Scope

Design and Install the Foundation Heat Exchanger (FHX)

- Properly size the FHX based on the building’s estimated cooling and heating loads, and lay out the FHX around the basement excavation and utility trench. If the length of the existing construction excavation is not sufficient, additional trench will be required.

- Put HDPE (high-density polyethylene) pipes into the trenches and backfill/compact with dirt. Conduct hydrostatic pressure tests to detect any water leakage, and repair if necessary.

Note: Because code requirements can vary by jurisdiction, be sure to confirm approval from your local code official prior to installation.

See the Compliance tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

The foundation heat exchanger (FHX) is a new concept of cost-effective ground heat exchanger that can be connected to water-to-water or water-to-air heat pump systems for space conditioning as well as domestic water heating. This new FHX technology was proposed to reduce costs by placing the heat exchanger into the excavations made during the course of construction (e.g., the overcut for the basement and/or foundation and run-outs for water supply and the septic field). Since they reduce or eliminate the need for additional drilling or excavation, FHXs have the potential to significantly reduce or eliminate the cost premium associated with the use of ground-source heat pumps (GSHPs). In general, the total length of the borehole or excavation needed for a building is a function of the building’s space- conditioning and water-heating loads. Therefore, in the case of very highly energy-efficient homes, space-conditioning and water-heating loads may be so low that the excavations required to construct the buildings are sufficient for installing the ground heat exchanger. But more typically, even when construction excavations are insufficient for the entire ground heat exchanger, there are cost savings associated with using an FHX and thereby minimizing the length of supplemental virgin excavations.

Sizing the FHX

The first step of FHX implementation in a new house is to size the FHX properly. An FHX design tool is available in Foundation Heat Exchanger Design Tool Manual developed by Oklahoma State University. The FHX design tool allows users to perform a simulation of the FHX to determine the monthly average and peak fluid temperatures entering the heat pump. For design purposes, the minimum and maximum heat pump entering fluid temperatures (EFTs) are the key design constraints that drive sizing of the ground heat exchanger. By changing the length of the FHX, the user can limit heat pump EFTs within the allowable bounds (a proper range of minimum EFT is 30 to 40°F [17 to 22°C] above the winter outdoor design temperature. For maximum EFT, a good starting point is 90 to 100°F [32 to 38°C]. Since not all houses will have adequate ground heat exchanger capacity with an FHX alone, in cases where the maximum FHX size is still inadequate, the design tool can automatically determine the additional horizontal ground heat exchanger (HGHX) (placed in series with the FHX) required to keep heat pump EFTs within allowable bounds.

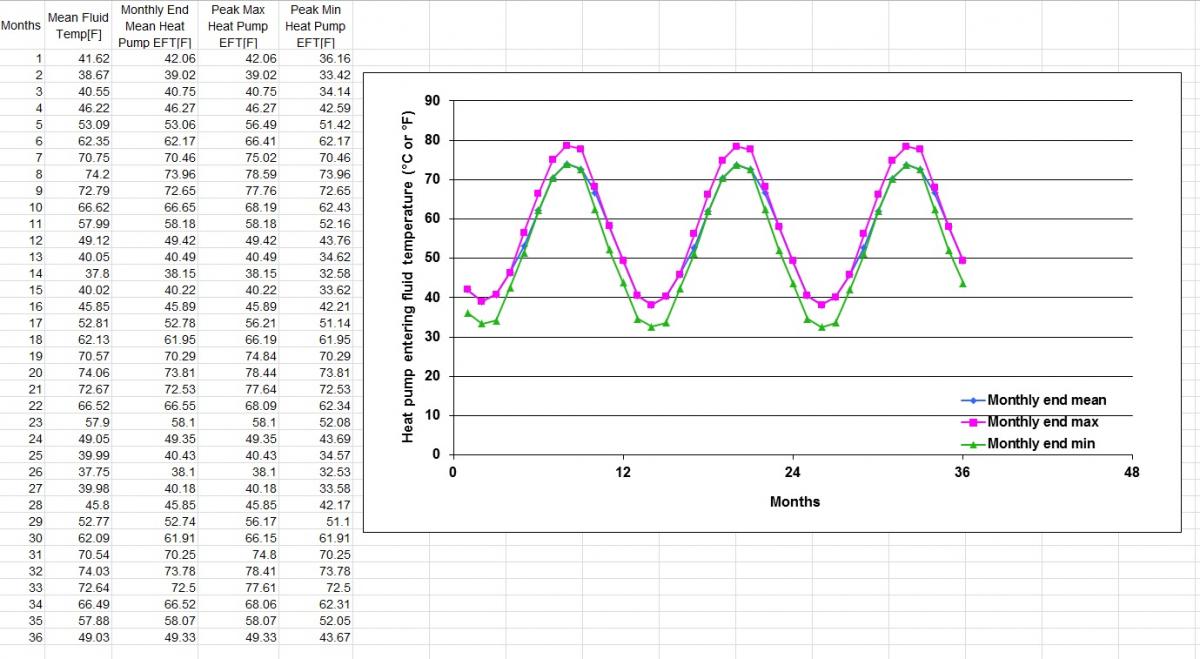

The FHX design tool requires as inputs the locations and dimensions of the FHX piping, pipe and soil thermal properties, specification of the working fluid, monthly average and peak space heating and cooling loads, duration of heating and cooling peak loads, monthly average water heating loads (if the building is served by a GSHP), heat pump performance characteristics, and simulation duration (see table below). The user clicks the “simulation” button on the spreadsheet to perform the simulation for the length of time entered (24 months recommended, using the results from the second year). The FHX design tool outputs monthly month-end values for (1) mean fluid temperature in the ground heat exchanger (averaged over the length), (2) mean heat pump EFT (i.e., mean temperature exiting the ground heat exchanger in response to the total monthly space-conditioning and water-heating loads), (3)

peak maximum heat pump EFT (in response to the peak cooling load occurring for the specified duration at end of month), and (4) peak minimum heat pump EFT (in response to the peak heating load occurring for the specified duration at end of month).

See the input and simulation result examples below. For access to this tool, contact Piljae Im at Oak Ridge National Laboratory, imp1@ornl.gov

Installation of the FHX

- After the FHX is sized, lay out the FHX runs over the house/site plan to see is the construction excavation and utility trenches are sufficient to provide the required length of heat exchanger pipe, or if additional conventional horizontal loop is needed.

- The FHX pipes could be a type of HDPE or PEX-A.

- When the FHX is installed in the excavation, adjust the distance between pipes to at least 1 to 1.5 ft for optimal performance.

- Join the pipes by heat fusion and connect them to the heat pump either directly or through a header.

- Conduct hydrostatic pressure tests to detect any water leakage, and repair it if necessary.

- Backfill the trenches with the excavated soil and compact the soil.

Note: Because code requirements can vary by jurisdiction, be sure to confirm approval from your local code official prior to installation.

Success

- Proper sizing is critical (enough length of FHX).

- Sound contact with dirt and loop is necessary (compact the dirt).

- Conduct hydrostatic pressure tests to detect any water leakage and repair it if necessary.

- Determine the soil thermal conductivity from existing cases in the vicinity.

Note: Because code requirements can vary by jurisdiction, be sure to confirm approval from your local code official prior to installation.

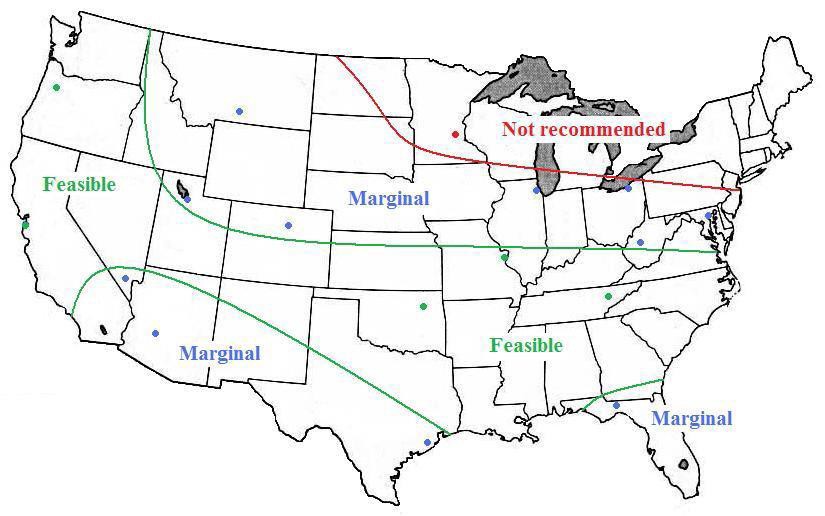

Climate

This preliminary analysis was used to construct the illustration below, which is a map of the United States showing where GSHP systems using FHXs in single-family residences appear to be feasible. There are three zones of feasibility: not recommended, marginal, and feasible. The “not recommended” zone indicates locations (such as Minneapolis) where an FHX cannot be expected to work, even with the addition of a 100 ft supplemental HGHX. The “marginal” zone includes locations that might require a supplemental HGHX (such as Billings and Houston), as well as locations where the heat pump EFTs may be fairly close to the constraints—say, within 2°F or so. Finally, the “feasible” area contains the locations where an FHX may be expected to work without being supplemented by an HGHX.

The possibility of soil freezing along the foundation was also investigated. It was found that the presence of an FHX placed in a typical basement excavation, which accommodates reasonable spacing of the pipes away from the basement wall, did not add to the freezing of the soil near the foundation, even for the most severe case simulated (Minneapolis HI). The only cause of soil freezing at the basement foundation wall was weather. There are two noticeable areas of freezing: around the FHX piping, and at a uniform depth at the ground surface. Although the soil does indeed freeze around the FHX piping, with reasonable pipe spacing from the wall, the freezing front never reaches the house foundation. Sub- freezing temperatures along the foundation are entirely due to weather effects, as the soil is frozen to a depth of about 3 ft along the entire length of the soil domain. Thus it can be concluded that the addition of an FHX will most likely not require any additional consideration regarding protecting the foundation from freezing, aside from what would be normal for any typical building in the region.

Compliance

Compliance

There is no specific compliance information associated with this measure.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.