Scope

For each condensate-producing HVAC component, install a corrosion-resistant drain pan under the equipment.

- Install a secondary drain pan of corrosion-resistant galvanized steel or durable plastic under HVAC equipment that has an evaporator coil.

- Install auxiliary drain lines and drain pans as required by code.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

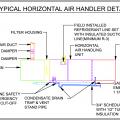

As air passes through the cold evaporator coil of an air conditioner or heat pump, its temperature is lowered below the saturation point. The moisture condenses out and falls as liquid into a collector positioned under the coil. This collector is a gutter-like device or shallow pan, which manufacturers call the primary condensate drain pan or just the condensate pan. The objective of the condensate drain pan is to thoroughly collect and then direct the condensate water to a condensate drain (Figure 1). While older HVAC systems used steel pans, today the major equipment makers use different plastic materials to build a smooth-surfaced, rust-proof condensate pan. To assist drainage and prevent pooling, some manufacturers slope the base of the pan toward the drain openings (KC Hart and Company).

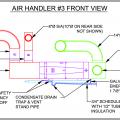

As the pan fills, it must continually drain to prevent it from overflowing and causing damage to the equipment and to the surroundings. Clogged drain lines and overflowing drain pans from equipment located in attics, basements, and closets can go undetected long enough to cause severe water damage in ceilings, floors, and walls. Poorly draining pans can collect stagnant water that can become a breeding ground for algae and bacteria (see KC Hart and Company). The drain pan should be checked periodically to look for stagnant water, blocked drain lines, overflowing pans, or corroded and leaking pans (Figure 2).

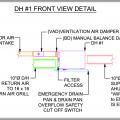

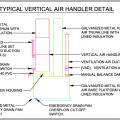

The International Residential Code requires that evaporator coils have a secondary drain pan if blockage of the drain pipe and overflow of the primary drain pan would cause damage to building components. (See the Compliance tab for detailed requirements.) The second drain pan should discharge to a conspicuous spot to alert occupants in the event of blockage of the drain pipe. For cooling systems installed in the attic, some installers will have this secondary drain discharge over a window so that it is more noticeable if it should start dripping. No trap should be installed on the auxiliary pan drain pipe. A separate overflow drain line should also be connected to the primary drain pan. This drain line, which is connected to a higher fitting on the primary condensate pan, should also drain to a conspicuous spot. Code requires that an additional auxiliary drain pan without a separate drain line be installed under the coils on which condensation will occur. This pan should be equipped with a water-level detection device (also called a float switch) that will shut off the equipment if the pan is in danger of overflowing (Figure 3). The primary drain line should also be equipped with a water-level detection device that will shut off the equipment in the event that the primary drain is blocked. Code requires that a water-level detection device should also be installed on equipment that is not required to have a secondary or auxiliary drain pan.

Although not required by codes, such water-level detection devices can also be equipped with an alarm to alert occupants that the equipment has been shut off due to high water levels in the drain pan.

Emergency pans should be made of a rust-resistant material such as plastic or galvanized steel. They should extend beyond the air handler or coil box by 3 inches or more on all sides. If the coil is attached to a high-efficiency furnace without condensate protection, this should be taken into consideration when sizing and placing a pan under the equipment. The condensate produced by the furnace can damage the building if it overflows during the heating season. The IMC/IRC requires the auxiliary pan to be a minimum of 1½ inches deep. See the Compliance tab for more details on code requirements for drain pans and drain pipes.

Blow-Through and Draw-Through Systems

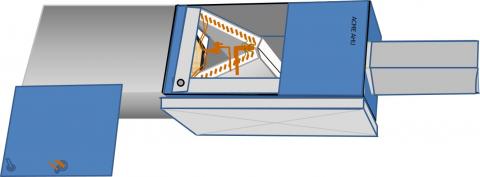

The evaporators of air conditioners and the indoor coils of heat pumps are installed so that a blower either pushes or pulls air over their cooling surfaces. When air is pushed across, putting the coil under positive pressure, it is considered a blow-through or positive pressure system. When air is pulled across the coil, it is a draw-through or negative pressure system. Many air handlers used with heat pumps or with modern AC cooling-only systems are draw-through systems. Blow-through systems are common when cooling coils are attached to a gas or oil furnace, as most furnace makers call for cooling coils to be placed downstream of the heat exchanger. Unless the furnace is listed and labeled safe to be downstream of a cooling coil (which is rare), passing cooled air over the heat exchanger will result in extensive corrosion of the furnace, premature failure of the heat exchanger, and moisture damage to the surroundings (KC Hart and Company).

Trapping

The drain line should be equipped with a trap, a u-shaped bend in the pipe that is either factory-made or site fashioned and has a minimum drop of 2 inches from the pan, plus 2 inches more for the trap seal, and a clean-out with a removable cap (Figure 4). The primary purpose of a condensate trap is to prevent air from moving in or out of the coil box or air handler during operation. Traps must be installed in a manner that will stop the air from passing through, but still allow the condensate to drain from the condensate pan. Failure to install a trap on a blow-through system can reduce system efficiency but in most cases the pan will still drain. A poorly functioning trap on a draw-through system will not only cause system inefficiency because it can pull in hot attic air, but the air being sucked through the drainpipe can prevent the pan from draining, causing it to run over. Without proper trapping, air pulled back into the equipment can lift the water up from the condensate pan and spray it onto nearby components which can cause corrosion of the equipment and if the condensate pan is contaminated, this can also become a health issue. For more on traps please see KC Hart and Company.

Drain Pipe

Over the years, PVC pipe has become the condensate drain material of choice for residential applications in many areas. The International Residential Code also allows cast iron, galvanized steel, copper, polybutylene, polyethylene, ABS, and CPVC to be used. Although it is rare to see plastic pipe insulated, sometimes it does need to be wrapped close to the equipment where the coolest water is exiting the pan to prevent it from sweating. With metal drains such as copper, failure to insulate the pipe and trap can almost guarantee a complete soaking of the surrounding surfaces from the secondary condensation generated by the cool water flowing through the drain pipe (KC Hart and Company).

According to the International Residential Code, the pipe should not be less than ¾ inches in diameter and should not be decreased in size from its connection at the condensate pan to the point where the condensate water finally clears the pipe. Drains should be installed pitched toward the discharge point. Manufacturers often recommend a drop of ¼-inch per foot; the code allows for 1/8-inch per foot.

Condensate Pumps

A condensate pump is used when a gravity drain is impractical or impossible to install. They are common on some basement-installed systems or where cooling has been added to an existing heating system located within the interior walls of a slab-foundation home. The plumbing from the cooling coil to the condensate pump reservoir or tank should be installed with traps and float switches as if the coil was draining like a typical gravity drain.

With condensate pumps, the cooling coil drains to the pump’s reservoir. As the water level rises, a float switch turns on the pump and water is pumped from the reservoir, usually through flexible plastic tubing, to a safe area. Should the pump fail or should the discharge line become blocked, a second switch will open a low-voltage circuit that shuts down the air conditioner and can even be wired to set off an alarm.

Proper Disposal of Condensate

According to the International Residential Code, “Condensate shall not discharge into a street, alley, or other area where it would cause a nuisance.” With residential properties, it is commonplace to discharge condensate at the exterior of the house, generally near the foundation (Figure 5). Use a splash pan to direct this water away from the foundation.

Follow local codes to determine the acceptability of directing the condensate drains into the domestic plumbing system. If the drain pipe is connected to a shared drainage system, a backflow prevention valve should be included.

Note: Unlike condensate from air conditioners and heat pumps, condensate from condensing furnaces and boilers can be highly acidic. Local code requirements should be followed regarding disposal of the condensate, either to the outdoors or to the sewer (Figure 6), and pretreatment of condensate, if required, before disposal to the sewer.

Success

Inspect to ensure that the cooling system has a secondary drain pan under the evaporator, that the system has a secondary drain line, and that the cooling coil is downstream of the heat exchanger in blow-through gas- or oil-furnace-based heating and cooling systems.

Inspect to ensure that the primary and secondary drain connections are made to the two lowest fittings on the air handler or coil box.

Climate

No climate-specific guidance applies.

CAD

Compliance

Retrofit

SCOPE

Inspect cooling equipment and heat pumps that have an evaporator coil to ensure a secondary drain pan exists.

- If a secondary drain pan is missing, install one made of durable plastic or galvanized steel. This secondary pan does not need a drain pipe. This pan should be equipped with a water-level-detection device conforming to UL 508 that will shut off the equipment served prior to overflow of the pan.

- Check the primary drain line for clogging.

- Clean the primary drain pan and inspect for corrosion and leakage.

For more on condensate drainage and disposal see the U.S. Department of Energy’s Standard Work Specifications.

See the new home Scope, Description, and Compliance tabs for more information.

DESCRIPTION

Unlike the plastic drain pans typically seen in modern equipment, many older models use galvanized steel pans under cooling coils. These should be checked for evidence of pitting and corrosion. Dirty or poorly draining pans can be breeding grounds for bacteria.

If leakage is detected under a pan, it could be due to a clogged drain line causing the pan to overflow or due to leaks in a pan that has rusted through. Mistaking a rusted-out pan for a simple blocked drain can be costly. A blocked drain can be unclogged and flushed out. Replacing the condensate pan often requires a total coil replacement, which can cost several hundred dollars or more.

COMPLIANCE

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Water Managed Building Materials = Interior Moisture Control Materials

Wood, drywall, and other building materials are susceptible to moisture damage in areas exposed to water such as bathrooms, sinks, and even entry areas. Water-resistant materials should be used in these areas. Tile and stone are water resistant when installed with cement-based underlayment and moisture barriers. Carpet should not be used in damp areas. Fiberglass-based wall board is an option in potentially damp areas such as basements.