Showing results 3001 - 3250 of 4973

Right – This home uses light tan stucco and white trim to reduce solar heat gain.

Right – This home was constructed with ICF blocks that extend from the footer to the roof line, providing consistent thermal resistance for the entire walls of the home

Right – This home was constructed with no- or low-VOC paints, glues, flooring, cabinetry, and finishes that decrease indoor air pollutants in accordance with EPA Indoor airPLUS specifications.

Right – This home’s above-grade walls are constructed in a factory where wall panels of 2x6 studs are assembled and sheathed with a coated OSB product, then windows are installed and flashed before shipping the panels to the site for assembly by crane.

Right – This home’s HVAC system consists of a ground source heat pump that provides heating and cooling with a rated efficiency of 5.0 COP.

Right – This home’s kitchen exhaust fan motor is housed in a box above the ceiling.

Right – This home’s roof and walls are constructed of SIP panels; metal studs provide fastening surfaces across the long expanses of ceiling in the open interiors.

Right – This home’s roof has zero penetrations because all venting is routed to gable walls.

Right – This hot-humid climate home employs several hurricane- and termite-resistant features including concrete block construction, borate-treated framing, a hip roof design with metal drip edge, impact-rated windows, and an unvented attic.

Right – This hot-humid climate home is constructed with concrete block that is insulated on the inside with rigid foam; the framing is borate-treated lumber; the roof design is a high-wind-resistant hip roof with only one small gable over the entry.

Right – This HRV is ducted separately from the home’s ductless heat pumps to provide filtered fresh air to sleeping and living areas and to exhaust stale air from the bathrooms and laundry.

Right – This HVAC condensing unit is elevated on a raised-slab

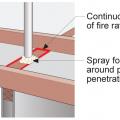

Right – This ICAT recessed light is sprayed with foam to act as gasket against the drywall.

Right – This IR image shows very little heat loss through the home’s exterior walls.

Right – This kitchen exhaust duct is made of smooth rigid metal and the duct is mastic sealed at joints

Right – This kitchen exhaust fan duct is made of smooth round steel duct that takes the shortest, most direct route to the outdoors and joints are sealed with mastic.

Right – This kitchen exhaust fan has a damper to prevent outside air from entering when the fan is not operating

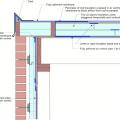

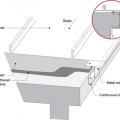

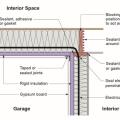

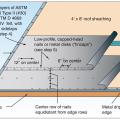

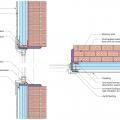

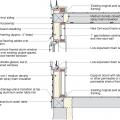

Right – This low-slope flat roof assembly has continuity of both the air and water barriers

Right – This low-slope roof and parapet assembly has continuity of both the air and water barriers

Right – This metal panel window shutter is installed in a track permanently mounted above and below the window frame and is secured with wing nuts to studs mounted on the track.

Right – This metal roof is being coated with a cool (high SRI) coating to reduce solar heat gain

Right – This model home for the Solar Decathlon competition incorporates vertical trellises and retractable exterior blinds to control solar heat gain.

Right – This modular home consists of prebuilt wall panels that are assembled on site.

Right – This modular home is constructed in a factory where climate and ergonomic conditions can be carefully controlled.

Right – This National Fenestration Rating Council (NFRC) label shows the insulation U-Factor, solar heat gain coefficient, visible transmittance, and condensation resistance for this triple-pane window.

Right – This net zero energy home has an electric vehicle charging station in the carport.

Right – This plug-in sensor detects indoor air quality issues in a home, including elevated levels of humidity, VOCs, smoke, carbon dioxide, or small particulates; if detected, the sensor can switch on the nearest exhaust fan to remove the pollutants.

Right – This regional production builder of DOE Zero Energy Ready certified homes provides monthly in-house training sessions to educate its staff on the energy-efficiency features of its high-performance homes.

Right – This roof consists of parallel truss chords which allows for cathedral ceilings.

Right – This sealed combustion gas furnace has a fresh air intake with an electronically controlled damper.

Right – This second-story deck also serves as a deep overhang to protect the entry door from weather

Right – This shrub has been pruned to allow views out the windows of this home while providing shade to walls, windows, and roof.

Right – This stacking ENERGY STAR-labeled washer and dryer save energy and water as well as space.

Right – This supply duct is thoroughly sealed at all joints with mastic to prevent air leakage and the duct is equipped with a damper to provide zoned heating and cooling along with other trunk ducts.

Right – This swale has sloped sides with appropriate vegetation to filter rainwater.

Right – This three studs in this corner are positioned to allow insulation against more of the exterior wall than standard three-stud corners.

Right – This tree shades walls, windows, roofs, and grounds for two adjacent homes.

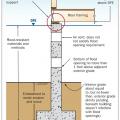

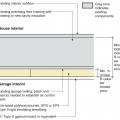

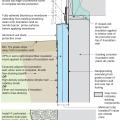

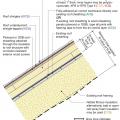

Right – This wall is constructed with the sill plate overhanging the top of the foundation wall so that when rigid foam is installed on the exterior of the foundation wall, its surface will align with the surface of the wall sheathing.

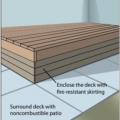

Right – To make decks more fire-resistant, enclose the bottom of the deck with a non-flammable skirt, and surround the deck with a non-flammable surface like pavers.

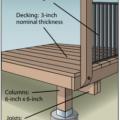

Right – To make decks more resistant to fires, for floor joists and beams, use heavy fire-retardant-treated timbers, concrete, or steel framing; for decking and stair treads, use treated wood, brick, or concrete pavers; and for railings, use treated wood,

Right – To minimize sound in the kitchen, the exhaust fan above the island-mounted stove top is located above the ceiling rather than just above the stovetop.

Right – Transfer grilles are installed over doorways to bedrooms in a new-construction home

Right – Transfer grilles, Jump ducts, and wall grilles provide passive returns for air returning from bedrooms to the central HVAC system

Right – Trimming tree branches a minimum of 10 feet from the house or any attached structures reduces the risk of home ignition.

Right – Trimming tree canopies a minimum of 10 feet from the house reduces the risk of home ignition.

Right – Two inches of rigid foam was installed on the ground before pouring the basement floor slab while precast, pre-insulated concrete panels comprise the basement walls.

Right – Two-thirds of acrylic tape is offset above the joint and over and above the fasteners

Right – two-thirds of the blue butyl flashing tape is above the sheathing seam; the top edge of the butyl flashing tape is covered with clear sheathing tape that is also offset so two-thirds is above the top edge of the butyl flashing.

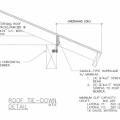

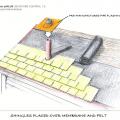

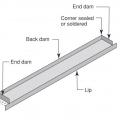

Right – Under metal roofing, sheathing is protected by metal edging over a fully adhered membrane and a slip sheet of loose laid building paper

Right – Vertical and horizontal furring strips are installed over a breathable membrane weather resistant barrier to create an air gap and drainage plane behind the wood siding that will be installed next.

Right – Walls, windows, and wiring are installed in the factory for these modular homes, which are installed at the site on basement foundations made of insulated concrete wall panels.

Right – Weatherstripping has been installed and remains in contact when the door is closed.

Right – Wind baffle installation maintains necessary code clearance between baffle and roof deck

Right – Windows are installed and flashed in the factory for these modular homes.

Right – Wiring holes in the exterior walls are sealed with canned spray foam to prevent air leakage into or out of the home.

Right – Wood-to-sheathing joints are caulked so the sheathing can provide an air barrier for the home.

Right – Workers lay radiant floor loops over the concrete reinforcement which is laid over a heavy vapor barrier installed over the sub-slab insulation before the slab is poured.

Right – Workers pour the concrete for the basement floor slab over a vapor barrier installed over rigid foam.

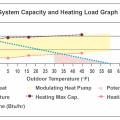

Right (decent): For a relatively high-capacity ccASHP sized per Approach 3 or 4 to meet nearly 100% of the heating load, this heat pump’s modulating zone has a decent overlap with the home’s heating load line, reducing short-cycling.

Right- An electronic controller operates an exhaust fan, a mechanical damper on a fresh air intake, and the central heat pump’s fan, which draws in fresh air through the damper and distributes it in sync with exhaust fan operation for balanced fresh air.

Right- Landscaping shades the entry on the south west corner of this hot dry climate building.

Right- The rigid foam sheathing is taped at all seams before installing the metal lathe for stucco cladding.

Right- This concrete block home in the hot-humid climate is insulated on the interior with rigid EPS foam; all framing uses mold- and termite-resistant borate-treated lumber.

Right- This flue pipe has been air sealed with sheet metal and fire-rated caulk and an insulation dam has been constructed to keep insulation from touching the hot flue pipe

Right- This house uses CMU construction for flood and termite resistance as well as thermal mass

Right-- IR photo shows how effectively spray foam insulated/air sealed attic kneewall and the floor cavities under kneewall

Right--A heavy polyethylene sheet covers the floor of this crawlspace providing a capillary break and vapor barrier to keep soil gases out of the house.

Right--The polyethylene ground cover for this insulated crawlspace is taped at seams and around posts before the insulation and slab are installed.

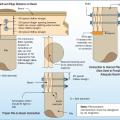

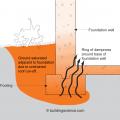

Right-Flood resistant foundation walls lift the floor framing above the DFE and include flood openings to let flood waters pass through.

Right-Polyethylene sheeting is correctly installed over aggregate and taped to pillars and foundation wall

Right-Wall-insulating sheathing is extended up to roof rafters and sealed around the framing with spray foam

Right: A well-constructed air handler closet

Right: Air seal all seams in the return air plenum before installing a new air handler

Right: All joints in the rigid foam are taped to keep stucco out of joints for even drying. Mesh tape (shown here) is used with expanded polystyrene (EPS); acrylic sheathing tape or self-adhered membrane is used with XPS

Right: Brick veneer is flashed correctly with weep holes and a fine mesh screen is installed to prevent pest entry.

Right: Ducts are completely buried beneath insulation to the depth specified in the plans

Right: ductwork is fully encapsulated with ccSPF prior to ceiling installation and burial

Right: Ductwork is installed in direct contact with lower truss cords. In this picture the main trunk is laying on the truss cords and branch ducts are temporarily held with strapping across truss cords. Ducts are well sealed with mastic

Right: Flashing the butt joints in lap siding installations is a better practice than relying on caulk to seal the joints.

Right: If existing straps are narrower than 1.5 inches, add sheet metal saddles to keep the duct from sagging and pinching

Right: Maintenance valves are installed at the inlet and outlet of this central heat pump water heater

Right: Refrigerant piping is sealed where it exits the return plenum

Right: Sized per Approach 1, this heat pump will have minimal short-cycling; since sized using Approach 1, it will require backup heat when temp is below 30°F but could still contribute significant heating down to heating design temp (-6°F) and lower

Right: Sized per Approach 3 or 4, this heat pump’s modulating zone has a large overlap with the home’s heating load line, resulting in minimal short-cycling; the unit may require a small amount of backup heat during the very coldest hours of winter.

Right: Sized per Approach 3, this heat pump’s modulating zone has a large overlap with the home’s heating load line; it will require backup heating but could still contribute significant heating for all hours of the heating season

Right: Spray foam air seals and insulates raised ceiling duct chase

Right: The bottom of the air handler cabinet is well sealed to the return platform

Right: The plenum liner is well sealed to the filter-backed grille

Right: This closet door for a heat pump water heater is louvered to allow warm air to enter and exhaust air to leave the closet

Right: This heat pump water heater is in a basement within the thermal boundary but not actively conditioned. It has over 770 ft² of space with easy access to the control panel and clearance for airflow to the air intake (top) and exhaust (side)

Right: This heat pump water heater is installed in a garage next to the furnace where there is a lot of space for accessing the unit, and for intake and exhaust; a foam pad insulates the base; the condensate line is correctly drained and pipe insulation

Right: This heat pump water heater is installed in a laundry room with enough space for the control panel and vents to be clear of obstructions; The HPWH can use heat from the dryer to heat water, but the seismic straps should be lower

Right: This heat pump water heater is installed in a small space so the, intake air is ducted from an adjacent room; the water heater since on a pad of foam insulation and has a good drain line configuration but the waterpipes lack insulation

Right: This heat pump water heater is installed in a utility closet where it can use heat from the clothes washer and heat pump clothes dryer and has access to a floor drain for condensate

Right: This house plan orients broad building surfaces away from the west and east, trees are used to shade the west and east, and large overhangs shade windows on the south wall

Right: This vent was correctly flashed providing proper waterproofing detailing for this siding penetration.

Right: Use mastic to air seal the return air plenum and to seal around refrigerant lines coming from the slab in the floor of the return

Rigid foam extends under the full slab and lines the inside edges of the foundation walls.

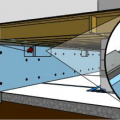

Rigid foam forms an insulating bond break between the foundation wall and the slab

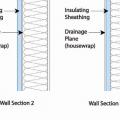

Rigid foam insulated sheathing placed exterior to house wrap, interior to house wrap, or take the place of the house wrap

Rigid foam insulates the interior of masonry walls behind the fireplace in this Building America home by Castle and Cooke in Winter Garden, Florida.

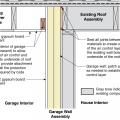

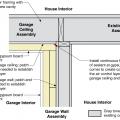

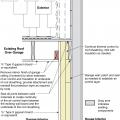

Rigid foam insulating sheathing installed over an existing garage ceiling with retrofits to air seal exterior wall before adding exterior wall insulating sheathing

Rigid foam insulating sheathing is installed on existing garage ceiling and covered with a new gypsum board fire protection layer installed over the foam.

Rigid foam insulation and a thin slab were installed over the dirt and gravel of this sealed crawlspace

Rigid foam insulation applied to the crawlspace walls, allowing a 3-in. pest control inspection strip at the top

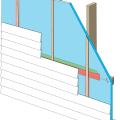

Rigid foam insulation can serve as the drainage plane when all seams are taped. Furring strips provide an air gap behind the cladding.

Rigid foam insulation is installed on the garage side of the shared garage wall and roof of an existing home

Rigid foam insulation was installed at the perimeter of the one-level apartments before installing ceiling drywall to ensure a minimum R-21 attic perimeter insulation.

Rigid foam provides the code-required insulation values for this floor and wall assembly so that fibrous cavity insulation can be avoided, reducing risk of floodwater damage

Rigid foam serves as the sheathing on these 2x6 24-inch on center walls; plywood is used only at the corners for wind bracing.

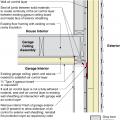

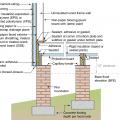

Rigid insulation and air-sealing can be used to thermally isolate garages from interior occupied space in multifamily row houses/townhouses.

Rigid insulation and air-sealing can be used to thermally isolate garages from multifamily row houses/town houses with basement foundations in IECC Climate Zones 3 or higher.

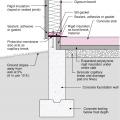

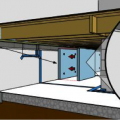

Rigid insulation and water control layers are installed on the exterior of a flat foundation wall; spray foam insulates the rim joist

Rigid insulation can be used as a thermal break between a garage slab with a heated plenum space and a separately cast garage slab without a heated plenum space.

Rigid mineral wool insulation is covered with ¼-inch wood battens which provides a air and drainage gap under the cedar and fiber cement siding.

Rim joists are insulated with R-20 of open-cell spray foam which is air sealing and insulating but vapor permeable.

Riprap is used as a common erosion control technique along beachfronts and streambanks

Roof decking has adhered radiant barrier that is perforated, in addition to the nail holes

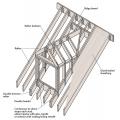

Roof dormer is braced with steel connectors and strapping to increase its resistance to uplift

Roof truss-to-masonry wall connectors embedded into concrete-filled or grouted masonry cell (left-hand side image has a top plate installed while the right-hand side does not).

Roof weather barrier wraps downward onto the walls to direct moisture down and away from the structure.

Roof-mounted solar panels shade the roof below them (left), significantly reducing the roof’s surface temperature (thermal image on the right - yellow region under the panels is cooler than the red and white region on the exposed portion of the roof)

Roof-mounted whole-house fans mount directly to the roof, so they are appropriate for use with unvented attic assemblies.

Roofing membrane is installed over polyisocyanurate rigid foam insulation and insulation cover board that has been cut to fit around locations for blocking for the PV system rack

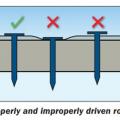

Roofing nails should be driven in straight and flush, not overdriven, underdriven, or angled

Roofing paper protects the top of the new plywood parapet while the base of the parapet is air sealed with spray foam and fibrous insulation is installed in the rafter cavities in this flat roof retrofit

Run-out duct is sealed with mastic

Run-out ducts are installed over partition walls

S.D. Jessup Construction built this custom for buyer home in the mixed-humid climate in Pilot Mountain, NC, and certified it to DOE Zero Energy Ready Home specifications in 2021.

S.D. Jessup Construction built this custom for buyer home in the mixed-humid climate in Pinnacle, NC, and certified it to DOE Zero Energy Ready Home specifications in 2019.

S.D. Jessup Construction built this custom for buyer home in the mixed-humid climate in Tobaccoville, NC, and certified it to DOE Zero Energy Ready Home specifications in 2017.

S.D. Jessup Construction, Inc. built this custom for buyer home in the mixed-humid climate in Pinnacle, NC, and certified it to DOE Zero Energy Ready Home specifications in 2020.

Sareth Builders built this custom spec home in the cold climate in Lorain, OH, and certified it to DOE Zero Energy Ready Home specifications in 2019.

Sareth Builders built this custom spec home in the cold climate in Lorain, OH, and certified it to DOE Zero Energy Ready Home specifications in 2019.

Scaffolding is continually raised as courses of foam brick are added so that the pour man can see both sides of the wall during the pour.

Screw-in LED light bulbs are a highly efficient alternative to residential incandescent bulbs.

Seal all joints and seams in the metal ductwork with mastic before installing insulation

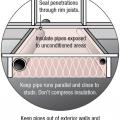

Seal all penetrations through the band joist

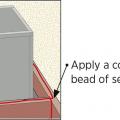

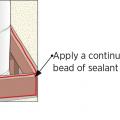

Seal all wood framing joints surrounding the chase with sealant and lay a bead of sealant along top edge of chase framing

Seal all wood framing joints surrounding the chase with sealant and lay a bead of sealant on top edge of chase framing

Seal bottom layer of rigid insulation with adhesive, tape and nails

Seal seams in fiber board ducts with out-clinching staples, UL-181A-approved tape, and mastic

Seal the crack between the sill plate and the foundation wall

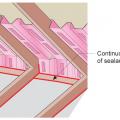

Seal the drywall to top-plate seams and the lower edge of baffles to the top plate to prevent the air coming from soffit vents from flowing under baffles into insulation.

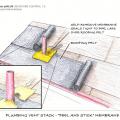

Seal the roof deck as follows: Sweep roof decking, tape seams, and cover underlayment or roofing felt as shown.

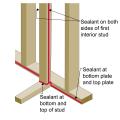

Sealant is installed to air seal along the top and bottom plates of exterior walls and along both sides of the first interior stud on intersecting interior walls

Seams in the ICF block are sealed so the EPS foam surface can serve as the drainage plane; no house wrap is needed.

Second layer of rigid insulation is adhered with foam

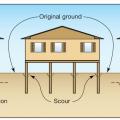

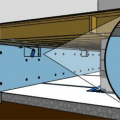

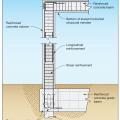

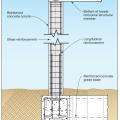

Section view of a deep pile foundation system constructed with reinforced concrete beams and columns to create portal frames, adapted from FEMA P-550, 2nd ed., case FEMA P-550, 2nd ed., case H.

Section view of a steel pipe pile with concrete column and grade beam foundation type, adapted from FEMA P-550, case B.

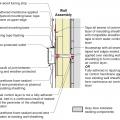

Section view of duct or pipe penetration through exterior wall showing flashing and air sealing details

Section view of electric box installation in exterior wall showing flashing and air sealing details

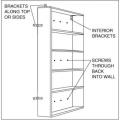

Secure bookcases to the wall with L brackets to prevent damage during seismic events.

Seismic Map of the 2018 International Residential Code adapted by FEMA to show Seismic Design Categories in color

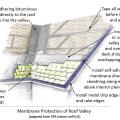

Self-adhering bituminous membrane covers the entire roof of this cold climate home, a practice common under metal roofs and also on complicated roofs

Self-locking drawers and cabinets can be installed to protect against damage from seismic events.

Separate exhaust fans can share a common exhaust if each exhaust fan is equipped with a back-draft damper to prevent cross contamination

Seperate dwellings with their own seperate exhaust terminations

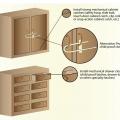

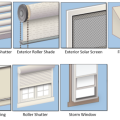

Seven categories of exterior window shading attachments, identified on the DOE Efficient Window Coverings website.

Shade trees planted on the east or west sides of a house are one of the most effective measures that can be taken to reduce heat gains

Shear Strength Comparison Between a Foundation Stud Anchor (on left) and a Shear Transfer Angle (on right)

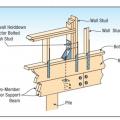

Shear wall hold-down connector with bracket attached to a wood beam for a home built on a pile foundation.

Sheathing is removed from a flat roof to retrofit with air sealing, insulation, and water control layers

Shed roofs provide more space for PV panels in this multifamily project near Denver, Colorado.

Sheer shades can provide very effective daylighting and glare control while maintaining a softened view to the outside

Sheets of phase-change material are installed over the cellulose insulation to help even out interior temperatures.

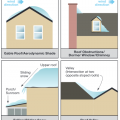

Shingle blow-off often starts at the eaves, as shown here after exposure to 115-mph hurricane winds.

Show potential buyers your energy-efficient features with cut-aways and side-by-side displays (Source: Tommy Williams Homes).

Showering accounts for 1.2 trillion gallons of water per year in the United States.

Shrubs, trees, and herbs create a tight network of roots and stems that bind the soil and slow the flow of water down hillsides.

Side and plan views of window-to-wall interface in masonry wall retrofit including three layers of rigid foam exterior insulation, box extensions, and flashing around new windows.

Side by side comparisons of standard roofing colors (top row) and cool colors (bottom row) shows that solar reflectance (R) can be reduced significantly using special coatings with almost no change to the color

Side view showing air-sealing and rigid foam insulation is installed over existing wall and ceiling under a room above, then covered with new gypsum board.

Side view showing how the existing garage wall and ceiling are air-sealed prior to installing rigid foam insulation on the garage side of the shared wall of an existing home.

Siding has been removed so cellulose insulation can be dense-packed into the exterior walls of this home

Simple Integrity built this custom for buyer home in the cold climate in Cooperstown, NY, and certified it to DOE Zero Energy Ready Home specifications in 2020.

Simplified schematic of a one-pipe steam system showing the main and risers with fast vents and the radiators with slow vents

Single framed wall converted to double wall and insulated with closed-cell spray foam

Single framed wall converted to double wall and insulated with closed-cell spray foam and loose-fill fibrous insulation