Scope

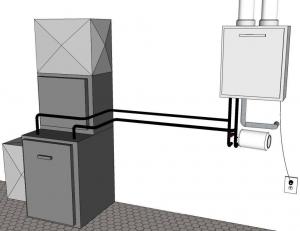

Assemble a combination space and water heating (combo) system as indicated in building plans. To maintain consistency with Building America’s energy savings goals, this measure guide focuses on the application of a condensing tankless water heater with a hydronic air handling unit (AHU) in single-family homes, but touches on other configuration options.

Install the selected combo system equipment per applicable local and state building codes and manufacturer specifications, and confirm proper operation. Ensure that health and safety measures are in place regarding minimum water temperature and temperature shock, and review proper maintenance and operation requirements with the homeowner.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Combined space and water heating systems use a single thermal engine to provide domestic water heating (DWH) and space heating for a home. The combination of an air handling unit (AHU) and tankless water heater in pre-engineered or engineered applications can enhance the energy efficiency of meeting these heating needs in residential applications.

This measure will focus on the most common forced hot air integrated systems consisting of:

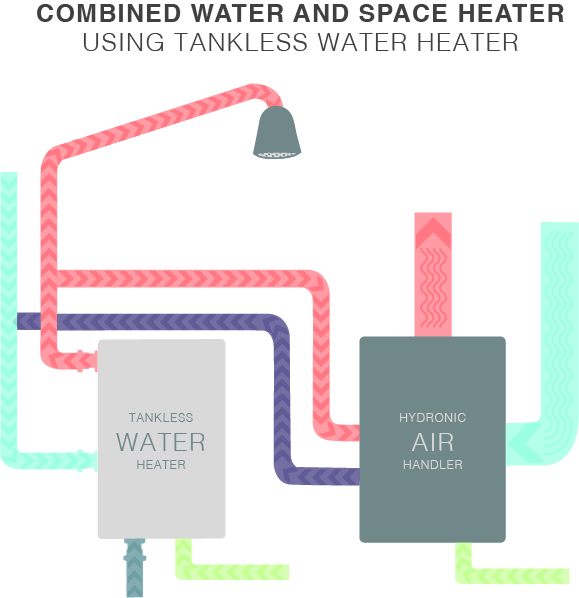

- Tankless water heater (an on-demand water heater). The tankless water heater serves two purposes in the hydronic system: first, it provides continuous hot water for use throughout the home. Second, when a call for heat is made, the tankless water heater acts as the heat-source for the air handler, providing both hot water and heating for the home at the same time (Figure 1). The tankless unit can be condensing or non-condensing. This guide focuses on high efficiency, condensing tankless water heaters in support of Building America’s energy savings goals.

- Hydronic air handler. The hydronic AHU features a hydronic heating coil in place of either electric heating elements or gas-fired heat exchangers. When in heating mode, a hydro pump circulates hot water between the tankless water heater and the hydronic coil.

- Cooling coil (optional, not included in detail in this measure). Though not required, systems in cooling-dominated climates may include a cooling coil. The cooling coil operates the same as any other cooling system and can be integral to the hydronic AHU or separate.

Heated water from the tankless unit passes through a water-to-air heat exchanger to heat the room air. A fan blower circulates the heated air through the heat exchanger and into the home’s air distribution network. If a demand for DHW occurs while there is a call for heat, the system shuts the AHU off until the DHW demand is gone. There are several advantages of this system:

- Easy integration into a home with a forced air furnace and storage water heater.

- Reduced potential for durability concerns experienced with non-integrated, high efficiency furnaces associated with cool return air.

- Better capacity modulation and comfort control compared with gas furnaces or electric heat pumps.

- Controls water flow rate, water temperature, and air flow rate independently. Air side can be set for continuous operation and water side modulated to provide continuous air filtration and good mixing (comfort) in the space with high-velocity diffusers – an advantage for ASHRAE ventilation requirements.

- Requires only a single combustion air and vent pipe, replacing two pipes (for separate heating and water heating appliances).

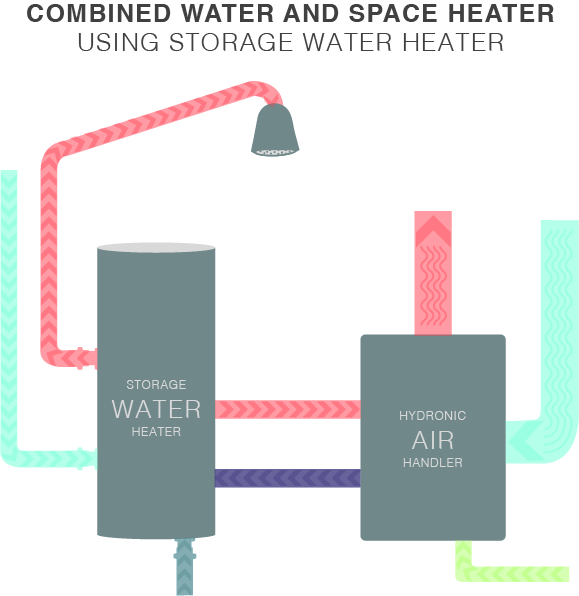

Combined systems, referred to herein as combos, can be purchased as pre-engineered packaged systems or can be custom-built by bringing together AHUs and water heaters built by separate manufacturers. Storage water heaters have historically been used in combo systems, but an influx of foreign tankless (on-demand) water heater technologies that are compact, high-capacity, and wall-hung have encroached the market. Because storage water heaters store hot water, they perform well by quickly delivering water at set point for short demands. However, they deliver varying water temperatures during long draws, because of temperature stratification in the tank. Tankless technology performs well with long draws at steady flow rates. Tankless water heaters in pre-engineered or engineered applications can enhance the energy efficiency of meeting these heating needs in residential applications.

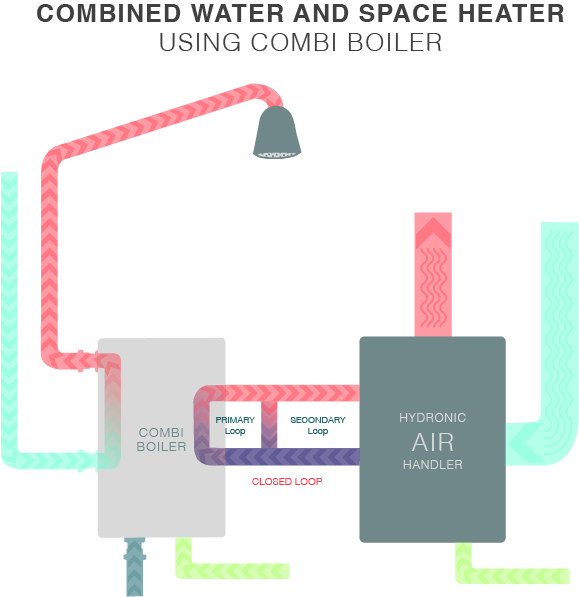

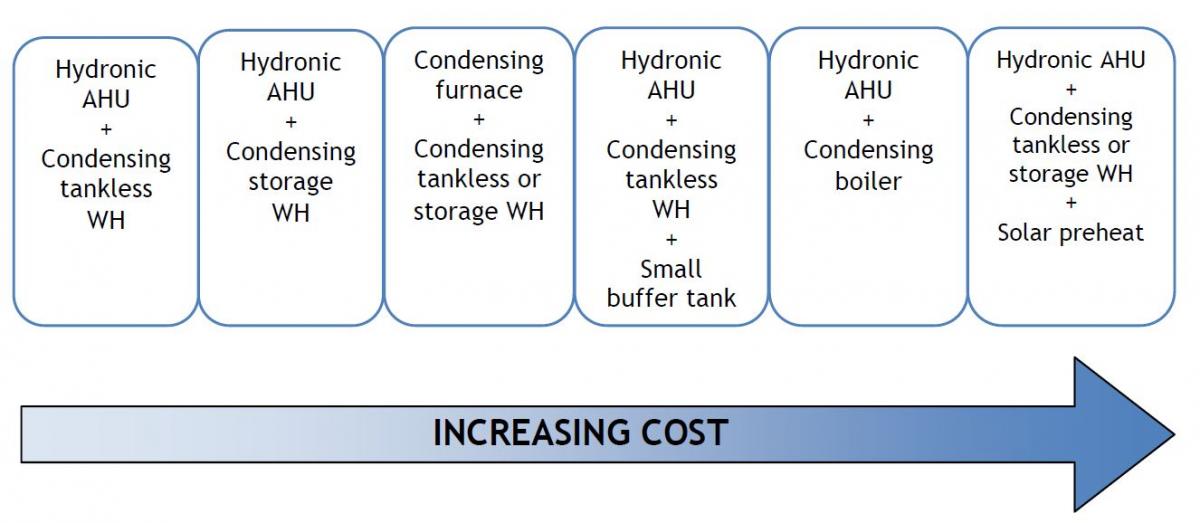

Combination space and water heating systems can be assembled with a range of equipment, such as condensing furnaces or boilers (Figure 2), storage or tankless water heaters (Figure 3), small buffer storage tanks, solar pre-heat, and radiant heating systems. Equipment selection will directly impact the cost of the system as well as the operating efficiency.

Pre-screen potential sites by assessing the residence envelope characteristics, outdoor design temperature, expected hot water usage, and furnace and hot water heater orientations.

Conduct a full assessment of the residence by calculating its heat load using a protocol such as Manual J. Properly size the combo system to meet the estimated space and hot water heating loads of the home by selecting a combination of water heater and AHU that delivers:

- adequate domestic hot water during predicted peak draws,

- warm air at adequate temperature and air flow during design conditions,

- and adequate heat exchange across the AHU water coil to promote high-efficiency water heater operation.

Benefits and Costs

Combined space and water heating systems can offer a wide variety of benefits:

- High efficiency and capacity - The packaged combo systems that are commercially available are roughly 95% efficient, compared to average nameplate efficiencies of installed equipment of 78% for forced air furnaces and 58 %for storage water heaters. The lack of a storage tank eliminates standby heating losses. The tankless water heater can also offer high heating capacity compared to conventional storage water heaters.

- Energy Savings - Studies indicate integrated systems can reduce energy consumption by up to 20% compared to separate water heating and space heating equipment. Combo systems can provide up to 10% whole house energy savings on average, while maintaining homeowners comfort (PARR, Building America Case Study).

- Single piece of equipment - A principal benefit to homeowners is their investment in just one piece of high efficiency equipment that serves two heating loads. The cost of this integrated system, including labor can be as low as $3,500 (PARR, Building America Case Study), but can be as high as $10,000 depending on complexity and contractor familiarity (Shoenbauer 2011). Contributing to additional costs are often-required gas line and venting upgrades.

- Space savings – The compact wall-hung nature of the integrated combo system, limited to a tankless water heater and an air handler, can offer significant space savings compared to a traditional furnace and storage water heater.

These systems do face barriers to wider adoption:

- Short draws – Compared to standard storage water heaters, the performance of tankless water heaters is negatively affected by multiple short-draws on the system. The compact heat exchanger results in a large pressure drop and units have a minimum hot water draw rate to initiate burner firing. Furthermore, burner ignition delay can result in water wastage and the “cold water sandwich” effect during low or intermittent draws.

- Cost and availability – There is uncertainty among potential customers and installers in terms of equipment installed costs, installation and service contractor coordination, customer awareness of benefits and natural gas service availability.

- Technical considerations – Combo systems require stable water temperature throughout the range of common flow rates and use patterns. Regular filter cleaning intervals are needed to avoid excessive mineral scale and galvanic corrosion. Consistency of water temperature at low flow rates can be an issue, depending on the minimum draw required to activate the burner (many tankless units have activation thresholds at 0.4 gpm, with some units able to accommodate even lower flow rates once activated). Most manufacturers implement a sensor to detect hot water draws. The sensor shuts the AHU down temporarily to give priority to domestic hot water needs. Room temperature recovery could be significant, depending on the domestic hot water demands, their durations, outside air temperatures, and thermostat cycles.

- Market barriers – A major barrier to wide acceptance of a new technology or practice is a customer’s perceived risk that purported benefits will never be realized and a vendor’s or installer’s perceived risk that working in this business will be unprofitable.

- Rating procedures – Current rating procedures are designed to assess single end-use equipment, such as furnaces and water heaters. They are inadequate for developing reasonable energy savings estimates for combo system equipment.

Accord to recent Building America research (Rudd 2012), there are a range of costs for combo systems varying by the equipment included in the configurations. Figure 4 provides a general estimate of those costs. System costs are also strongly influenced by contractor familiarity with the system and installation best practices as well as whether the equipment is being placed in a new construction or retrofit scenario. In retrofit scenarios, there can be additional costs associated with gas line upgrades to accommodate the condensing tankless water heater, duct work (insulation, air-sealing, etc.), and adjustments to piping runs from the existing separate water heater and furnace.

How to Implement a Forced Hot Air Combined Space and Water Heating System

These systems are designed to be professionally installed due to their complexity and the potential need for gas line upgrades (1/2” to 3/4” pipe) to have adequate capacity for the high firing rate of a tankless water heater, and for adjustments to duct work and piping. Combo systems are ideal for new construction applications that minimize duct work and piping runs as well as ensure proper sizing of the gas line, but can be applied in retrofit scenarios as well. The opportunity to properly design and size the system for new construction allows for improved comfort at optimal heating supply air temperatures and flows. There are fewer issues surrounding room temperature recovery after domestic hot water prioritization when ducts are placed within the conditioned space. In retrofit scenarios, it is important that the existing duct system is well-insulated and air-sealed to ensure efficient system performance and there must be the ability for short through-wall or through-roof direct venting.

- Site Inspection and Pre-Screening* – In retrofit scenarios, it’s important to confirm that the home has an acceptable layout and existing equipment, piping, and duct work to accommodate a combo system. The size of the gas service supply line and meter should be checked along with the ability for direct venting to be installed. Combo systems utilizing condensing water heater technology perform best when hot water is delivered to the AHUs at 140°F or less. As such, AHU maximum space heating capacities are limited to about 60,000 Btu/hr. On the other hand, water heater turn-downs limit minimum space heating capacities to about 15,000 Btu/hr.

- *Note: This step will be altered if the system is being installed in a new construction scenario to instead focus on system design given site characteristics.

- Combo System Sizing – Proper sizing of water heaters should include burner input and rated efficiency, and for AHUs, the heating and cooling loads plus air flow requirements. Sizing should take into account the calculated space heating load (and cooling loads if applicable), as well as the local coldest water supply temperature. Secondary sizing considerations include the duration of showers desired, the presence of laundry facilities, and whether or not night-time setback may be used. The information gathered during the inspection and pre-screening will allow the contractor to complete sizing calculations and properly size the combo system. It may also lead to specific equipment recommendations. If utility bills from the previous 1-3 years can be obtained from the customer, it may also be beneficial to prepare a high-level utility bill analysis that can give insight into the past heating requirements of the home.

Installation

Once the home has been determined to be a reasonable fit for a combo system, the contractor can proceed with the installation of the system itself and other ancillary upgrades as required. The installation should ensure domestic hot water (DHW) priority to avoid situations where the AHU would be providing less than 100°F air to heat the home (Rudd 2012). This temperature is too low and can lead to a “cool draft” sensation in homeowners. Delivered air should be in the range of 110°F – 115°F to avoid homeowner comfort concerns. At the same time, the installation should ensure that the water heater is set at the lowest temperature possible to maintain space heating load.

The installation must first be in accordance with the manufacturer’s instructions, and also comply with currently adopted local codes. The following items describe elements of a quality combo system installation.

- The AHU should be located as close to the water heater as reasonably possible to provide adequate water circulation and limited heat losses from piping. Piping runs should be insulated. Check with the manufacturer’s instruction for maximum distances permitted.

- If water damage could occur from a leak, drain pans should be installed under the water heater and AHU. Drain pans should have a connection to a drain.

- All piping and components must be approved for use with potable domestic hot water, including the use of non-lead based solder. Do not use existing hydronic piping systems; these may be contaminated with chemicals.

- The piping between the water heater and AHU should be no smaller than ¾-inch diameter, with a minimum number of fittings, such as elbows and tees. Any flexible piping must have smooth bends (i.e., it should not be kinked in a way that would restrict water flow). Refer to the manufacturer’s guidelines for piping sizes.

- A check valve should be used in the circulation loop to avoid back flow during domestic hot water draws, and to prevent thermal siphoning through the heating coil during the summer while air conditioning. Most water heater manufacturers provide this check valve. However, if it is not provided, one spring-loaded check valve should be installed in the return piping from the AHU to the water heater. Care should be taken in selecting a low pressure drop check valve, and installing the valve in the appropriate flow direction.

- All shutoff valves in the circulation loop should have full-size openings for low pressure drop in the normally open position.

- An air bleed valve or air separator should be installed at the highest point in the circulation loop to purge air from the loop at startup. An automatic or manual bleed valve can be used. Some AHU manufacturers install bleed valves at the top of the water coils, but an additional means for bleeding air is needed if that bleed valve is not at the highest point in the circulation loop.

- If a backflow preventer is required by local codes in the cold water supply piping, it should have a bypass drain provision; otherwise, a bladder-type expansion tank should be used to limit peak pressures.

- A means for draining should be located at the lowest point in the heating loop piping to drain the entire system.

- An anti-scald mixing (tempering) valve should be used to obtain 120°F -125°F domestic hot water from the water heater to reduce the risk of scalding.

- A condensate drain pipe or a condensate pump must be provided and connected to a drain to remove condensate from the water heater.

- If two water heaters must be combined to meet the required heat input, they should be plumbed in parallel rather than in series, so each water heater will heat equally under all conditions.

- If two AHUs are used with one water heater, they should be plumbed in parallel. Separate check valves should be used for each AHU to limit the pressure drop.

- Direct-vent condensing water heaters bring air from the outside, and combustion gases are exhausted to the outside. As such, some on-demand water heater manufacturers require use of special concentric venting where the outer passage way brings air in from outside, and the inner passageway expels the combustion gases. Using-direct vent water heaters resolves most combustion safety concerns in single family and multifamily high efficiency buildings. In high-density single family and multifamily buildings some jurisdictions require a prescribed distance between adjacent buildings for sidewall venting and a vertical vent orientation may be required.

- If snow accumulation is anticipated, a snorkel vent should be used where the pipe exits the building so as to raise the vent opening above the snow line.

- The circulation loop should be flushed by drawing at least five gallons of water through the system after installation and before using the pump.

- The AHU and gas piping should be electrically grounded according to applicable codes.

- A clean air filter should be installed initially in the AHU, and it should be cleaned or changed as often as needed to maintain efficient heating and cooling performance.

- Means for freeze protection must be considered if any part of the combo system is located in unheated spaces. Such means may include electrical pipe traces or a combination of insulation and continuous water flow. See manufacturer’s recommendations.

- If hard water may be used (e.g., well water) an evaluation of water quality should be conducted to assure hardness does not exceed the manufacturer’s maximum target levels.

Success

Combination space and water heating systems can be assembled with a range of equipment, such as condensing furnaces or boilers, storage or tankless water heaters, small buffer storage tanks, solar pre-heat, and radiant heating systems. Equipment selection will directly impact the cost of the system as well as the operating efficiency.

Pre-screen potential technologies by assessing the residence envelope characteristics, outdoor design temperature, expected hot water usage, and furnace and hot water heater orientations.

Conduct a full assessment of the residence by calculating its heat load using a protocol such as Manual J. Properly size the combo system to meet the estimated space and hot water heating loads of the home by selecting a combination of water heater and AHU that delivers:

- adequate domestic hot water during predicted peak draws,

- warm air at adequate temperature and air flow during design conditions,

- and adequate heat exchange across the AHU water coil to promote high-efficiency water heater operation.

Combo systems require stable water temperature throughout the range of common flow rates and use patterns. Regular filter cleaning intervals are needed to avoid excessive mineral scale and galvanic corrosion. Consistency of water temperature at low flow rates can be an issue, depending on the minimum draw required to activate the burner (many tankless units have activation thresholds at 0.4 gpm, with some units able to accommodate even lower flow rates once activated). Most manufacturers implement a sensor to detect hot water draws. The sensor shuts the AHU down temporarily to give priority to domestic hot water needs. Room temperature recovery could be significant, depending on the domestic hot water demands, their durations, outside air temperatures, and thermostat cycles.

Health and Safety

A common health and safety concern with combo systems is related to water stagnation in the space heating recirculation loop, which may be unused during the cooling-dominated summer months. The water in this loop will drop in temperature unless regularly circulated with heated water from the condensing tankless unit. Any time temperature in a water heating system drops between 77°F and 122°F (25°C and 50°C), it becomes a potential source for Legionella bacteria (WHO 2011), which can cause an acute respiratory infection in exposed individuals, particularly those with weaker immune systems such as children and the elderly. Some manufacturers have built-in controls to automate circulation and prevent the water temperature from dropping too low. Alternatively, a pump cycling timer could be installed with controls to ensure hot water is circulated for at least 1 minute at least once a week to completely cycle all the water through the hydronic recirculation loop (Rudd 2012).

Durability and Performance

Some manufacturers provide general recommendations to address thermal shock with the installation of a thermal shock dampening manifold installed after the thermostatic mixing valve. The purpose is to defeat cold water “sandwiches” and other low flow related temperature instabilities without introducing excess storage that produces heat loss. Some tankless water heaters are also equipped with an automated and fully modulating bypass for DHW temperature stability to avoid cold and hot water “sandwiches.”

Tankless water heaters have varying low water flow thresholds. Typically there is a general threshold (such as 0.4 gallons per minute) and then a secondary lower threshold that can be maintained once the unit has been activated (such as 0.26 gallons per minute). Low threshold activation is needed to assure availability of hot water at common low flow rates. This is especially important in homes that have installed water conservation devices, such as faucet aerators and other low flow fixtures.

Combo systems require the tankless water heater to supply the air handler unit (AHU) with sufficiently hot water to achieve supply air temperatures of 105°F or higher, which generally requires the tankless unit to produce hot water at 120°F to 160°F. Heating water to this temperature can result in the development of mineral scale and galvanic corrosion, which can require an annual cleaning/maintenance routine to ensure that system performance remains unaffected by build-up. The inlet strainer in a tankless water heater is designed to protect the modulating water valve and flow meter. Potential clogging of the inlet strainer and accumulation of calcium or lime scale in the heat exchanger and piping can be a concern. Additional pre-straining of the water just before it enters the tankless unit is an important step for keeping maintenance intervals as reasonable as possible, generally every year (Rudd 2012). Some manufacturers have built-in controls and indicators that designate when the unit is beginning to lime-up and should be flushed.

Climate

There is no formal codes and standards guidance on climate-specific applications of this technology. However, there are considerations that have been noted in past field-based research.

Warmer Climates

The application of combo systems in warmer climates can capture positive energy savings benefits. In warmer climates, the temperature of hot water delivered to the air handler can be turned down from 140°F – 160°F to about 120°F. This lower temperature allows the system to achieve high condensing efficiencies, thereby saving energy and money for the homeowner.

However, warmer climates have smaller overall heat loads that often result in the system operating at less than full-load. Operating at turned down loads negatively impacts the system’s overall efficiency. This issue can be exacerbated in smaller homes with even lower than average heating loads. Currently, commercial systems can accommodate turned down rates of as low as 10% in some cases. Most commercially available condensing tankless systems tend to have large gas input rates (minimum of 150,000 Btu/hr to a maximum of 200,000 Btu/hr). As larger systems, they are more likely to be run at a turned down rate in warmer climates, further restricting opportunities to achieve condensing high efficiencies. Although non-condensing tankless systems are available, they do not offer the energy efficiency benefits of condensing units.

Past research has noted that manufacturers should consider offering smaller systems that would be able to achieve full-load, condensing efficiencies while meeting the more modest heating demands of warmer climates.

Colder Climates

By contrast, the application of condensing tankless combo systems in colder climates can be beneficial since they will often run at full-load. However, the temperature of the hot water delivered to the air handler is often higher (140°F – 160°F) in order to meet the larger heating load. This higher temperature setting makes it more challenging to achieve condensing efficiencies.

Manufacturers have indicated they are working to developing condensing tankless systems can rely on lower temperature hot water to the air handler to boost their efficiency, while still ensuring the water is hot enough to meet health and safety standards.

In cold climates, it is critical to use sealed-combustion, direct-vent, or power-vented equipment. It is also critical to make sure that the air intake and exhaust discharge vents are located sufficiently above anticipated snow line. The intake should be sufficiently separated from the exhaust vent to prevent frost buildup on the cold air intake pipe. The exhaust discharge must be sufficiently high so that frozen condensation that may accumulate on the ground will not block the exhaust pipe. Condensate lines should be directed to an indoor drain.

Compliance

Compliance

As noted in other recent Building America research (Rudd 2012), there is currently a lack of accepted standards or well-vetted guides for best practices of combo system design. Available guidance is generally limited to small-scale, field-based research efforts completed throughout the U.S.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Gas Technology Institute, lead for the Partnership for Advanced Residential Retrofit (PARR), a DOE Building America Research Team