Scope

Include adequate, sturdy wall space for balance of system components when building a Renewable Energy Ready Home (RERH).

- Attach a piece of plywood to the wall for mounting solar photovoltaic (PV) equipment including the inverter, meter and shut off switch.

- Take into account space requirements and layout for solar photovoltaic system components early in the design process.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

A renewable energy-ready home (RERH) is one that is built with the wiring and plumbing conduit and other components in place to facilitate the future installation of solar photovoltaic (PV) panels and/or solar water heating panels. Some energy-efficiency programs, like the U.S. Department of Energy’s DOE Zero Energy Ready Home Program, require homes to be renewable-energy ready.

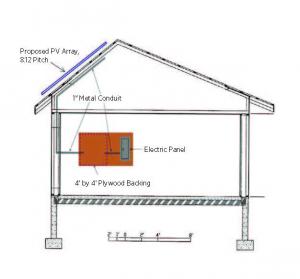

Solar PV system inverters can be quite heavy (>80 pounds), necessitating a solid backing to mount the inverter. To meet the requirement for the DOE Zero Energy Ready Home program, a 4ft x 4ft piece of finished plywood should be mounted near the electrical service panel for the PV balance of system components, including the inverter, meters and disconnects.

The purpose of the plywood backing is to

- Ensure a dedicated space for these components.

- Provide a secure foundation for mounting future equipment.

- Facilitate the future installation of these components by the installer.

The 4 ft. x 4 ft. plywood sheet should be fastened to the wall studs and mounted so that its center is roughly 4.5 feet above the floor. The dedicated inverter area may be located inside or outside the home. In either case, the dedicated inverter location should be free of direct sunlight, excessive heat, or any harsh or extreme weather conditions. It is also recommended that the inverter mounting area not share a common wall with a living space, such as an adjacent bedroom, where slight noise and vibration may be considered a nuisance. In all cases, the builder should conform to all local or national codes when meeting this specification.

The builder should clearly identify the location of the designated area on electrical and architectural diagrams. This area should be labeled as the RERH balance of system component.

How to Designate Space for the Balance of System Board

- To meet the requirements of the DOE Zero Energy Ready Home program, designate a dedicated space approximately 4.5 ft above the floor for the future balance of system components, 4 ft tall by 4 ft wide. Consider locating the wall space directly beneath the roof space for the future PV system to minimize the wiring conduit required.

- Label the space by placing a water resistant 10 in. x 6 in. label or sign in the center of the plywood that reads “Renewable Energy Ready Home - Solar PV Inverter/Service Panel Location.”

- Record the balance of system wall location on the floor plan to be provided to the homeowner.

The Balance-of-System (BOS) components include all of the electrical, mechanical and hardware elements integrated into the PV system (see Figure 1). Some of those elements are: the inverter, the charge controller, disconnect switches, the rack and mounting system for the array, and a battery bank. Many of the BOS components need to be protected from the weather elements. The parts that are required to be installed in weather-resistant enclosure require proper working and maintenance clearances. A secure mounting space is required for those components as well.

Inverter

This converts the direct current (DC) power coming off of the panels (or from the battery bank) into alternating current (AC), the convention for household electricity. Inverters vary in terms of their capacity (how much electrical current they can handle) and the “quality” of the AC they produce (some household loads—lights, appliances—can tolerate lower-grade current, while others—printers, computers—have more exacting needs).

Charge Controller

This manages the flow of electrical power from the panels to the battery bank and household loads.

Battery Bank

PV systems need deep-cycle batteries; this means that they are almost always lead-acid, big, and heavy. The cost of a battery bank depends on its capacity—just how much electricity is needed in storage to deal with nighttime power needs and cloudy days. While charging, batteries produce hydrogen gas; therefore, if used, battery banks require proper ventilation for safe operation. When handling leaky batteries, use care to avoid damage from the sulfuric acid.

Success

Ensure adequate utility room early in the house design process to allow for ample space for solar photovoltaic (PV) and water heating system components. Confirm with local code officials early in the design process what steps are needed to guarantee that installation of PV panels will meet with local codes, homeowner's association covenants, and historic district regulations.

Protect the electrical and mechanical components of the PV system from bulk moisture, high temperatures, and direct sunlight. The utility room should be properly ventilated and maintain average indoor temperatures. Proper clearances and working spaces should also be maintained.

Climate

The DOE Zero Energy Ready Home PV-Ready Checklist (Revision 07) is required only under the following condition related to climate (See the Compliance Tab for other exceptions):

- Location, based on zip code, has at least 5 kWh/m2/day average daily solar radiation based on annual solar insolation using the PVWatts online tool. See map below.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Building Science Corporation, lead for the Building Science Consortium (BSC), a DOE Building America Research Team

Pacific Northwest National Laboratory

Sales

Solar Electric Ready Home = Solar Electric Ready Home

As solar photovoltaic (PV) panels have significantly come down in price, many homeowners are installing them to produce clean power and reduce their electric bills. Many more homeowners are likely to want this option for the future. Solar electric-ready homes make this possible with minimal to no disruption or cost penalty using simple no-cost/low-cost details and best practices integrated during construction. This includes ensuring adequate unshaded roof space for the PV panels, installing conduit from the attic to the electric service panel, securing documentation that the roof is designed to support the extra weight of the PV array, and providing adequate space near the electrical panel for balance of system components.