Showing results 2351 - 2400 of 4973

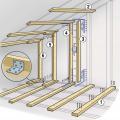

Right - Furring strips create an air gap to allow penetrating moisture to drain instead of wicking into walls; they also provide a nailing surface for siding.

Right - Furring strips were installed with blocking to allow adequate room for 4 inches of mineral wool.

RIght - Furring strips, house wrap, and siding are installed in the field after assembling panelized walls.

Right - Gasket installed at marriage wall connection prior to assembling modules

Right - Here, air control is established by taping the seams of the plywood panel sheathing. The roof sheathing is also trimmed flush with the wall sheathing to allow a simple and airtight connection between the roof and wall assemblies

Right - Hole drilled to verify sealant is present - Hole will be sealed after verification

Right - House wrap is carefully installed from the top of the roof line to the foundation; seams are overlapped and taped to provide a continuous air- and weather-resistant barrier

Right - House wrap is lapped back over first layer of flashing tape, then a second layer of flashing tape is applied to the sides around the duct; 13 of 14.

Right - House wrap is overlapped “shingle” style to direct moisture down and away from the house; seams will be taped so house wrap serves as both an air and weather barrier.

Right - HVAC ducts should be well-supported with minimal bends and pinching.

Right - Impact-resistant glass protects windows from wind-borne debris and is always in place, requiring no manual deployment during a storm.

Right - In areas prone to costal flooding, elevate the bottom floor well above the design flood elevation.

Right - In cooler climates, landscape shading should focus on the east- and west-facing walls, while leaving the south side of the house clear for solar access in winter (well-sized roof overhangs could provide summer shading for the south-facing windows)

Right - In hot climates, paint flat roofs light colors to reflect solar heat gain.

Right - Install backflow prevention devices on plumbing pipes to prevent wastewater from entering the home's plumbing system.

Right - Installation steps for the L-bent strap method of bracing a gable end wall

Right - Insulating sleeve for small through-the-wall HRV unit with sealing gasket; 3 of 14.

Right - Ladder blocking allows insulation to be installed in exterior walls at interior-exterior wall intersections.

Right - Lawn clippings were placed evenly to create a layer of mulch around the garden.

Right - Leaf guards allow rainwater into the gutter but keep combustible debris out, increasing the home's resistance to wildfires.

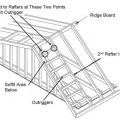

Right - Lookout or outrigger framing for a gable overhang provides two points at each outrigger to add metal connectors to strengthen the overhang against wind uplift.

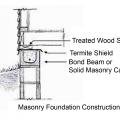

Right - Make concrete masonry unit foundations more termite resistant by using a solid masonry block or bond beam for the top course, installing a termite shield, and using a borate-treated sill plate.

Right - Manometers are placed away from the indoor side of the fan during blower door testing

Right - Mastic is being installed to air seal the wood-to-wood joints in this wall.

Right - Metal connectors provide uplift resistance at the rim joist between floors in new construction for a continuous load path.

Right - Metal connectors provide uplift resistance at the stud-to-bottom plate connection in new construction for a continuous load path.

Right - Metal drip edge flashing is installed above hose bib and top of metal flashing is taped to wall.

Right - Metal drip edge on this south Florida CMU home protects the top of the fascia and edge of the roof deck from water, wind-blown rain and embers, and insects.

Right - Mineral Wool insulation is installed on the exterior of wall with furring strips.

Right - Mold- and water-resistant fiber glass insulating sheathing is installed after panelized walls are assembled on site.

Right - Mulch covers the empty spaces in this garden, retaining moisture, moderating temperatures, and providing nutrients as it decomposes.

Right - New flashing has been installed to complete the air and water control layers at the window openings of this wall retrofit that includes insulating the wall cavities with spray foam

Right - Open-cell polyurethane spray foam to R-28 on underside of roof turns new attic into conditioned space for HVAC.

Right - Open-web floor and ceiling trusses provide space for ducts in conditioned space.

Right - Painter's tape is used to hold back house wrap while flashing layers are completed around the electric outlet.

Right - Panelized walls came to site with house wrap and furring strips pre-installed; seams will be overlapped and taped on site.

Right - Panelized walls came to site with house wrap pre-installed and ready to unfurl to cover foundation-to-sheathing seam.

Right - Panels of 7/16-inch treated plywood are inexpensive but take time to install and are difficult to install on higher windows.

Right - Peel and stick flashing and flashing tape seal a plumbing pipe that penetrates an exterior wall.

Right - Permeable rigid mineral wool insulation and appropriate water-management flashing details are integrated with new rigid foam siding to keep water away from the sill beam above the foundation wall

Right - Pieces of metal flashing are installed under each tile course along the valley centerline to prevent debris accumulation between and below concrete roof tiles.

Right - Plywood storm protection covering for windows is installed with removable threaded-rod fittings.

Right - Plywoood sheathing is taped at the seams to create a continuous air barrier that prevents air infiltration through critical junctures in the wall, such as at corners and between floors.

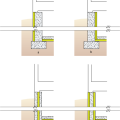

Right - Potential locations for basement insulation in new construction, slab insulation should always be underneath, with walls insulated (a) inside, (b) outside, (c) sandwiched inside, or (d) inside and outside of walls.