it should be tested to make sure it is operating properly. Organizations like the Residential Energy Services Network (RESNET) and North America Technician Excellence (NATE) train home energy raters to test homes for HVAC performance, as well as for energy efficiency, health, safety, and durability. Testing by these certified third-party home raters can verify that a home is meeting the HVAC and other performance requirements of state and local building codes and of home-performance programs like ENERGY STAR Certified Homes.