Scope

Keep ducts and HVAC equipment clean, dry, and free of dust and debris during construction. Clean ducts before occupancy.

- Ask the HVAC contractor to create a plan listing how they will protect the ducts and equipment during installation.

- Inspect ducts prior to installation to ensure they don’t contain oil or debris.

- Prior to installation store ducts and mechanical equipment in a clean, dry environment. Wrap the equipment with plastic if necessary to keep out dust.

- Avoid operating the HVAC system during construction to prevent dust from being pulled into the system. Do not run HVAC equipment while dry-walling, sanding, or sawing.

- Maintain a clean work area by sweeping and vacuuming throughout construction.

- After installation and before operation, cover HVAC air handlers and duct registers or duct openings with plastic until construction (including installation of flooring, carpets, cabinetry, and finish carpentry) is completed. If registers have not been installed yet, cover the duct openings with plywood for safety.

- After construction is complete and before operating HVAC, clean the ducts using a vacuum and pneumatic brushing system made for duct cleaning. Do not use wet solutions or ultraviolet light systems.

- After cleaning ducts, run the central furnace or air handler with a filter installed. Replace the filter before occupancy.

This guide explains how to remove construction debris—particularly airborne dust and other particulates—from flexible ducts after completion of residential new construction and prior to occupancy of the home by the homeowners. The same methods could also be used to clean flexible ducts after a major renovation of a home.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

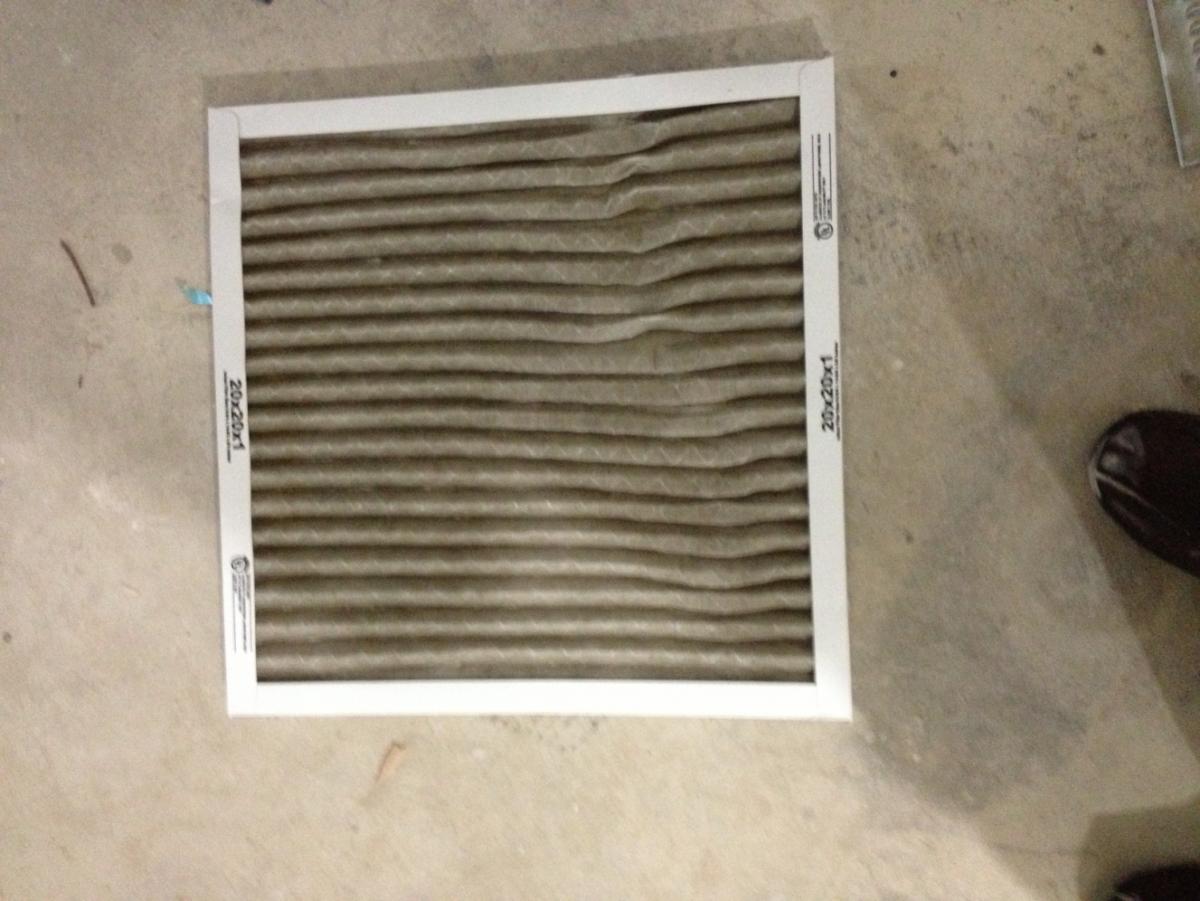

New construction and remodeling projects inevitably generate large amounts of dust and particulates from activities like sawing, sanding, and dry walling. These airborne particulates can travel through the air and be drawn into the ducts and mechanical equipment of the home’s heating, ventilation, and air conditioning (HVAC) system, even if the system is not running. The furnace filter in Figure 1 is clogged with construction dust. Construction debris including sawdust, scraps of materials, carpet fibers, nails, and screws often find their way into open floor ducts (Figure 2 and Figure 3). Flex ducts with their grooved interior surfaces (Figure 4) are especially prone to collecting dust and dirt during the construction process.

Once inside the ducts, these particulates and debris can reduce the efficiency and equipment life of system components and can block airflow through the ducts. If allowed to remain in the ducts, particulates can be blown throughout the home over time or become a reservoir for microbial growth or odors. Although this would negatively impact the indoor air quality for all occupants of the home, it is particularly serious for those who have allergies, respiratory problems (e.g., asthma, chronic obstructive pulmonary disease [COPD]), or cardiovascular issues.

Following the completion of construction, the flexible ducts should be cleaned as described in this guide to remove the debris. However, flexible ducts are lightweight and can be easily punctured, torn, crushed, pinched, or damaged during cleaning. Therefore, they must be cleaned carefully and with appropriate tools.

The cleaning should be performed only by HVAC professionals who meet the minimum qualifications of the Air Conditioning Contractors of America (ACCA) Standard 6. The ducts should be cleaned by vacuuming them out with vacuums and brushes intended for cleaning ducts. Do not use antimicrobial approaches such as wet solvents, sanitizers, or ultraviolet (UV) light. These will not suffice as a substitute for physically removing the particulates from the flexible ducts by vacuuming. Liquids should not be used in the duct cleaning process.

This guide describes the cleaning of flexible ducts; however, the HVAC mechanical equipment (i.e., air handling unit) should be cleaned thoroughly when the ducts are cleaned. ACCA Standard 6 recommends that all parts of the entire HVAC system be cleaned at the same time after construction of a new home is completed and prior to occupancy by the homeowners.

Keeping Debris out of Ducts

An ounce of prevention is worth a pound of cure when it comes to keeping the duct system debris-free. Implementing the following suggestions during construction will help to minimize the amount of cleaning that is needed after construction is finished:

- Maintain a clean job site to reduce the amount of dust and dirt that accumulates within the home.

- As part of the overall quality assurance/quality control (QA/QC) plan, ask the HVAC contractor to create a duct and equipment protection plan or indoor air quality management plan. It should define the methods that will be used to protect the ducts and reduce particulate accumulation in the HVAC system and methods for cleaning the ducts and air handling unit after construction.

- Follow the Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA 2007) guidelines for indoor air quality best practices during demolition, construction, or renovation (i.e., SMACNA IAQ Guidelines for Occupied Buildings under Construction, Second Edition, ANSI/SMACNA 008-2008, Chapter 3).

- Inspect all new flexible ducts prior to installation to ensure they do not contain any oil or debris.

- Prior to installation, store all HVAC equipment in a clean, dry, and dust-free environment. If necessary, wrap the ducts and mechanical equipment components in plastic to keep them clean. Note: It is also critical to keep moisture out of the refrigerant lines of heat pumps and air conditioners because the oil used for lubricant in refrigeration systems is highly hygroscopic; it will absorb any moisture in the lines and turn into an acidic sludge that eats away at compressor windings and clogs valves. These lines should be soldered closed until the equipment is ready for operation. See the guide Compression Cooling for more information.

Once the HVAC system is installed, begin preventive maintenance steps immediately.

Avoid operating the HVAC system during construction if possible to prevent air from being pulled into the system. Although trades may wish to have the HVAC system operating to maintain their level of comfort while working inside the house, alternative strategies should be followed, such as using electric space heaters for warmth. Gas space heaters should be avoided to reduce the risk of adding more moisture to the house from combustion byproducts. It is critical not to run the HVAC system during work activities that create dust, such as when dry walling, sawing, or sanding. Although a fiberglass filter can be installed to keep large debris from entering the mechanical equipment and ducts, it does not prevent fine dust from getting into the mechanical equipment components or ducts.

After HVAC installation and before operation, seal the ends of all installed ducts including all register boots and intakes to keep the ducts clean until construction is completed (including installation of flooring, carpets, cabinetry, and finish carpentry). The duct openings can be covered with clear plastic wrap or plastic carpet protector secured with painters tape (see Figure 5). Cover any openings in floors with OSB or plywood to prevent a tripping hazard.

Cover all installed air handling units with plastic during construction (the HVAC equipment should be turned off).

Vacuum each area of the home as construction work is completed in the areas.

Clean the ducts and replace the filters as described below.

Tools and Equipment for Cleaning Ducts

To clean flexible ducts, use tools are intended for duct cleaning and that will not damage the interior surfaces of the ducts. Use a vacuum cleaner equipped with a soft bristle brush and with adequate suction and airflow to remove particles without damaging the ducts.

As described in ACCA Standard 6, particulate collectors and canister vacuums used indoors should be equipped with high efficiency particulate air (HEPA) filters and be free of gases or vapors. They should be sized appropriately to avoid particle release into the indoor environment. A HEPA filter is one that can remove 99.97% of particles passing through it sized 0.3 microns or bigger.

Common flexible duct cleaning tools are cable-driven or pneumatic brushing systems using soft bristle brushes. Pneumatic brushing systems directly contact and brush the interior surfaces of the ducts to dislodge debris. Size the duct surface brushing systems according to the cleaning manufacturer’s instructions for the size and type of ducts being cleaned. After brushing is completed, use pressurized compressed air to “wash” the newly cleaned surfaces of the ducts to transport the dislodged particulates to a high volume particulate collector. ACCA describes a high volume particulate collector as equipment that is capable of moving air at a high rate (i.e., greater than 800 cfm) and having a primary filtration cabinet designed for volume collection of debris and particulates (ACCA 2007).

How to Clean Flexible Ducts

(to be done by HVAC professionals who meet the minimum qualifications of ACCA Standard 6)

- Clean all tools and equipment before bringing them onto the work site.

- Operate all cleaning equipment in accordance with the cleaning equipment manufacturer’s guidelines. Equipment should be appropriate for the cleaning operation being undertaken.

- Be sure that all HVAC system functions are turned off and that all pilot lights are extinguished.

- Install containment barriers (i.e., plastic sheeting or temporary partitions) to separate dusty areas from areas being cleaned.

- Conduct a visual assessment of the interior and exterior of the flexible ducts for particulate buildup or any other debris. Because flexible ducts do not have access panels, it may be possible to view only the supply or return openings of the ducts, as well as the external condition of the ducts. Do not use ducts that are wet or show any signs of mold.

- To prevent an undesired release of particulates, maintain appropriate negative pressure differentials (i.e., 0.01 to 0.02 inches water column, per ACCA Standard 6) within the duct system with respect to the house. If the equipment used to create negative duct pressurization does not have HEPA filtration, the equipment must be exhausted to the outdoors. NOTE: Use caution when establishing a negative pressure because gas-fired equipment could back draft, introducing flue gases indoors or causing a fire.

- Before proceeding with cleaning flexible ducts, the workers who are doing the cleaning should wear NIOSH-approved respirators or dust masks, along with nitrile gloves.

- Place the hose end of the vacuum cleaner, equipped with the flexible bristle brush, into the connection point of either end of the duct to dislodge and transport any particulates in the ducts. Be careful not to damage, penetrate, or cut through the mylar surface of the ducts during cleaning. Use of the following sequence will prevent cleaned portions of the duct system from becoming recontaminated:

- Start at the HVAC system’s return air intakes and begin vacuuming the inside of the flexible ducts.

- Follow the pathway of the designed airflow through the inside of the ducts to the air handling unit.

- Vacuum the inside of the ducts outward from the air handling unit through accessible supply lines and discharge points.

- NOTE: The air handling unit should be cleaned at the same time the ducts are cleaned.

- After debris has been collected in the cleaning equipment, do not open the vacuum or particulate collector indoors.

- After cleaning the ducts, replace all existing filters in the air handling unit. Place the soiled filters in plastic bags and seal the bags with duct tape prior to carrying them through the house to the outdoors. Properly dispose of all used HVAC filters in accordance with applicable federal, state, and local regulations.

- Remove and wet-clean all registers, diffusers, or grilles with a detergent-type cleaner (i.e., with a pH ranging from 3 to 12 [ACCA 2007]). Rinse them with clean water, dry them, and return them to their locations.

Success

Never use antimicrobial approaches such as wet solvents, sanitizers, or ultraviolet (UV) light as a substitute for physically removing the particulates from the flexible ducts with a vacuum and brushes.

Avoid the use of biocides and sealants, which can pose health risks to the eyes, nose, and skin of the construction workers and subsequently the occupants of the home.

Replace any ducts that are wet or contain evidence of biological growth or mold. If moisture is found in the ducts, try to identify the cause and source prior to replacing the ducts. Replacement of flexible ductwork must meet local, state, and federal code requirements. Follow the duct manufacturer’s instructions for re-installation of the ducts.

Do not cut access panels or holes in the flexible ductwork. Access flexible ducts only from the supply or return openings of those ducts.

Climate

No climate-specific information applies.

Compliance

Compliance

Retrofit

SCOPE

Whenever construction activities will generate a lot of dust or debris, such as in large remodeling and building addition projects, protect the existing air distribution system by turning off the central HVAC and closing and covering supply and return registers.

When installing new ducts as part of an addition or upgrade project, keep the duct openings and duct registers covered until all construction work is completed. Prior to starting up the system, vacuum out any debris that may have entered the ducts.

If the duct system is being prepared for the addition of spray foam insulation to seal connections or insulate register boots, view the Standard Workforce Specifications.

If the duct system is being prepared for the addition of Injected Spray Sealant to reduce overall system leakage, view the BASC Guide: Injected Spray Sealant for Existing HVAC Ducts.

DESCRIPTION

Follow the practices and precautions for new construction on the Description tab of this guide. Construction activities can produce dust and debris even at small scope or scale. When this result is reasonably expected, turn off the HVAC system and cover all nearby duct system inlets and outlets prior to beginning any construction or remodeling work inside the home. Unlike with new construction, much of the system is already inaccessible behind architectural and finish materials so prevention is the first and best control method.

Additions: See Existing HVAC System Upgrade or Expansion for a discussion on when and how to add spaces to an existing distribution system. Coordinate all protection and clean-up activities as you would with new construction. As with new construction, use ACCA Manual D and provide a schematic of the layout to the home owner for future reference.

Existing Buildings: See Assessment of Existing HVAC Systems for a discussion of how to determine whether a flawed duct design may be contributing to poor HVAC system performance. Filters and elbows clogged with debris are a common cause of poor HVAC system performance.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.