Scope

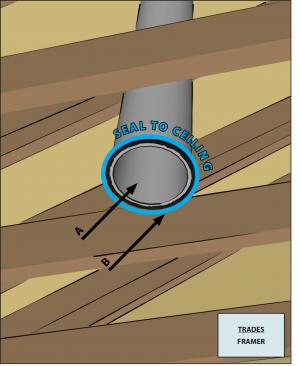

Air-seal around light tubes to minimize leakage to and from unconditioned attic space.

- Seal all gaps around the light tube at the ceiling plane with caulk and/or spray foam.

- Seal and flash around the light tube at the roof plane.

- Select a light tube kit that includes a lens and a gasket..

- Cover the tube with R-8 or greater duct insulation that includes a vapor barrier.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

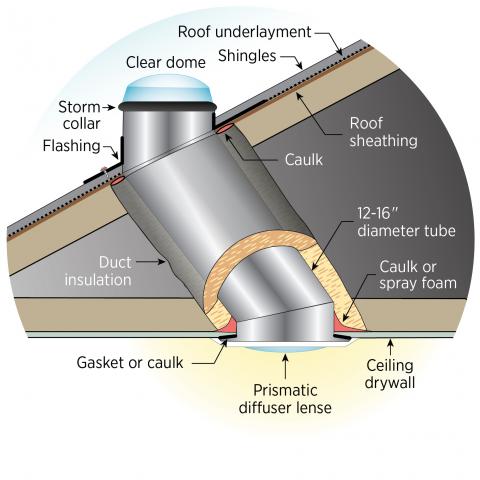

A light tube (also known as a solar tube or tubular skylight) is a tube that brings light from the roof to a room inside the house. One end of the tube has a clear dome that is mounted on the roof to allow in sunlight from any angle. The sunlight is directed down the tube, which is lined with highly reflective material that carries the sunlight to a diffuser mounted at the ceiling. The diffuser distributes the light inside the room. Light tubes can save energy by replacing electric lights for daytime light in rooms that do not have windows. Energy savings can be lost however if the tube is not air sealed and insulated.

Sun tunnels can also work at night with the use of solar night lights (Figure 1).

How to Air Seal a Light Tube

- Locate a spot centered between ceiling joists. Cut the ceiling hole no larger than necessary and use a saw that will provide a clean smooth cut, which will be easier to seal.

- Following the manufacturer’s instructions, cut a hole in the roofing to the appropriate size. Apply a bead of caulk to the underside of the flashing collar that will be installed on the roof. Use a shingle ripper or reciprocating saw to loosen the roof shingles above the hole where the tube will be installed. Slip the flashing base under the loosened shingles above the hole. Screw the flashing into place. Cover the screw heads with caulk.

- Assemble the tube and use metal tape or mastic to seal any seams in the tube. Install the light tube according to the manufacturer’s instructions, installing any gaskets or seals supplied by the manufacturer. Ensure that a manufacturer-supplied gasket or caulk is applied around the base of the tube in the bottom tube assembly between the flange and the drywall (Figure 2).

- From the attic side, caulk or spray foam where the tube meets the drywall.

- Cover the tube with R-8 or greater duct insulation that includes a vapor barrier. Use mastic, metal tape (not duct tape), or fasteners to seal the insulation to the light tube.

Success

Visually inspect and verify that the light tube is sealed at the ceiling deck and roof deck and is covered with insulation and an air barrier. Blower door testing and use of an infrared camera may help indicate whether a light tube is sufficiently air tight.

Climate

No climate specific information applies.

Training

Compliance

Retrofit

SCOPE

In existing homes, air seal and insulate around a new or existing light tube (also known as a solar tube) to minimize air leakage to and from unconditioned attic spaces.

- If adding a new light tube, see the Description tab.

- Inspect any existing light tubes for water damage and air leaks. Repair or replace any damaged materials. Add air sealing and/or insulation as needed.

- See the Scope and Description tab for additional instructions.

For more information on conditions that may be encountered when working in existing attics, see the Pre-Retrofit Assessment of Attics, Ceilings, and Roofs. Also see the U.S. Department of Energy’s Standard Work Specifications (SWS) guidance on air sealing skylights and shafts.

DESCRIPTION

- Inspect any existing light tubes for water damage and air leaks. Repair or replace any damaged materials. Add air sealing and/or insulation as needed, as needed.

- See the Description tab for additional installation information.

COMPLIANCE

Alterations

2009 IECC and 2009 IRC, 2012 IECC and 2012 IRC

2012 IECC, Section R101.4.3 / 2012 IRC N1101.3 and 2009 IECC 101.4.3 / 2009 IRC N1101.4.3 Alterations – General. Alterations to an existing building or portion of a building should comply with the provisions of the code as they relate to new construction without requiring unaltered portion(s) of the existing building to comply with this code.

2015 IECC and 2015 IRC, 2018 IECC and 2018 IRC

2015 IECC/2015 IRC, Section R501.1.1/N1107.1.1 Existing Buildings – General. Alterations to an existing building or portion of a building should comply with Sections R502/N1108, R503/N1109, or R504/N1110. Unaltered portions of the existing building are not required to comply.

R503.1/N1109.1 Alterations. General. Alterations to any building or structure should comply with the requirements of the code for new construction. Alterations should not negatively impact conformance of a building or structure to the provisions of this code; that is, code conformance should be the same as existed for the building or structure prior to the alteration. Alterations should not create an unsafe or hazardous condition or overload existing building systems. Alterations should be such that the altered building or structure uses no more energy than the existing building or structure prior to the alteration.

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

Sales

Tight Air Sealed Home = Comprehensive Draft Protection

Poorly air-sealed homes are less comfortable and cost more to maintain because they provide a pathway for drafts, cold spots, moisture, and insects into the home. Comprehensive draft protection includes a continuous air barrier around the whole house along with caulking and sealing in all holes and cracks. This includes around wiring, plumbing, ducts, and flues; where wall framing meets flooring; around windows; where drywall meets top plates and sill plates; where rim joists meet foundation walls and subfloors; etc. Spray foam insulation can be used at rim joists, floors above unconditioned space, and in attics to insulate and air seal at the same time.