Showing results 3001 - 3100 of 4973

Right – This home uses light tan stucco and white trim to reduce solar heat gain.

Right – This home was constructed with ICF blocks that extend from the footer to the roof line, providing consistent thermal resistance for the entire walls of the home

Right – This home was constructed with no- or low-VOC paints, glues, flooring, cabinetry, and finishes that decrease indoor air pollutants in accordance with EPA Indoor airPLUS specifications.

Right – This home’s above-grade walls are constructed in a factory where wall panels of 2x6 studs are assembled and sheathed with a coated OSB product, then windows are installed and flashed before shipping the panels to the site for assembly by crane.

Right – This home’s HVAC system consists of a ground source heat pump that provides heating and cooling with a rated efficiency of 5.0 COP.

Right – This home’s kitchen exhaust fan motor is housed in a box above the ceiling.

Right – This home’s roof and walls are constructed of SIP panels; metal studs provide fastening surfaces across the long expanses of ceiling in the open interiors.

Right – This home’s roof has zero penetrations because all venting is routed to gable walls.

Right – This hot-humid climate home employs several hurricane- and termite-resistant features including concrete block construction, borate-treated framing, a hip roof design with metal drip edge, impact-rated windows, and an unvented attic.

Right – This hot-humid climate home is constructed with concrete block that is insulated on the inside with rigid foam; the framing is borate-treated lumber; the roof design is a high-wind-resistant hip roof with only one small gable over the entry.

Right – This HRV is ducted separately from the home’s ductless heat pumps to provide filtered fresh air to sleeping and living areas and to exhaust stale air from the bathrooms and laundry.

Right – This HVAC condensing unit is elevated on a raised-slab

Right – This ICAT recessed light is sprayed with foam to act as gasket against the drywall.

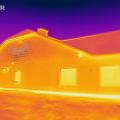

Right – This IR image shows very little heat loss through the home’s exterior walls.

Right – This kitchen exhaust duct is made of smooth rigid metal and the duct is mastic sealed at joints

Right – This kitchen exhaust fan duct is made of smooth round steel duct that takes the shortest, most direct route to the outdoors and joints are sealed with mastic.

Right – This kitchen exhaust fan has a damper to prevent outside air from entering when the fan is not operating

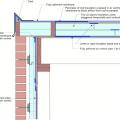

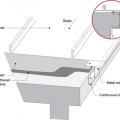

Right – This low-slope flat roof assembly has continuity of both the air and water barriers

Right – This low-slope roof and parapet assembly has continuity of both the air and water barriers

Right – This metal panel window shutter is installed in a track permanently mounted above and below the window frame and is secured with wing nuts to studs mounted on the track.

Right – This metal roof is being coated with a cool (high SRI) coating to reduce solar heat gain

Right – This model home for the Solar Decathlon competition incorporates vertical trellises and retractable exterior blinds to control solar heat gain.

Right – This modular home consists of prebuilt wall panels that are assembled on site.

Right – This modular home is constructed in a factory where climate and ergonomic conditions can be carefully controlled.

Right – This National Fenestration Rating Council (NFRC) label shows the insulation U-Factor, solar heat gain coefficient, visible transmittance, and condensation resistance for this triple-pane window.

Right – This net zero energy home has an electric vehicle charging station in the carport.

Right – This plug-in sensor detects indoor air quality issues in a home, including elevated levels of humidity, VOCs, smoke, carbon dioxide, or small particulates; if detected, the sensor can switch on the nearest exhaust fan to remove the pollutants.

Right – This regional production builder of DOE Zero Energy Ready certified homes provides monthly in-house training sessions to educate its staff on the energy-efficiency features of its high-performance homes.

Right – This roof consists of parallel truss chords which allows for cathedral ceilings.

Right – This sealed combustion gas furnace has a fresh air intake with an electronically controlled damper.

Right – This second-story deck also serves as a deep overhang to protect the entry door from weather

Right – This shrub has been pruned to allow views out the windows of this home while providing shade to walls, windows, and roof.

Right – This stacking ENERGY STAR-labeled washer and dryer save energy and water as well as space.

Right – This supply duct is thoroughly sealed at all joints with mastic to prevent air leakage and the duct is equipped with a damper to provide zoned heating and cooling along with other trunk ducts.

Right – This swale has sloped sides with appropriate vegetation to filter rainwater.

Right – This three studs in this corner are positioned to allow insulation against more of the exterior wall than standard three-stud corners.

Right – This tree shades walls, windows, roofs, and grounds for two adjacent homes.

Right – This wall is constructed with the sill plate overhanging the top of the foundation wall so that when rigid foam is installed on the exterior of the foundation wall, its surface will align with the surface of the wall sheathing.

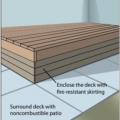

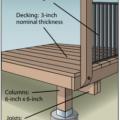

Right – To make decks more fire-resistant, enclose the bottom of the deck with a non-flammable skirt, and surround the deck with a non-flammable surface like pavers.

Right – To make decks more resistant to fires, for floor joists and beams, use heavy fire-retardant-treated timbers, concrete, or steel framing; for decking and stair treads, use treated wood, brick, or concrete pavers; and for railings, use treated wood,

Right – To minimize sound in the kitchen, the exhaust fan above the island-mounted stove top is located above the ceiling rather than just above the stovetop.

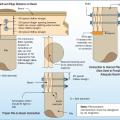

Right – Transfer grilles are installed over doorways to bedrooms in a new-construction home

Right – Transfer grilles, Jump ducts, and wall grilles provide passive returns for air returning from bedrooms to the central HVAC system

Right – Trimming tree branches a minimum of 10 feet from the house or any attached structures reduces the risk of home ignition.

Right – Trimming tree canopies a minimum of 10 feet from the house reduces the risk of home ignition.

Right – Two inches of rigid foam was installed on the ground before pouring the basement floor slab while precast, pre-insulated concrete panels comprise the basement walls.

Right – Two-thirds of acrylic tape is offset above the joint and over and above the fasteners

Right – two-thirds of the blue butyl flashing tape is above the sheathing seam; the top edge of the butyl flashing tape is covered with clear sheathing tape that is also offset so two-thirds is above the top edge of the butyl flashing.

Right – Under metal roofing, sheathing is protected by metal edging over a fully adhered membrane and a slip sheet of loose laid building paper

Right – Vertical and horizontal furring strips are installed over a breathable membrane weather resistant barrier to create an air gap and drainage plane behind the wood siding that will be installed next.

Right – Walls, windows, and wiring are installed in the factory for these modular homes, which are installed at the site on basement foundations made of insulated concrete wall panels.

Right – Weatherstripping has been installed and remains in contact when the door is closed.

Right – Wind baffle installation maintains necessary code clearance between baffle and roof deck

Right – Windows are installed and flashed in the factory for these modular homes.

Right – Wiring holes in the exterior walls are sealed with canned spray foam to prevent air leakage into or out of the home.

Right – Wood-to-sheathing joints are caulked so the sheathing can provide an air barrier for the home.

Right – Workers lay radiant floor loops over the concrete reinforcement which is laid over a heavy vapor barrier installed over the sub-slab insulation before the slab is poured.

Right – Workers pour the concrete for the basement floor slab over a vapor barrier installed over rigid foam.

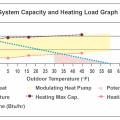

Right (decent): For a relatively high-capacity ccASHP sized per Approach 3 or 4 to meet nearly 100% of the heating load, this heat pump’s modulating zone has a decent overlap with the home’s heating load line, reducing short-cycling.

Right- An electronic controller operates an exhaust fan, a mechanical damper on a fresh air intake, and the central heat pump’s fan, which draws in fresh air through the damper and distributes it in sync with exhaust fan operation for balanced fresh air.

Right- Landscaping shades the entry on the south west corner of this hot dry climate building.

Right- The rigid foam sheathing is taped at all seams before installing the metal lathe for stucco cladding.

Right- This concrete block home in the hot-humid climate is insulated on the interior with rigid EPS foam; all framing uses mold- and termite-resistant borate-treated lumber.

Right- This flue pipe has been air sealed with sheet metal and fire-rated caulk and an insulation dam has been constructed to keep insulation from touching the hot flue pipe

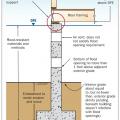

Right- This house uses CMU construction for flood and termite resistance as well as thermal mass

Right-- IR photo shows how effectively spray foam insulated/air sealed attic kneewall and the floor cavities under kneewall

Right--A heavy polyethylene sheet covers the floor of this crawlspace providing a capillary break and vapor barrier to keep soil gases out of the house.

Right--The polyethylene ground cover for this insulated crawlspace is taped at seams and around posts before the insulation and slab are installed.

Right-Flood resistant foundation walls lift the floor framing above the DFE and include flood openings to let flood waters pass through.

Right-Polyethylene sheeting is correctly installed over aggregate and taped to pillars and foundation wall

Right-Wall-insulating sheathing is extended up to roof rafters and sealed around the framing with spray foam

Right: A well-constructed air handler closet

Right: Air seal all seams in the return air plenum before installing a new air handler

Right: All joints in the rigid foam are taped to keep stucco out of joints for even drying. Mesh tape (shown here) is used with expanded polystyrene (EPS); acrylic sheathing tape or self-adhered membrane is used with XPS