Scope

Install air filters on any ducted heating and cooling systems to filter air passing through the return air duct and outdoor air that is mechanically supplied to the air handler.

- Locate the filter where it can be easily accessed by the homeowner for replacement or cleaning.

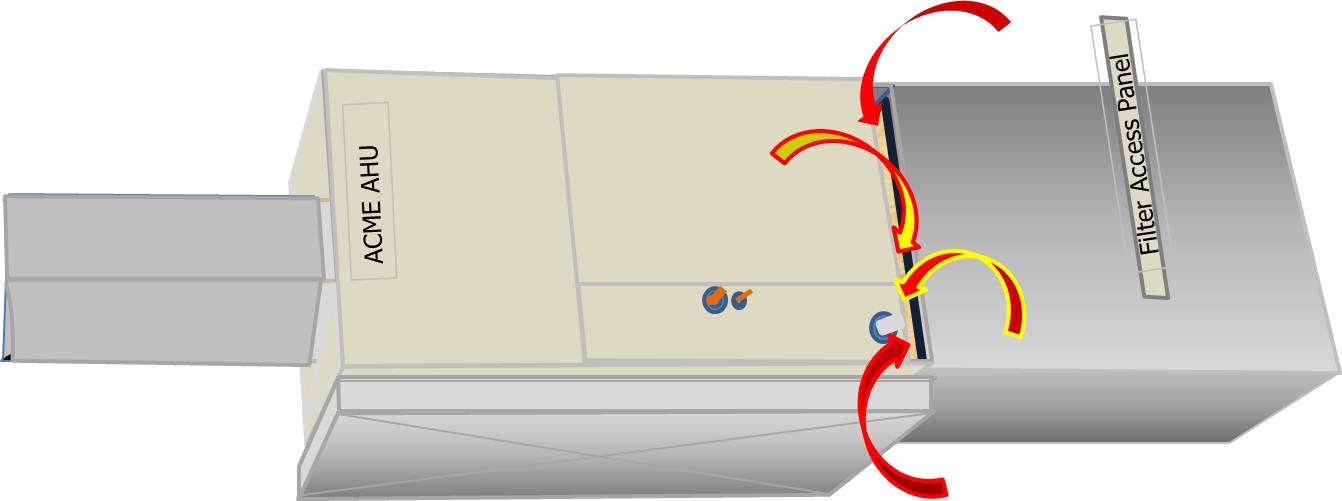

- If the filter is installed in a filter media box attached to the air handler, the access panel for the filter should be fitted with a flexible, air-tight gasket to prevent air leakage.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Air filters are an important component of forced air HVAC systems. Filters are installed on the return side of the HVAC air handler to clean the air to protect the HVAC motor and to improve indoor air quality. Filters should also be installed in fresh air intakes to clean outside air that is brought into the home. Filters with higher MERV (Minimum Efficiency Reporting Value) ratings of MERV 6 or above can trap pollutants like pollen, dust mites, and mold spores. However, a dirty, clogged filter can dramatically reduce air flow, increasing furnace run time and increasing both wear on the motor and energy consumption. For optimum operation of both the filter and the HVAC equipment, the filters should be replaced or cleaned frequently. Therefore, the filters should be located in a place that is easily accessible for the home owner.

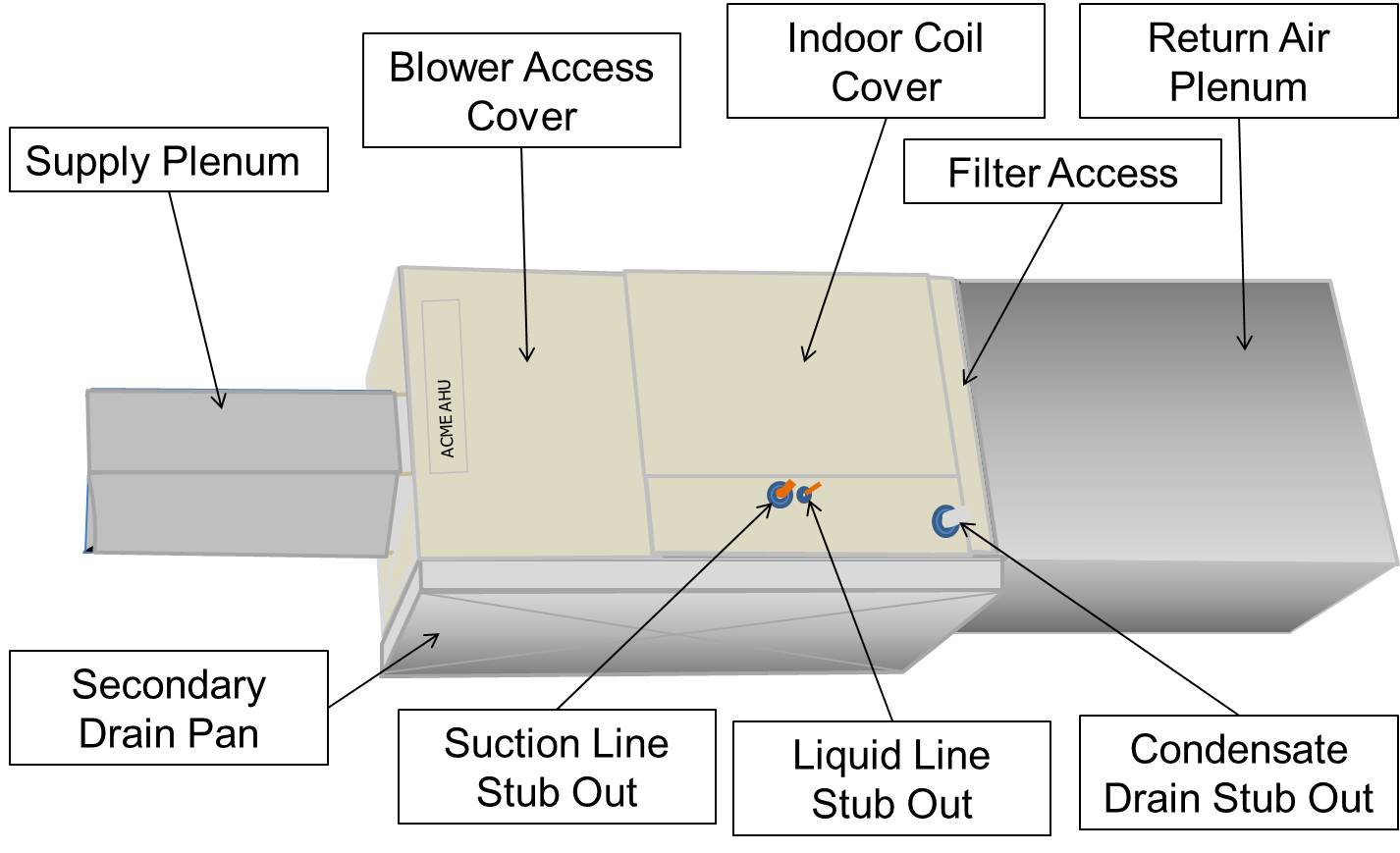

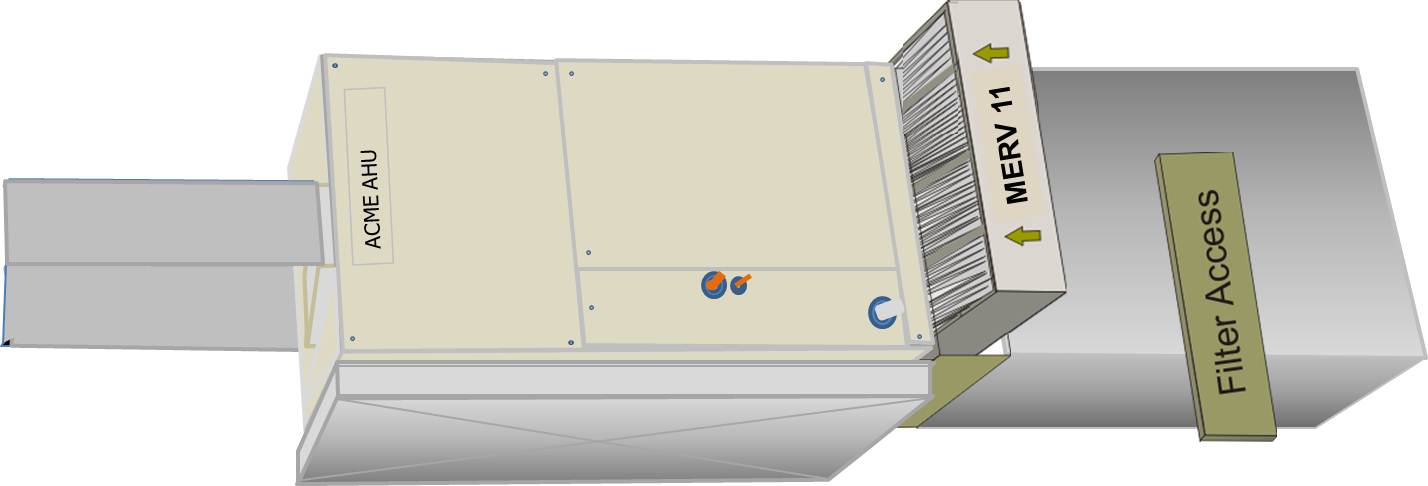

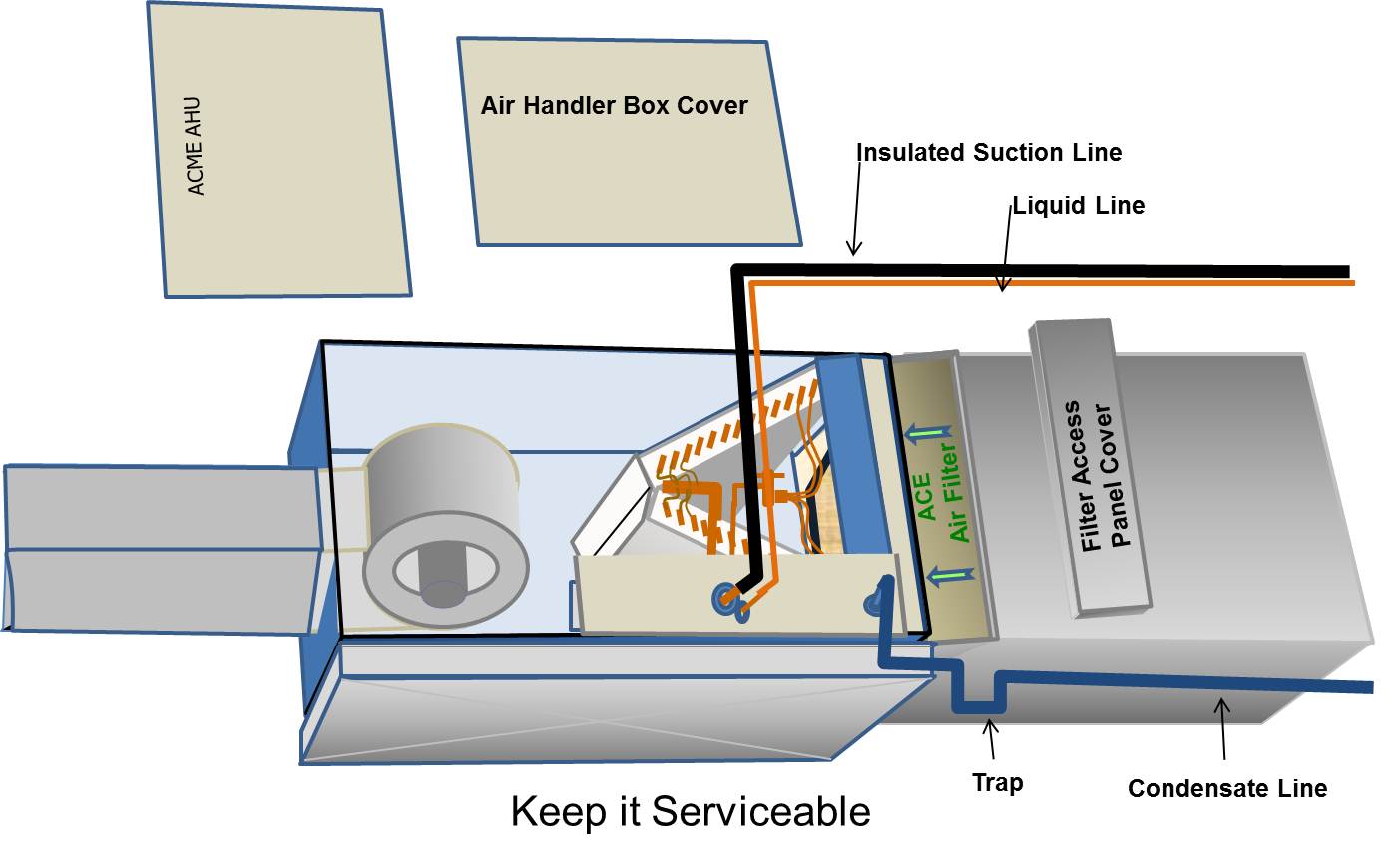

If the furnace air handler is in an accessible location (such as a utility room, a basement, or an attic with a pull-down staircase), the filter can be installed in the air handler at the return plenum. The air handler box should be equipped with a filter media box that has a removable access panel cover that has a gasket for an air-tight seal when closed. The filter box might be prefabricated by the manufacturer or could be fabricated on site. The filter media frame should be appropriate for the size and type of filter desired. The filter dimensions and filter depth both influence filter capacity and air flow velocity. Filter sizing must be taken into account when designing the HVAC system to ensure that the HVAC system can handle the associated pressure drop, especially with high MERV filters. Increasing the filter surface area will decrease pressure drop; options for increasing surface area could include using more deeply pleated filters or larger dimensioned filters. Filters must be sized using the Air Conditioning Contractors of America (ACCA) Manual D (ANSI/ACCA 2009). For more information on furnace filter types, MERV ratings, and sizing, see the guide High MERV Filter.

If the furnace is in the attic, the attic should be equipped with a staircase or pull-down stairs and a permanently installed walkway that the homeowner or service technician can use to get to the furnace.

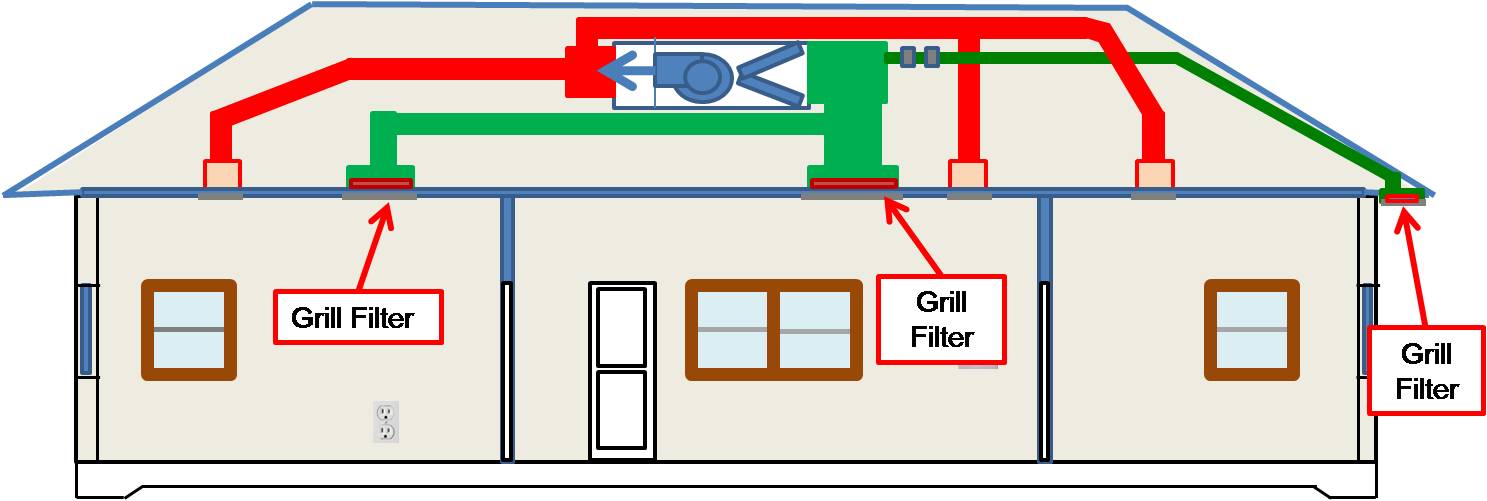

If the furnace air handler is located in an inaccessible location such as a crawlspace or attic without a staircase, then the furnace filters should be located in the return grilles, with a filter located in each return grille.

If the home is equipped with a fresh air intake that is ducted to the air handler, a filter should be installed at the fresh air intake and the fresh air intake should be located where it is accessible so the filter can be replaced or cleaned as needed.

How to Install a Filter in a Furnace Air Handler

1. Fabricate and install a filter media box on site. Install the filter media box between the return air plenum and the air handler box. Or, purchase an air handler that includes a pre-fabricated filter box. Ensure that the box is the right size for the filter to be installed. Filters must be sized using ACCA Manual D (ANSI/ACCA 2009). Improperly sized filters can cause mechanical failure.

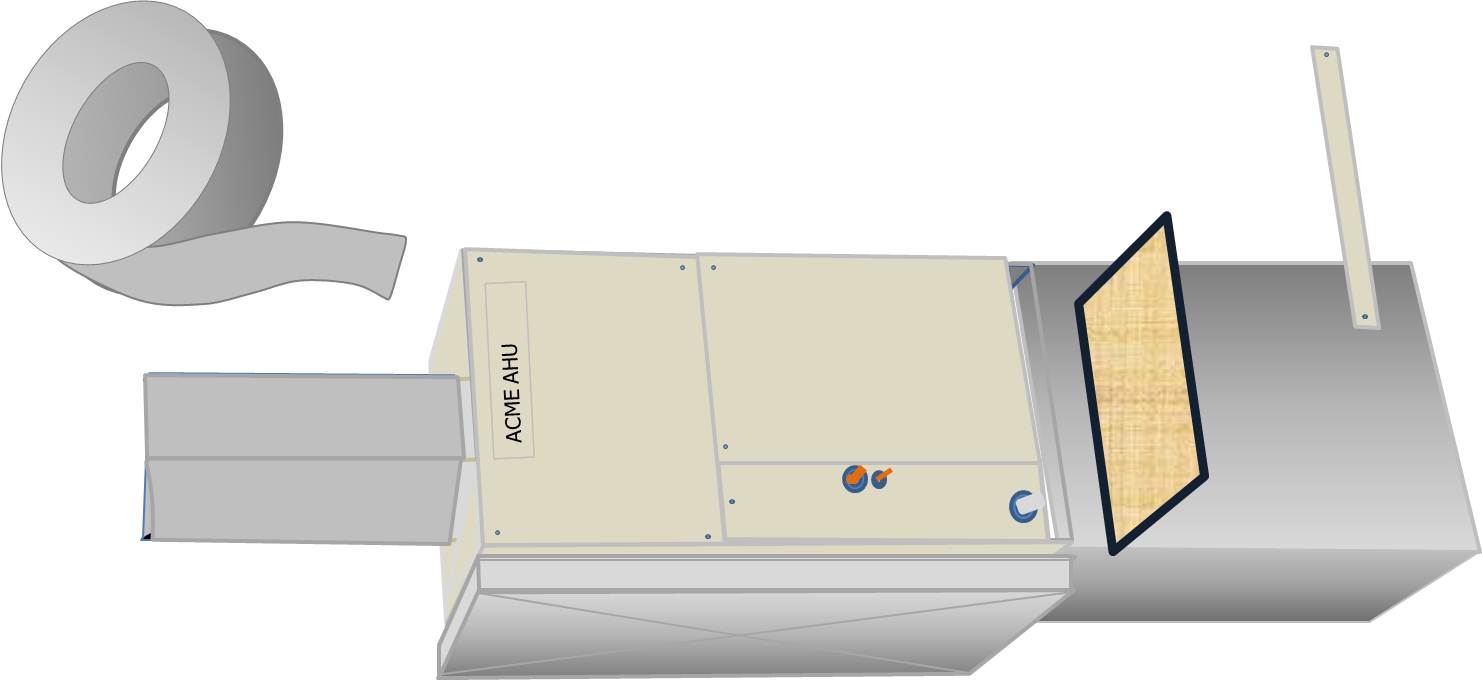

2. Slide the filter into the slot and place the filter access panel cover over the opening. The panel cover should have a gasket to ensure an air-tight seal. The cover can be fastened at the edges with duct tape or magnetic tape, which provides additional air sealing and can be easily removed when the filter is checked for cleaning or replacement. If the filter cover is left off or unsealed, the air handler can pull unconditioned and/or unwanted air into the home. Leakage at the filter cover can contribute to poor indoor air quality if the air handler is located in a garage or other areas where the air quality is not desirable.

3. Complete air handler installation by installing wiring and condensate piping. Ensure that piping and wiring do not block access to the filter.

How to Install a Filter at the Return Grille

1. If the furnace is in a location that is difficult for the homeowner to access (for example, a crawlspace or an attic that does not have stairway or drop-down stairway access), then install filters inside the return grilles in the home.

2. Ensure that grilles can be opened from within the home. Install grilles that can be removed safely, for example, grilles that are attached by a hinge along one side to minimize the risk that they will accidentally fall down while being opened.

3. Install MERV 6 or higher filters that match the sizing designation specified by the HVAC designer in accord with Manual D (ANSI/ACCA 2009). Do not install filters with MERV ratings higher than that for which the HVAC system was designed. Higher-than-specified MERV filters will increase air resistance, increasing energy usage and possibly contributing to equipment failure. For more about filter sizing, see High MERV Filter.

How to Install a Filter at the Fresh Air Intake

- Choose a location to install the outside air intake, such as a porch ceiling or eave, that is away from polluting sources and easily accessible to the home owner to facilitate filter replacement (see Figures 2 and 9). For more on outside air intake locations, see Ventilation Air Inlet Locations.

- Cut a hole for the air intake with dimensions similar to the grille and the filter to be installed. When selecting a filter size and MERV rating, consider air flow resistance because the pressure drop of this outdoor air intake duct and filter must be included in the Manual D calculations when designing the entire HVAC duct system. A MERV 6 filter should be adequate.

- Install a register box (boot) to which the duct will be attached. Most register boxes are at least 4 inches deep. This space will keep the duct terminus from touching the filter. Allowing several inches of distance between the filter and the duct terminus helps to decrease the velocity of the air flow through the filter and also ensures that the full surface area of the filter is used, which will improve filter performance and increase filter life.

- Install a hinged grille at the exterior of the fresh air intake opening (see Figure 8).

- Install wire mesh insect and bird screen.

- Place the filter on the interior side of the grille and close the grille.

- Include instructions informing the homeowner to check this filter periodically for replacement with a similar MERV-rated filter.

- If the outside air intake must be located in an inaccessible location, construct and install a filter media frame in a filter box that is positioned in an accessible place at the duct connection to the air handler return air plenum or somewhere along the fresh air intake duct that is accessible to the home owner.

Success

In homes with ducted HVAC equipment, the HVAC contractor should specify and install furnace filters at the return plenum of the air handler or at all return grilles and on any outdoor air intakes. The HERS rater should inspect to make sure that the filters are installed correctly. If the filter is installed at the furnace, inspect that a filter media box has been installed to house the filter and that this box has an access panel with a gasket to prevent air leakage.

Climate

No climate-specific information applies.

Training

Compliance

Retrofit

SCOPE

Replace the air filters in ducted heating, ventilation and air-conditioning (HVAC) equipment with new filters having a MERV rating of 6 or higher and a resistance to airflow that does not exceed the allowable pressure drop for the HVAC system.

- Check the condition of the HVAC filters. If the filters are loaded with particulates, replace with new, higher MERV filters when performing HVAC-related home performance upgrades and when responding to comfort complaints. Make sure the new filters do not exceed the allowed pressure drop for the HVAC system.

- If the homeowner requests a high-MERV (or HEPA) filter, verify the pressure drop will still be within acceptable limits.

- Provide homeowners with information for future filter replacement, such as the date of the next filter replacement, designed pressure drop for the filter, and installation instructions.

- Follow safe work practices as described in the U.S. Department of Energy’s Standard Work Specifications when replacing and handling HVAC filters and inspecting air handlers.

DESCRIPTION

How to Install and Specify High-MERV Filters in an Existing Home

- At the HVAC equipment, identify the return grille label, if available. Write down the initial resistance (inches water column, inch w.c.) of the HVAC filter at the design airflow rate (cubic-feet per minute, cfm).

- Go to each HVAC filter location and write down the dimensions of the existing filters. If there are air gaps around any of the filters, then use a measuring tape to determine the appropriate dimensions.

- When purchasing or ordering new HVAC filters, use the resistance-to-airflow specified on the return grille label to purchase a replacement with the appropriate resistance-to-airflow. If the return grille label doesn’t exist and specified filter resistance-to-airflow for the HVAC equipment is unavailable, try to determine the resistance-to-airflow of the spent filter (either on the filter, or via internet or retail sales person). If no information is available for the resistance-to-airflow, consider purchasing the same or a similar model of HVAC filter as the spent filter. Use the filter dimensions you’ve written down to ensure the replacement is the proper size. Identify filters with a MERV rating of 6 or higher. If possible, select a filter with the static pressure measurements listed on the packaging or online.

- Once you’ve acquired new HVAC filters, note the installation date and recommended replacement date on the edge with permanent marker so the homeowner can track the replacement cycle. Also note the MERV level and the specified air filter resistance-to-airflow if these are not already printed on the filter.

- Turn off the HVAC equipment or set the thermostat so it won’t operate while replacing the filters.

- Remove the spent filters from the ducted HVAC equipment.

- When installing the new HVAC filters, remove the plastic wrap but do not remove the cardboard framing. Identify the airflow arrow and align the filter so the arrow points toward the HVAC equipment in the return duct or return register grille.

- Insert the HVAC filter into the designated slot.

- Restore any levers, gaskets, seals, or grilles to their appropriate condition.

- Turn the HVAC equipment back on or return the thermostat to the appropriate temperature.

- Contractors, show homeowners how to replace their HVAC filters and advise that they be replaced every three months, or more often if needed, especially in homes with HVAC equipment that runs six to twelve months per year, with four or more occupants, pets, smoking indoors, allergic occupants, or construction taking place within or outside the home. Show the homeowner the installation date and recommended replacement date noted on the filter frame.

- Contractors, advise homeowners to check HVAC filters periodically. Filters should be replaced immediately if the filters are clogged with debris, have collapsed fins, are making a banging noise when the system comes on, or are damp or moldy.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Proper Installation of Filter =

Professionally installed air filtration ensures filters are sized to ensure adequate air flow for a home’s heating and cooling air handler and filter racks are airtight. The correct size helps ensure particles and contaminants in the air stream are effectively captured while delivering a comfortable flow of heated or cooled air. This also avoids overtaxing the air handler fan that supplies conditioned air to the home. Professional installers will locate the filter box in an easily accessible place, to encourage regular replacement. Airtight filter racks ensure the comfort system operates more efficiently without excessive leaks.