Showing results 3251 - 3500 of 4973

Single framed wall converted to double wall and insulated with open-cell spray foam

SIP homes built in coastal locations should be constructed so that the lowest level is well above the BFE.

SIP panel walls are less susceptible to air leakage and convection issues than stick-built walls

SIP panels should be stacked high, dry, and flat

SIP wall and roof panels can be sealed at all seams with a tenacious air sealing tape.

SIP walls do not require interior walls or trusses for support, providing for open interiors.

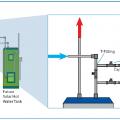

Size comparison between two 50-gallon water heaters: a traditional electric-resistance-only water heater on the left and a heat pump water heater on the right

Size the filter box for the appropriate filter, according to ACCA Manual D, taking into account pressure drop across the system.

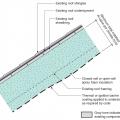

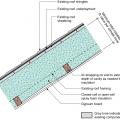

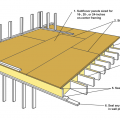

Sleepers (tapered wood furring strips) are installed over the existing board sheathing to slope the new sheathing toward the drain in this flat roof retrofit

Sloped roof with cavity spray foam insulation sprayed on underside of roof deck and covered with sprayed-on thermal or ignition barrier coating.

Sloped roof with cavity spray foam insulation, strapping, and gypsum board thermal barrier

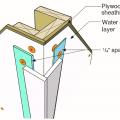

Small spacer strips consisting of ¼-inch plastic strips provide a drainage gap behind wall cladding with a gap that is too small to pose a fire risk from embers entering the gap.

Small, battery-powered evaporative coolers can be appropriate for personal cooling in arid climates (only)

Smoke generators are used to identify air leakage sites during depressurization testing

Soffits can be secured by caulking to the wall, sealing between each soffit panel and the wall channel, and screwing the wall channel to the soffit panels.

Soil types include sand, silt, and clay- the more sand, the more quickly the soil drains.

Solar electric panels provide electricity for the home and an electric car charging station.

Solar panels can be hooked up to batteries to provide emergency power during outages and to help meet daily power needs after the sun goes down

Solar tubes are installed in the hallway to bring sunlight into the interior of the home.

Solar tubes pop up above the roof’s surface to draw sunlight into the home’s interior.

Solar-powered LED lights installed inside this sun tunnel (or solar tube) provides light at night alongside daylight provided by the sun tunnel during the day, thus reducing the need for electric light.

Solid wood blocking was installed in the walls to accommodate future grab bars in both bathrooms.

Some builders create pan joists by attaching a solid sheet good to the bottom of a floor joist to create a return air pathway

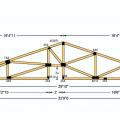

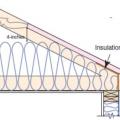

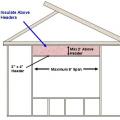

Some builders use cantilevered trusses to get full height insulation over the exterior wall.

Some radiators are behind covers so the cover must be removed to identify the air vent

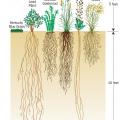

Some species of native prairie plants have much deeper root systems than Kentucky blue grass, increasing the ability of those plants to retain and filter stormwater

Some whole-house fans are equipped with an automatic drop-down cover to provide an air seal at the ceiling level when the fan is not in use

Some whole-house fans use an automatic insulated cover achieve high R-values when the fan is not in use

Sources of heat gain in a house include solar gains, infiltration, conduction through walls and roof, occupants, and internal equipment

Sources of heat gain in a house include solar gains, infiltration, conduction through walls and roof, occupants, and internal equipment

Southeast Volusia Habitat for Humanity built this affordable home in the hot-humid climate in Edgewater, FL, and certified it to DOE Zero Energy Ready Home specifications in 2014.

Southern Energy Homes built this affordable home in the mixed-humid climate in Russellville, AL, and certified it to DOE Zero Energy Ready Home specifications in 2014.

Southern Energy Homes constructed the first DOE Zero Energy Ready certified manufactured home and the DOE collected 15 months of performance data on it, a HUD code home, and an ENERGY STAR home.

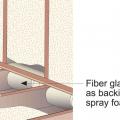

Southern Energy Homes worked with DOE researchers to develop an efficient way to dense-pack blown fiberglass into the low attics of manufactured homes.

Special molded corners provide continuous insulation layer at the corners to improve structural strength and minimize thermal bridging

Specially designed roof trusses come with a two-foot by two-foot notch cut next to the center post providing space to install an insulated duct chase inside the home’s conditioned space but above the normal ceiling height.

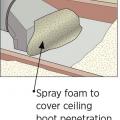

Spray foam adhesive provides an extra water resistant layer to the joints and seams on the inside of attics.

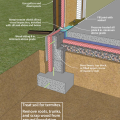

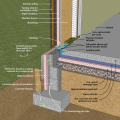

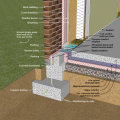

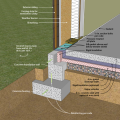

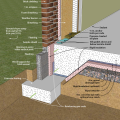

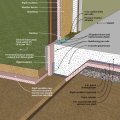

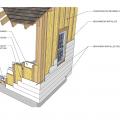

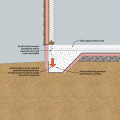

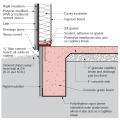

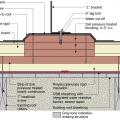

Spray foam and rigid foam were used under the slab while rigid foam wraps the exterior of the foundation walls.

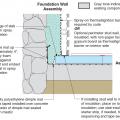

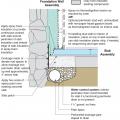

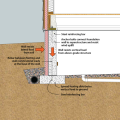

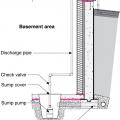

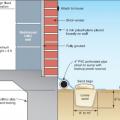

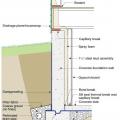

Spray foam extends down the foundation wall to the slab, which has been retrofitted by adding dimple plastic drainage mat and rigid foam insulation.

Spray foam extends down the inside of the foundation wall to the uninsulated slab; because the wall lacked exterior perimeter drainage, the slab was cut and an interior footing drain was installed.

Spray foam insulates and air-seals the ceiling deck and top plates of this vented attic.

Spray foam insulates the rim joist and air seals the subfloor-rim joist and rim joist-top plate connections

Spray foam insulates the top plates and air seals them to the ventilation baffles before ceiling drywall is installed.

Spray foam insulation air-seals and insulates the floor above the garage; the joist will be filled with fibrous insulation in this flash-and-batt approach.

Spray foam insulation extends down the foundation wall to the slab, which has been retrofitted by cutting the slab to install drainage mat against the wall and a new perimeter footing drain, along with rigid foam plastic above the slab.

Spray foam insulation insulates and air seals around plumbing pipes and top plates in the attic.

Spray foam insulation is applied along the underside of the roof deck to provide a conditioned and non-vented attic space for ducts and air handlers.

Spray foam insulation is installed in open wall cavities to air seal and insulate

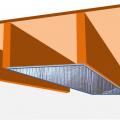

Spray foam insulation used for raised ceiling duct chase

Spray foam insulation used for raised ceiling duct chase.

Spray foam insulation was installed on the underside of the roof deck and on gable end attic walls to create an unvented attic

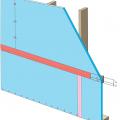

Spray foam is installed between new studs over the existing siding in this deep energy retrofit

Spray foam provides a critical seal between the subfloor, rim joist, and sill plate

Sprayer-applied sealant seals every seam in the sheathing and framing of this double-walled home.

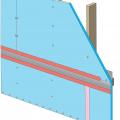

Staggering sheathing seams makes it harder for moisture to infiltrate the wall to the air gap, where furring strips will allow permeating moisture to drain if needed.

Standard 2 in. by 4 in. stud secures duct chase - made of rigid insulation in this example

Standard roof trusses are narrow at the eaves, preventing full insulation coverage over the top plate of the exterior walls

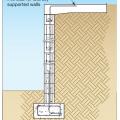

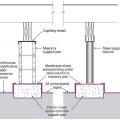

Stem wall foundation design, including additional reinforcement to resist moving floodwaters and short (1.5-ft) breaking waves (Source: Adapted from FEMA P-550, Case F).

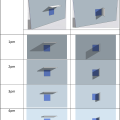

Step 1. Apply roof underlayment over roof deck and up the sidewall over the rigid foam insulation

Step 1. Remove the existing wall cladding to prepare to retrofit an exterior wall.

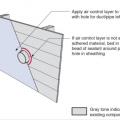

Step 2. Install a continuous air and water control layer over the existing wall sheathing.

Step 2. Install shingle starter strip then kick-out diverter as first piece of step flashing.

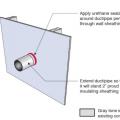

Step 3. Apply urethane sealant around the duct or pipe in the retrofitted exterior wall.

Step 3. Place the first shingle and the next section of sidewall flashing over upper edge of diverter

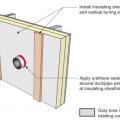

Step 4. Install insulating sheathing and vertical furring strips on the retrofitted exterior wall; seal around pipe or duct with urethane sealant.

Step 4. Install remaining sidewall flashing, appropriate counter flashing, and shingles

Step 5. Apply self-adhesive flashing over top edge of the wall flashing, diverter, and rigid foam insulation

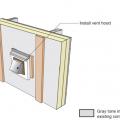

Step 5. Install sheathing tape flashing over the duct or pipe and wood blocking on either side for later attachment of trim.

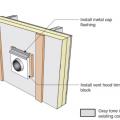

Step 6. Install vent hood trim block, metal cap flashing; seal top edge of flashing with sheathing tape.

Step 8. Attach the new cladding to the furring strips over the rigid foam for the exterior wall retrofit.

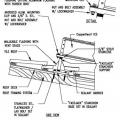

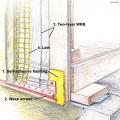

Step and kick-out flashing at all roof-wall intersections extending ≥ 4 in. on wall surface above roof deck and integrated with drainage plane above

Step and kickout flashing should be installed at all roof-wall intersections to protect the wall and divert rainwater runoff into a gutter.

Sterling Brook Homes built this custom home in the hot-humid climate in Double Oak, TX, and certified it to DOE Zero Energy Ready Home specifications in 2014.

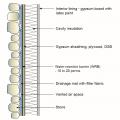

Stone cladding system with a drainage mat provides a small, vented gap (≤ ¾ inch), over a water-resistant barrier house wrap that has a perm rating of 10 to 20 perms so it can serve as a vapor throttle.

Stone mulch provides a pervious walking surface while retaining moisture and minimizing erosion.

Storm-blown shingles reveal that the starter strip was incorrectly installed; rather than cutting off the tabs of the starter, the starter was rotated 180 degrees (right arrow) so the exposed portion of the first course of shingles (left arrow) was...

Straps are spaced too far apart causing the straps to compress the duct under its own weight

Streetscape Development built this custom home in the cold climate in Libertyville, IL, and certified it to DOE Zero Energy Ready Home specifications in 2013.

Strengthen an existing roof by applying two-part spray-applied polyurethane foam adhesive to all sheathing and framing joints from the underside of the roof

Strips of roofing membrane are used to flash around a skylight on a flat roof retrofit

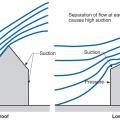

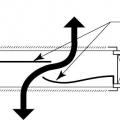

Strong wind passing over a sloped roof cause positive pressure on windward side and negative pressure on leeward side and at vortices above windward eave

Structural insulated panels offer a continuous layer of thermal protection and draft resistance around the home and come from the factory precut for fast assembly.

Structural insulated panels provide a continuous layer of insulation sandwiched between two continuous layers of OSB for thermal protection and sturdy construction.

Stucco is installed over rigid insulation, which is installed over a drainage plane consisting of a drainage gap and building wrap layer over the sheathing

Stucco wall assembly with a drainage mat providing a small vented gap (experience has shown that ≤ 3/8 inch is effective), and a water-resistant barrier house wrap serving as a vapor throttle.

Stuff cavities under kneewalls with rolls of fiberglass batt and spray foam in place

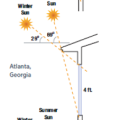

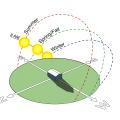

Sun angles vary by latitude, season, and time of day. Sun angles shown here are calculated for noon on June 21 and December 21.

Sun paths through the sky in winter, spring, summer, and fall show that a home receives the most sun from the south in the winter and from the east/west in the summer

Sunroc Builders built this affordable home in the hot-humid climate in Lakeland, FL, and certified it to DOE Zero Energy Ready Home specifications in 2016.

Sunroc Builders built this affordable home performance hot-humid climate in Winter Haven, FL, and certified it to DOE Zero Energy Ready Home specifications in 2015.

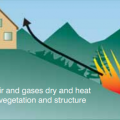

Super-heated air and gases from wildfires will dry and heat the fuel, both vegetation and structures, in the path of the oncoming, uphill-moving fire.

Supply-only ventilation with a fresh air intake ducted to the return side of a horizontal air handler unit located in the attic

Supply-only ventilation with a fresh air intake ducted to the return side of a vertical air handler unit located in the house

Sustainable 9 Design + Build built this custom for buyer home in the cold climate in Edina, MN, and certified it to DOE Zero Energy Ready Home specifications in 2019.

Sustainable Nine built this custom for buyer home in the cold climate in Cooperstown, NY, and certified it to DOE Zero Energy Ready Home specifications in 2020.

Sustainable Nine built this custom for buyer home in the marine climate in Everson, WA, and certified it to DOE Zero Energy Ready Home specifications in 2020.

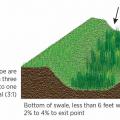

Swales are trapezoidal channels dug to receive storm-water overflow, with specific vegetation planted to improve aesthetics, filter stormwater runoff, and prevent erosion.

Swales are troughs that collect site stormwater and filter it with vegetation, soil, and gravel layers.

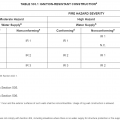

Table 2 Passive Cooling

Table of Maximum Fenestration U-Factor Requirements for New Homes as Listed in the 2009-2021 IECC and IRC

Tall annuals, like the sunflowers in this picture, can provide very effective shade in summer (left), provide a pleasant view from inside (right), and allow sun into the home in winter when the plants die back.

Tape horizontal joint with minimum 3" wide tape placing tape offset high on the joint, adhearing to the upper sheet without wrinkles

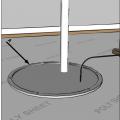

Tape seals gaps between the vapor barrier and pipes that penetrate through the subslab vapor barrier.

Tape the joint between the top insulation sheet and the Z-flashing with 2" wide tape to improve air tightness

Taped plywood creates a continuous sheathing layer while cork adds a layer of continuous insulation to the outside of the wall.

Taped seams on the coated roof sheathing improve this home’s resistance to damage from high winds.

Targa Homes built this attached home in the marine climate in Seattle, WA, and certified it to DOE Zero Energy Ready Home specifications in 2021.

TC Legend Home built this affordable home in the marine climate in Bellingham, WA, and certified it to DOE Zero Energy Ready Home specifications in 2014.

TC Legend Home built this affordable home in the marine climate in Seattle, WA, and certified it to DOE Zero Energy Ready Home specifications in 2013.

TC Legend Homes built this custom for buyer home in the marine climate in Bellevue, WA, and certified it to DOE Zero Energy Ready Home specifications in 2021.

TC Legend Homes built this custom for buyer home in the marine climate in Bellingham, WA, and certified it to DOE Zero Energy Ready Home specifications in 2019.

TC Legend Homes built this custom for buyer home in the marine climate in Seattle, WA, and certified it to DOE Zero Energy Ready Home specifications in 2016.

TC Legend Homes built this custom for buyer home in the marine climate in Seattle, WA, and certified it to DOE Zero Energy Ready Home specifications in 2018.

TC Legend Homes built this custom home in the marine climate home in Bellingham WI, and certified it to DOE Zero Energy Ready Home specifications in 2015.

Temperatures in deep undisturbed soil at a given location are approximately equal to the annual average air temperature for that location

Tempered glass windows usually have an etched marking on the glass in the corner of the window that includes the supplier's name, place of fabrication, date manufactured, thickness, and certifications or safety standards the glass meets.

Terminate 4" tape with 2" wide tape placing tape offset high on the joint, 2/3 of the tape should be adhered to the sheet of insulation

Termite Infestation Probability Map, Adapted from the 2021 International Residential Code (IRC), Figure R301.2(7)

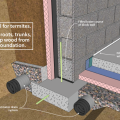

Termite mud tubes on floor joists indicate the presence of termites in the crawlspace

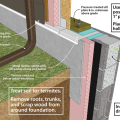

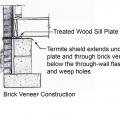

Termite shield extends under sill plate and through brick veneer below the through-wall flashing and weep holes.

Termite shield is installed at the top of the foundation wall before installing sill plates; all seams and holes are sealed with epoxy

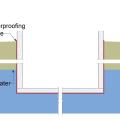

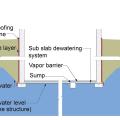

The “continuous waterproofing” approach can be used to control groundwater in cases where the building foundation is below the groundwater table.

The “down” and “out” approach to flashing – metal flashing directs water down and out of building assemblies

The “draw down” approach can be used to control groundwater in cases where the building foundation is below the groundwater table.

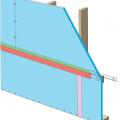

The “institutional” perfect wall works in all climate zones; water, air, vapor, and thermal control layers are exterior of the sheathing, assembly allows drying to interior and exterior

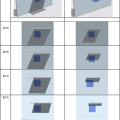

The 2-foot extended-width overhang on the left allows more wintertime solar heat gain to this west-facing window than the 2-foot side fin on the right (results shown for west-facing window, mid-winter, 36N latitude)

The 2-foot overhang on the left performs better than the 2-foot vertical fin on the right for providing shade in the summer and solar heat gain in the winter (results shown for west-facing window, 2pm, 36N latitude).

The 2x4 wall studs are staggered along the 2x6 sill plate providing space to weave insulation around each stud to stop thermal bridging through the wall.

The 3/8-inch gap under the door allowed wind-driven rain to enter the house in hurricane winds of 140 to 160 mph.

The 6 kW of solar panels consists of a solar shingle product that is similar in size to asphalt shingles and is integrated into the roof to provide most of the home’s power needs.

The 6.8-kW solar photovoltaic panels on this energy-efficient home produce enough electricity to power the home and an electric car.

The 8-foot deck/overhang on the left provides better summer shading than the 2-foot extended-width overhang, which performs better than the 2-foot window-width overhang, which performs better than the 2-foot vertical fin (late summer, 36N latitude)

The 8-foot-deep west-facing overhang on the left provides much better shading late in the day than the 2-foot-deep overhang on the right (results shown for west-facing window, late summer, 36N latitude).

The ability to choose a light color range allows one to customize the lighting of any space

The AC unit has a drip pan and automatic shutoff in case the condensate drain gets clogged.

The addition of low-E permanent exterior storm windows is typically accepted for most historic preservation projects

The advance-framed 2x6 24-inch on-center walls are covered with netting then filled with R-23 blown fiberglass.

The air handler of the air-to-water heat pump is equipped with a very high efficiency air filter and a damper-controlled fresh air intake.

The air intake or exhaust grilles in this second-story soffit will be very difficult to safely access to measure airflow

The air tightness of the garage-to-house air barrier can be tested with a blower door kit and two manometers

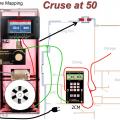

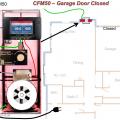

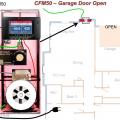

The air tightness of the house-garage air barrier can be tested using a CFM50 test that is first run with the garage door to outdoors closed

The air tightness of the house-garage air barrier can be tested using a CFM50 test that is run first with the garage door to outdoors closed and then with the overhead garage door to outdoors open

The airflow direction is labeled on the edge of the filter to ensure it is properly oriented when installed.

The application of intumescent coating/protection layer protects this elevated floor system from below.

The asymmetrical design of this home offers a large uninterrupted south-facing roof plane for solar photovoltaic and solar thermal panels.

The Attachments Energy Rating Council (AERC) uses this label to indicate certified low-E storm window products.

The attic duct chase insulated and sealed to the attic floor with spray foam

The attic is insulated along the underside of the roof deck with 8 inches of open-cell spray foam.

The attic is sealed and insulated along the underside of the roof deck with 5.5 inches of polyurethane spray foam, providing conditioned space for the HVAC system.

The attic knee walls were constructed from 2x6s and insulated with R-19 batt, backed with 1 inch of XPS foam board with taped joints to provide a solid air barrier over the insulated surfaces.

The attic kneewall and the open floor cavities under kneewall are both sealed and insulated in one step with spray foam insulation

The back dam of the window sill will force water out

The back-draft damper on this exhaust fan is closed to prevent cross contamination

The back-draft damper on this exhaust fan is open when the exhaust fan is operating

The back-draft damper open when the fan is actively exhausting and closes when the fan is off

The base of the plywood parapet is air sealed with spray foam and fibrous insulation is installed in the rafter cavities in this flat roof retrofit

The basement is constructed with precast concrete walls lined with R-21.3 foil-faced rigid foam while an R-10 layer of XPS rigid foam covers the ground under the slab.

The basement is half in and half out of the ground with only 4 feet below grade, which allows for full 36-inch-tall windows that are completely above grade.

The basement slab is wrapped in a blanket of insulation including R-27 of closed-cell spray foam under the slab and R-22 ICF blocks wrapping the slab edges.

The basement walls are covered with a dimpled plastic water barrier then wrapped with 3 inches of XPS rigid foam with seams taped to keep out water.

The basement walls’ interior framing is set in 3 inches from the concrete to allow space for closed-cell foam that is sprayed directly on the concrete, then blown cellulose is added to fill the wall cavity.

The batt insulation shown here was properly installed to fill the ceiling cavities.

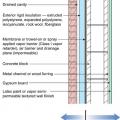

The below-grade wall assembly includes dampproofing, draining details, and insulation.

The black coating on these walls is a liquid-applied asphalt-based air and moisture barrier.

The blocking for a new PV roof-mounting system is integrated with new rigid foam and the air and water control layers installed over an existing flat roof

The blocking is completely flashed with roofing membrane before the PV rack hardware is attached on a flat roof

The blower wheel (fan) on this ductless wall-mounted indoor unit has accumulated dust and mold - a common issue for this design.

The blue foam sill gasket visible on the foundation wall will help ensure an air-tight connection with the double-wall assembly above.

The board in the center of this photograph shows blue stain (not lumber mold), a discoloration of the wood caused by a fungus affecting the living tree, which did not harm the structural integrity of the wood.

The brick house foundation piers on discrete footings (in the foreground) failed by rotating and overturning while the piers set in the concrete mat survived Hurricane Katrina.

The brick veneer lacked adequate ties to keep the brick from peeling off the wall in an earthquake.

The builder in this very cold climate installed three layers of unfaced mineral wool batt in the double wall with a code-required vapor barrier between the middle and inner layers of wall insulation that is taped to barriers in the ceiling and floor.

The builder installed 1.5 inches of soy-based spray foam on the outside of the walls over the OSB sheathing, then kept a ¾ inch gap between the foam and the brick veneer siding to allow moisture vapor from the bricks to dissipate.

The builder installed a rain screen product that provides an air gap and drainage plane between the coated OSB sheathing and the cladding; the fabric layer folded over the bottom edge forms an insect screen.

The builder installed this OSB under the roof rafters and air sealed the seams with tape then added a dropped drywall ceiling to provide a service cavity for ducts and wiring, while minimizing holes into the attic.

The builder laid down a 4-inch base of aggregate rock, then covered that with a plastic vapor barrier that is taped at all seams and around all penetrations before installing the rigid foam under-slab insulation.

The builder leaves a half inch gap between the exterior and interior walls so drywall can be slid between the two.

The builder staggers 2x4 studs on 2x6 top and bottom plates which provides gaps to fill in insulation around the framing for a continuous blanket of insulation.