Scope

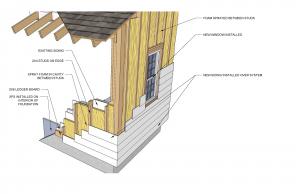

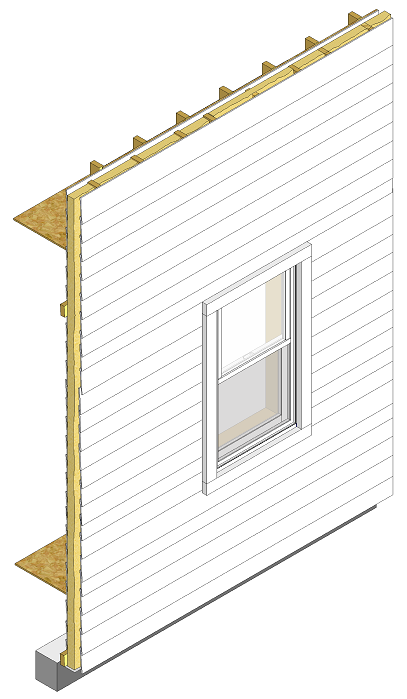

Install spray foam on the exterior of the existing home after framing over the existing siding. Then install new siding over the new studs and spray foam for this deep energy retrofit technique.

In this design, add exterior spray foam insulation with stand-off furring. The design includes a 2x6 ledger board at the bottom and top of the wall, as well as 2x4 studs that are installed on edge to provide wall cavities that can hold a 3 inch layer of spray foam applied to the exterior face of the existing wall. New windows are installed, as well as new siding on top of the insulation. In addition, extruded polystyrene (XPS) is installed in the interior of the foundation walls and spray foam insulation is added to the attic space.

This retrofit measure requires a crew that can perform a number of different tasks (e.g., framing, flashing, window install, trim carpentry). Because of the project sequencing, this project does not lend itself to piecemeal subcontracting various tasks (e.g., framing subcontractor, window installer, drainage plane installer, trim carpenter).

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

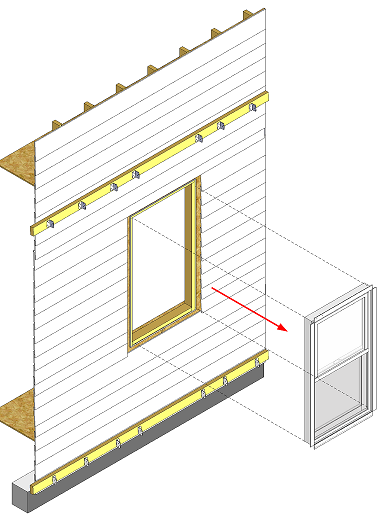

One method to significantly increase the insulation level of an existing home without sacrificing interior space is to install spray foam insulation on the exterior of the home. This measure involves installing 2x4 studs over the existing siding. The 2x4s are held slightly away from the wall with metal clips so that when the spray is applied to fill the new 2x4 wall cavities, it can fill in between the 2x4s and the existing walls (see Figure 1). The advantages of this strategy include using spray foam to encapsulate existing siding materials that might include lead paint, reducing the thermal bridging or transfer of heat through the existing wall studs, and creating a vented rain screen assembly to promote drying.

This strategy might be considered by homeowners who are already considering replacing siding or windows or who are conducting some other exterior upgrade.

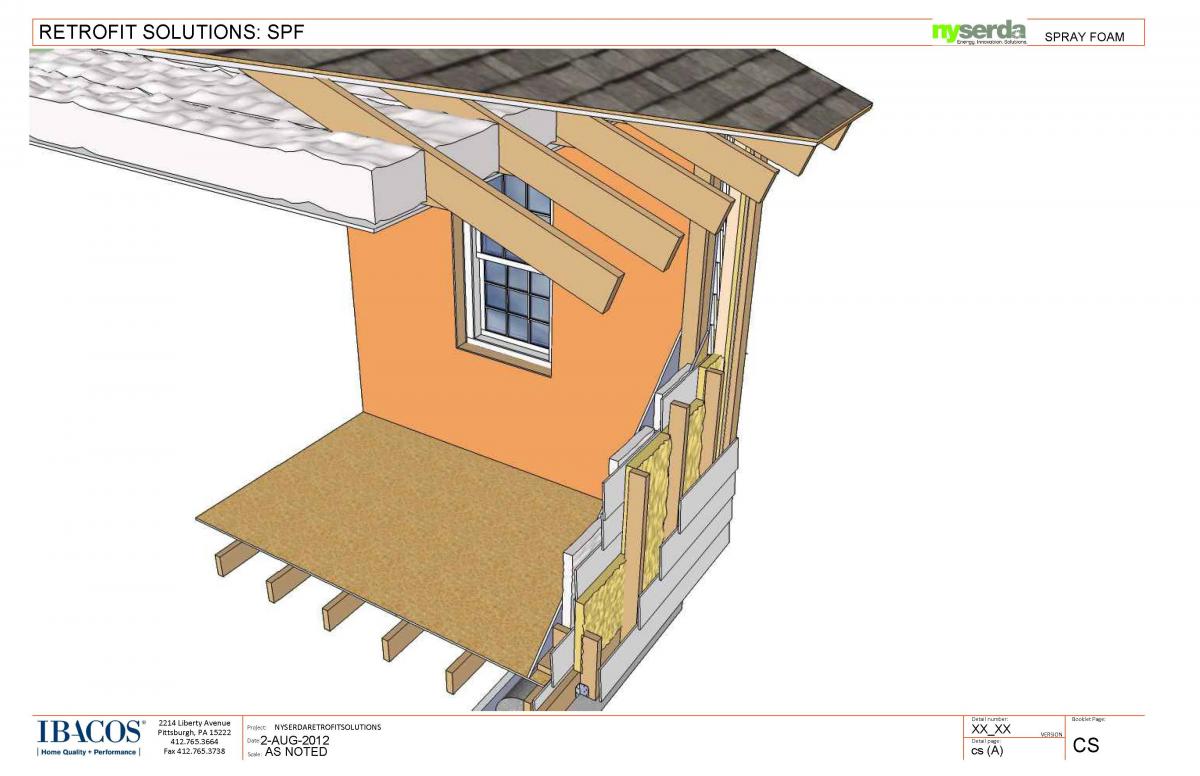

In a field study conducted by IBACOS in New York (see Figure 2), the exterior spray foam strategy was designed, implemented in a test facility to determine techniques for working around wall penetrations like wiring and doors, then installed on site in an actual home. Results from the field study (Herk and Poerschke 2015) found this strategy achieved the following energy-related targets:

- Whole-house air leakage improvements that can approach or be lower than 0.25 CFM 50/shell square foot (SSF) upon completion.

- Center of wall R-value of approximately R-25.

- An exterior wall insulation retrofit strategy that can be accomplished for approximately $12 to $18 per SSF. This includes the installation of new wall framing and the removal/installation of windows, window trim, insulation, and bug screen. Siding was a cost that is not included in this number.

Although it is likely that this retrofit technique can be applied to most siding types, at this time, research has not been done to determine the suitability of the application on brick or stone siding.

How to Install Spray Foam Insulation on Existing Walls

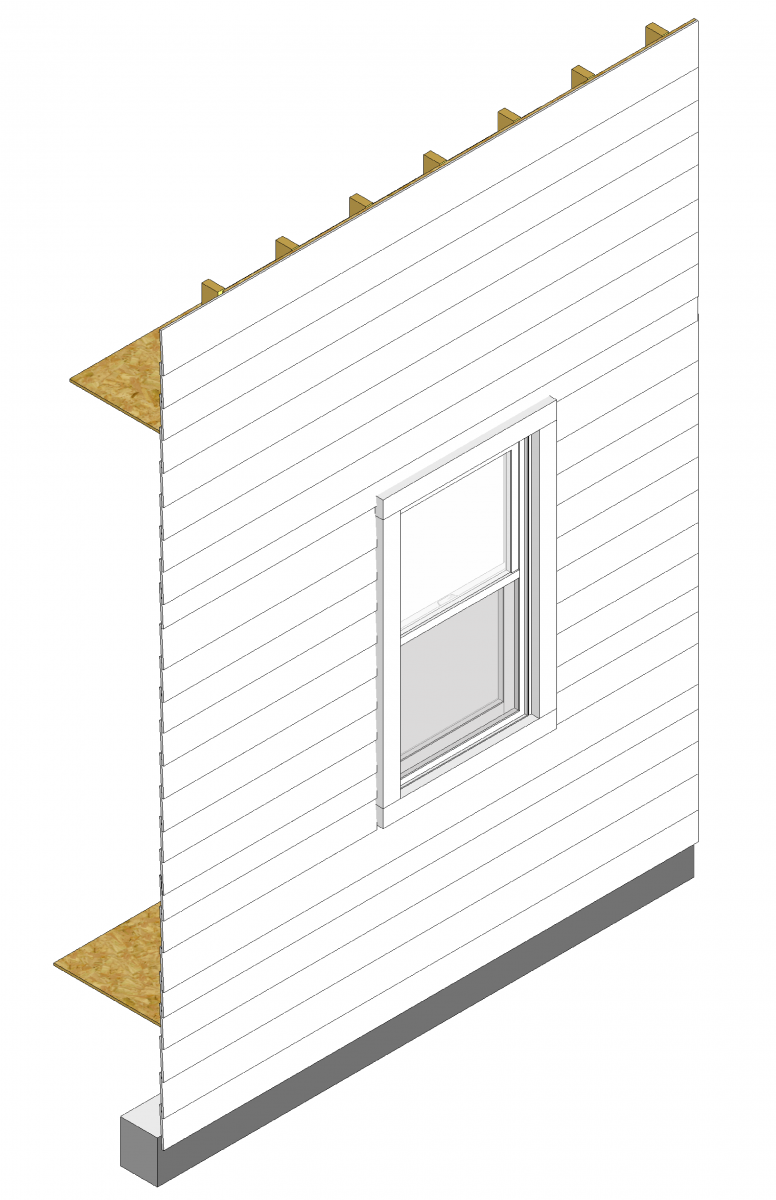

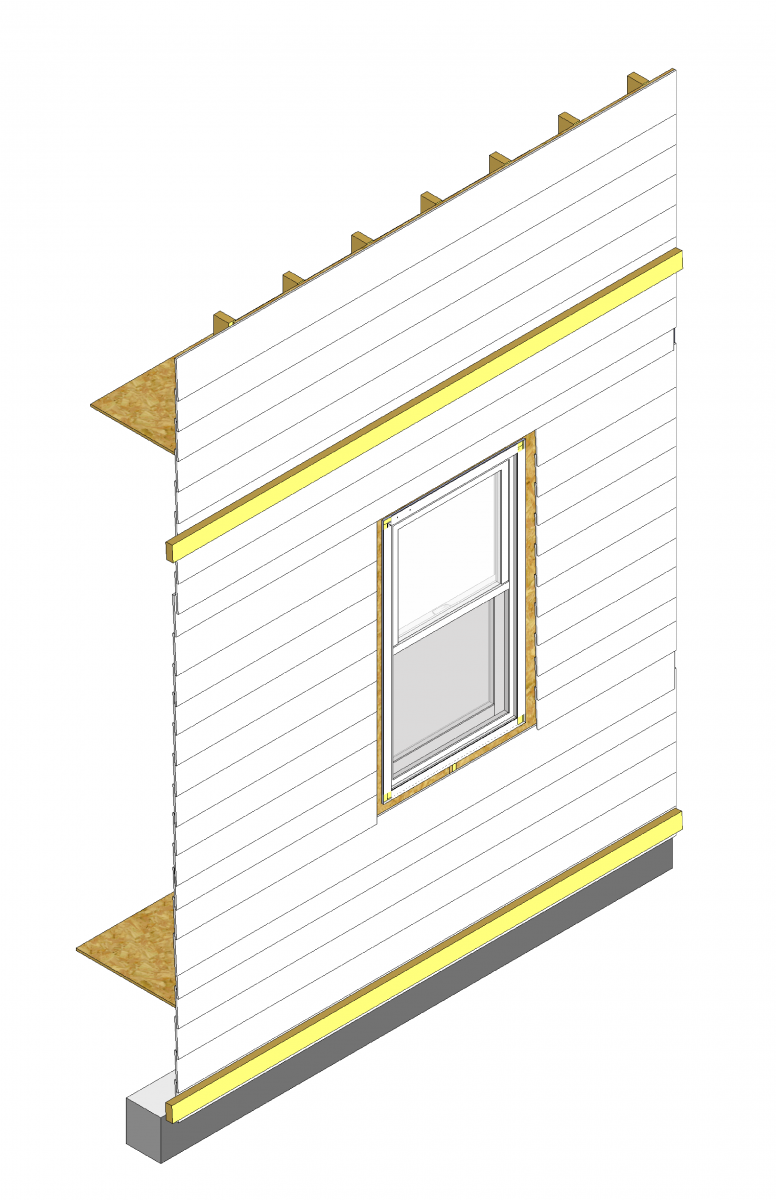

Assess the existing condition of the wall. (See Figure 3.) Be sure to look for and make note of loose or crooked siding. These types of siding imperfections could lead to an uneven ledger board or stud, which then could result in a wavy siding application.

Figure 3. Assess the existing condition of the wall. (Source: IBACOS.) Remove the existing window trim and fasten the ledger boards through the existing exterior cladding and sheathing. (See Figure 4.) If the existing wall surface is uneven, shim the ledger boards if necessary to keep the new framing and any doors and windows that will be installed a uniform distance from the existing wall.

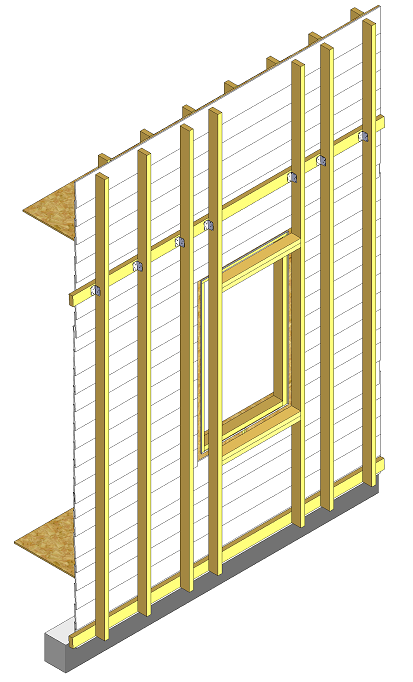

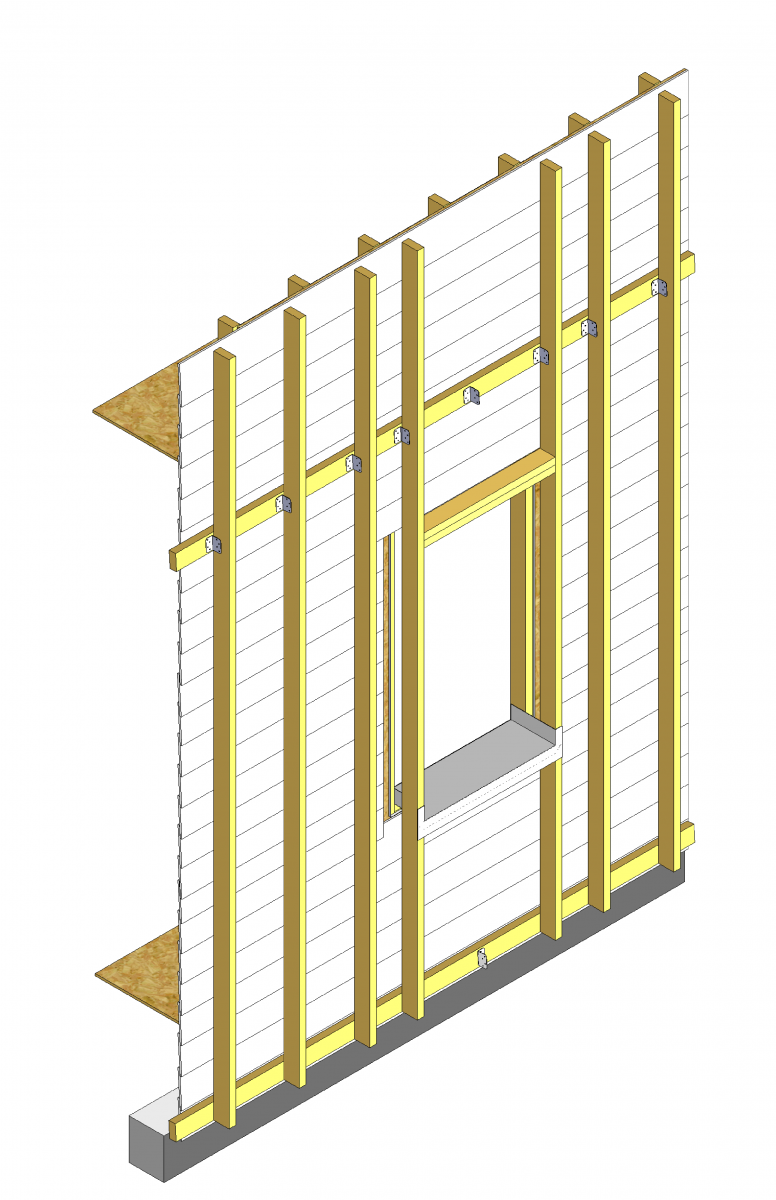

Figure 4. Remove the existing window trim and fasten the ledger boards through the existing exterior cladding and sheathing. (Source: IBACOS.) Attach metal “L” clips on the top and bottom ledger board—one on either side of where a new vertical 2x4 will be attached. (See Figure 5.) Remove the existing window and install new framing for the new window.

Figure 5. Attach metal “L” clips on the top and bottom ledger board for new vertical 2x4s. (Source: IBACOS.) Install the vertical 2x4s, spaced as needed based on structural calculations and siding manufacturer requirements. These are attached to the ledger boards using the metal “L” clips and they create a framework to hold the spray foam. (See Figures 6 and 7.)

Figure 6. Install the vertical 2x4s, spaced as needed based on structural calculations and siding manufacturer requirements. (Source: IBACOS.)

Figure 7. Ledger board, metal brackets, and vertical 2x4s have been installed in preparation for exterior spray foam in this retrofit exterior wall insulation technique. (Source: IBACOS.) Install two horizontal framing members on the top and bottom of the rough opening for the new window. Slightly slope the sill framing to the exterior. (See Figure 8.)

Figure 8. Install two horizontal framing members on the top and bottom of the rough opening for the new window. Slightly slope the sill framing to the exterior. (Source: IBACOS.) Install the sill pan in the window frame. (See Figure 9.)

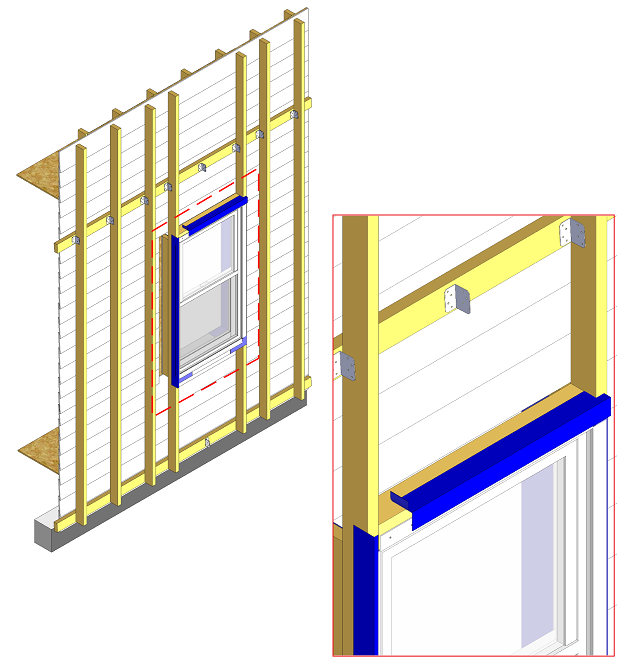

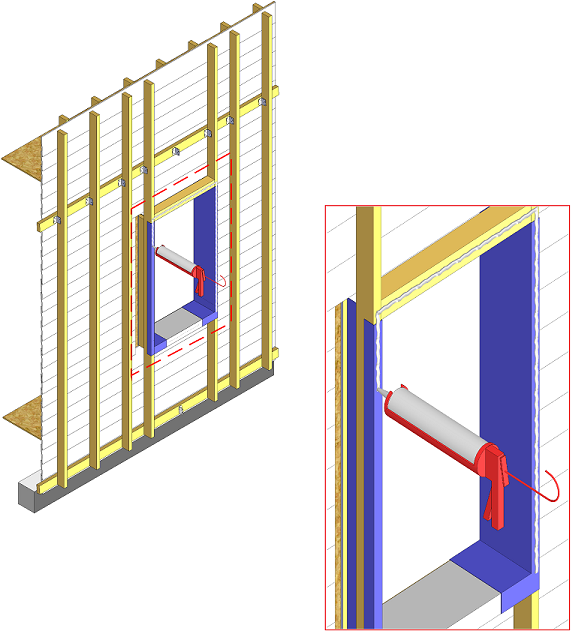

Figure 9. Install the sill pan in the window frame. (Source: IBACOS.) Install flexible flashing over the sill pan and at least 6 inches up the sides of the jamb. (See Figure 10.)

Figure 10. Install the flexible flashing over the sill pan and at least 6 inches up the sides of the jamb. (Source: IBACOS.) Install caulk on the face of the rough opening at the jambs and head. Do not caulk the sill. (See Figure 11.)

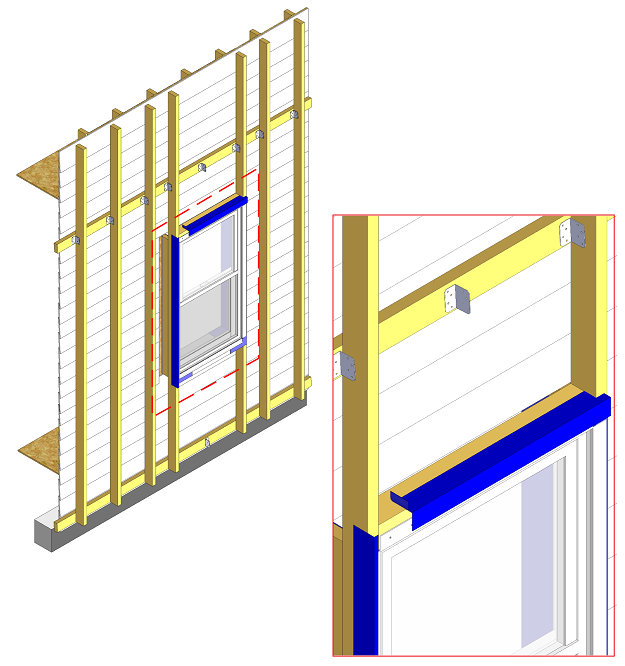

Figure 11. Install caulk on the face of the rough opening at the jambs and head. Do not caulk the sill. (Source: IBACOS.) Install the new window or re-install the old window. (See Figures 12 and 13.)

Figure 12. Install the new window. (Source: IBACOS.)

Figure 13. Windows are installed in new framing in preparation for adding exterior spray foam insulation. (Source: IBACOS.) Install the jamb flashing (flat on the face of the window flange). (See Figure 14.)

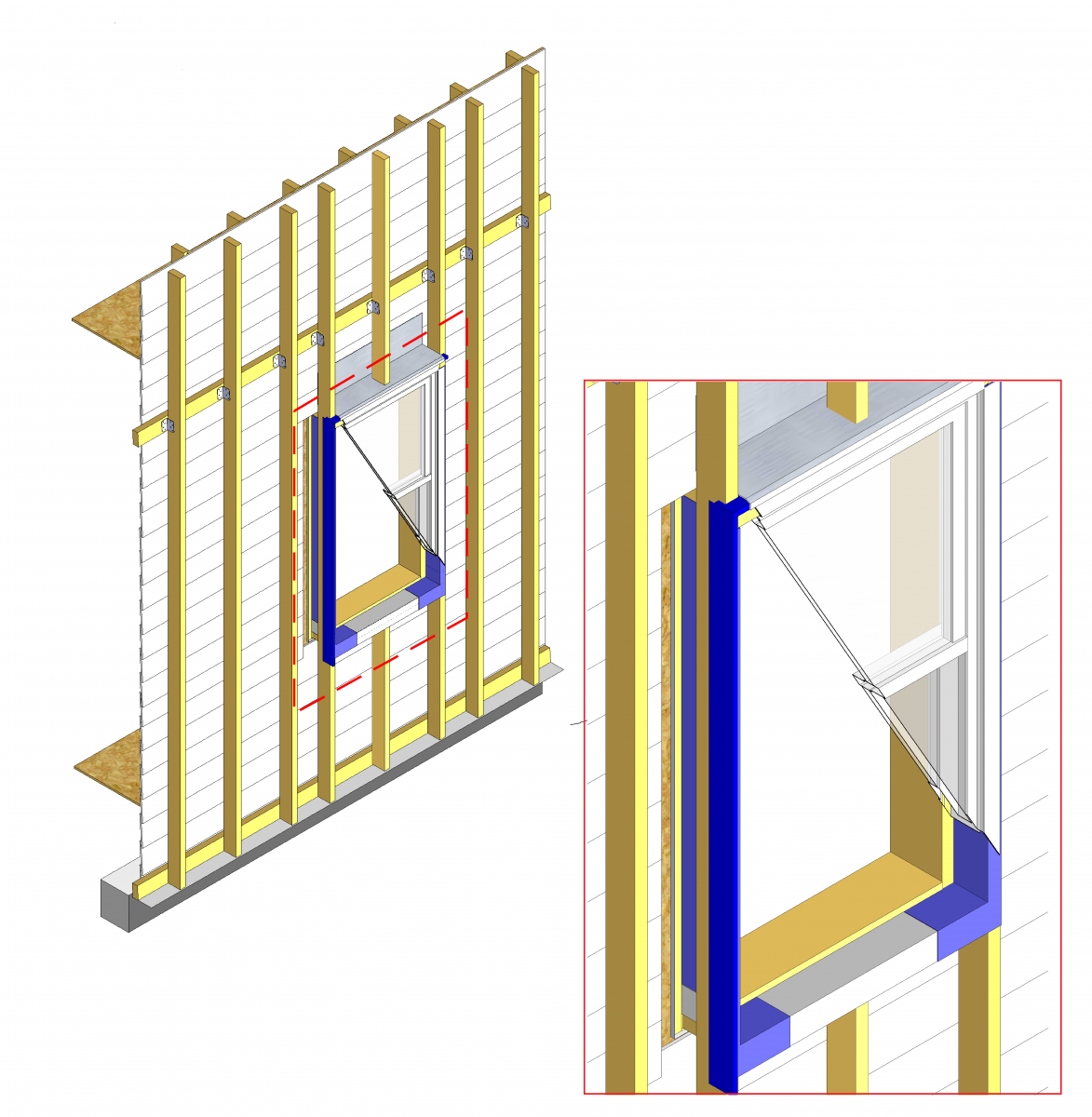

Figure 14. Install the jamb flashing (flat on the face of the window flange). (Source: IBACOS.) Install the head flashing from the face of the existing wall to lap over the head of the new window. Also, tape the flashing at the head using straight flashing tape lapped over the horizontal part of the head framing. (See Figure 15.)

Figure 15. Install head flashing from the face of the existing wall to lap over the head of the new window. (Source: IBACOS.) Install the vertical framing members above and below the new window, and install the insect screen to the bottom of the new wall. Air seal the window from the interior using non-expanding foam sealant and install internal jamb extensions to prevent exterior spray foam from getting into the house. (See Figures 16 and 17.) Cover the windows and exposed foundation with plastic to minimize the possibility of damage due to overspraying with the spray foam.

Figure 16. Install the vertical framing members above and below the new window, and install the insect screen to the bottom of the new wall. (Source: IBACOS.)

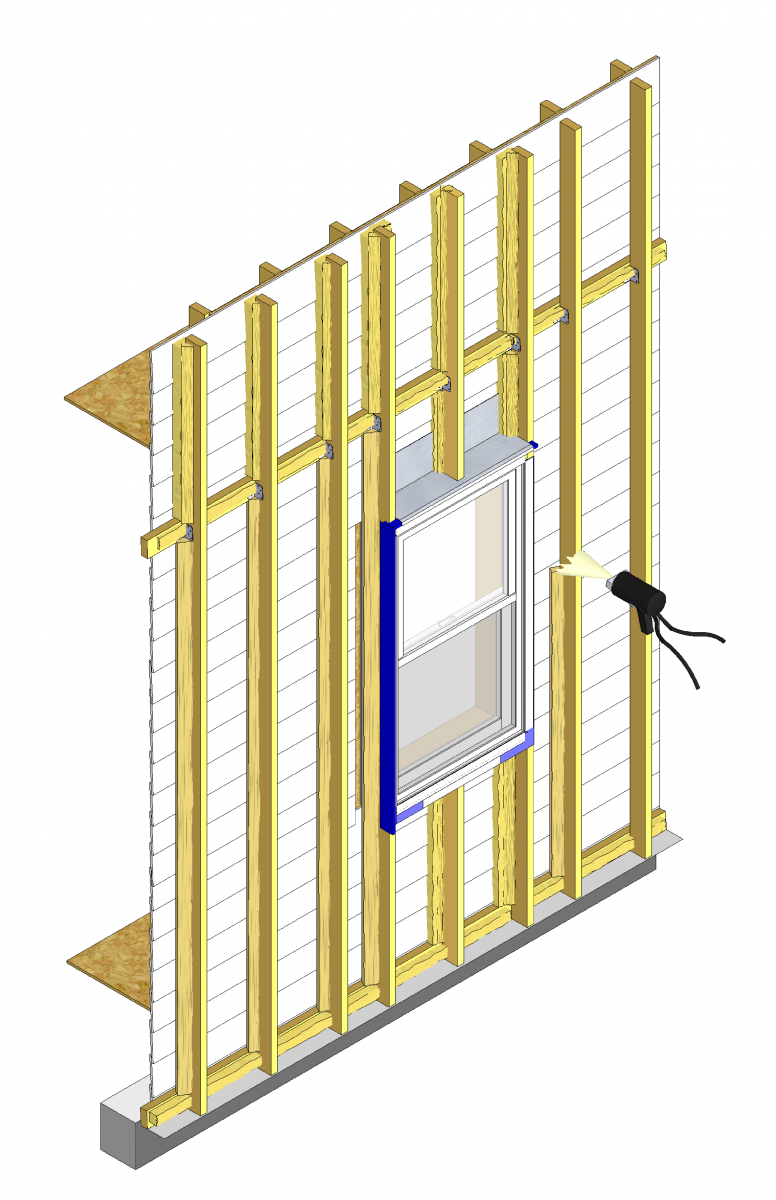

Figure 17. First spray foam along the inside edges of each vertical 2x4 to “picture frame” the area. (Source: IBACOS.) Spray insulation within the cavities of the new wall. (See Figure 18.)

Figure 18. Spray insulation within the cavities of the new wall. (Source: IBACOS.) Install the new cladding and install the new window trim. (See Figure 19.)

Figure 19. Install the new cladding and install the new window trim. (Source: IBACOS.)

Success

- Cover the windows and exposed foundation with plastic to protect against foam overspray.

- Use extra metal clips or picture frame spraying technique to keep studs in place while installing spray foam in new stud cavities.

- For efficiency, hire one contractor or crew that can perform most or all of the tasks involved in this retrofit measure (e.g., framing, flashing, window install, trim carpentry).

Climate

No climate specific information applies.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

IBACOS, lead for IBACOS, a DOE Building America Research Team