Scope

Do not use building cavities as part of a forced air supply or return system.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Nearly all codes restrict the use of cavity spaces as supply ducts. However, it has been common practice to use cavity spaces as return air pathways. Building cavities used as return air plenums are probably the biggest duct leakage culprits we have in the HVAC industry today.

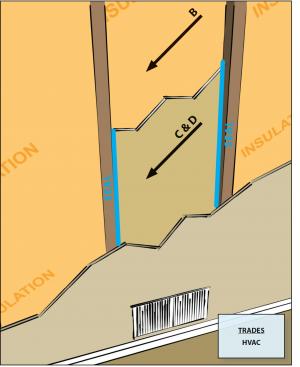

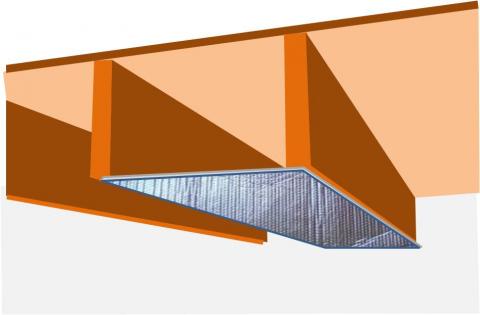

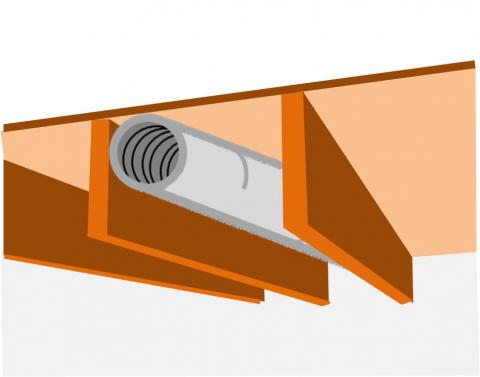

Still commonly used is the panned floor joist. Using floor joists as return ducts by panning can cause leakage because negative pressure in the cavity will draw air from the outside into the cavity through the construction joints of the rim area at the end of the joist cavity.

Figure 1 shows a floor joist cavity used as a return air duct by nailing a sheet good, such as gypsum board, sheet metal, foil insulation, or OSB to the bottom of the floor joists. There are manufacturers advertising “insulating” sheet good products to aid in this practice; however, using panned floor joists as an HVAC air pathway is highly discouraged because air leakage will be very difficult, if not impossible, to prevent.

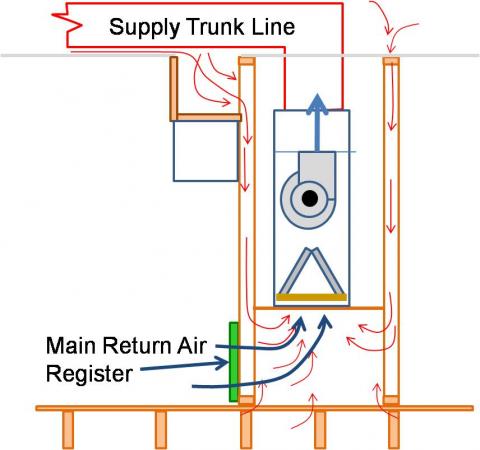

Cavities (or interstitial spaces) within walls are also sometimes used as supply or return air pathways. These cavities often connect inside air with outside air from an attic or crawlspace. It is very difficult to make such cavity spaces airtight. When cavity spaces are used as return air pathways or supply air ducts, a few issues will arise. Because cavity spaces are leaky, building pressure imbalances across the building envelope will occur, driving building infiltration. A cavity space used as a return air pathway will pull pollutants into the building from unknown sources. Another issue (less talked about) with using cavity spaces as return air pathways is fire safety. Building materials such as wood products do not meet the flame and smoke spread criteria as do approved duct materials. Using cavities as return or supply ducts is not a fire hazard in itself but will encourage a fire to spread throughout the building. In humid climates, a cavity space used as a return air pathway will pull humid air into the cavity space, possibly encouraging mold or rotting of building materials.

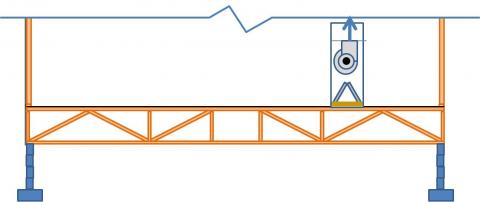

Other common framing cavities used as return air pathways or plenums are air handler platforms, open floor truss cavities, and dropped ceilings.

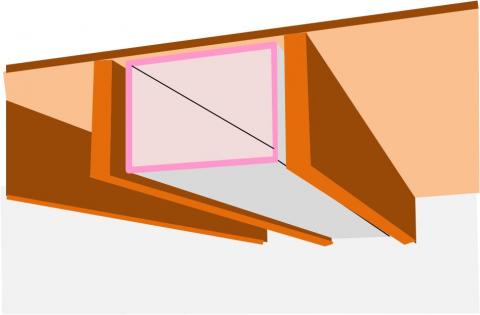

While none of these spaces make acceptable air pathways on their own, some building cavities such as floor joists can make acceptable duct chases to contain an insulated, air-sealed, metal or flex supply or return duct.

How to Use Building Cavities as Duct Chases for Supply and Return Pathways:

- Plan duct layout at the design stage. Indicate floor joist cavities, dropped ceiling soffits, or other building cavities that will be used as duct chases. Calculate required duct sizes using ACCA Manual D (ACCA 2009). Ensure that the cavity spaces are free of obstructions and large enough to hold the duct plus insulation.

- Use only approved duct materials such as galvanized steel, aluminum, fiberglass duct board, and flexible duct that meet local code smoke and flame spread criteria.

- Make sure that all supply and return duct connections are sealed with mastic or approved tape.

- Because ductwork in cavity spaces is likely to be inaccessible, test the duct system for airtightness with a duct blaster test before installing the drywall.

- At a minimum, line the air handler platform with duct board and mastic seal the corners.

Success

Use recognized and acceptable duct materials for all HVAC airways. For residential construction, acceptable duct materials include galvanized steel, aluminum, fiberglass duct board, and flexible duct. Consider duct layout in the initial framing design stage. Do not use a building cavity space alone as a supply or return air pathway. For the cavity to serve as a supply or return air pathway, it must contain a sealed, insulated duct made of approved duct materials. Use a duct blaster test to detect duct leakage and to confirm proper air flow at each duct supply outlet.

Climate

No climate specific information applies.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.