Scope

Do not install lumber, plywood, or other building materials that show visible signs of water damage or mold.

- Inspect materials before purchasing and do not purchase materials with visible signs of mold or water damage.

- Store all building materials in a dry location.

- Visually inspect all building materials prior to installation.

- If mold is present in materials stored on the job site, efforts should be made to remove all visible signs of mold (by damp wiping with water and detergent). If removal methods are not effective, the material shall be replaced. However, stains that remain after damp wipe are acceptable. Lumber with "sap stain fungi" is exempt from this Item as long as the lumber is structurally intact.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Whether selecting building materials from a supplier or installing materials that have been stored on site, it is important to avoid using materials that show visible signs of water damage or mold. Site supervisors should be vigilant to make sure building materials are properly covered and stored at the construction site to keep them dry.

Water damage. Wood products swell when they take on moisture. This change in dimension can create problems when installing the materials. Pieces may not align well when swollen and will shrink when they dry out leaving gaps. Uneven wetting and drying will cause wood to warp. Rapid drying can cause materials to crack. Fasteners that were tight when the materials were wet, can loosen when the materials dry (Reitz 1978). Products like OSB and plywood that have become saturated and then dry may not return to their specified (dry) dimensions, creating problems when the finish roofing, siding, and flooring materials are installed over them (Fisette 2005). Water can also cause the adhesive bonds to weaken, causing delamination of plywood and destroying its structural integrity.

Generally, installing finish materials over any wet substrate will cause problems. The moisture from a damp substrate will migrate into the cover materials, compromising adhesive bonds and causing more delicate finish materials to swell, crack, and warp (Forest Products Laboratory 2010).

Mold. When lumber and other water-absorbing building materials are allowed to get wet and cannot dry quickly, mold will often grow on the surface. Mold is a problem first and foremost because it is as an indicator of high moisture content. In addition, mold may present an indoor air quality problem. Some molds produce mycotoxins, which are compounds that may be irritating to people with allergies, inducing respiratory discomfort (including asthma) and fever. Mycotoxins are not volatile and cannot "off-gas" into indoor air (Robbins and Morrell 2006).

Owing to the legal attention that so-called "toxic molds" have received, installing moldy materials in a building can also expose building professionals to legal liabilities.

Storing Materials to Avoid Mold Growth

Dry building materials won't stay dry and mold-free unless they are properly stored. When stored outside or in a damp basement or garage, building materials can absorb water from the ground and from damp air. To avoid problems, follow these recommendations when handling and storing building materials on job sites:

- If possible, do not unload the lumber in the rain. This may mean rescheduling deliveries during times of wet weather or taking other precautions to avoid materials getting wet when they are delivered to the building site.

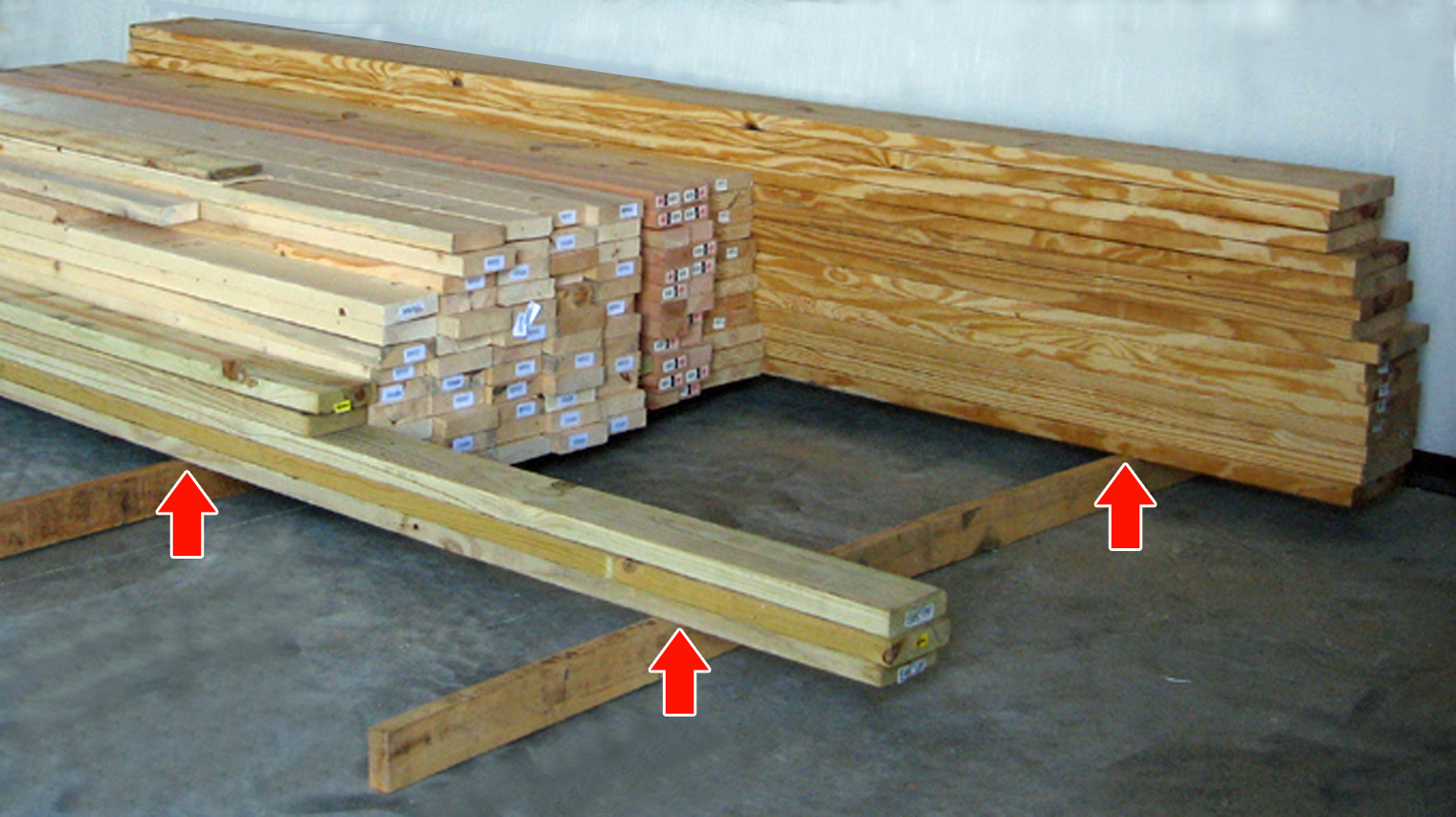

- Avoid storing materials on the ground. Keep stored building materials elevated off the ground with pallets or stickers (i.e., long pieces of lumber). (See Figure 1.) This will prevent materials from absorbing water from the ground, and will allow air to circulate, promoting drying.

- Elevate the materials on pallets or stickers even when storing them on a concrete slab. The moisture content of concrete is usually much higher than other building materials, and the concrete will transfer this moisture to any materials directly in contact with it.

- On large construction sites where bound bundles may be offloaded from a roller truck, it is sometimes difficult to avoid materials being unloaded onto the ground. Efforts should be made to move the bundles with a forklift to a protected location on pallets or stickers. Or, break apart the bundles and restack.

- Protect materials from the weather. Store lumber in a garage or other covered area, if possible. If the materials are outdoors, cover them with tarps to protect them from rain and snow. Leave the ends of the covered pile open to allow air to circulate through the materials. See Figure 2.

- Inspect bundles that are delivered with pre-applied protective coverings. Any tears or openings in the covering will expose the material to water, and water trapped inside the protective covering can accelerate moisture problems.

- If possible, schedule deliveries to limit the amount of time that building materials must be stored on the job site prior to their installation (Reitz 1978).

Visible Inspection of Building Materials

The most effective method of identifying water damage and mold on building materials is by visibly inspecting it (Robbins and Morrell 2006).

Do not select lumber or other wood products that show signs of mold - a black, powdery stain on the surface as seen in Figure 3.

Some "stain molds" may go deeper than surface molds, but often these will have only affected the living tree and are no longer actively growing. Blue stain, shown in Figure 4, is common but it does not adversely affect the wood; it is not an indicator of high moisture content and blue-stained wood may still be selected as a suitable framing material.

Look for mold on other wood-based building materials, such as plywood, OSB, and millwork. Any wood product, such as the OSB sheathing shown in Figure 5, is susceptible to growing mold when moisture levels of the material remain high for extended periods of time without drying.

Always protect drywall from moisture. Wet drywall is especially susceptible to growing mold, as seen in Figure 6. Even the moisture-resistant drywall product commonly referred to as "green board" may support mold growth.

Avoid water damaged materials. Look for other visible signs of water damage such as water stains or separation of wood fibers. Pay particular attention when selecting plywood panels to avoid panels that have delaminated, as shown in Figure 7. If plywood becomes soaked, the moisture can affect the adhesive bonds between plies, effectively destroying the structural integrity of the panel.

Measuring Moisture Content

Controlling moisture is the best way to avoid mold and to maintain the dimensional stability of building materials. To ensure that building materials have low moisture content and will not support mold growth, test with a moisture meter before installing the materials, or before covering up or enclosing the materials (EPA 2012).

Acceptable moisture levels of common building materials:

- Lumber. The moisture content of framing lumber and wood sheathing materials should not exceed 18% moisture content before the building is enclosed (EPA 2018).

- Concrete floors. Industry practice, following Swedish standards, calls for concrete floors to be at a relative humidity of lower that 80% near the center of the slab section before installing wood-based flooring over the top (PCA 2012).

- Drywall. There is no accepted standard for drywall. However, drywall is manufactured to a much lower moisture content than the moisture content accepted for wood framing (USG 2007). When drywall is installed over wood studs and ceiling joists or trusses, the moisture content of the two different materials will equalize. The net result will be a moisture content lower than the wood. A drywall moisture content higher than 18% would be unacceptable, as it would raise the moisture content of the framing above acceptable levels. Generally, moisture on drywall will be readily apparent in the form of discolored finishes or deteriorating surfaces.

Equilibrium Moisture Content

The moisture content of a building material depends on the relative humidity of the surrounding air (Simpson 1998). The moisture in the material will want to equalize with the amount of moisture in the air. This is referred to as "equilibrium moisture content" and should be taken into account when testing a material's moisture content. The table below shows the approximate moisture content that wood building products will stabilize to at various levels of relative humidity (i.e., the equilibrium moisture content) (FPMDI 1998). As an example, when the relative humidity of indoor air is maintained at 50% or below, wood products in the building will stabilize to an equilibrium moisture content of 9%.

| Relative Humidity of Air (%) | Equilibrium Moisture Content of Wood (%) |

|---|---|

| 0 | 0 |

| 25 | 5 |

| 50 | 9 |

| 75 | 14 |

| 99 | 23 to 30 |

How to Remove Mold

- When small amounts of mold are present, clean the surface with a mild detergent and warm-water solution. Use the gentlest cleaning method that effectively removes the mold. Hydrogen peroxide-based solutions may be effective in removing mold stains. Do not use bleach when trying to remove mold. Bleach will not render the spores inactive, and bleach is a lung and skin irritant, which presents an unnecessary risk to the workers using it (NYCDHMH 2008).

- Non-porous materials (such as metals, glass, and hard plastics) usually can be cleaned.

- Semi-porous and porous structural materials, such as wood and concrete, can be cleaned if they are structurally sound.

- Porous materials (such as ceiling tiles, drywall, and insulation with more than a small area of mold growth) cannot usually be cleaned and should be discarded (NYCDHMH 2008).

- Allow cleaned materials to dry. Visibly inspect and select mold-free pieces for installing (NYCDHMH 2008).

- If efforts to remove the mold are unsuccessful, discard the materials. Do not take the chance of installing it.

Success

Visibly inspect all construction materials prior to purchase and again prior to installation.

Discard pieces with visible mold.

If construction materials must be stored on site, store in a dry covered area or cover with tarps. Store elevated on pallets or boards.

Climate

Precautions should be taken to avoid moldy and water-damaged materials in all climate zones.

The incidence of mold and water damage is higher in wet regions due to the increased chance of rain and snowfall, and slower drying cycles, which will promote mold growth.

In dry climates, there will be fewer opportunities for rain and snow to wet materials stored on construction sites, and building materials will tend to dry faster, reducing the likelihood of mold growth. However, building materials may become wet from any moisture source, not just climate sources. Efforts to properly store materials and inspect for mold and water damage before installing materials should be taken regardless of the climate zone.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Water Managed Building Materials = Interior Moisture Control Materials

Wood, drywall, and other building materials are susceptible to moisture damage in areas exposed to water such as bathrooms, sinks, and even entry areas. Water-resistant materials should be used in these areas. Tile and stone are water resistant when installed with cement-based underlayment and moisture barriers. Carpet should not be used in damp areas. Fiberglass-based wall board is an option in potentially damp areas such as basements.